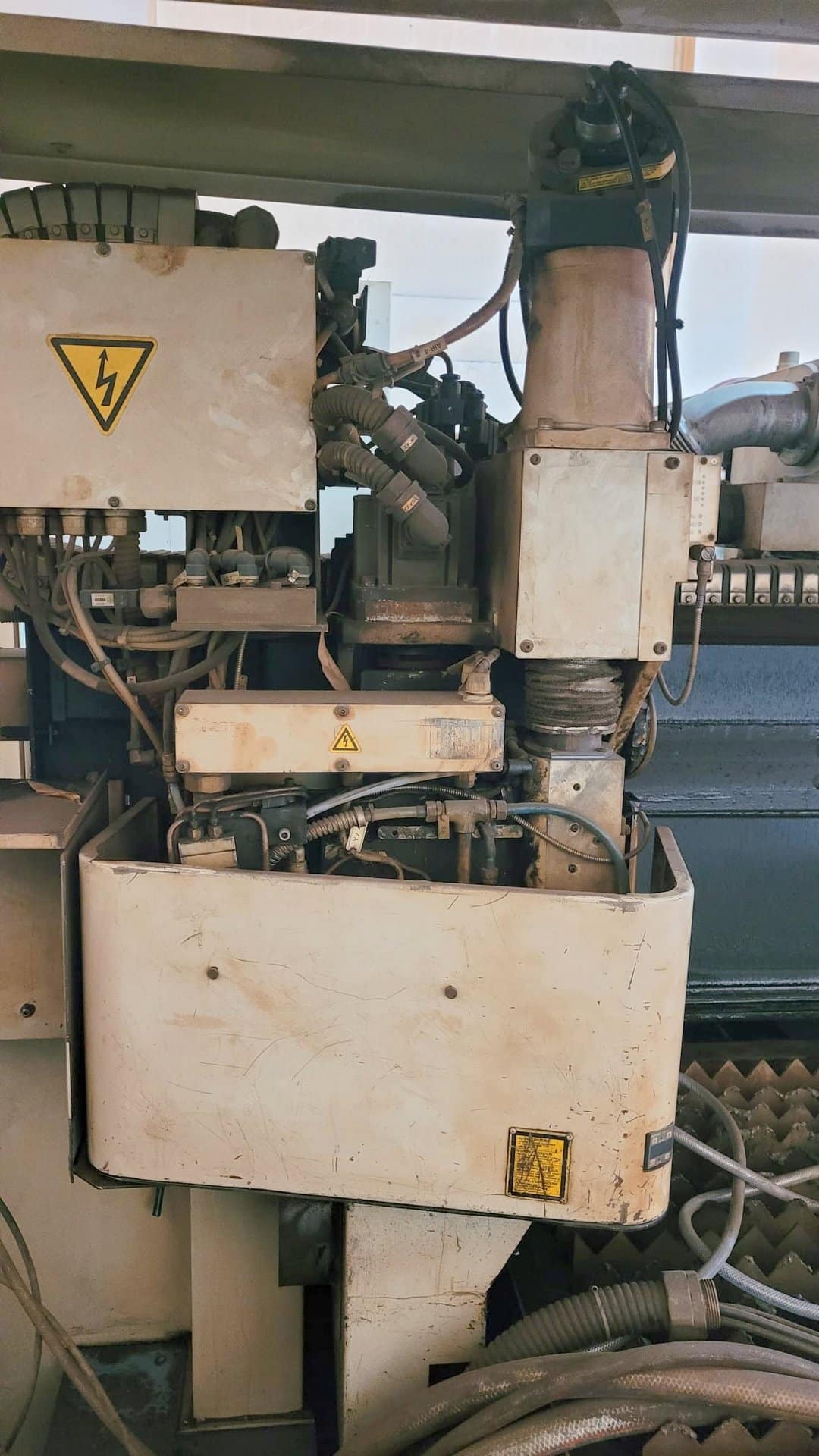

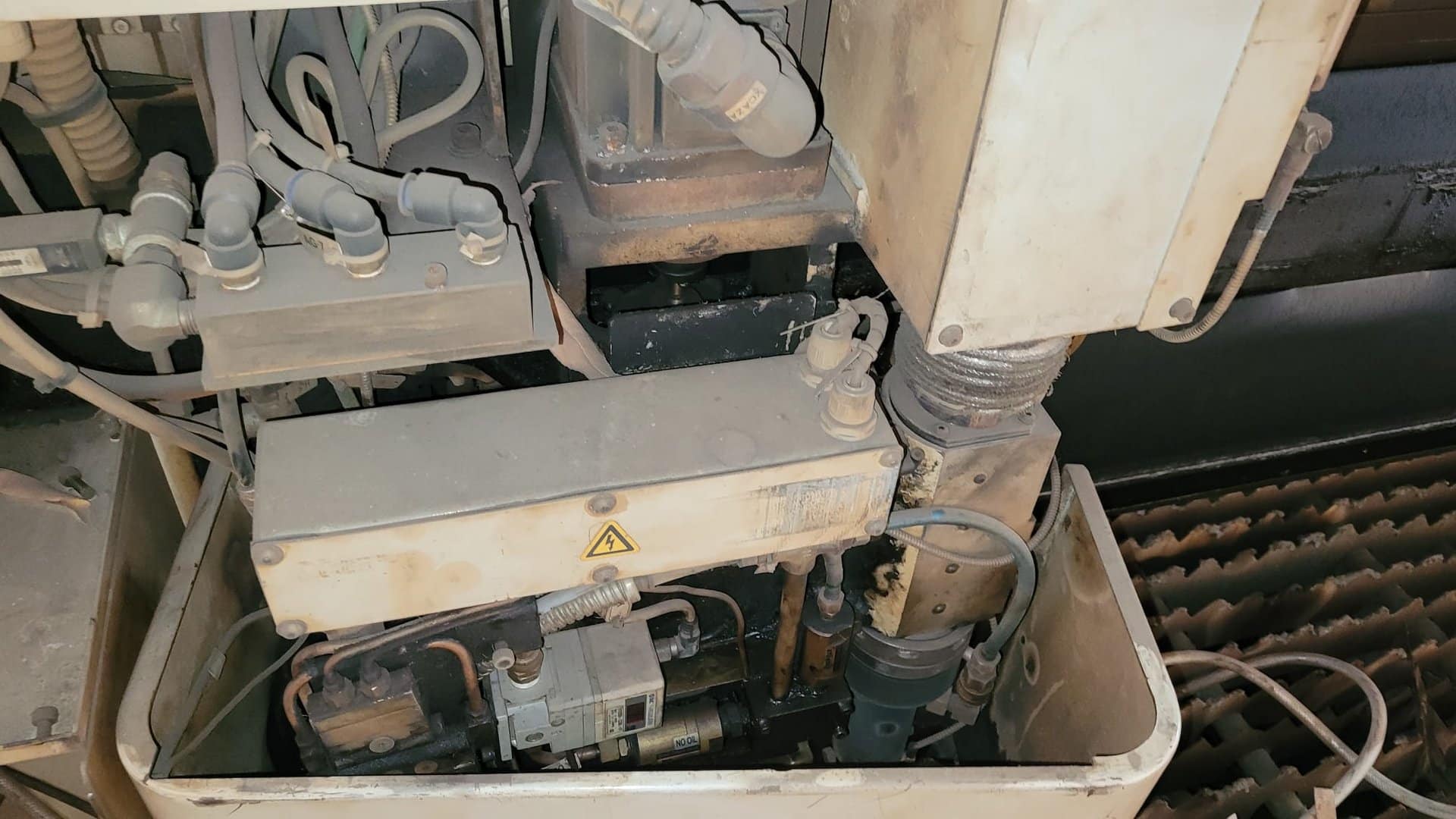

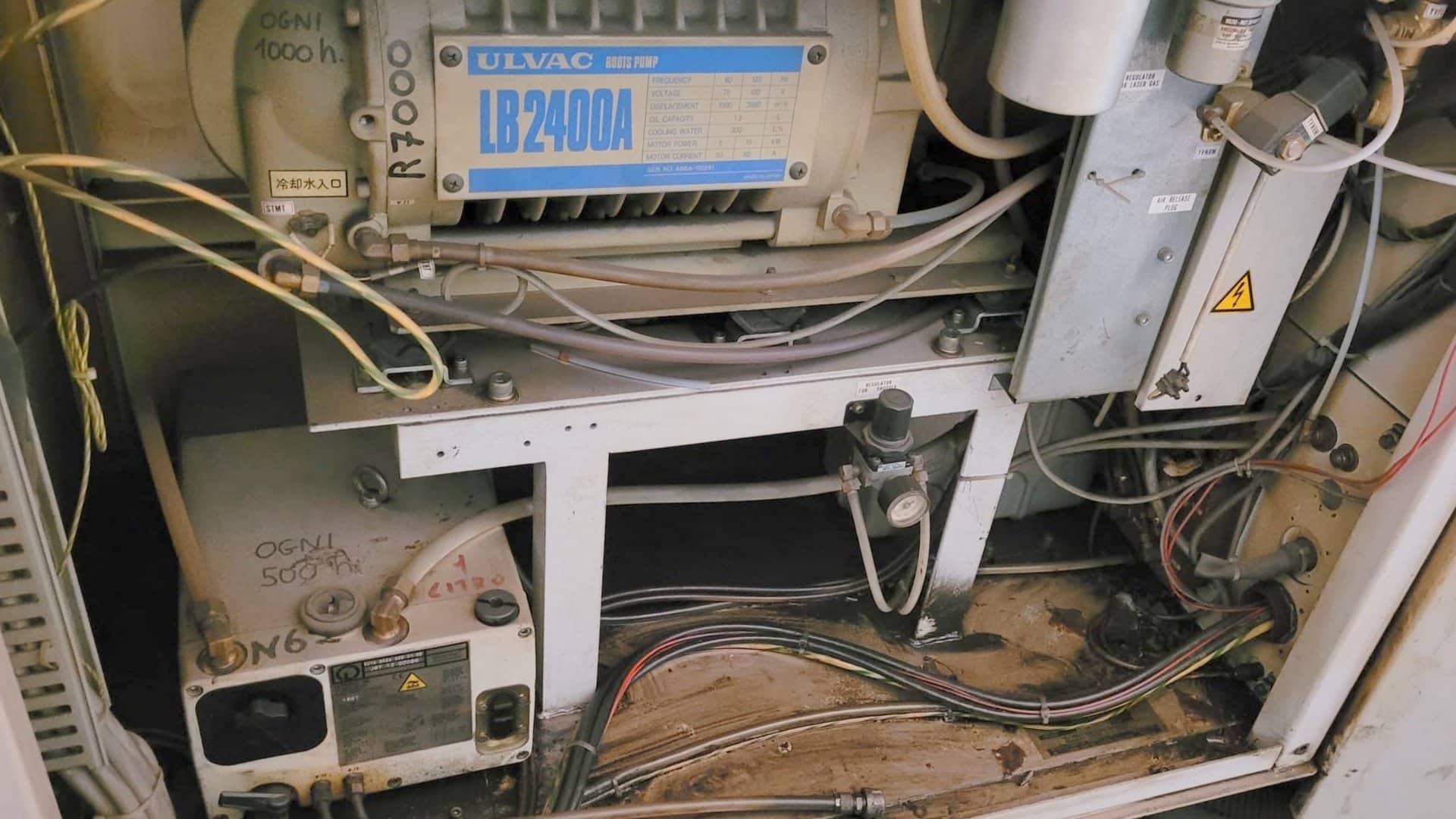

MAZAK SUPER TURBO X510 Hi PRO Supercharged laser cutting machine manufactured in 1999 in Japan, is designed for precision cutting of sheet metal made of structural steel, stainless steel and aluminium. The compact design with high stability makes the machine ideal for small factories as well as for series production.

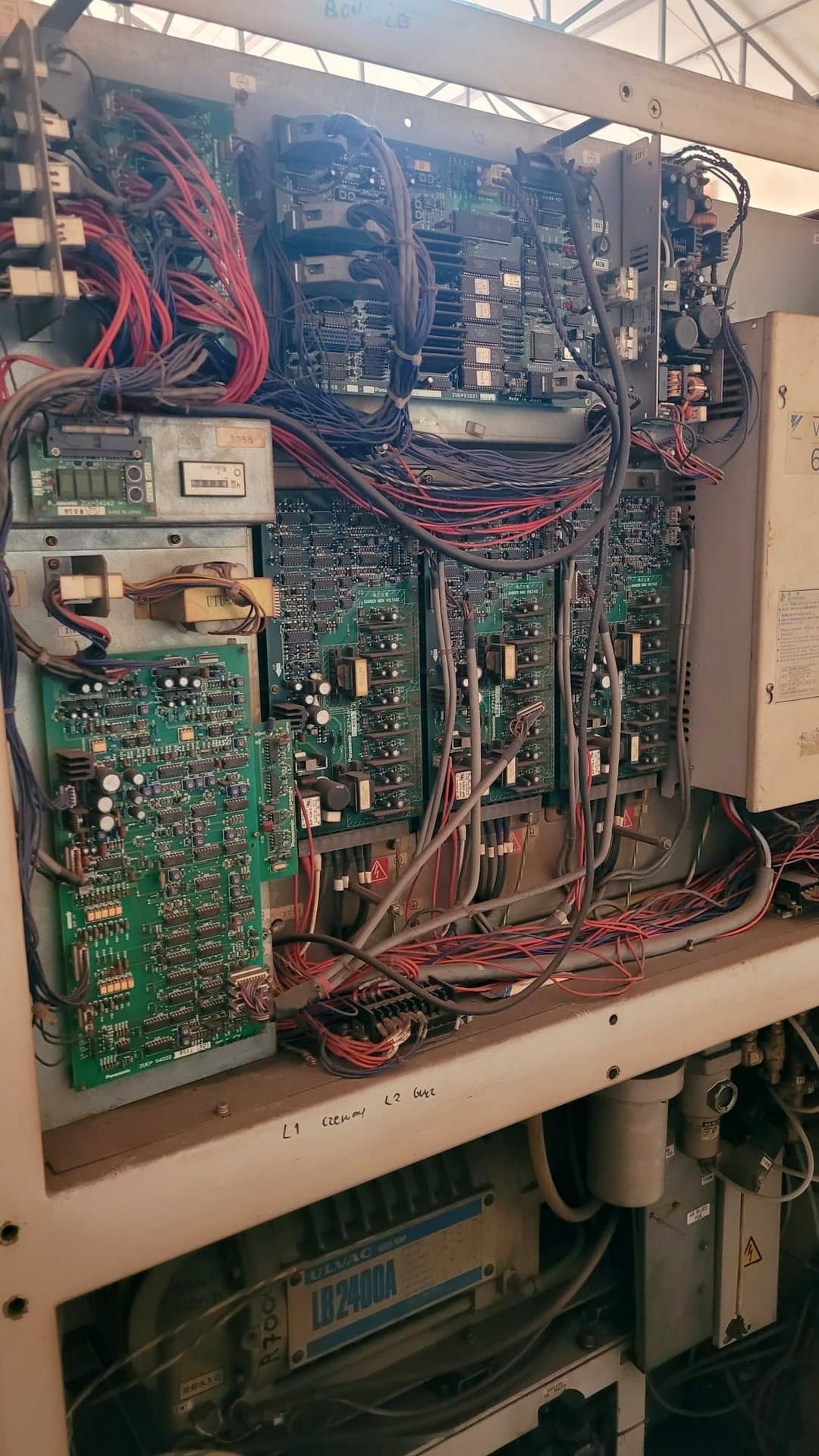

The MAZAK SUPER TURBO-X510 Hi-PRO Supercharged laser cutting machine has a large work table with a length of 3050 mm and a width of 1525 mm on which ball supports are used to facilitate the loading and unloading of workpieces. Workpieces with a maximum thickness of 20 mm are machined with the utmost precision using a stable 2 kW laser beam, guaranteeing excellent machining results. The machine is equipped with, among others, a MAZATROL CNC controller and SiCam 14.10 software for programming the cut shapes and generating the necessary files. The total weight of the machine is 13400 kg.

Technical specifications of the MAZAK SUPER TURBO X510 Hi PRO Supercharged laser

- laser power: 2 kW

- work table dimensions (L x W): 3050 x 1525 mm

- feed rates in the X/Y/Z axis: 3235/1545/100 mm

- maximum workpiece thickness (structural steel): 20 mm

- maximum workpiece thickness (stainless steel): 12 mm

- maximum workpiece thickness (aluminium): 8 mm

- maximum sheet weight: 700 kg

- maximum sheet dimensions (L x W x H): 3050 x 1525 x 19 mm

- laser beam type: mixture of He, N2 and CO2

- operating hours: approx. 45000 h

- dimensions (L x W x H): 7250 x 2875 mm

- machine weight: 13400 kg

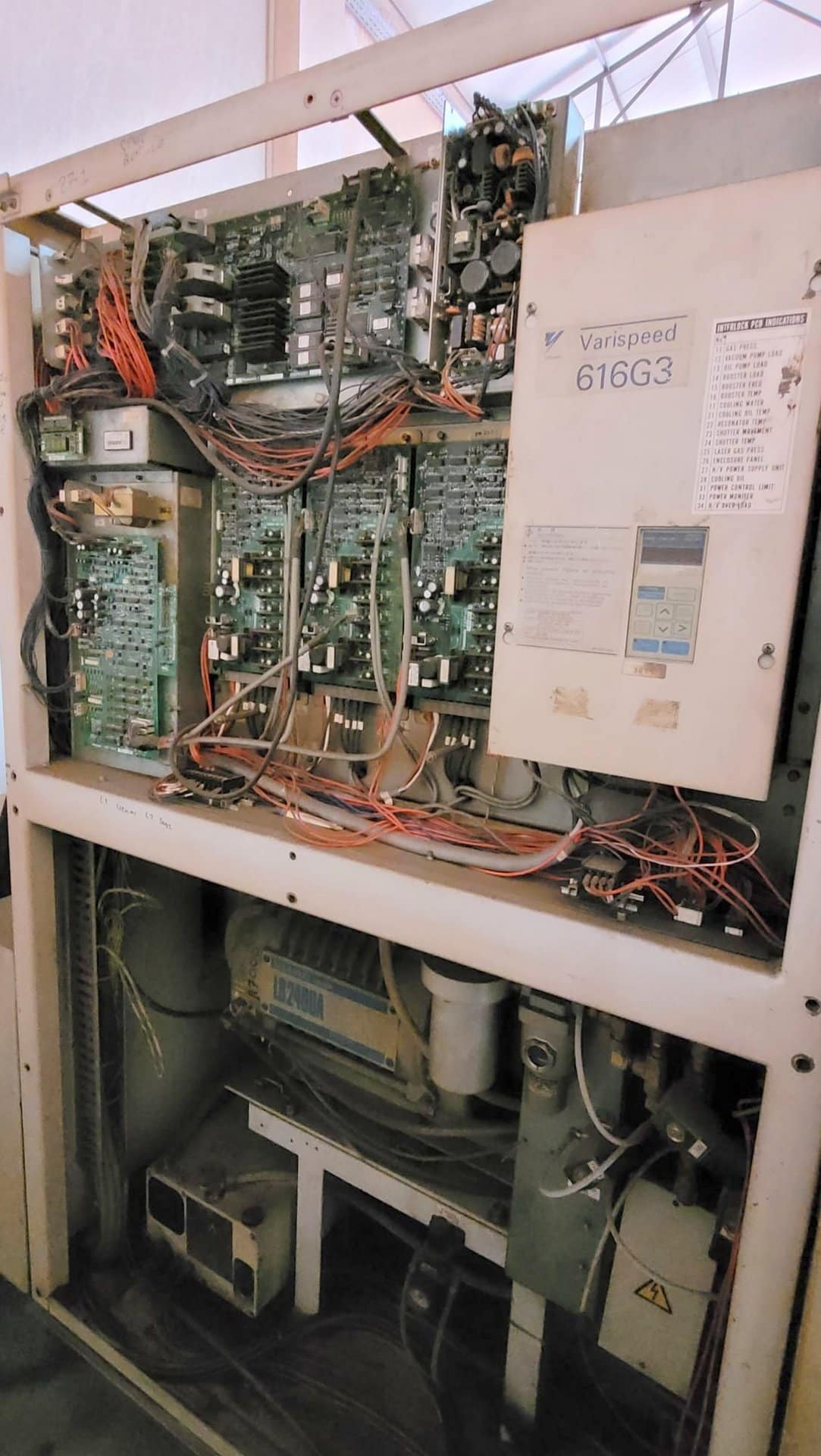

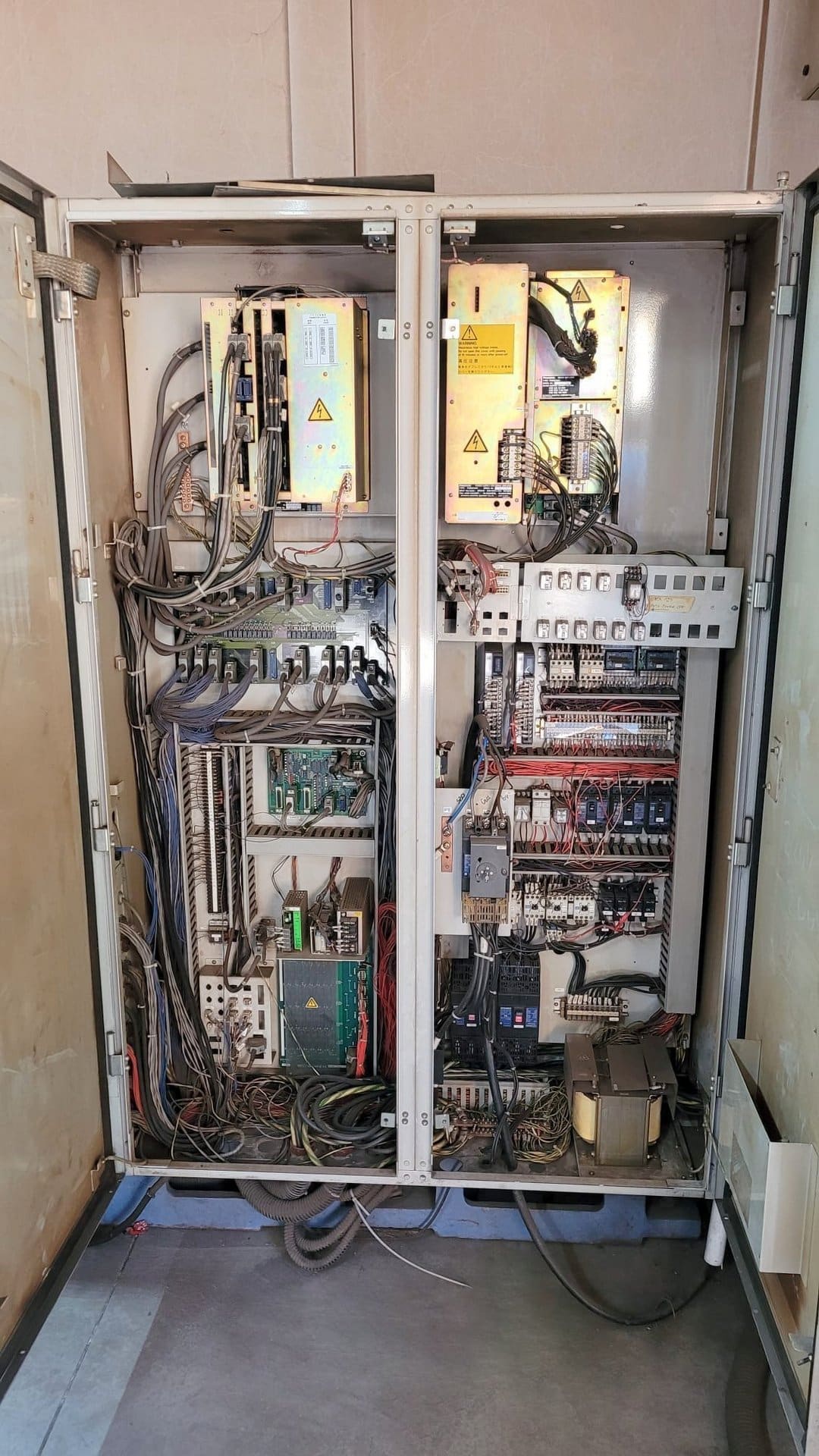

Equipment of the MAZAK laser cutting machine

- CNC control: MAZATROL

- resonator: YB-L200B 7M 6E

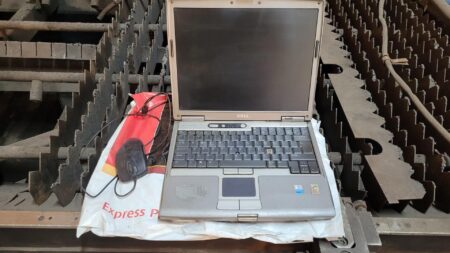

- software: SiCam 14.10

- cooling system: ORION RKL-75000D-CE

- transformer

- pneumatic sheet clamps

- ball supports

- RS-232C port

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe