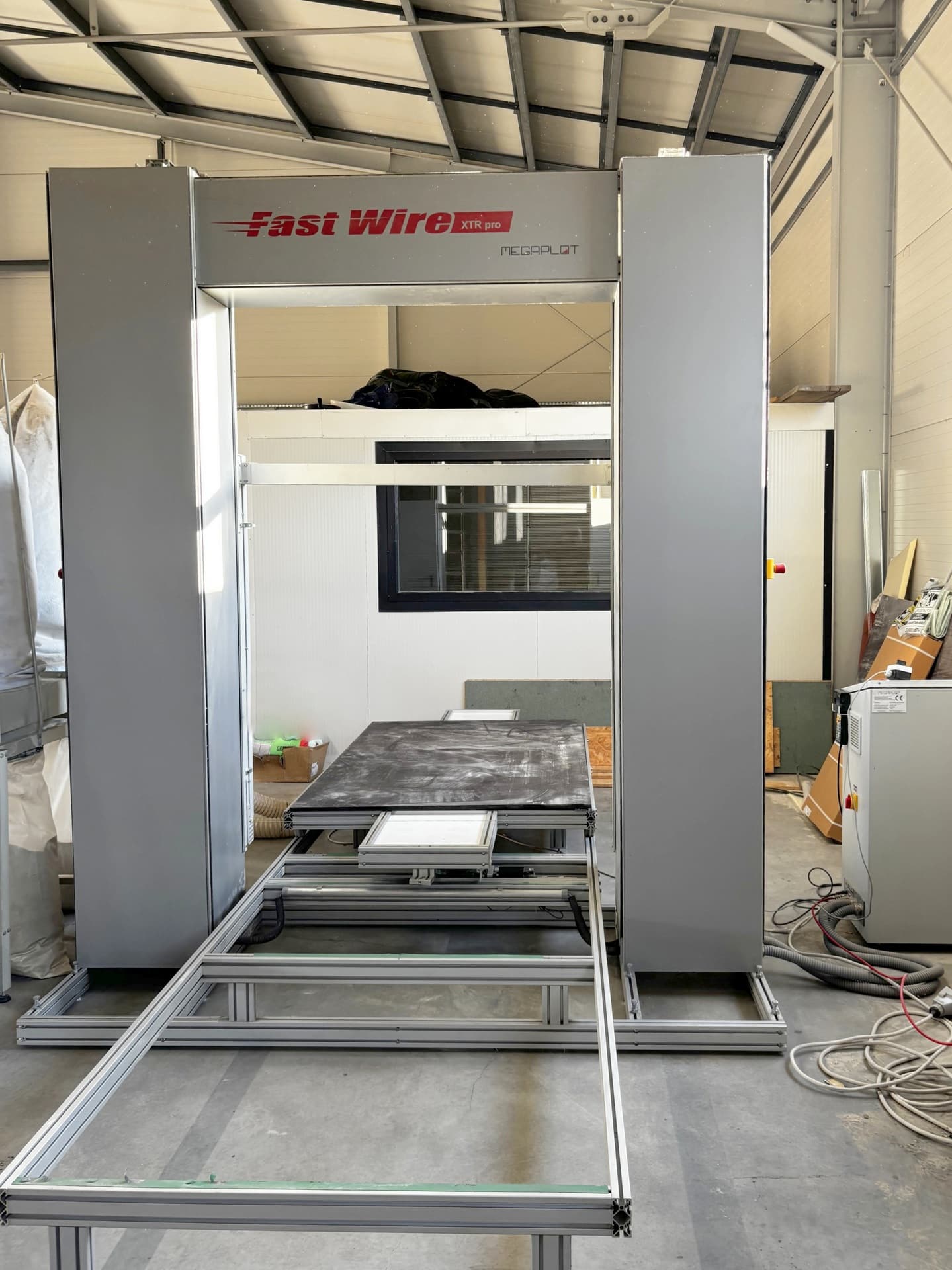

MEGAPLOT XTR PRO 1200 CNC foam cutting machine was built in 2020 in Poland by Megaplot J.Wójcicki M.Jagła SJ. The machine enables precise cutting of any shape in a wide range of rigid foams, soft foams and rockwool. Cutting is performed fully automatically by means of an endless wire, which accelerates to a speed of 280 km/h. Project files, including shapes and their layout, can be prepared in any graphics program (CorelDraw, AutoCAD etc.). This is because the advanced FastWire software supports all major file formats. The MEGAPLOT XTR PRO upholstery foam cutting machine is also equipped with a controller which enables simulation of the cutting process and setting of the machining parameters with their change during the cutting. All this makes the offered machine an excellent choice for businesses producing, among others, insulation elements, packaging and upholstered furniture.

Technical specifications of the MEGAPLOT XTR PRO 1200 foam cutter

- machinable materials: polyurethane foam (PU, PUR, upholstery sponge), polyisocyanurate foam (PIR, POLYISO, ISO), polypropylene foam, polyethylene foam, glass wool, rockwool, glass foam, etc.

- working area (L x W): 1200 x 2000 mm

- working height: 1300 mm

- maximum cutting wire speed: 280 km/h

- ambient temperature: 0-40°C

- relative humidity: 95%

- power supply of the MEGAPLOT XTR PRO 1200 machine: 400 V

Equipment of the MEGAPLOT FastWire XTR PRO foam cutting machine

- industrial controller

- software: FastWire

- pneumatic wire tension

- wire break sensor

- dust extraction unit

- portable control unit (pendant)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe