MG MH 2010 B 4-roll CNC plate rolling machine was built in Italy in 2007. The machine is used for bending workpieces made of among others black steel, stainless steel or aluminium, with a maximum length of 2050 mm and a thickness of 10 mm. The plate bending machine is characterised by a solid body, made of high-quality welded steel and four hardened rollers. The top and bottom rollers are driven by a hydraulic motor, while the other side rollers are designed for pre-bending and actual rolling.

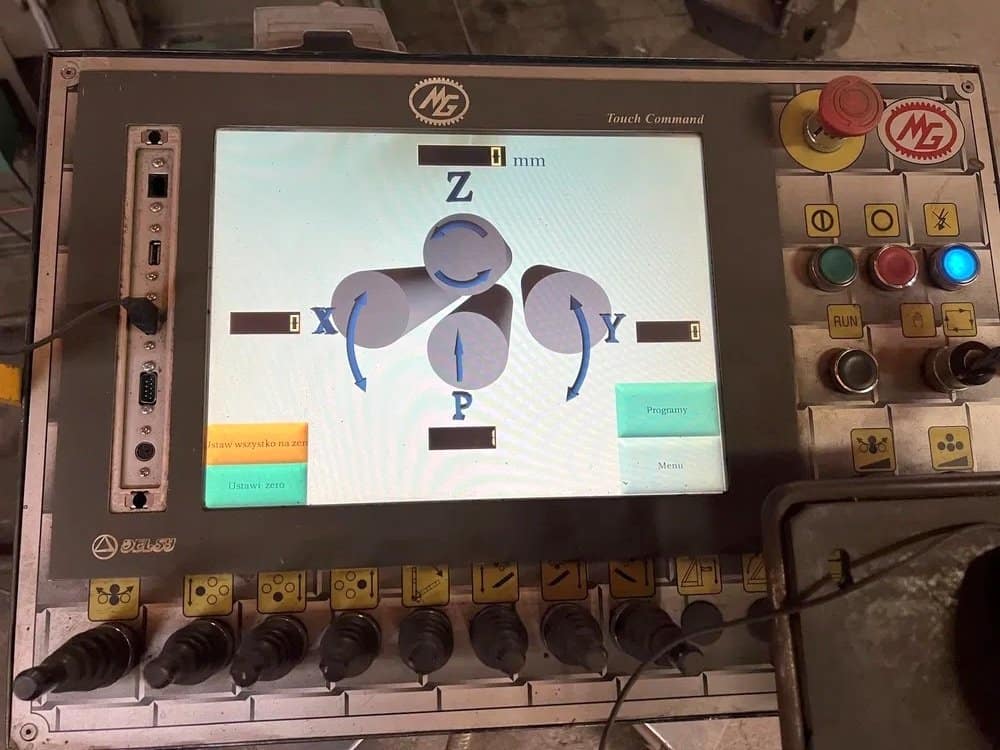

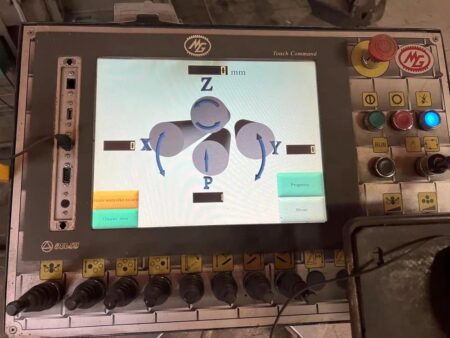

The workpiece is clamped firmly between the central rollers, after which it is turned and rolled using the side rollers, which guarantees excellent bending precision. The hydraulic bending machine is also equipped with a CNC control MG Touch Command with a convenient touchscreen control panel, which allows programming of various bending processes. The total weight of the plate rolling machine is approximately 4000 kg.

Technical specifications of the MG MH 2010 B plate rolling machine

- CNC controller: MG Touch Command

- number of rolls: 4

- number of driven rolls: 2

- diameter of upper roller: 210 mm

- diameter of bottom roller: 190 mm

- diameter of side rollers: 160 mm

- maximum length of metal sheet: 2050 mm

- maximum thickness of metal sheet: 10 mm

- main motor power: 4 kW

- total weight of MG-Hezinger MH 2010 B machine: approx. 4 t

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe