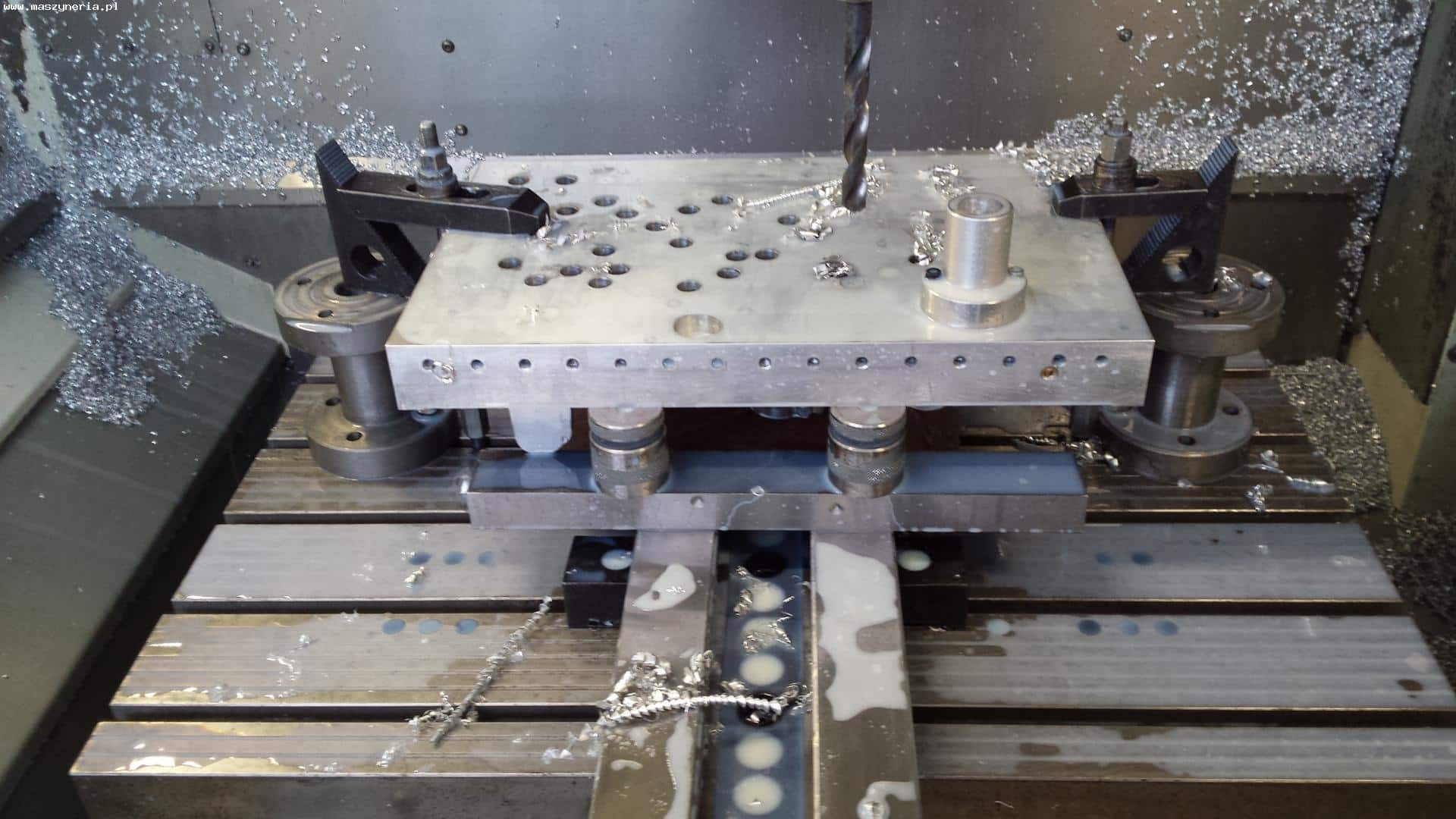

Milling center DECKEL MAHO DMC 64 V LINEAR built in Germany in 2002. The DMG factory service replaced the spindle bearings on the machine and ground the cone of the spindle nose. The CNC milling machine is equipped with a numerical control Siemens Sinumerik 810/840 D Shop Mill and a work table with dimensions of 850×630 mm with a maximum load of 600 kg. The machining center has a spindle rotating at a speed of 12,000 rpm.

Characteristic parameters of the DECKEL MAHO DMC 64 V LINEAR machining center

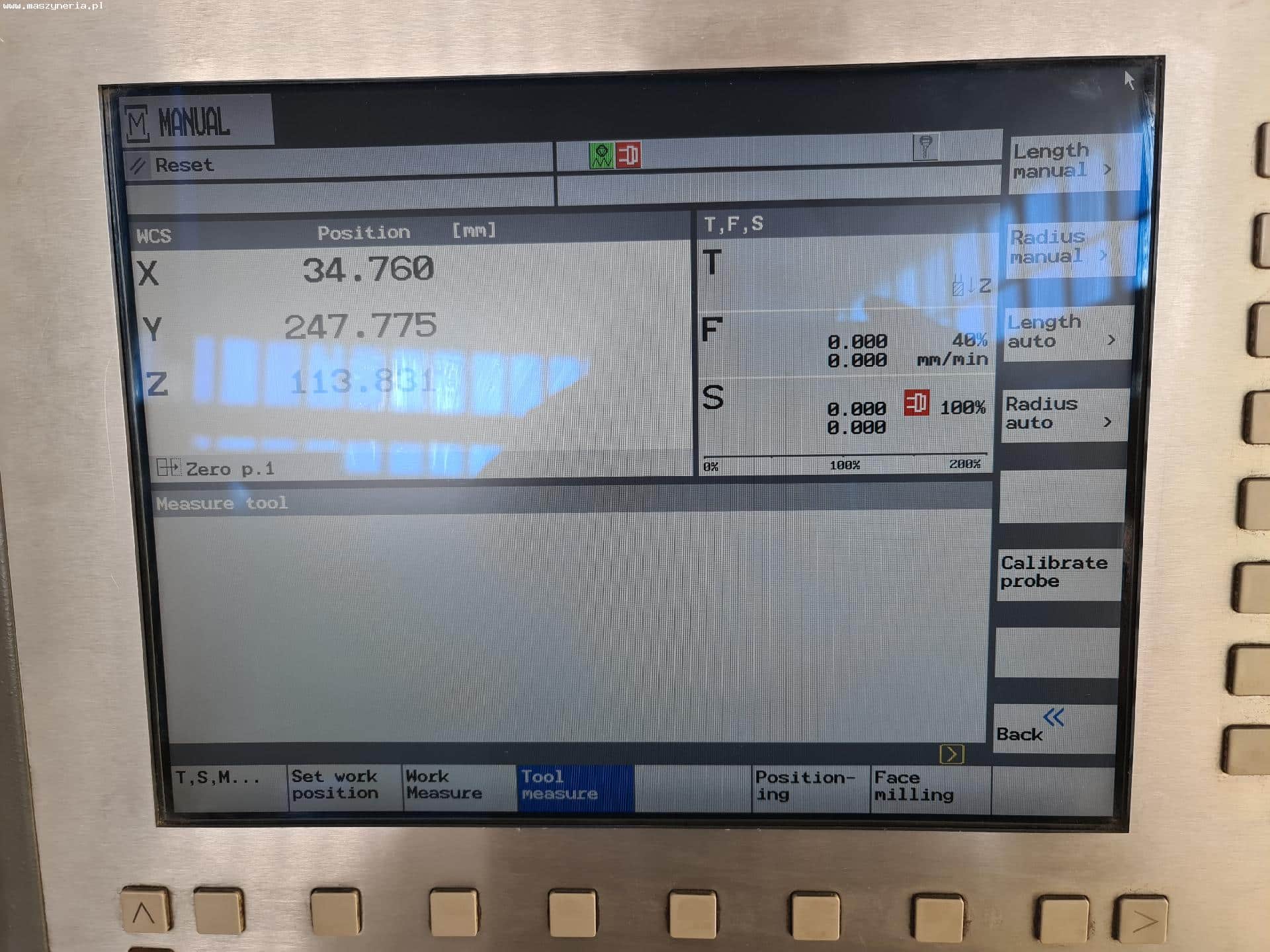

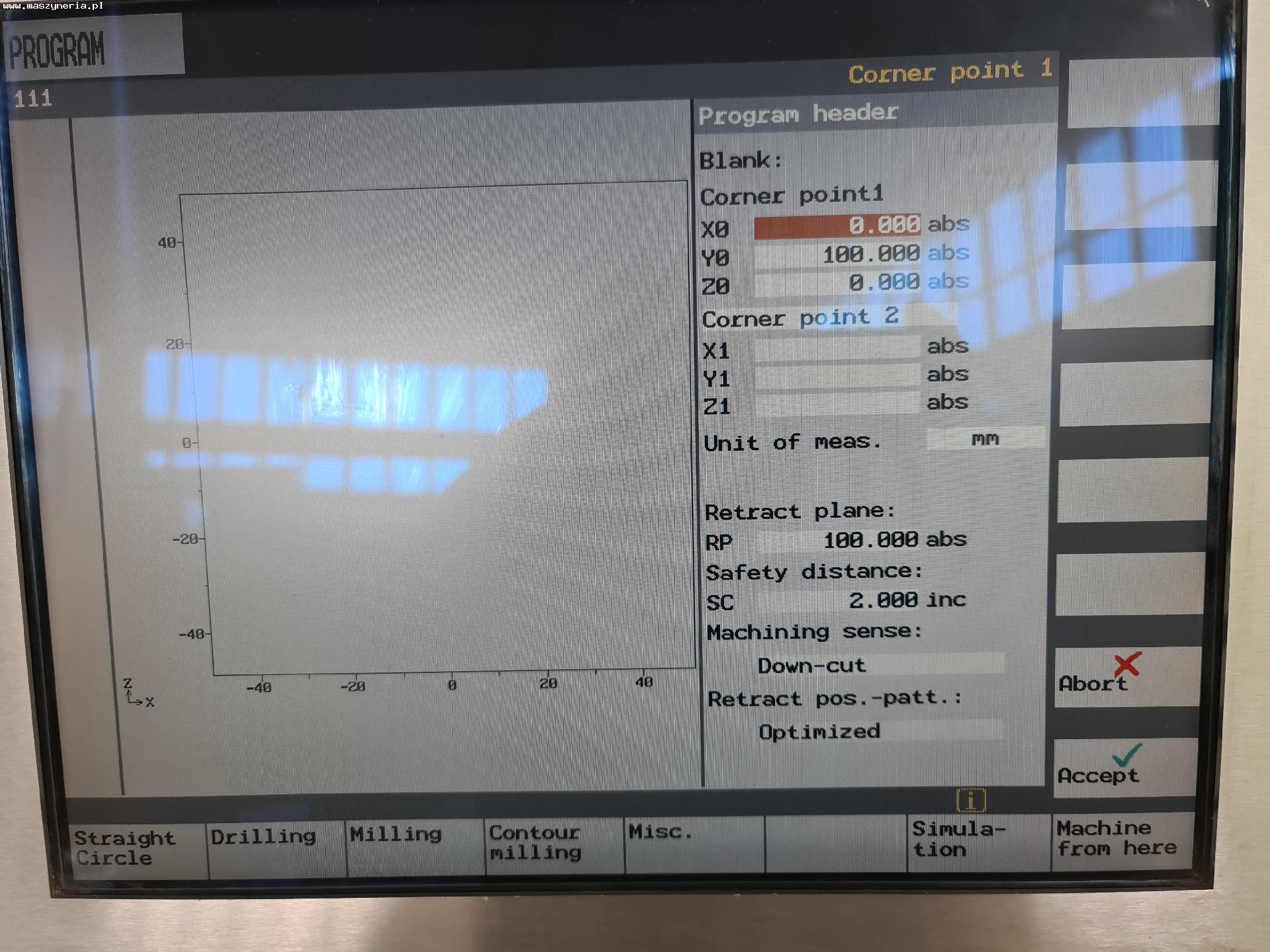

– CNC control: SIEMENS Sinumerik 810/840 D Shop Mill

– switch-on time: 33953 h

– cutting time: 7897 h

– working table size: 850 x 630 mm

– maximum table load: 600 kg

– X axis travel: 640 mm

– Y axis travel: 600 mm

– Z axis travel: 500 mm

– maximum feed speed: 40 m / min.

– maximum feed force: 7000 N

– accelerated feed X, Y, Z: 60, 40, 40 m / min.

– spindle speed: 12000 1 / min.

– tool taper: SK 40

– number of tools in the magazine: 30

– cooling through the spindle: 20 bar

– X axis drive: linear motor

– Y and Z axis drive: ball screw with motor

Additional information about the CNC milling machine:

– additional function Splitline-interpolation purchased

– flushing the machine cabin

– flush gun

– direct measurement system

– tool cooling through the spindle 16 bar / 30L / min.

– a tank with a SPB 3-600 coolant filter

– chip conveyor

– it is possible to connect the probe

– complete technical documentation

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano