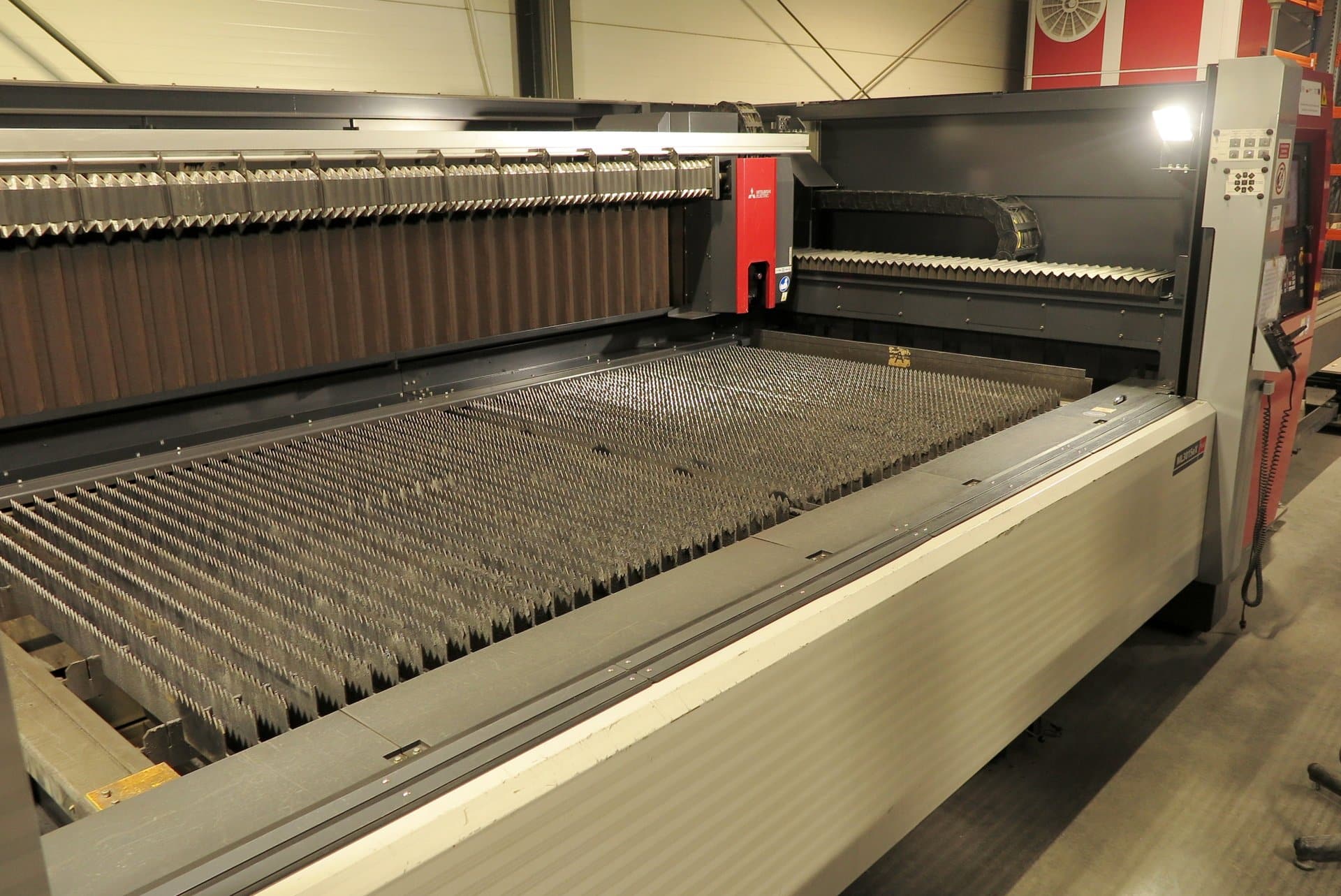

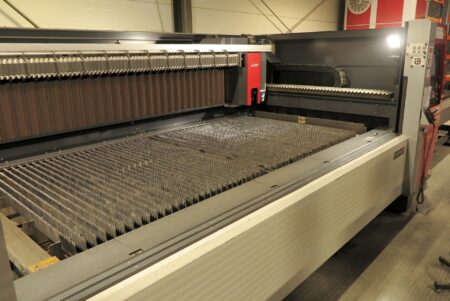

MITSUBISHI ML3015eX PLUS laser, built in 2017 by the renowned Japanese brand Mitsubishi Electric, is designed for cutting workpieces made of mild steel, stainless steel, aluminium, copper and brass. The machine uses the latest technology available on the market, including the extremely powerful Cross-Flow type MITSUBISHI ML45CF-R laser resonator with transverse laser gas flow.

The laser cutting machine provides burr-free cutting of the highest quality and low surface roughness using a laser beam with a maximum power of 4.5 kW, created by electrical discharges in a special gas mixture with a relatively slow flow and in a direction perpendicular to its axis. Real-time power monitoring and a constant laser beam length ensure high cutting quality over the entire working area and prevent power deviations of more than ± 1%, which are needed to process highly reflective materials.

The ML3015EX(S2)-45CF-R laser cutting machine has a large work area with a length of 3050 mm and a width of 1525 mm, on which sheets with a maximum weight of 930 kg and dimensions (L x W) of 3050 x 1525 mm can be processed. The equipment also features, among others, the intuitive MITSUBISHI M700 CNC control with touchscreen and the ECO Mode function, which reduces standby energy consumption by up to 99% by gradually switching off components during unplanned breaks. The total weight of the machine is 10700 kg.

Technical specifications of the MITSUBISHI ML3015eX PLUS laser cutting machine

- laser power: 4.5 kW

- laser type: CO2

- maximum work area (L x W): 3100 x 1565 mm

- maximum workpiece size (L x W): 3050 x 1525 mm

- feed rates in the X/Y/Z axis: 3100/1565/150 mm

- speed of positioning with simultaneous operation of the X and Y axes drives: 100 m/min

- maximum workpiece weight: 930 kg

- maximum sheet thickness (mild steel): 28 mm

- maximum sheet thickness (stainless steel): 22 mm

- maximum sheet thickness (aluminium): 18 mm

- maximum sheet thickness (copper): 4 mm

- maximum sheet thickness (brass): 4 mm

- maximum operating speed: 50 m/min

- positioning accuracy: ± 0.05 mm

- positioning repeatability: ± 0.01 mm

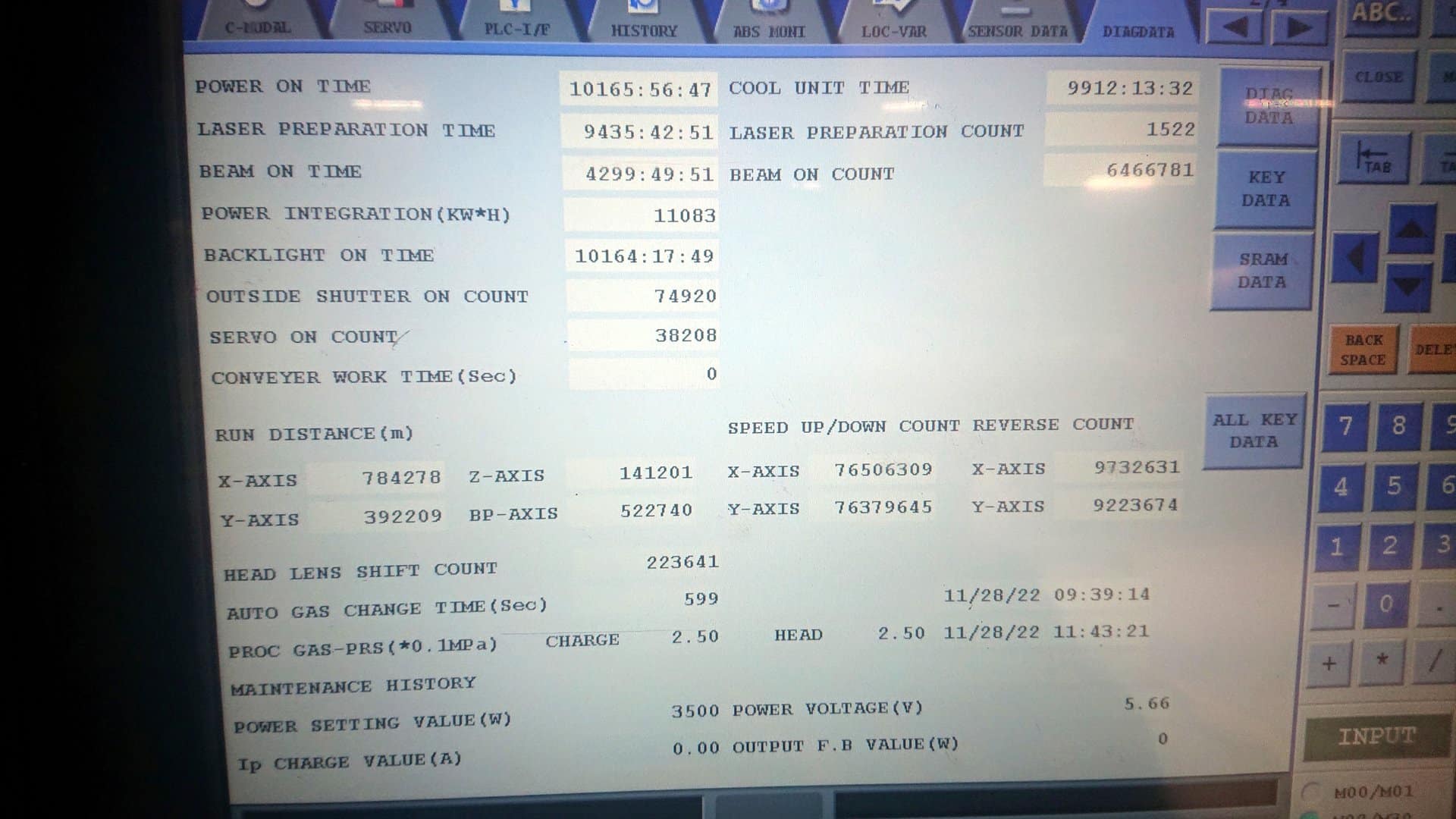

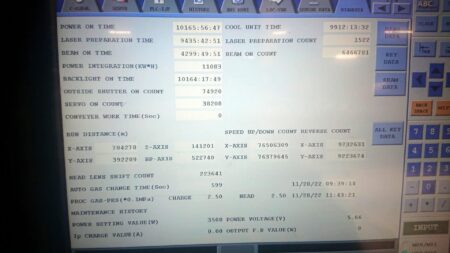

- beam operating hours: 4299 h

- start-up time: 3 min

- laser gas consumption: 3 l/h

- compressed air consumption: 400 l/min

- power supply: 3x 200 V; 50/60 Hz

- dimensions (L x W x H): 10210 x 3130 x 2260 mm

- laser source weight: 2200 kg

- ML3015eX PLUS machine weight: 10700 kg

Equipment of the laser

- CNC control: MITSUBISHI M700

- laser resonator: MITSUBISHI ML45CF-R

- cutting head: MITSUBISHI PH-XS

- exchangeable table (2 pcs.)

- 15″ touch screen

- 7.5″ and 10″ lenses

- auto focus

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe