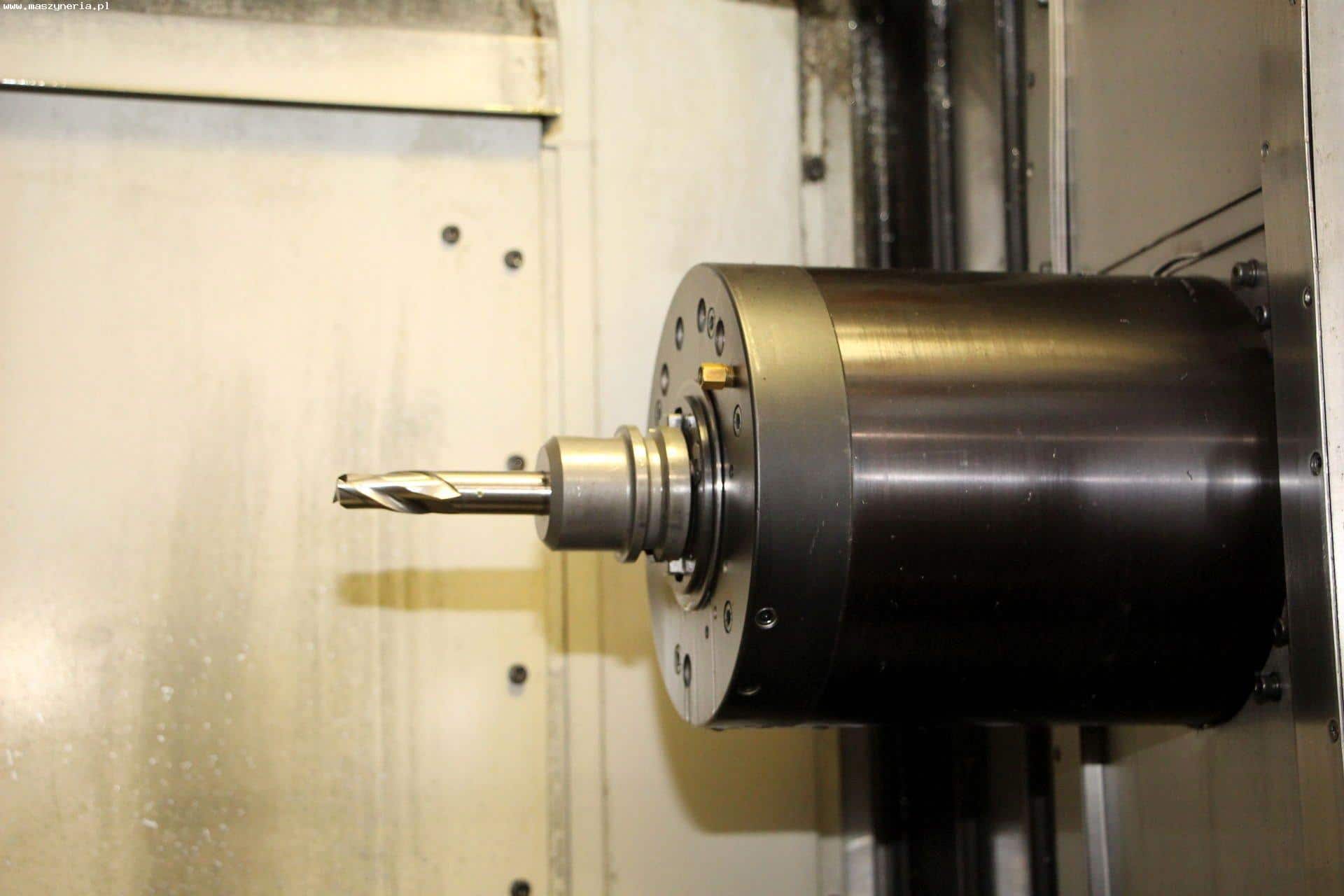

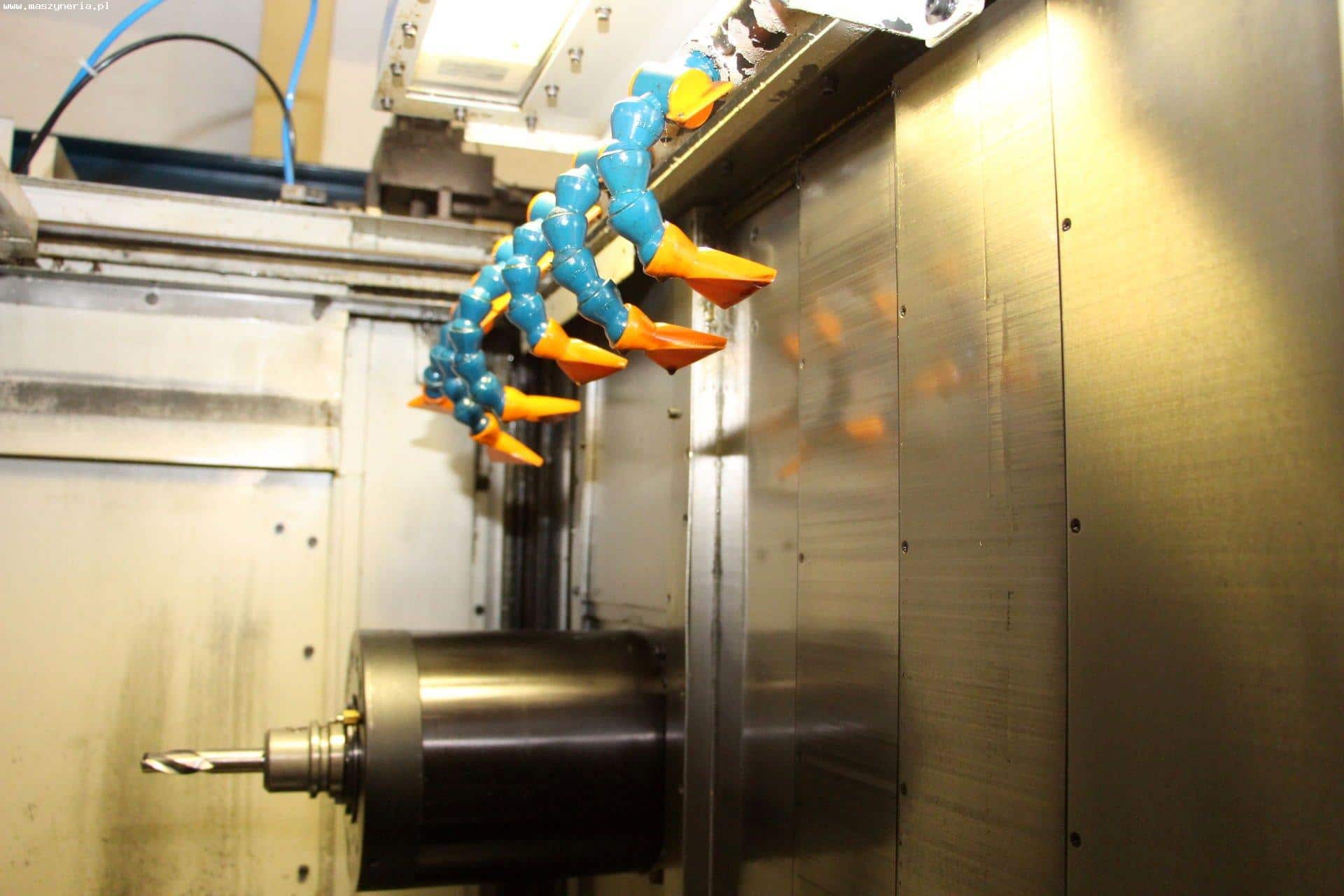

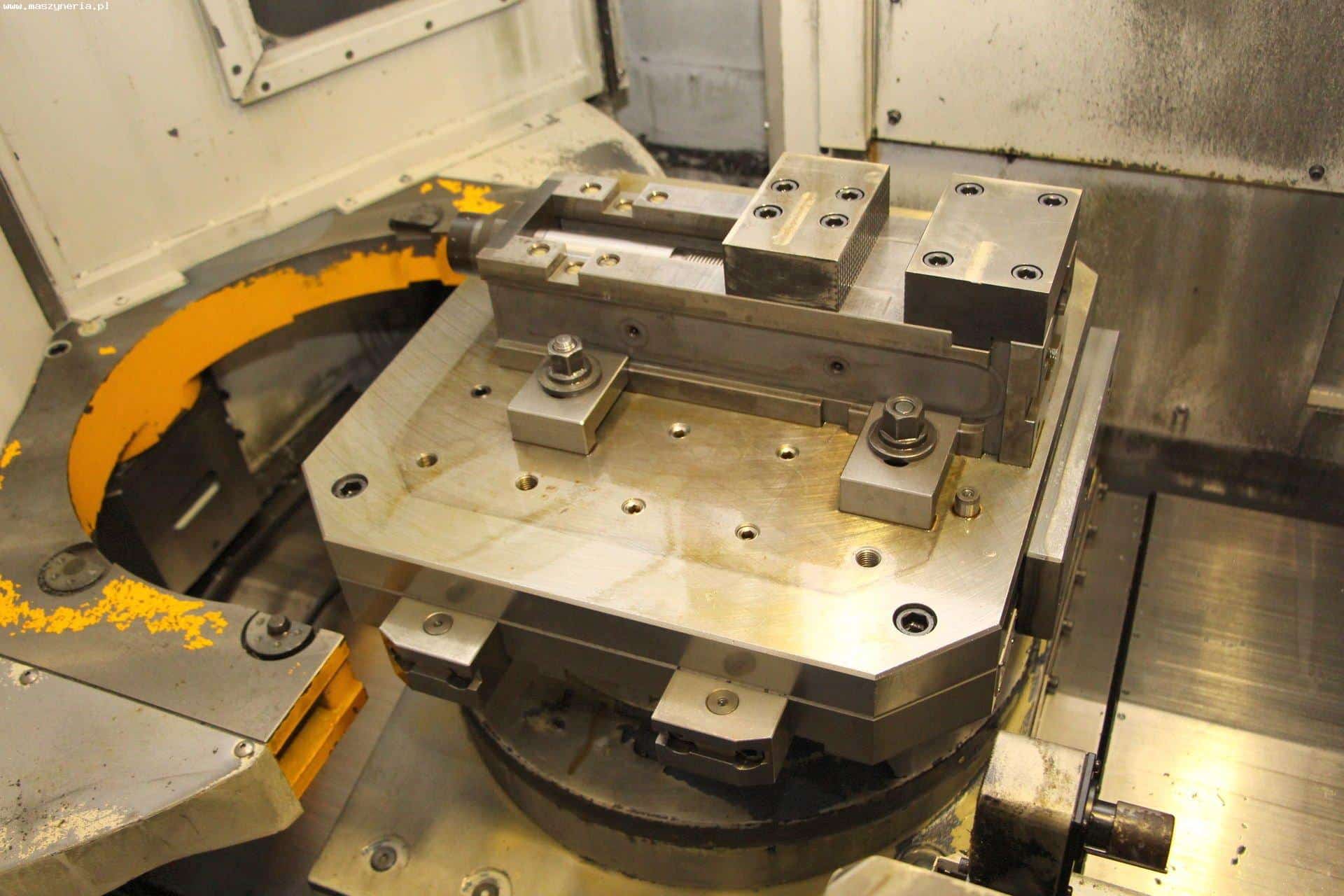

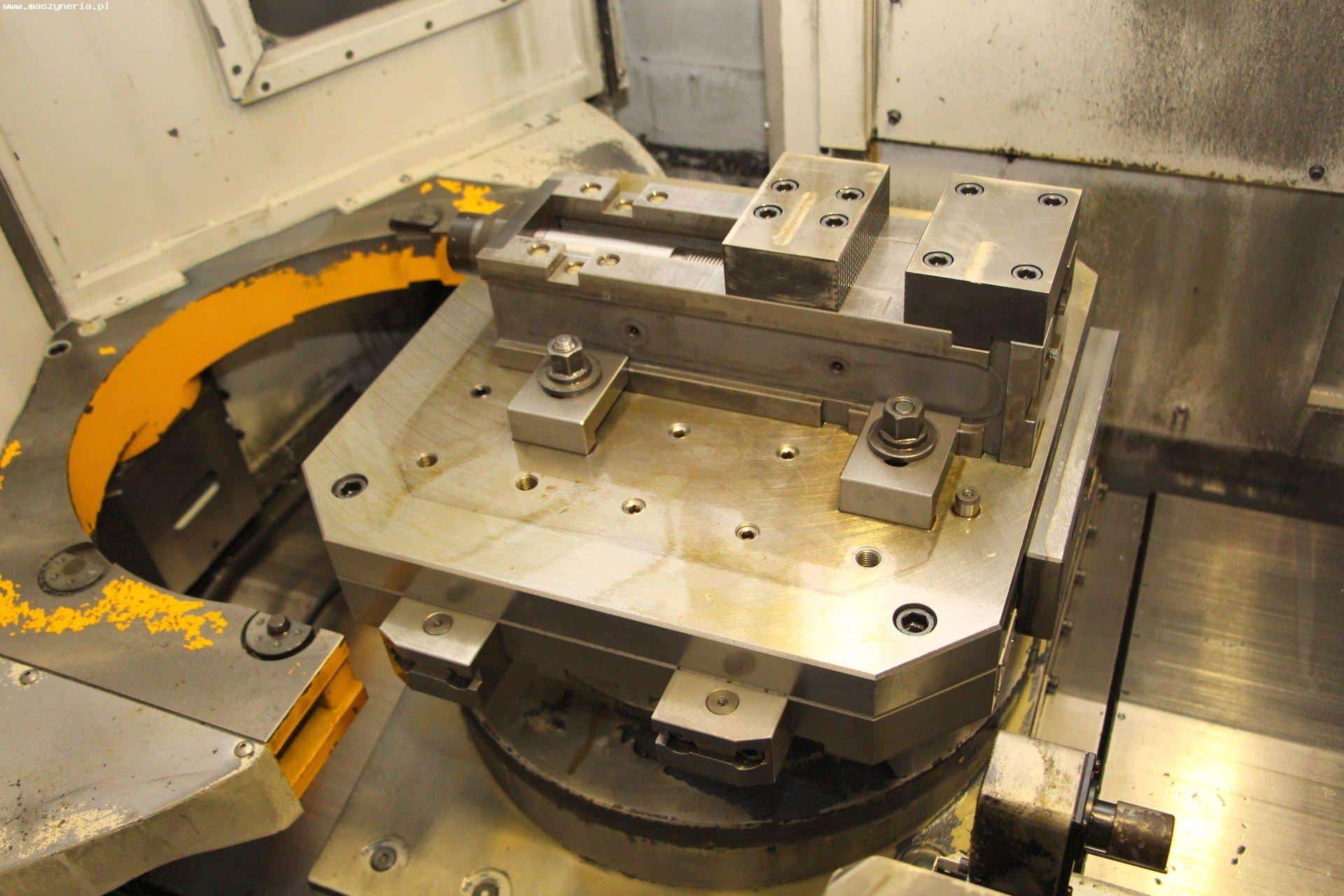

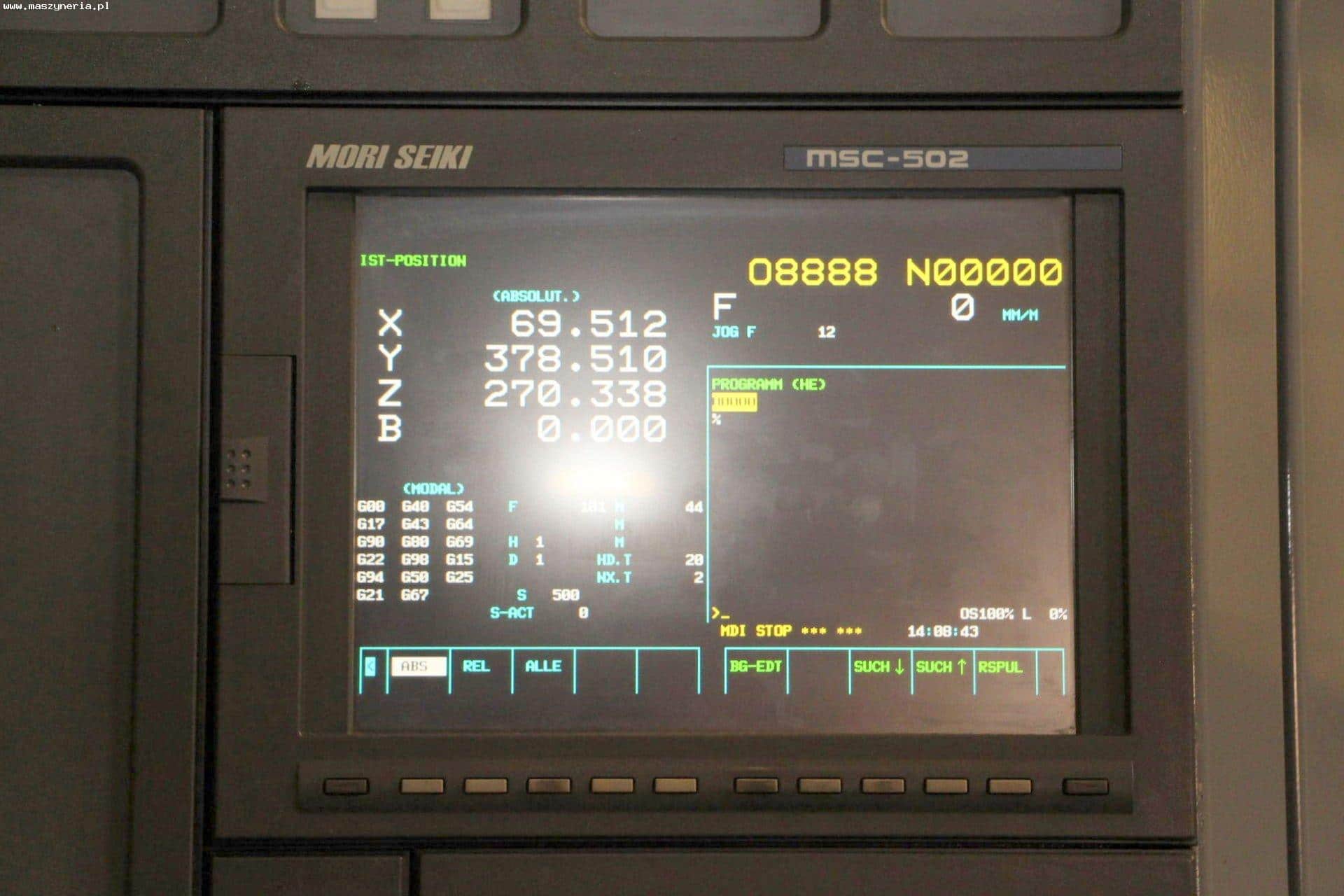

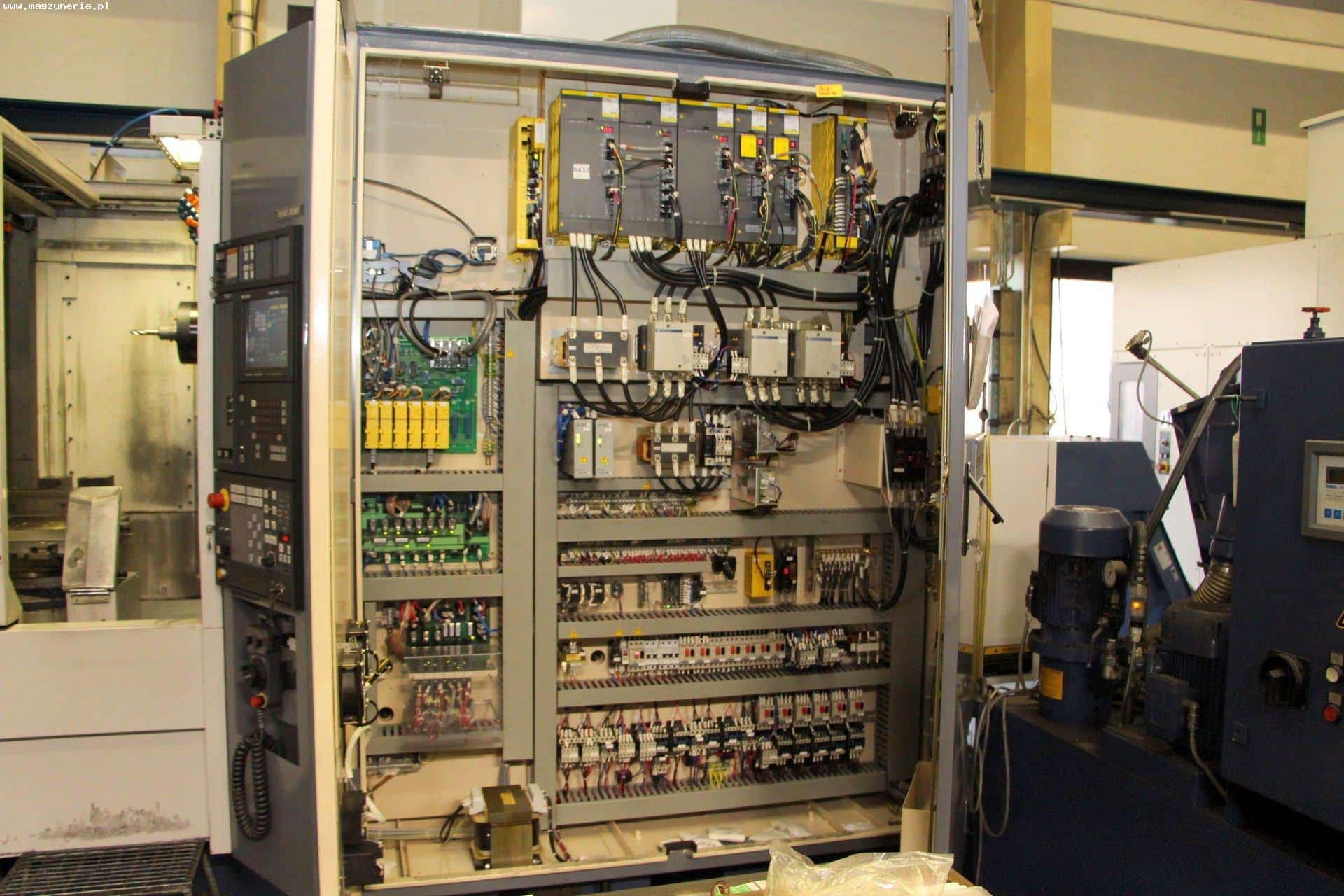

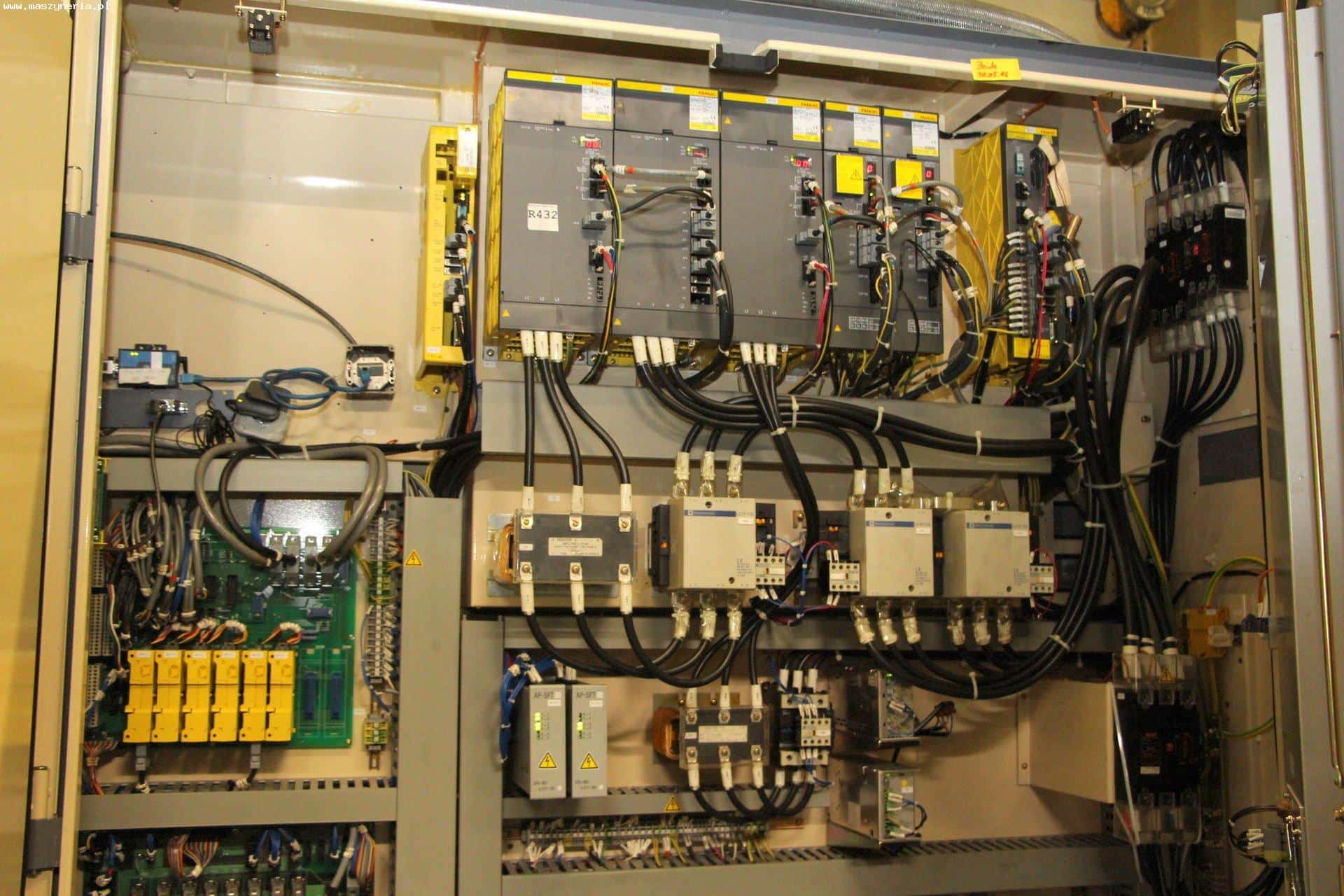

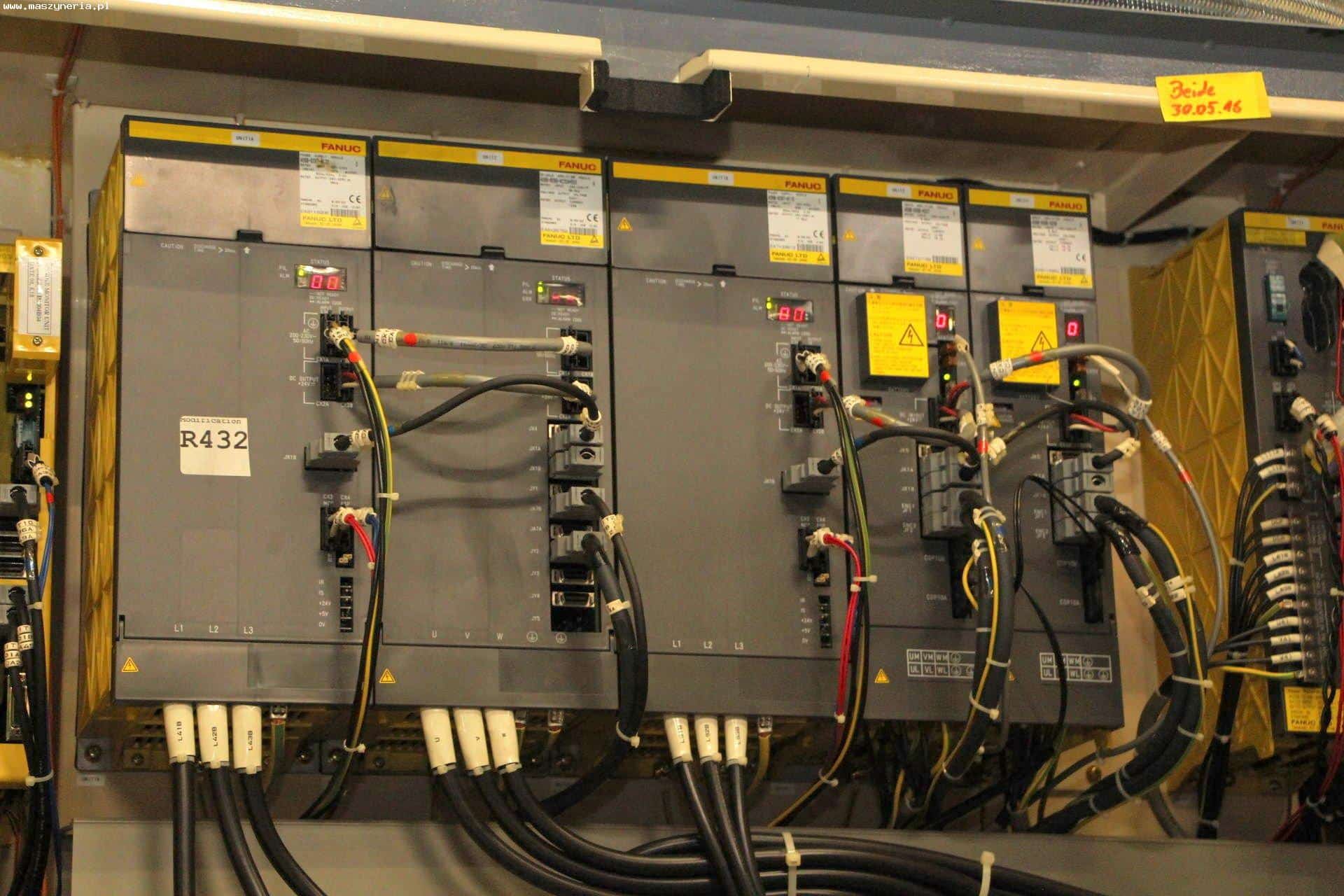

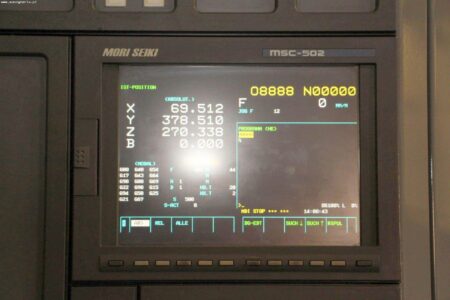

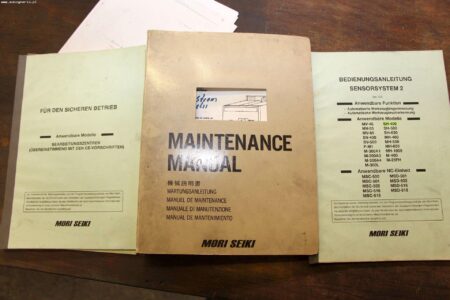

MORI SEIKI SH-500/40 Horizontal Milling Center was built in Japan in 1999 by the brand MORI SEIKI CO. LTD. The machining center works in three axes (X, Y, Z), and their maximum feeds are 630 mm, 600 mm and 650 mm, respectively. The milling center has a revolver tool magazine with a rotating pallet change system that can accommodate 40 tools with a maximum weight of 12 kg each. The machine can process details with a maximum diameter of 730 mm, a height of 700 mm and a weight of 500 kg. The machining center is controlled by MORI SEIKI MSC-502 type CNC controller . The surface of the work table is (L x W) 500 x 500 mm. The machine spindle rotates at 12,000 revolutions per minute. The milling center is offered at a price with different types of holders.

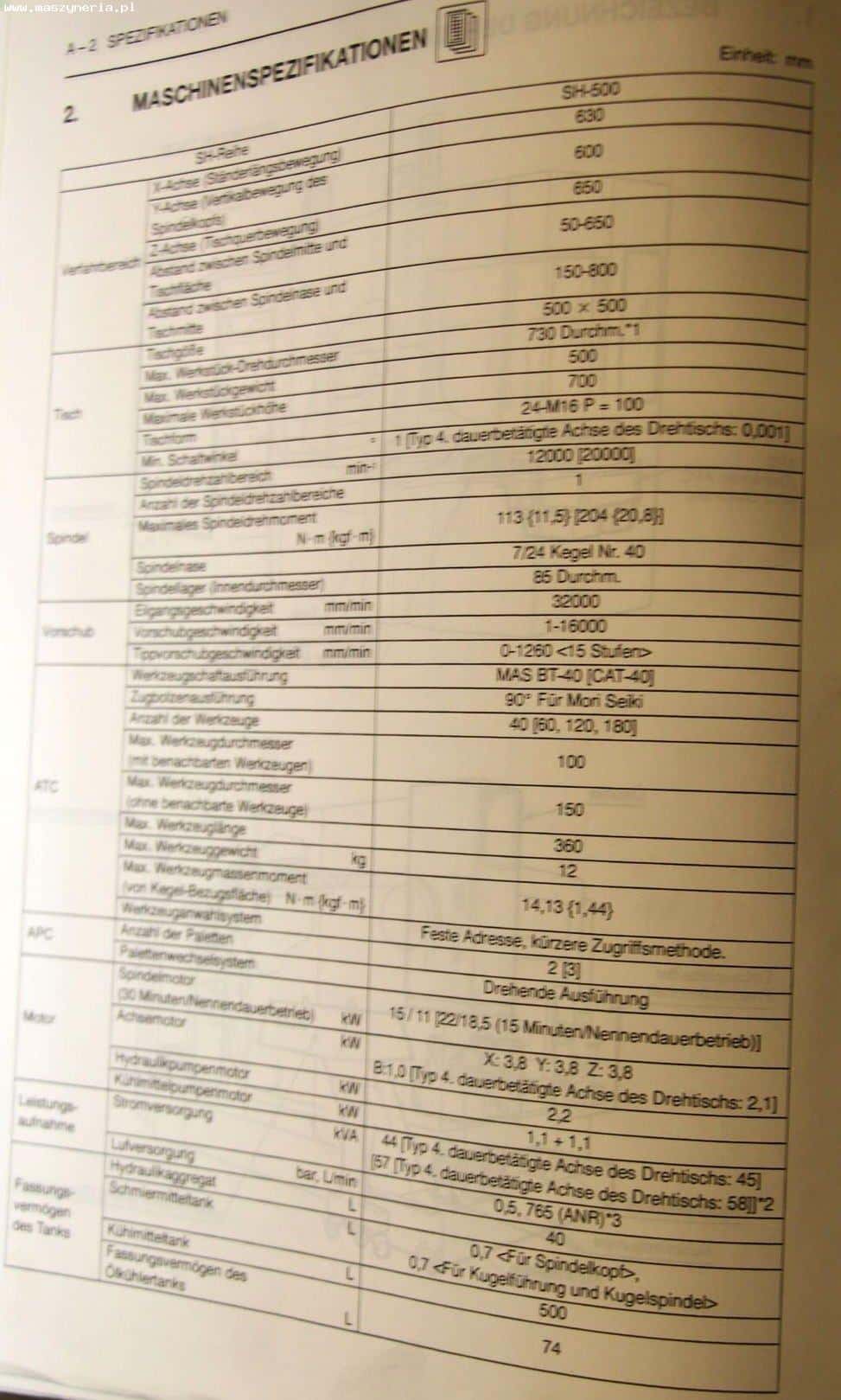

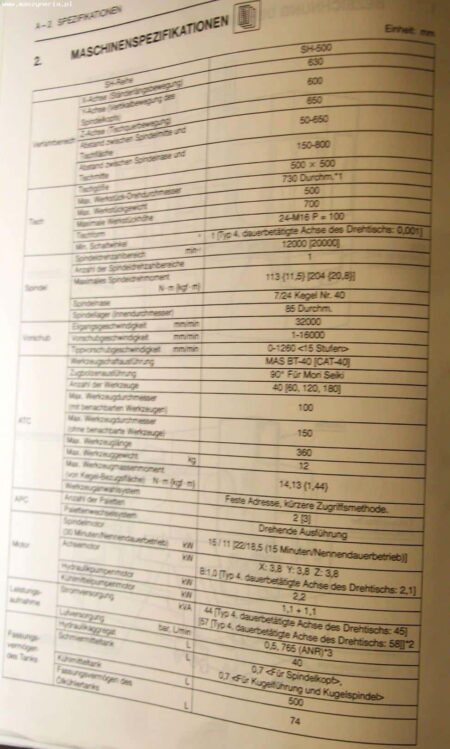

Technical parameters of the MORI SEIKI SH-500/40 CNC milling machine

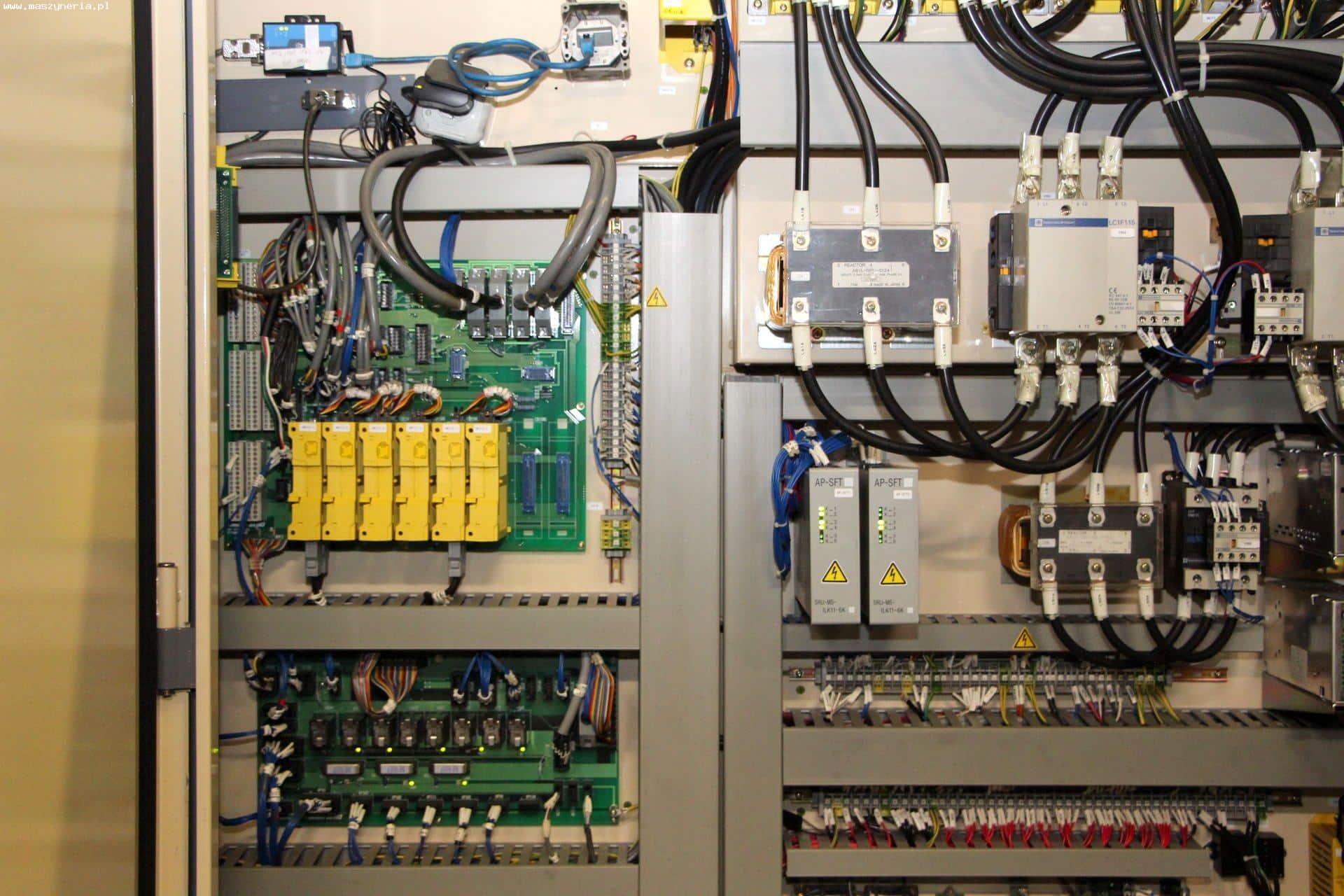

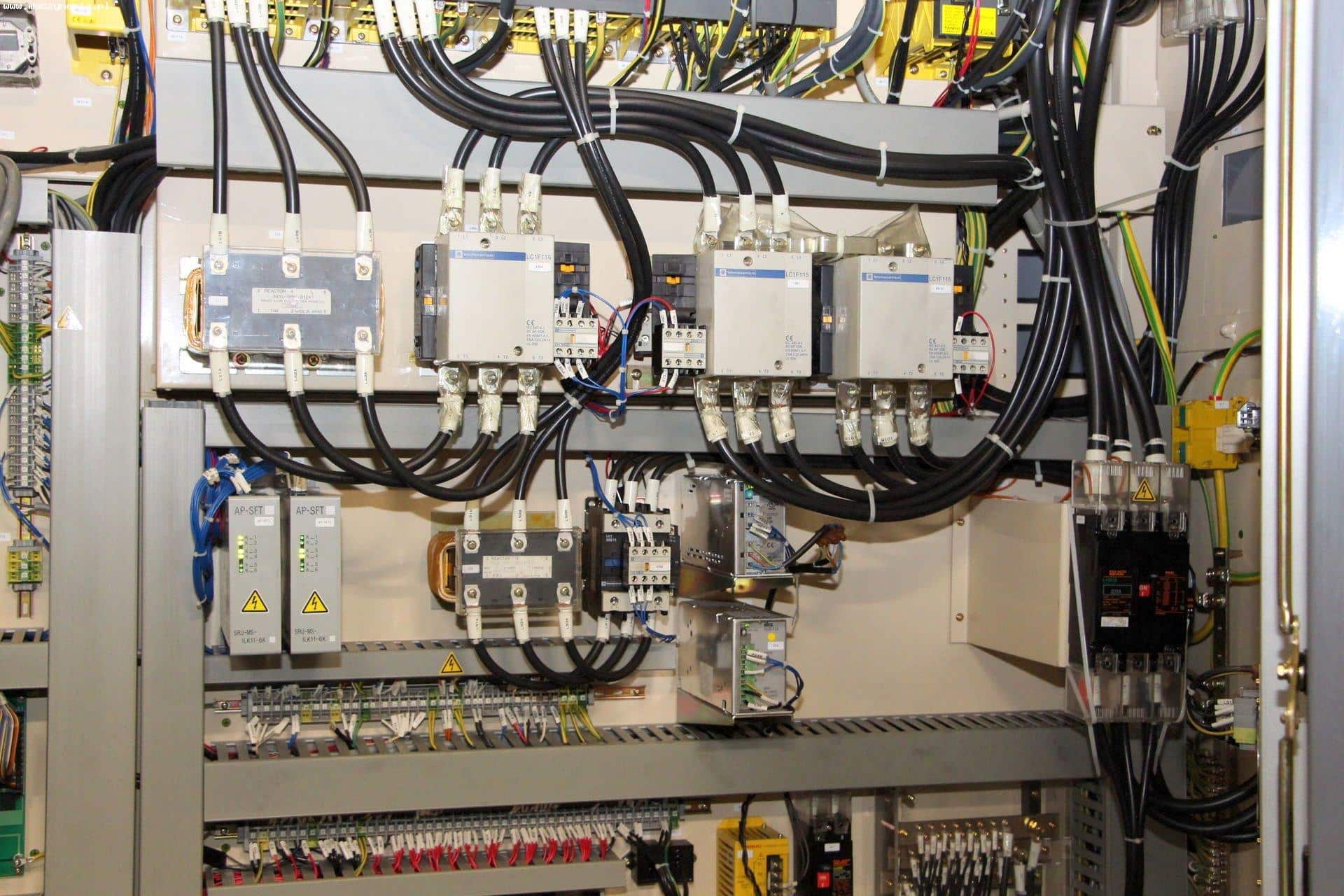

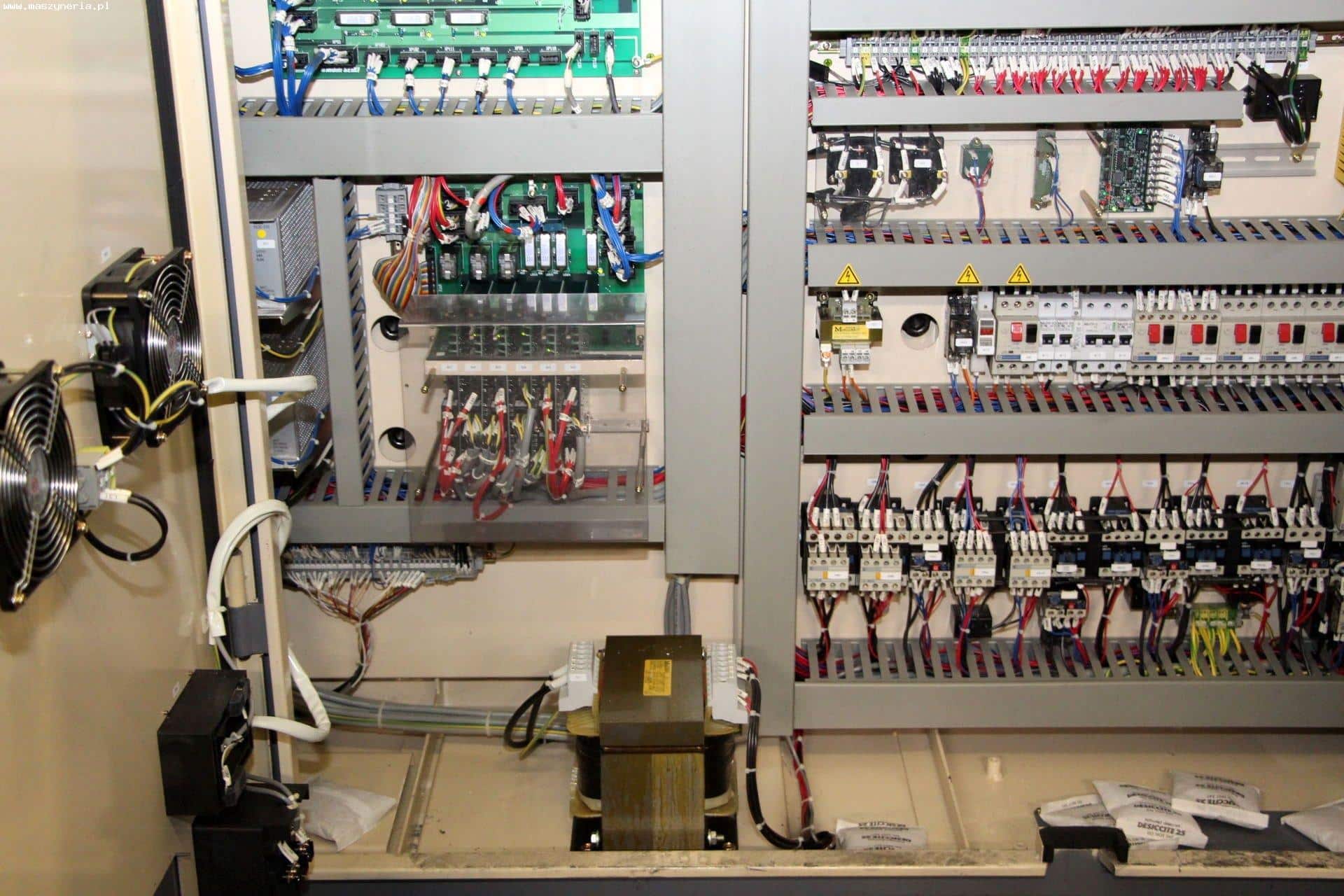

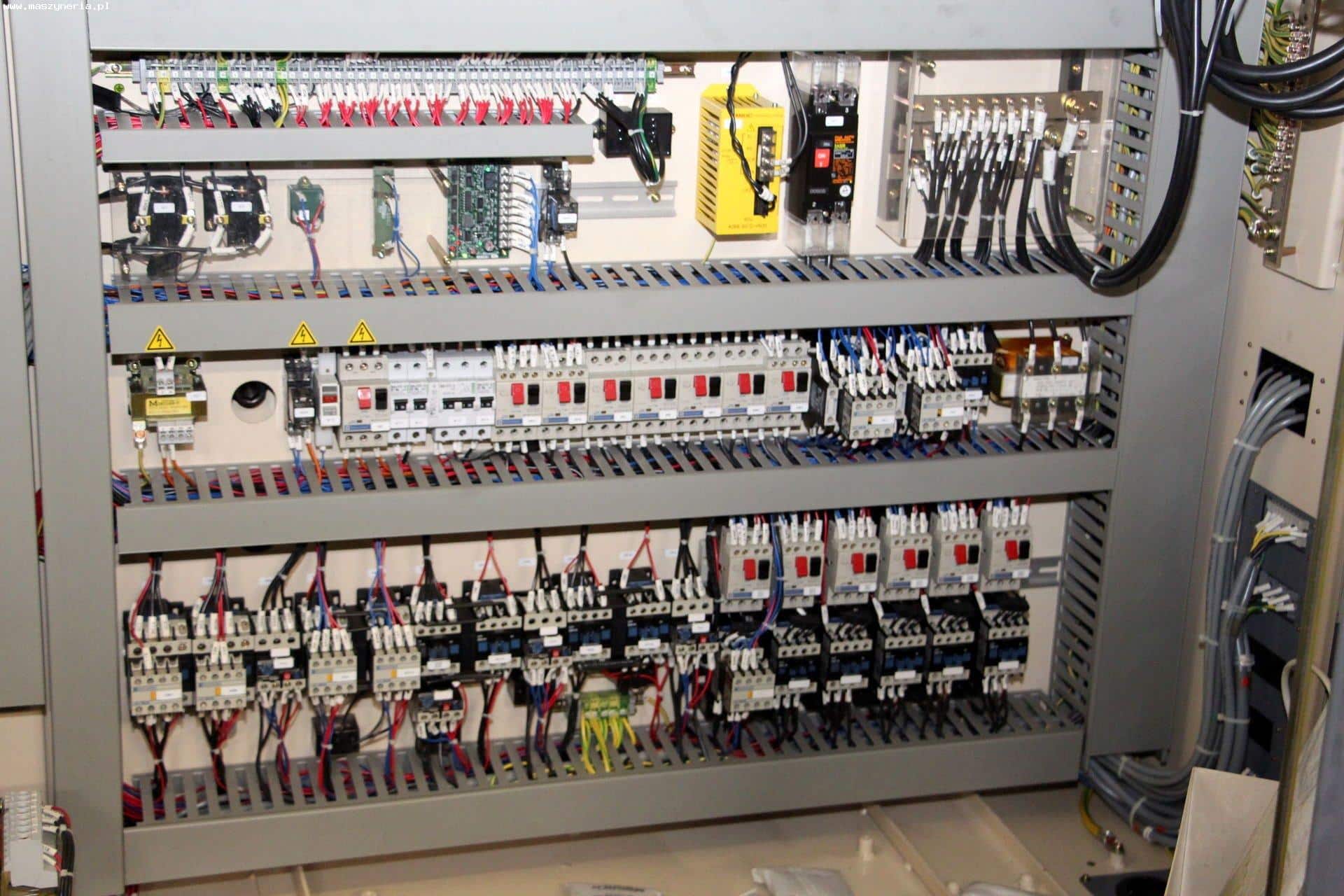

– CNC control: MORI SEIKI MSC-502

– X / Y / Z axis travel: 630/600/650 mm

– accelerated feed: 32,000 mm / min.

– feed speed: 1-16000 mm / min.

– maximum weight of the workpiece: 500 kg

– maximum diameter of the workpiece: 730 mm

– maximum height of the workpiece: 700 mm

– table size: 500 x 500 mm

– spindle speed range: 12,000 rpm.

– distance between the spindle center and the table surface: 50-650 mm

– distance between the spindle tip and the center of the table: 150-800 mm

– coolant tank: 500 l

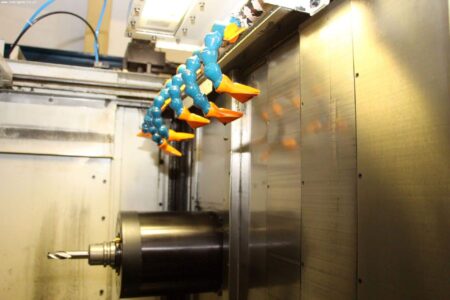

Tool magazine – ATC MORI SEIKI SH-500/40 CNC machining center

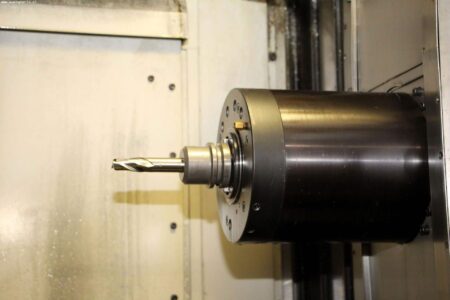

– tool shank version: MAS BT-40 (CAT-40)

– tightening bolt version: 90 degrees for MORI SEIKI

– pallet change system: rotary version

– number of tools: 40

– maximum tool diameter (with adjacent tools): 100 mm

– maximum tool diameter (without adjacent tools): 150 mm

– maximum tool length: 360 mm

– maximum weight of tools: 12 kg

– maximum tool mass moment (from the cone reference surface): 14.13 (1.44) Nm (kgf m)

– number of pallets: 2 (3)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano