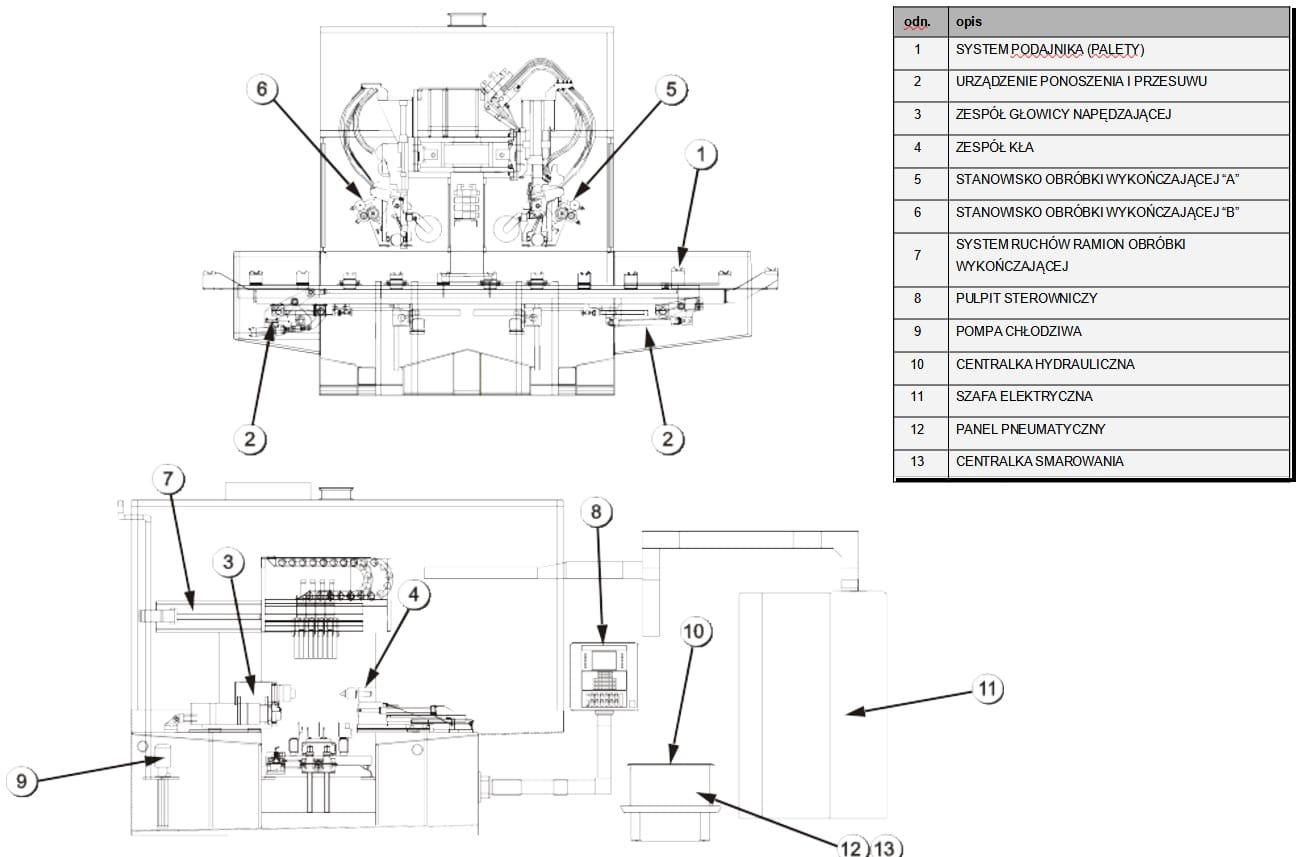

The NAGEL 2TF6-63K54/10S/NC crankshaft belt grinding machine was built in 2002 by the German company Nagel Maschinen- und Werkzeugfabrik GmbH. The crankshaft machining line, equipped with a SIEMENS Sinumerik 840D CNC controller, is designed for finishing crankshaft main journals and crankpins.

After the actuator has been started, the lifting unit takes the workpiece from the feeder and places it on the machine pallet. The opposing fang and driving head move into the machining area, and the centring and rotation of the workpiece by the drawing pins takes place. After the lifting and traversing unit has moved out of the working area , the lifting unit returns to the bottom and the finishing stations start machining .

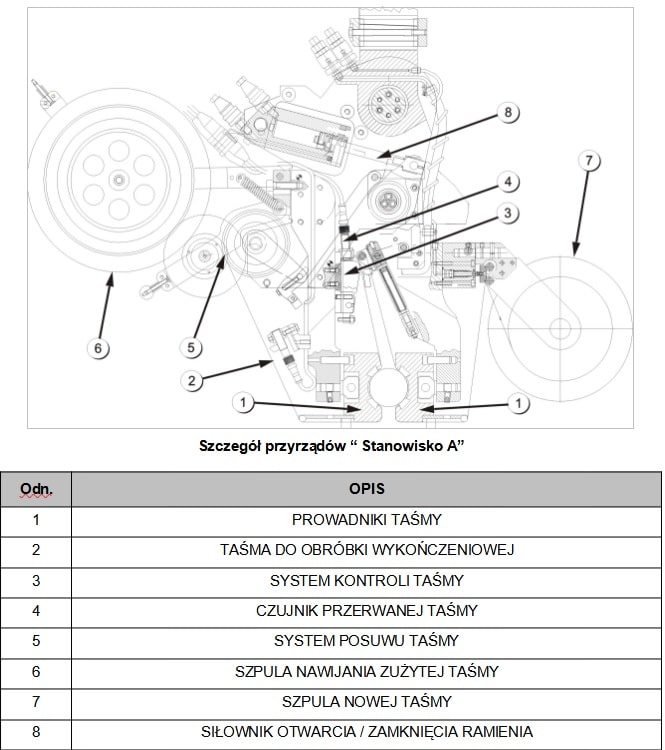

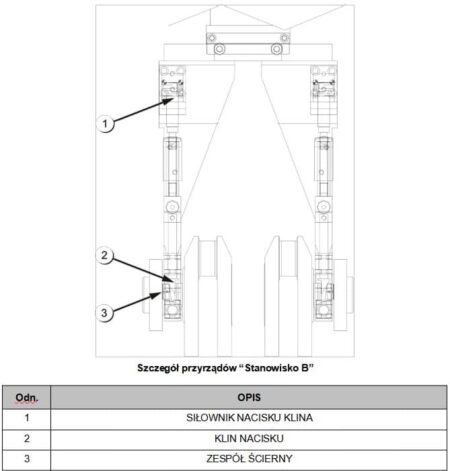

The machine has two finishing stations – “A” and “B”. Finishing station “A” has an arm with 9 lapping fabric slides, 4 slides for journal machining and 5 slides for journal machining, performing the first machining of the workpiece. At the “B” finishing station, the sealant seat, the corresponding chamfer and the hub seat are machined.

When the machining is completed, the arms open and the finishing unit returns to its original position. The lifting assembly moves up and the fang and drive head release the workpiece . The pallet with the workpiece is then moved towards the feeder at the exit of the NAGEL 2TF6-63K54/10S/NC machine.

Technical data of the NAGEL 2TF6-63K54/10S/NC crankshaft belt grinding machine

- CNC controller: SIEMENS Sinumerik 840D

- PLC controller: SIEMENS Simatic S7-300

- cycle time: 36 sec.

- finishing cycles time: 24 sec.

- approximation cycle time: 12 sec.

- electrical supply: 400 V pz; 50 Hz

- working pressure: 0.6 Mpa

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe