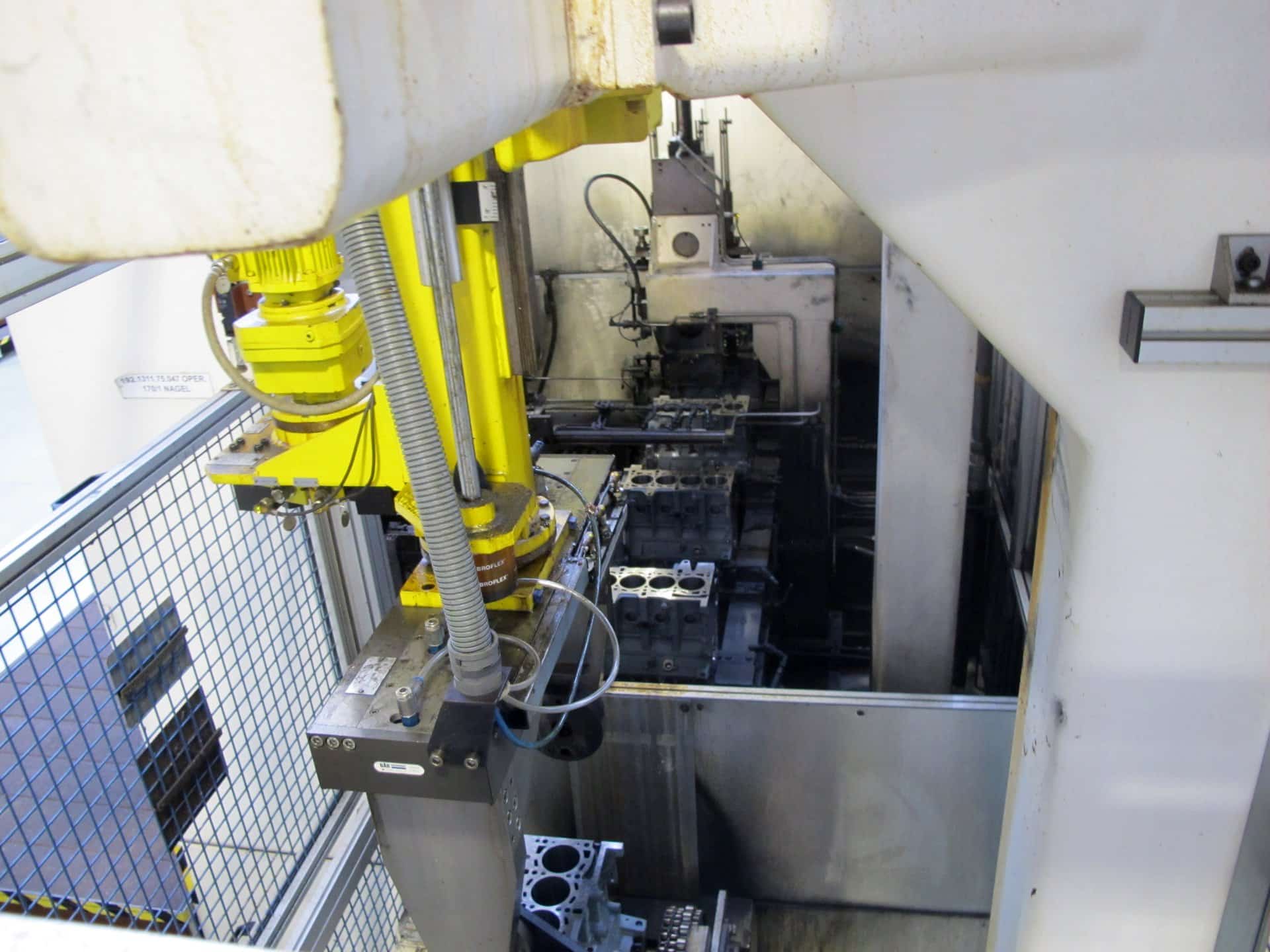

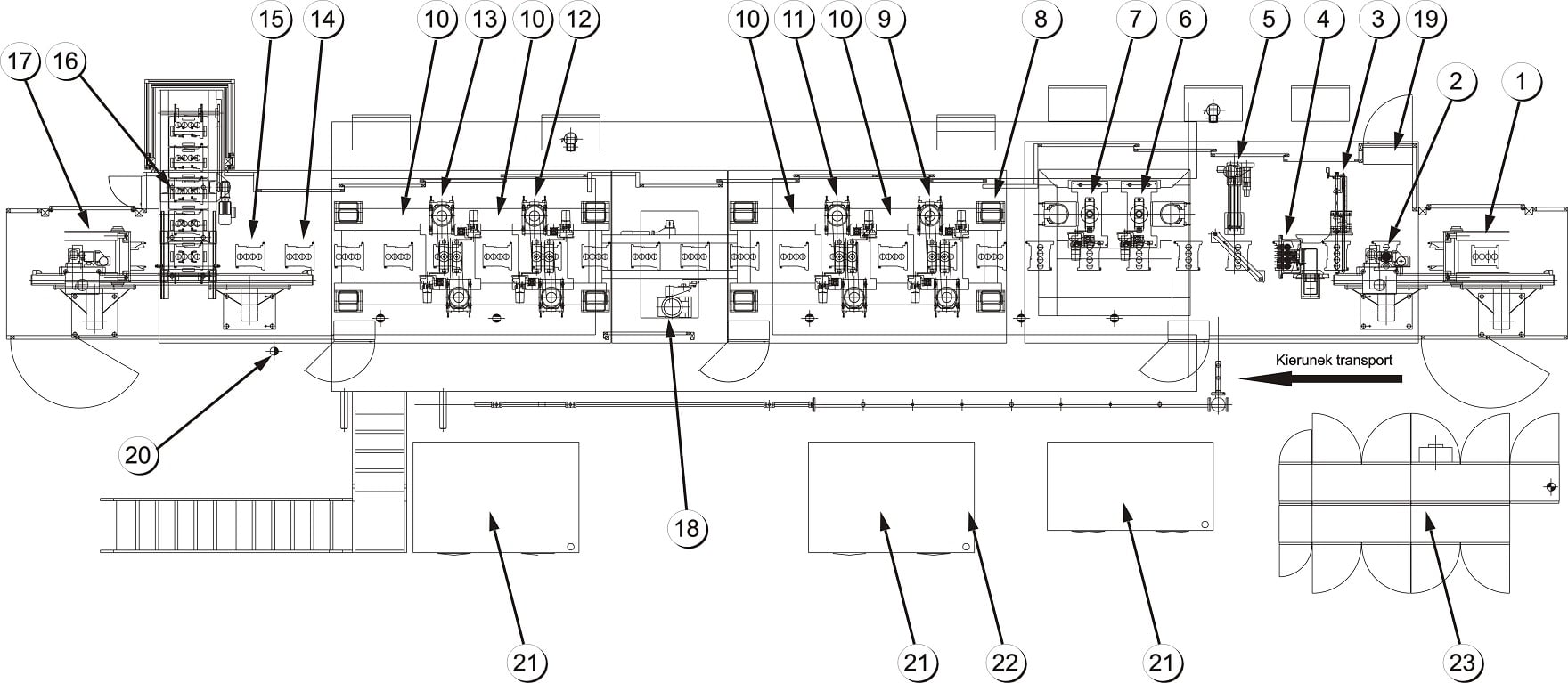

NAGEL 8 VS 8-60 + 2 VS 10-100 T honing machine, manufactured in 2002 in Germany, is a specialised machine for roughing and finishing crankshaft axles and engine hull cylinders. The machining line for the engine hull consists of 25 stations, between which the workpieces are moved by a moving bar consisting of two cylinders and positioning supports and pins, which hold the workpiece during transport.

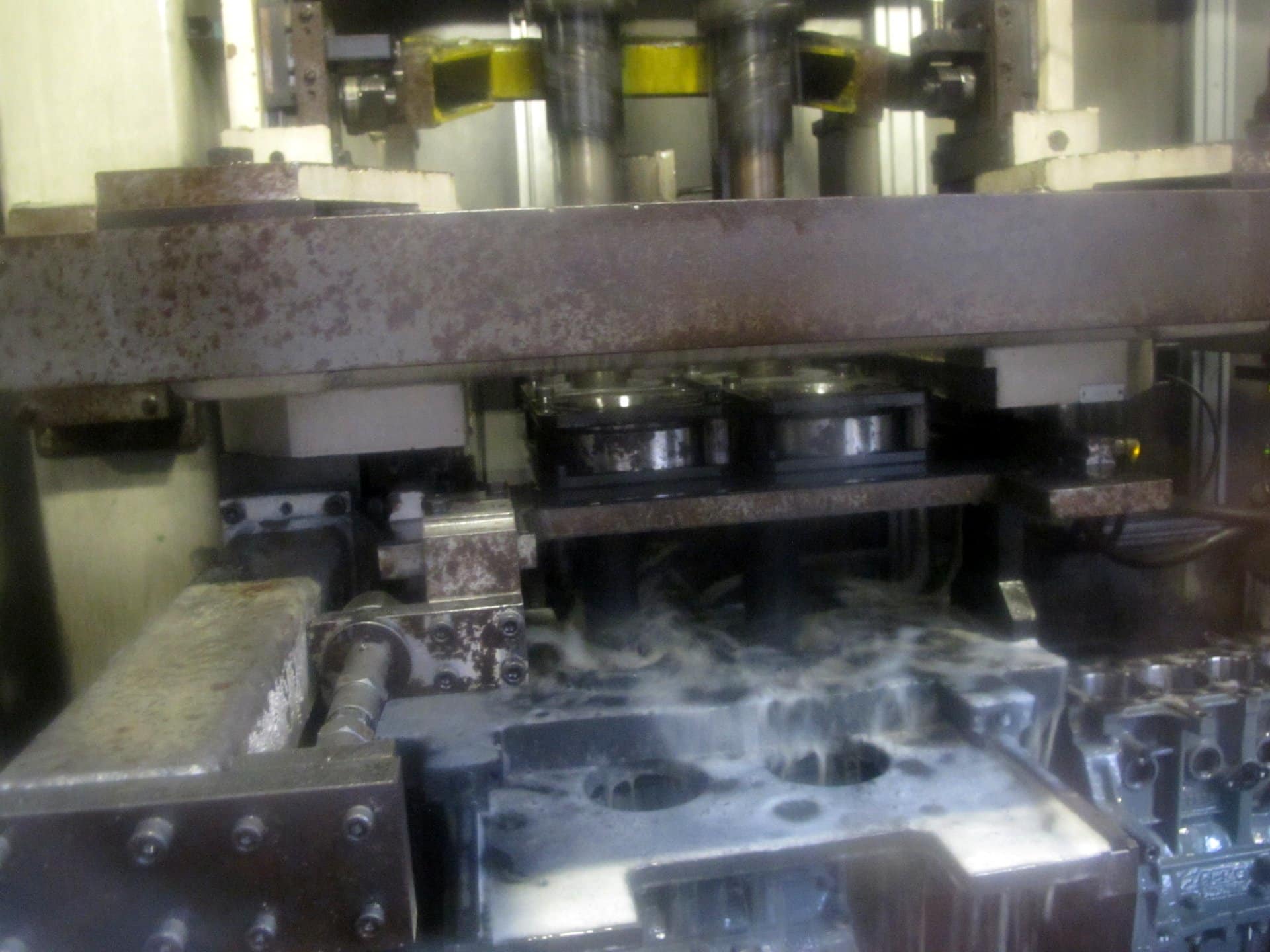

Stations 2 and 3 of the machine are responsible for inspecting the crankshaft axes and cylinders. The tolerances of the workpiece are checked before it is machined. After leaving the inspection stands, the coolant feed opening to the engine casing is cleaned at station 4. After the workpiece is turned, stations 6 and 7 carry out the roughing and finishing of the crankshaft axle respectively.

Stations 10 and 11 carry out rough machining of 1+3 and 2+4 cylinder bores, while stations 18 and 20 carry out their finishing. At station 23, after the machining is completed, the hull is marked. The MV 15 INTEGRAL marking machine marks the workpiece with the operator code, machining time and day and the machine code.

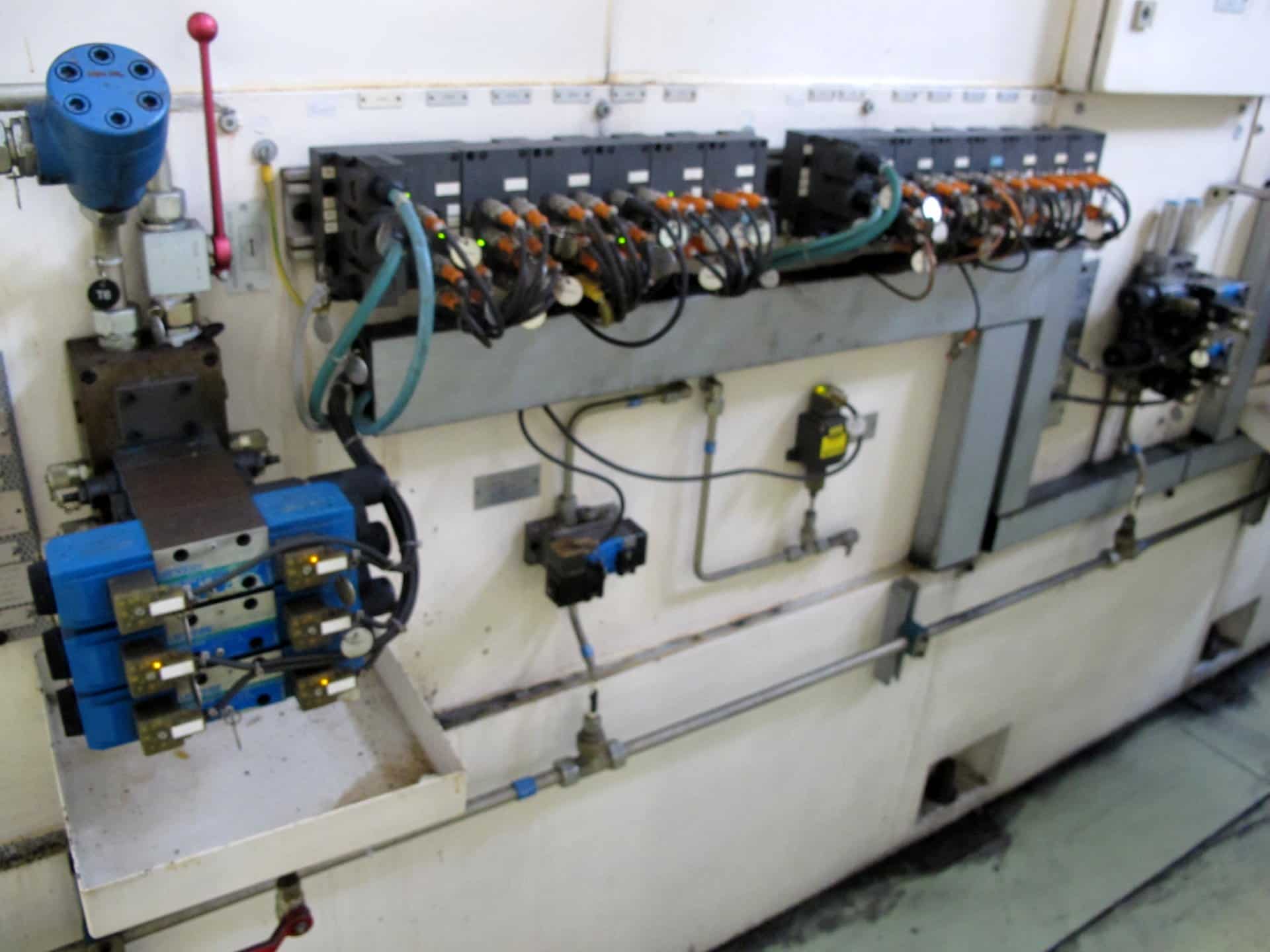

The machine processes 100 workpieces per hour at 100% load. The machine is equipped with a SIEMENS SINUMERIK 840D CNC control and a SIEMENS SIMATIC S7-300 PLC controller. The total weight of the machining line for the engine hull is 45 t.

Technical data of the NAGEL 8 VS 8-60 + 2 VS 10-100 T honing machine

- PLC controller: SIEMENS SIMATIC S7-300

- CNC control: SIEMENS SINUMERIK 840D

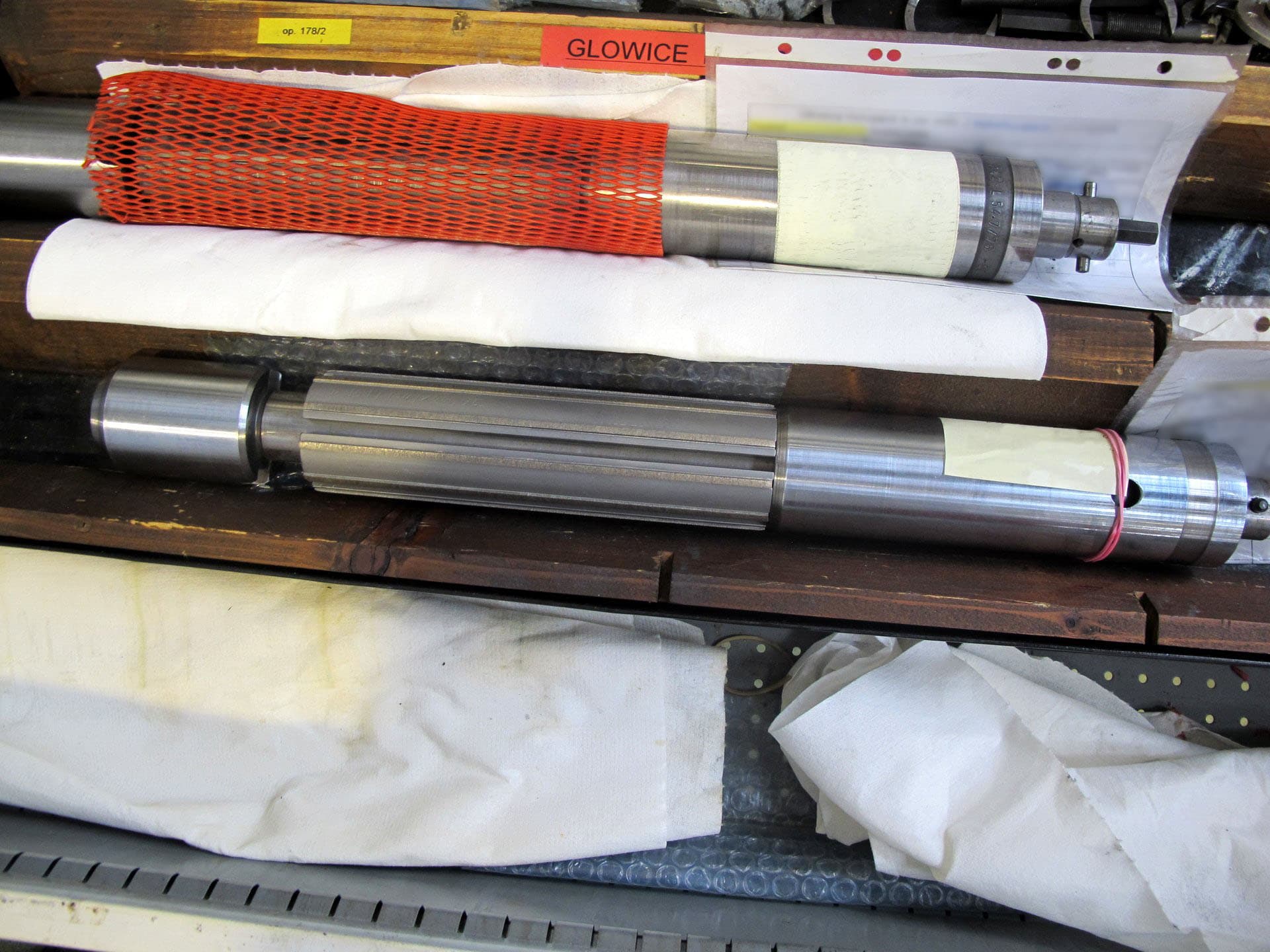

- smoothing spindle control: NAGEL MS-U3

- marking machine: MV 15 INTEGRAL

- machine capacity: 100 machined items/hour (at 100% load)

- machining diameter (VS 8/VS 10): 69.6 mm/ 54.7 mm

- pre-treatment machining diameter: 69.54 ± 0.015 mm / 54.65 ± 0.025 mm

- processing length: 150 mm/ 5×20 mm

- smoothing time: 28 sec. / 22 sec.

- post processing time: 8 sec. / 14 sec.

- clocking time: 36 sec.

- number of smoothing spindles: 8 / 2

- spindle speed: 130 – 465 rpm

- operating voltage: 380 V; 50 Hz

- power consumption: 178 kW

- machine height: 5100 mm

- total weight: 45 t

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe