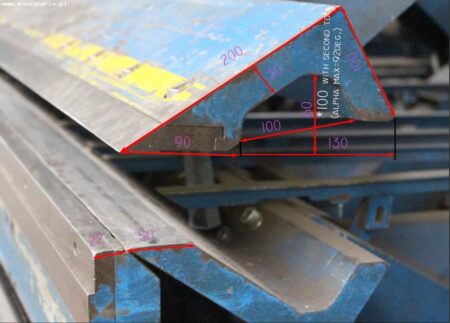

NC hydraulic folding machine LIPTOVSKE STROJARNE XOS 8000/4 was built in Slovakia in 1999. The working length of bending is 8050 mm, and the maximum thickness of the processed sheet is 4 mm (aluminum). The machine is equipped with a beam deflection compensation system (Bombierung), as well as a hydraulic thickness adjustment of the bent sheet metal. The hydraulic system has the most efficient pump that has been installed in these machines. The machine is equipped with an additional, replaceable “high” tool that allows to perform unique functions, allows you to bend narrow, high catheters (“U” profile) and semi-closed catheters (“C” profile). Additionally, the bending machine has a screwed strip that supports bending of thick sheets. The hydraulic folding machine with the connected hydraulic station has the dimensions of approx. 1.5 x 11 m. For transport, it is possible to disconnect the hydraulic station. The machine will then have a size of approx. 8.5 m.

Technical data of Liptovske Strojarne XOS 8000/4 bending machine

– bending length: 8050 mm

– maximum thickness of bent sheet metal, steel: 3.0 mm

– maximum thickness of sheet metal, aluminum: 4.0 mm

– machine weight: 11500 kg

Accessories for Liptovske Strojarne XOS 8000/4 bending machines

– rotary shear

– pressure beam deflection compensation (Bombierung)

– a very efficient pump

– spare parts, e.g. sleeves for the bending mechanism, relays, electronic control system components

– additional replaceable “high” tool

– technical documentation (hydraulic and electrical diagrams and user manual)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano