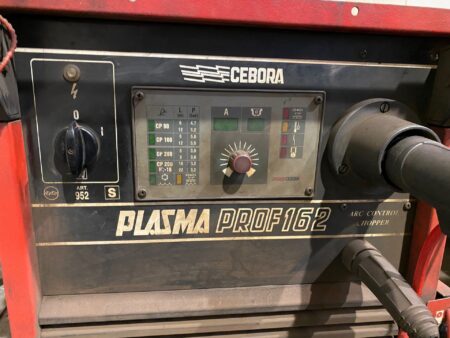

The Nessap 1600 KOMBI plasma cutter was produced in the Czech Republic in 2002 by RIZENE STROJE s.r.o. The plasma cutter portal moves on special guides equipped with a double-sided drive, thanks to which there are no vibrations or jamming. The plasma cutter cuts the sheet metal with a thickness of 30 mm, and the feed rate of the torch is from 0.1 m/min to 10 m/min. The machine has a table (L x W) 3000 x 1500 mm and a portal with a plasma torch. The cutter is equipped with a Nessap CNC control, an anti-collision system and a Cebora Plasma Prof 162 plasma aggregate. The total weight of the machine is 1800 kg.

Technical parameters of the Nessap Kombi 1600 plasma cutter

– surface of the working table (L x W): 3000 x 1500 mm

– maximum thickness of the material to be cut: 30 mm

– minimum feed rate of the burner: 0.01 m/min

– maximum speed of the burner: 10 m/min

– positioning accuracy: min. step 0.01 mm

– maximum power consumption: 22 kW

– dimensions of the plasma cutter (length x width x height): 4100 x 2500 x 1700 mm

– machine weight KOMBI 1600: 1800 kg

Accessories for NESSAP KOMBI 1600 plasma cutter

– CNC control: Nessap

– plasma aggregate: Cebora Plasma Prof 162

– anti-collision system

– plasma torch

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe