OKUMA LB3000EX II CNC turning center was built in 2014 in Japan. This highly technologically advanced machine designed for the most demanding production challenges is distinguished by its extensive machining capabilities, reliable components and extensive equipment. This is what makes the machine ideal for efficient turning, milling, drilling, threading and slotting of workpieces with the highest precision and accuracy.

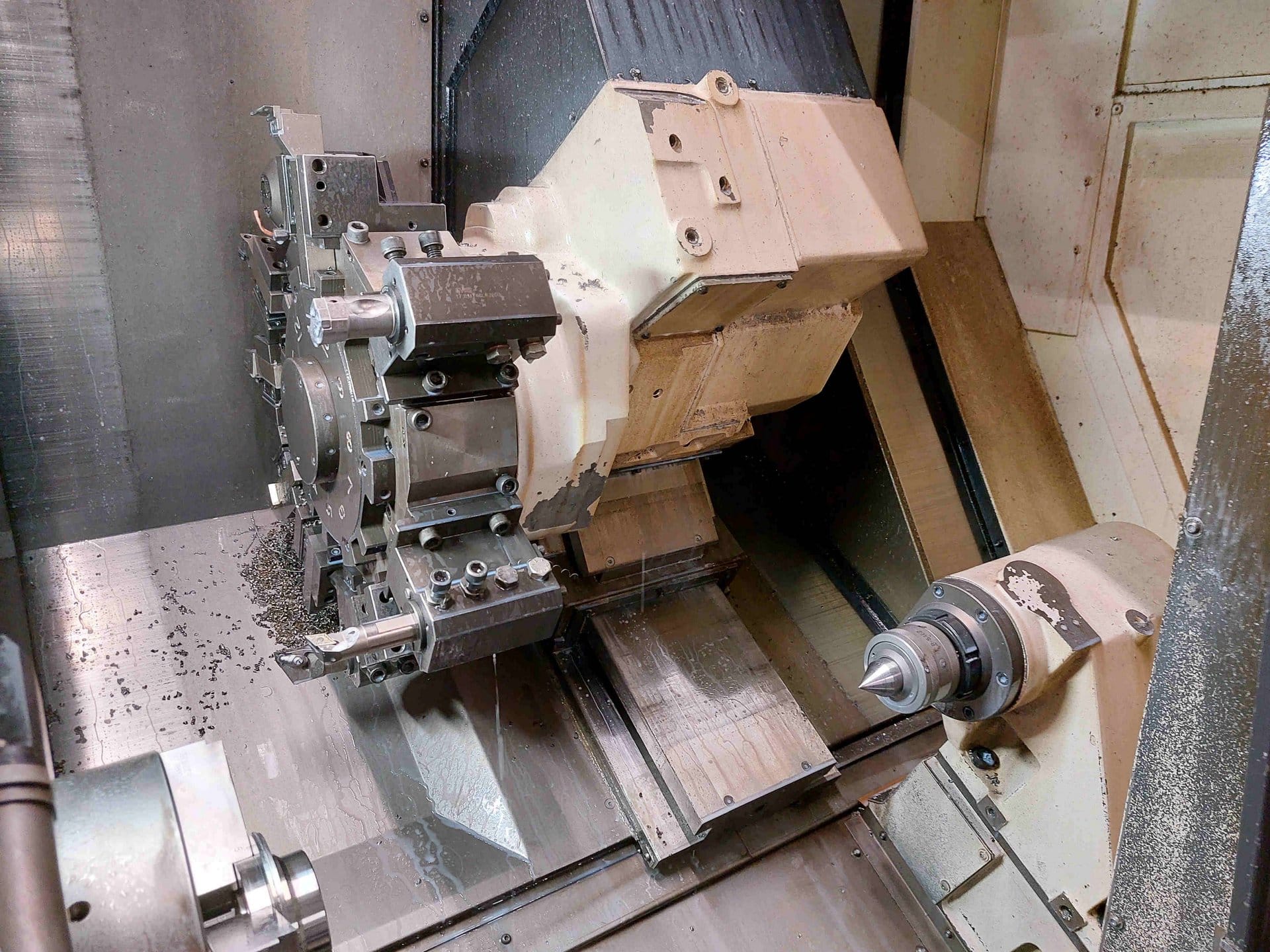

In order to guarantee high dimensional stability and rigidity, an inclined bed is used inside the machine, on which the spindle and turret head are optimally positioned. In addition, special sensors have been placed in the key zones of the bed, spindle and head support, which monitor the current temperature status and actively correct the working travels. This solution helps to ensure proper thermal properties inside the working area.

The LB3000 EXII MY C 450 lathe also features the innovative Machining Navi L-g technology, which calculates the most beneficial machining parameters for a given task based on an analysis of the acoustic spectrum. As a result, vibrations and oscillations are completely eliminated, resulting in better workpiece surface quality, extended tool life and reduced spindle load.

The offered OKUMA LB3000EX-II CNC lathe also has a wide range of equipment, including an NC tailstock with the ability of setting clamping force, lathe chucks, Y-axis and an intuitive OKUMA OSP-P300L CNC controller with many useful functions. The total weight of the machine is 4750 kg.

Technical data of the OKUMA LB3000EX II turning center

- feed rate in the X/Y/Z axis: 260/120/510 mm

- maximum spindle rotational speed: 5000 rpm

- spindle passage: ⌀ 80 mm

- spindle torque: 427 Nm

- C axis indexing: every 0.001°

- maximum driven tool speed: 6000 rpm

- driven tool drive torque: 40.4 Nm

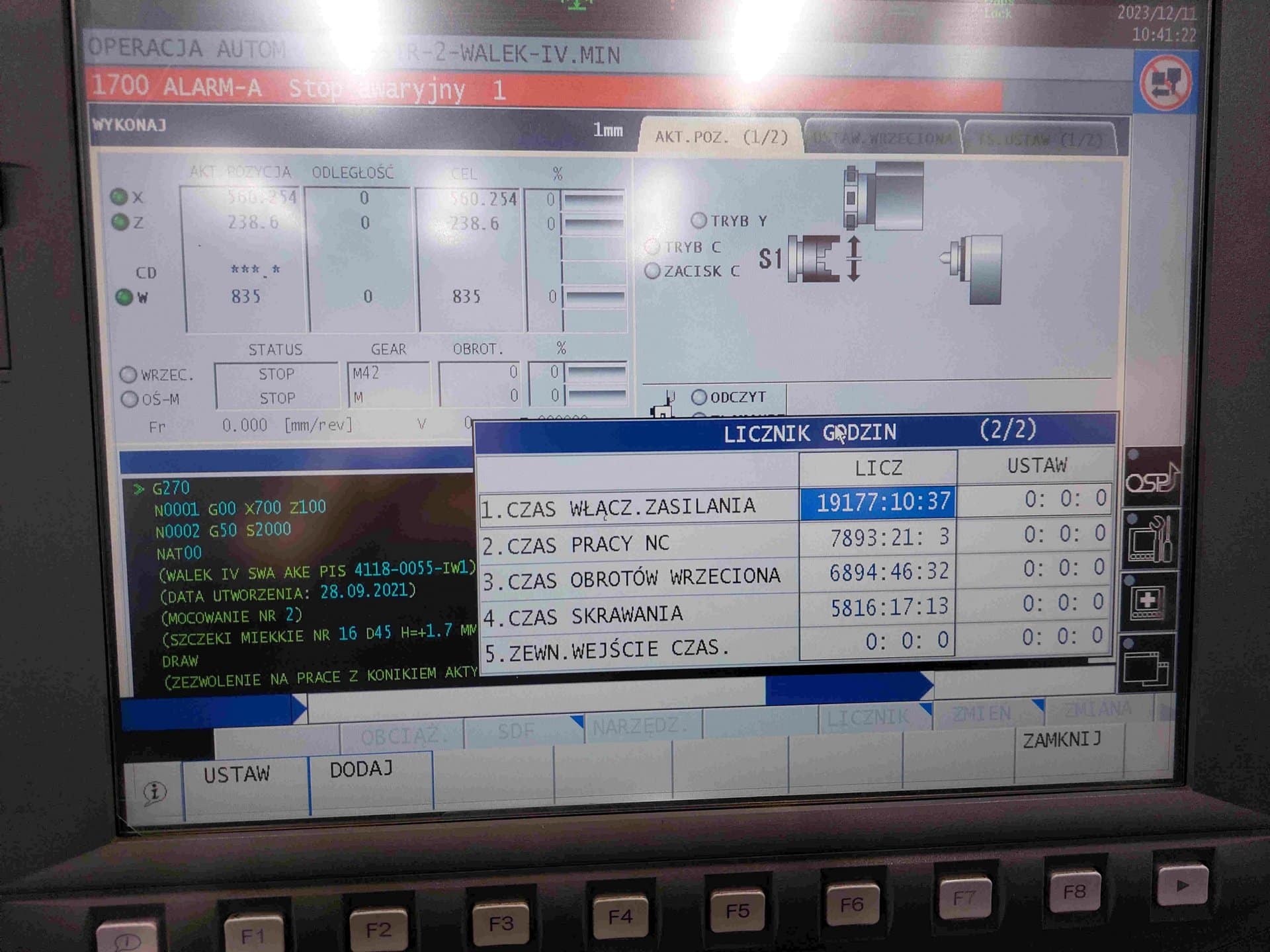

- cutting time: 5816 h

- machine switch-on time: 19177 h

- vibration reduction technology: Machining Navi L-g

- thermal stabilisation system (spindle): TAS C

- thermal stabilisation system (structure): TAS S

- connection power: 29 kVA

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W x H): 2310 x 1734 x 2250 mm

- weight of machine: 4750 kg

Equipment of the Space Turn LB3000 EX II lathe

- CNC control: OKUMA OSP-P300L

- Y axis

- C axis

- NC tailstock with the ability of setting clamping force

- tool measurement touch probe

- jaw-typelathe chuck 250 mm diameter

- lathe chuck range 4-30 mm with collets and reduction sleeves

- chuck (end face) range 6-19 mm

- chuck (end face) range 13-26 mm

- face driver: NEIDLEIN 73012 FSB 01

- tooling (lathe knives, threading knives, knife adapters, holders, boring bars, soft jaws, hard jaws, reduction sleeves, clamping collets, gear/spindle milling chuck etc.)

- 12-position toolholder in BMT 60 technology with the option of driving all tools

- tool holder: KINTEK H132KC

- CAS (Collision Avoidance System)

- chip conveyor

- oil mist extraction: LOSMA DARWIN 600 M

- LAN module

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe