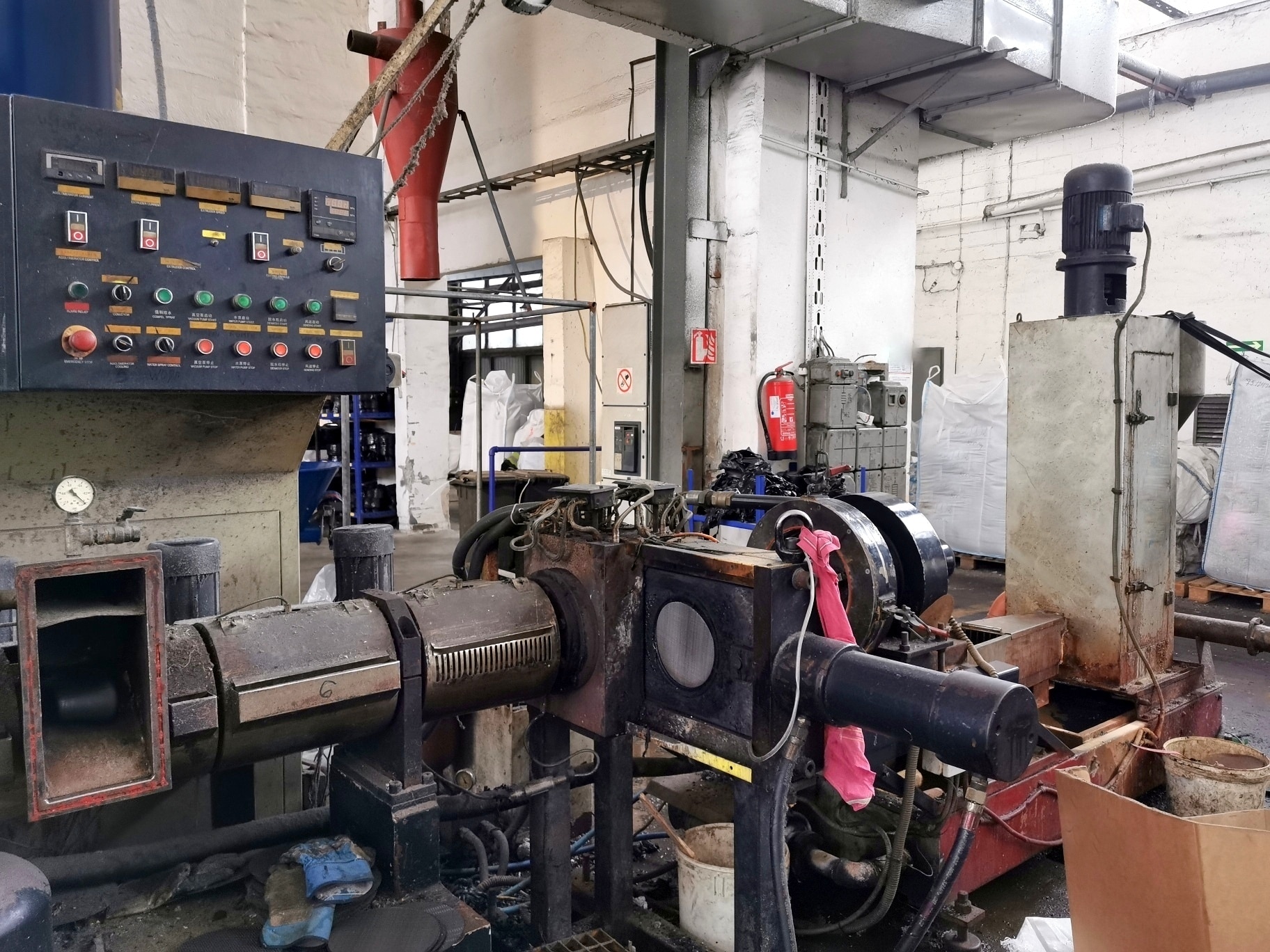

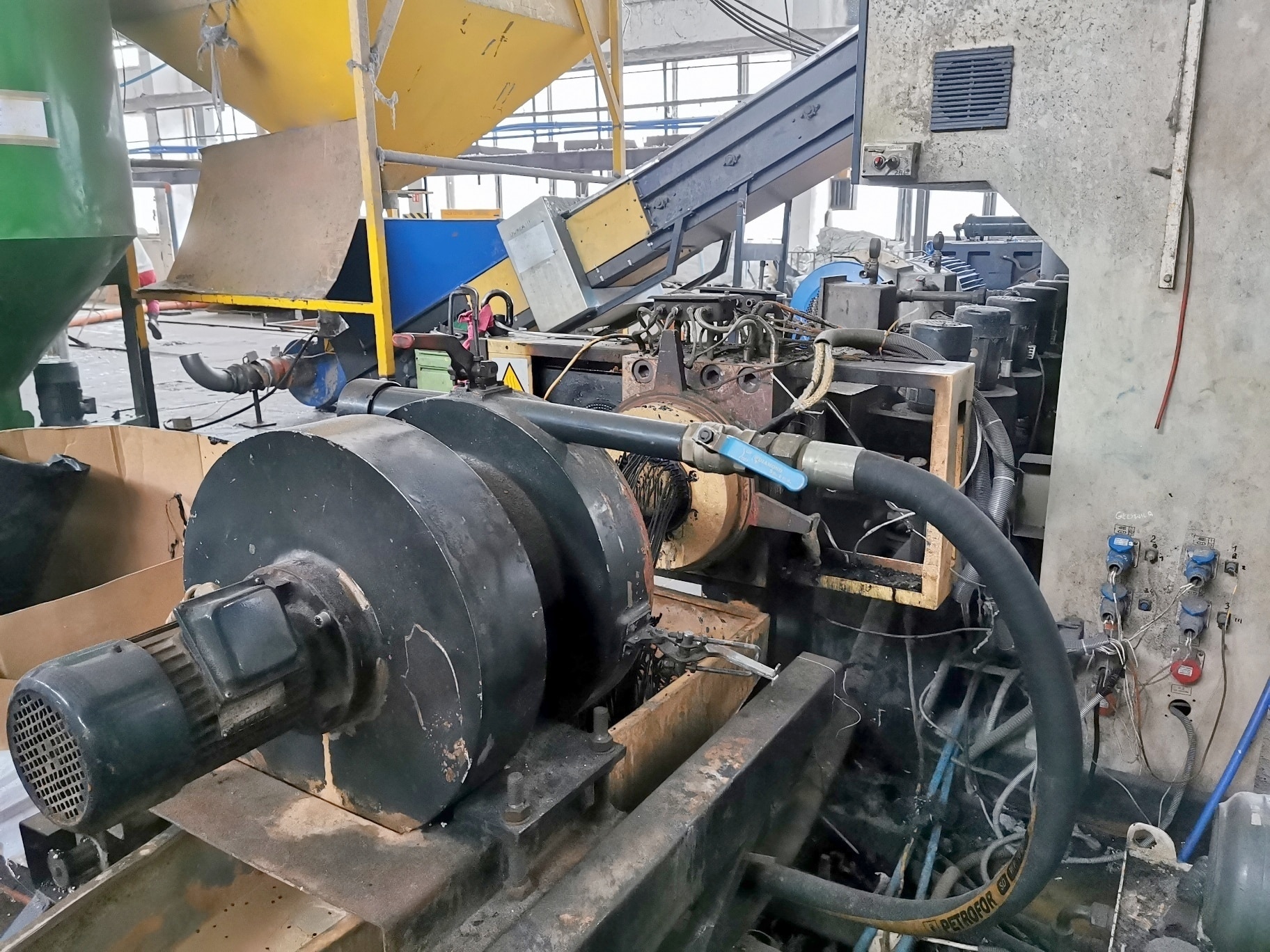

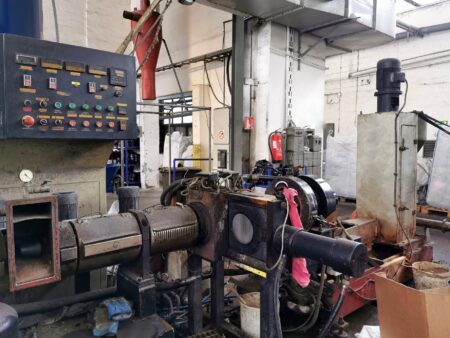

PE 300 plastic recycling and regranulation line was built in China in 2011 by Zhangjiagang Wuhe Machinery Co. LTD. The extruder for plastics used in the processing and manufacturing of various types of materials can produce up to 300 kg of parts in one hour of operation. The complete PE and PP plastic extrusion line includes a compactor, screw, cylinder, conveying system, heating system and temperature control panel.

Material production begins by heating the plastic to a maximum temperature of 300°C in the 11 heating zones of the PE 300 granulating line, controlled by thermoregulators. The extruder then presses the material further through a 100 mm diameter screw located in a cylinder with abrasion and rust protection. At the end of the process, the machine head moulds the plastic to give it the right properties and shape.

The PE 300 extruder is equipped with thermoregulators with a digital display to control the current temperature of the cylinder and a special device to protect the extruder from overvoltage.

Technical specifications of the PE 300 extruder

Extruder WH100/36

- capacity: 250-300 kg/h

- screw diameter: ø 100 mm

- motor speed: 1480 rpm

- thermoregulators: RKC

- contactors: SCHNEIDER

- hydraulic plate screen changer with diameter of ø 200 mm

- air-cooled screw and cylinder

- 7 heating zones with a power of 5 kW each

- 7 cooling sections with fans of 0.37 kW each

- motor power: 90 kW

- vacuum pump power: 3 kW

Compactor

- number of moving knives: 9

- number of fixed knives: 15

- speed of knives: 1000 rpm

- temperature sensor

- motor power: 55 kW

- cooling system motor power: 1.5 kW

Hydraulic, plate screen changer

- condenser: SL-411

- diameter of filtration surface: 200 mm

- screen change time: <2 s

- maximum pressure: <20 Mpa

- low oil level alarm

- heating power: 15 kW

- oil pump power: 3.75 kW

Centrifuge

- motor speed: 1480 rpm

- motor power: 5.5 kW

- water pump motor power: 4 kW

Fan feeder

- fan speed: 2800 rpm

- pipe diameter: 100 mm

- fan power: 3 kW

Cutting with head in water mist

- number of knives: 2

- motor speed: 2900 rpm

- motor controlled by ABB inverter

- motor power: 1.5 kW

- head heating power: 4.5 kW

- water pump power: 4 kW

Belt feeder

- motor power: 1.5 kW

- belt width: 600 mm

- belt length: 600 mm

Silo

- capacity: 1,2 m3

Other machine data

- total power: 213 kW

- DTR – Technical and Operating Documentation

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe