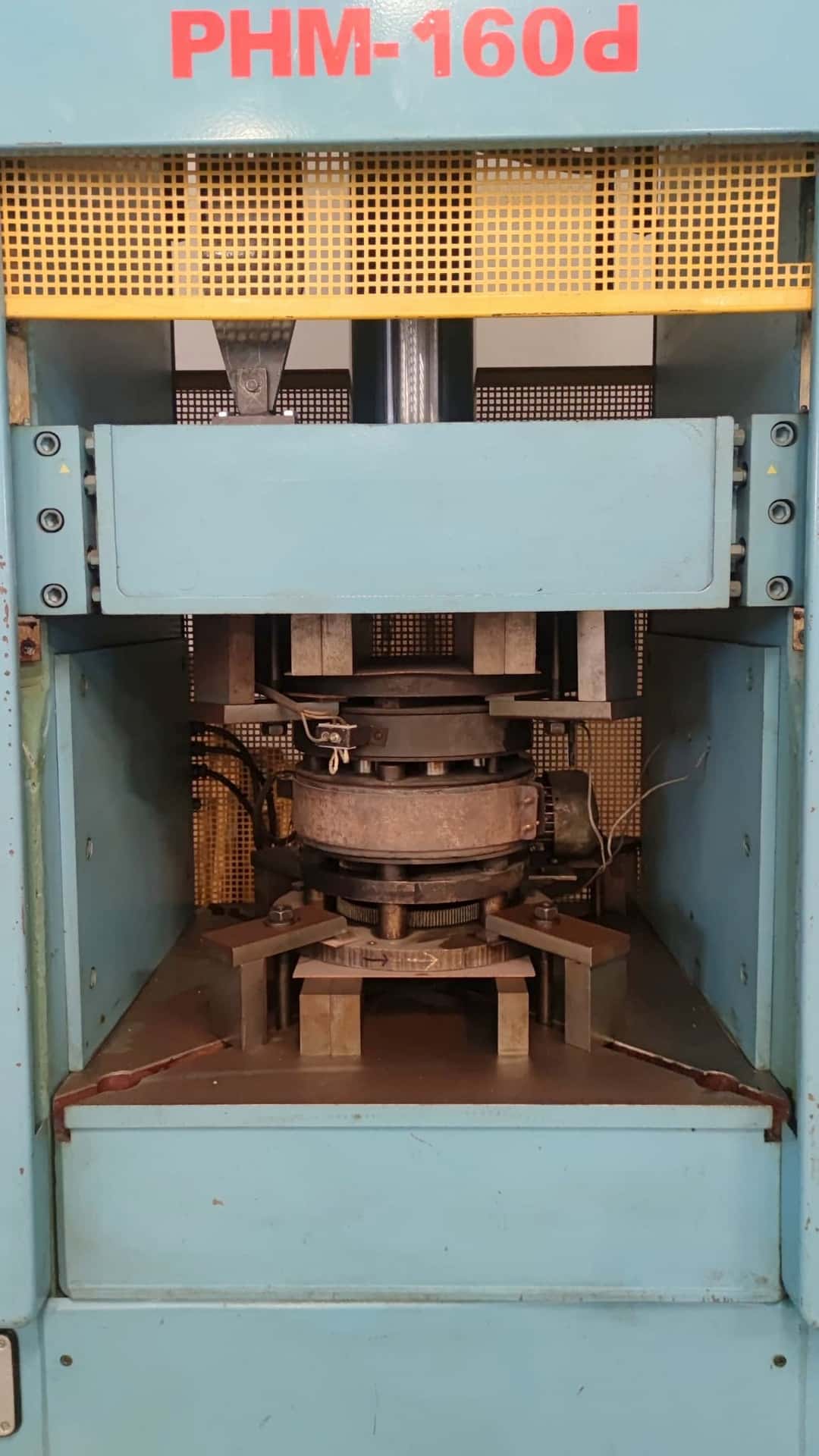

PONAR ŻYWIEC PHM 160 D hydraulic press manufactured in Poland in 1990 is used for machining metal and processing plastics (e.g. polofen or melamine) or rubber. The machine characterised by its high reliability, performs precise machining with a force of 160 tonnes in manual mode as well as in semi-automatic or automatic mode, thanks to its being equipped with time relays. The gantry press is also equipped with, among others, a hydraulic ejector with a force of 60 tonnes and two temperature controllers for the upper and lower parts of the heating plate. The offered machine was purchased from the university and has never worked during typical production. The total weight of the machine is 4000 kg.

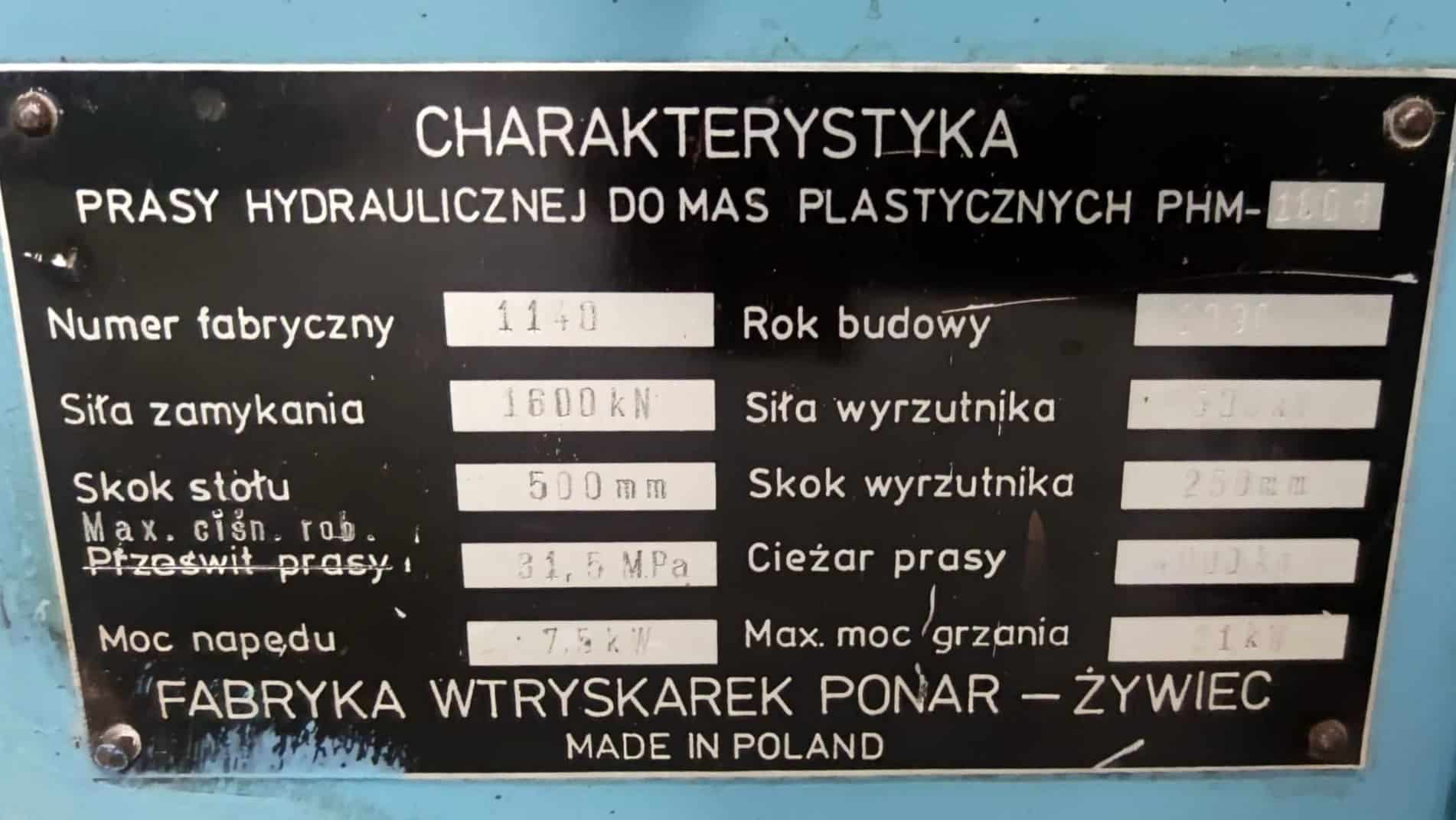

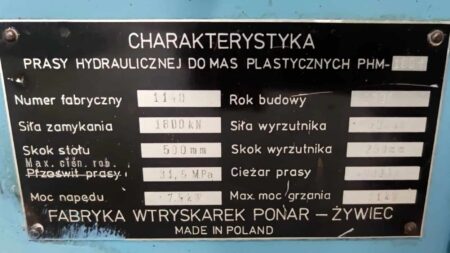

Technical parameters of the PONAR ŻYWIEC PHM 160 D press

- maximum pressing force: 160 t (1600 kN)

- ejector force: 60 t (600 kN)

- working table surface (L x W): 800 x 800 mm

- pressing speed: 5.6 mm/s

- closing speed: 91 mm/s

- opening speed: 98 mm/s

- maximum distance between tables: 1000 mm

- hydraulic ejector stroke: 250 mm

- travel of movable table: 500 mm

- maximum heating power: 1 kW

- drive power: 7,5 kW

- maximum operating pressure: 31.5 MPa

- dimensions (L x W x H): 1762 x 940 x 3290 mm

- total weight of machine PHM 160 D: 4000 kg

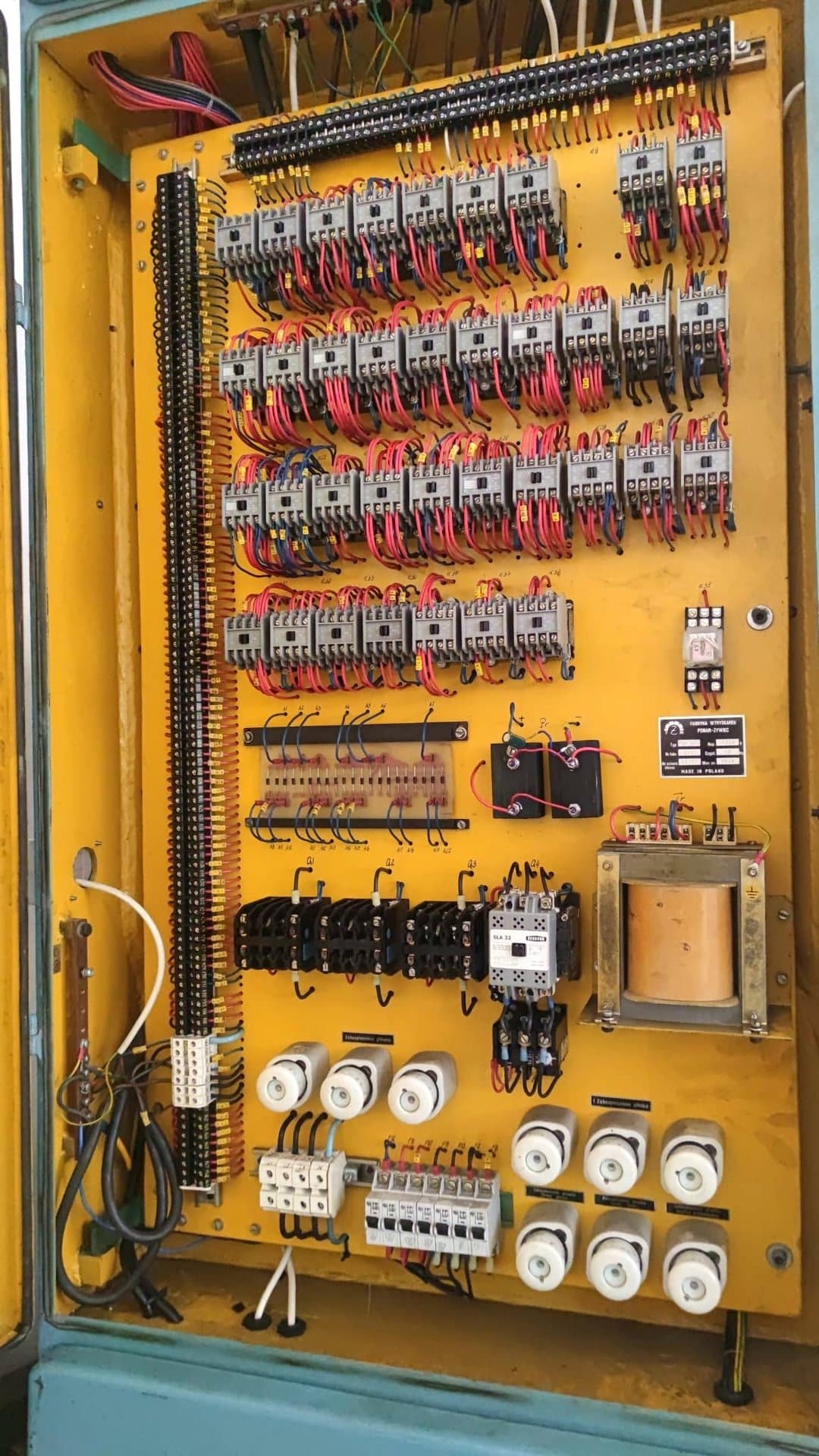

Equipment of the hydraulic press

- hydraulic ejector

- temperature sensor (2 pcs.)

- temperature controllers for the upper and lower part of the heating plate (2 pcs.)

- time relays for semi-automatic or automatic mode (4 pcs.)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe