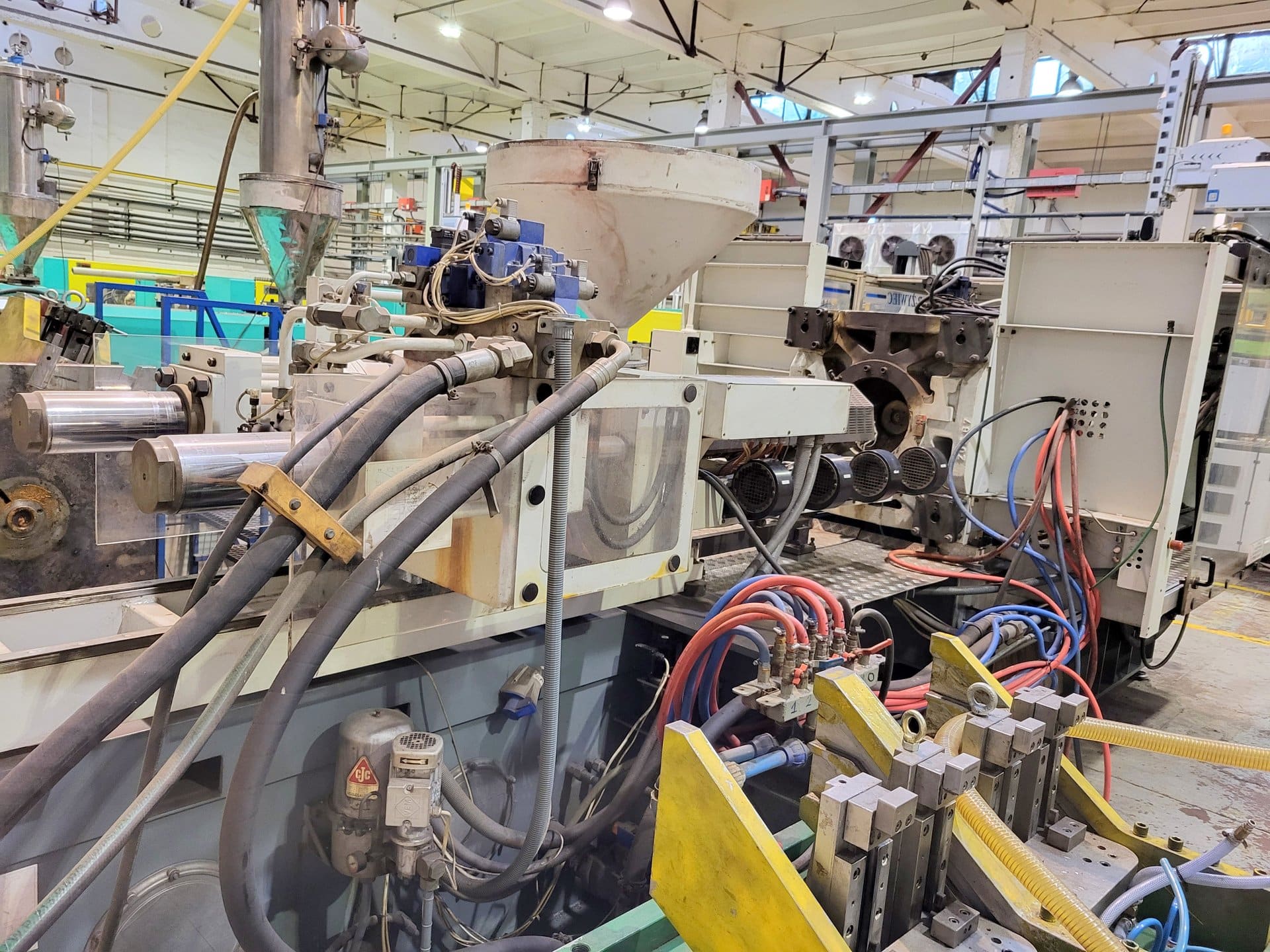

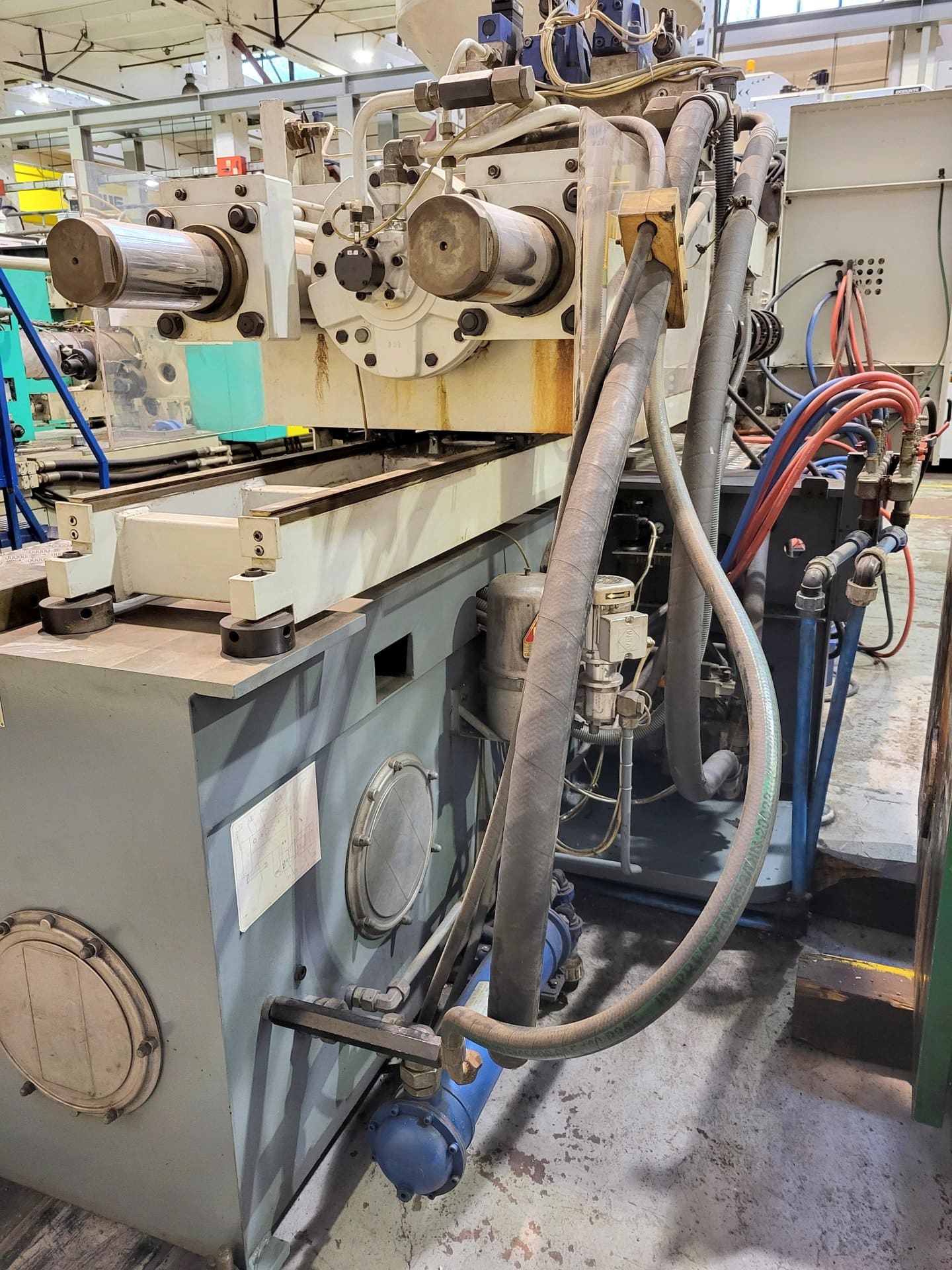

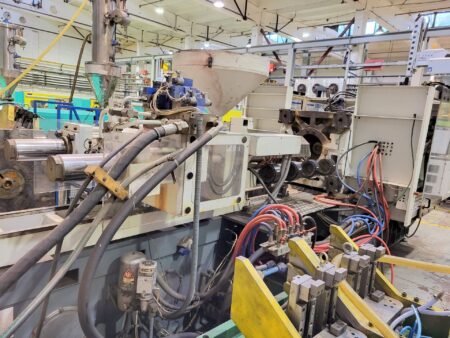

PONAR ŻYWIEC VT-280T injection moulding machine built in 2006, is used for processing of plastics using the injection moulding method. The extremely powerful machine works with moulds with a height from 200 to 600 mm, which are mounted on plates measuring 905 x 905 mm. The combination of high-quality components and the high clamping force of 280 tonnes makes it possible to obtain products of the highest quality.

The PONAR ŻYWIEC VT 280 T injection moulding machine is equipped, among others, with an efficient screw with a diameter of 65 mm and a MOOG-BUHL CNC controller, allowing for the programming of the machine’s operating modes and for the control of all plastic processing parameters. The total weight of the machine is 14000 kg.

Technical data of the PONAR ŻYWIEC VT-280T injection moulding machine

- CNC controller: MOOG-BUHL

- mould clamping force: 280 t (2800 kN)

- mould opening force: 28 t (280 kN)

- injection weight: 955 g

- injection volume: 1062 cm3

- injection capacity: 290 g/s

- injection pressure: 171 MPa

- screw diameter: 65 mm

- mould plate size (L x W): 905 x 905 mm

- maximum clearance between plates: 1170 mm

- maximum mould opening stroke: 570 mm

- minimum mould height: 200 mm

- maximum mould height: 600 mm

- clearance between columns: 620 x 620 mm

- ejector stroke: 150 mm

- number of heating zones: 4+nozzle

- heating power: 22 kW

- drive power: 37 kW

- oil tank capacity: 620 l

- maximum pressure of hydraulic system: 17.5 MPa

- total power requirement: 59 kW

- power supply: 3×380 V; 50 Hz

- overall dimensions (L x W x H): 7410 x 1960 x 2300 mm

- total weight of the VT-280 T machine: 14000 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe