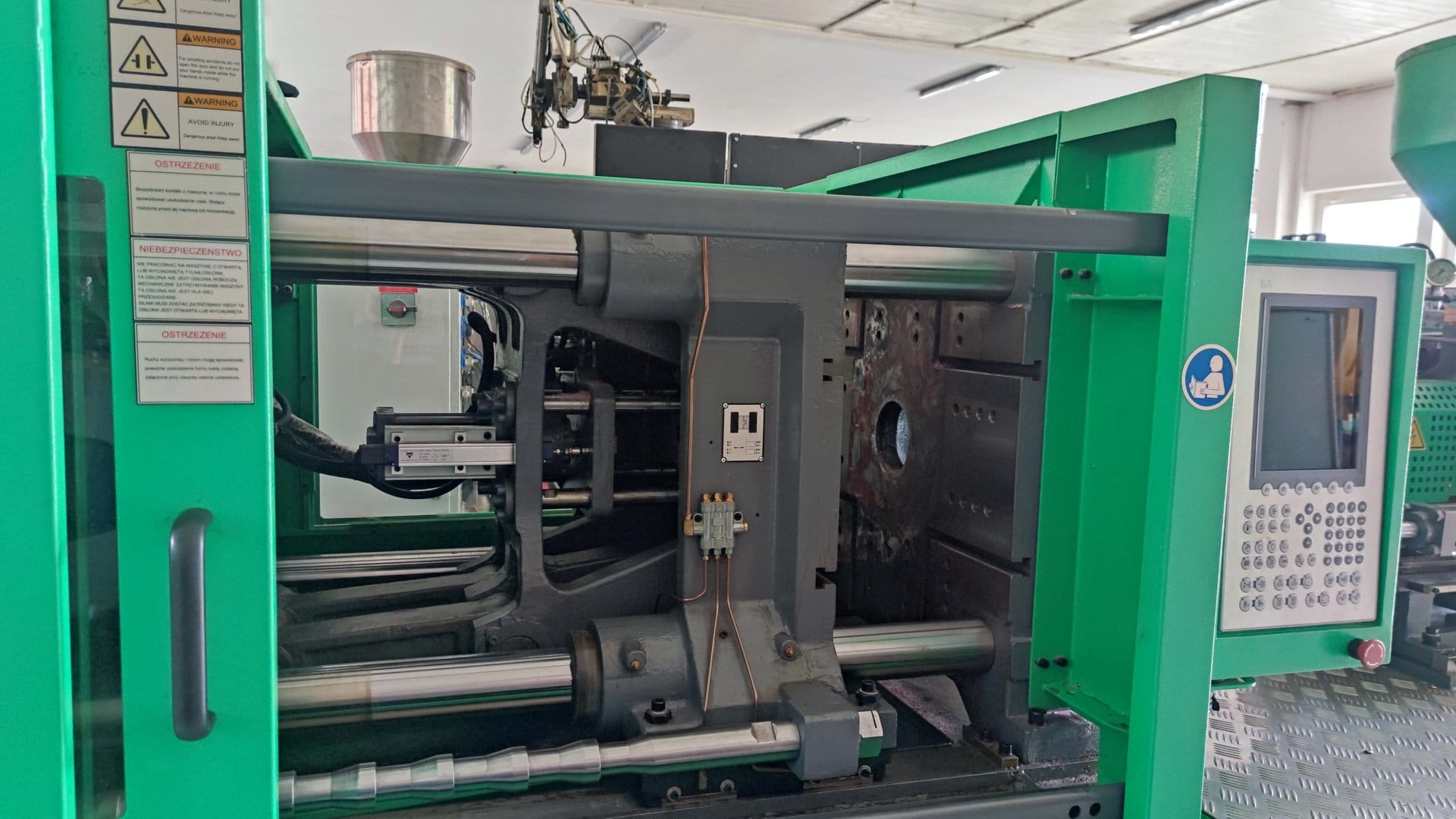

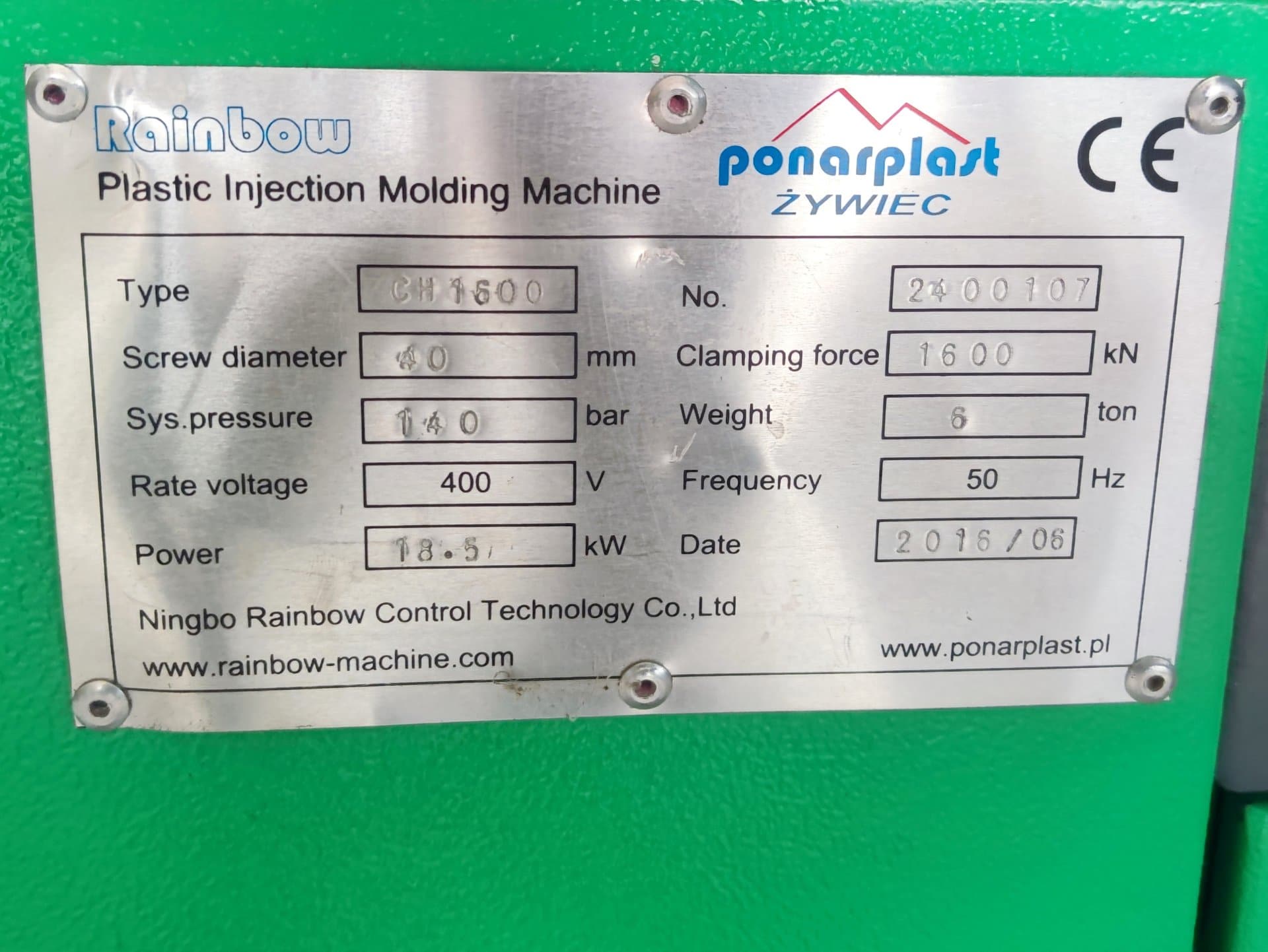

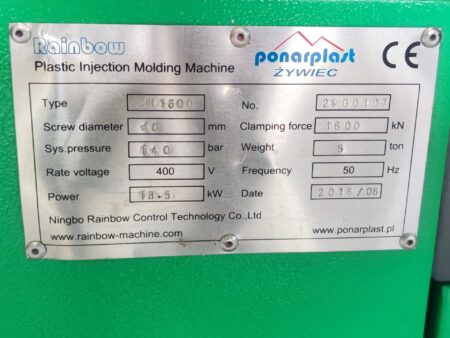

PONARPLAST ŻYWIEC RAINBOW CH-1600 injection moulding machine was built in 2016. The plastic injection moulding machine works with moulds with a height from 180 to 580 mm with a clamping force of 160 t. The plastics are fed into the machine’s injection unit receiving the correct plasticity state, after which the correct shape is given. The injection moulding machine for plastics has a screw with a diameter of 40 mm, moving with a maximum speed of 200 rpm. The total weight of the RAINBOW CH-1600 injection moulding machine is 6 t.

Technical specification of PONARPLAST ŻYWIEC RAINBOW CH-1600 injection moulding machine

- clamping force: 160 t (1600 kN)

- injection volume: 283 cm3

- injection weight: 257 g

- injection pressure: 2145 bar

- screw diameter: 40 mm

- screw speed: 200 rpm

- minimum mould height: 180 mm

- maximum mould height: 520 mm

- ejector stroke: 135 mm

- ejector force: 46 kN

- opening stroke: 435 mm

- distance between columns: 530 x 470 mm

- oil tank volume: 260 l

- heating power: 9.9 kW

- power: 18.5 kW

- power supply: 400 V; 50 Hz

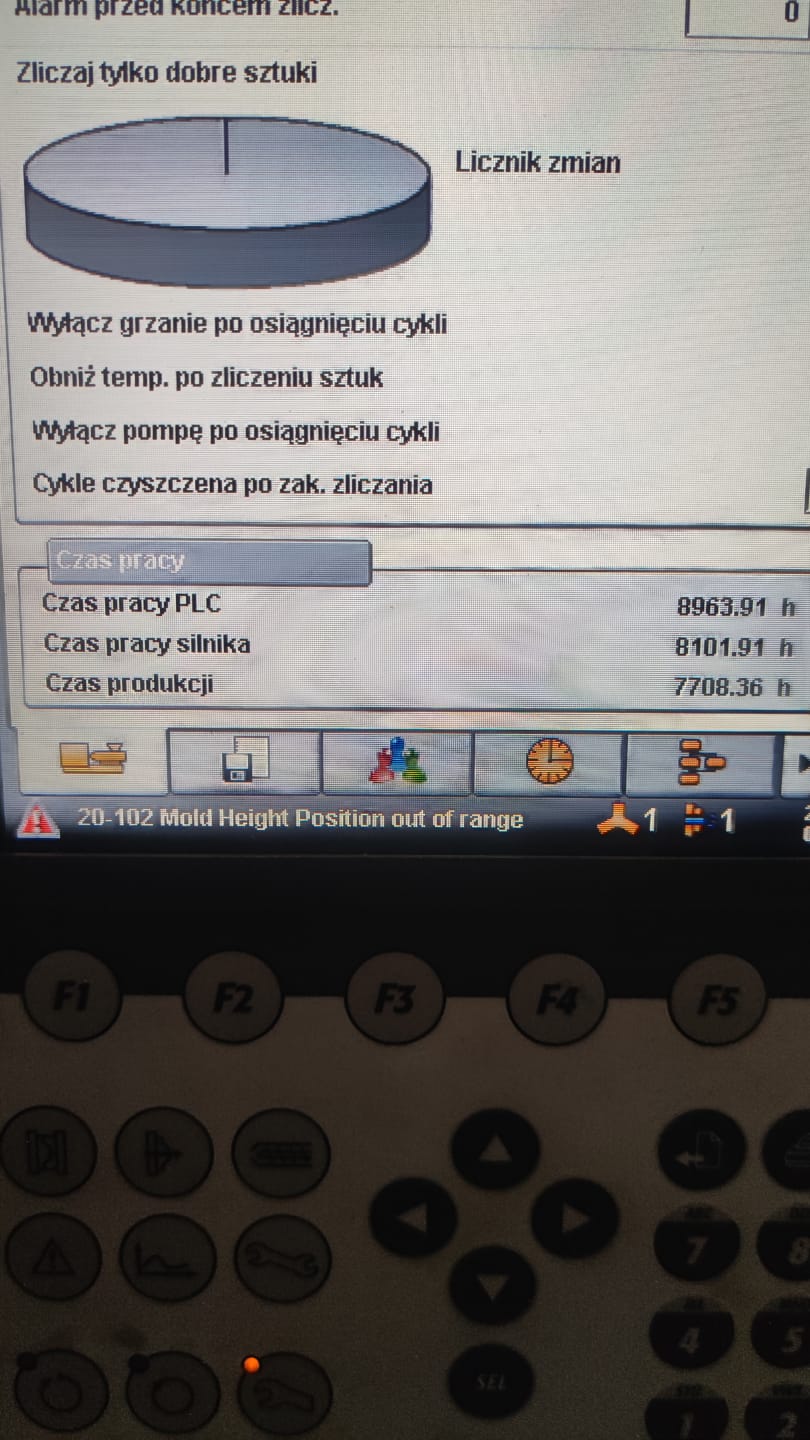

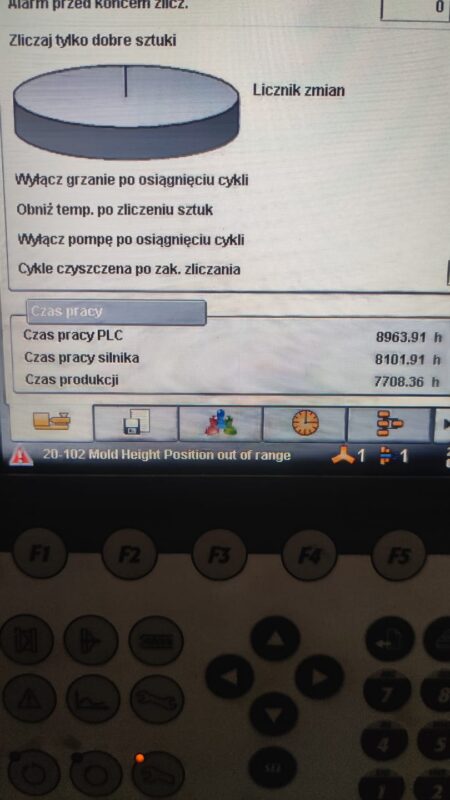

- working hours: 8963 h

- machine dimensions (L x W x H): 4.93 x 1.48 x 1.98 m

- total weight: 6000 kg

Equipment of the injection moulding machine

- plastic feeder

- central lubrication

- pads (8 pcs.)

- air valves (2 pcs.)

- core pull (2 pcs.)

- clamps for mould fixing (8 pcs.)

- hot channel socket

- DTR – technical and operation documentation of the machine

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe