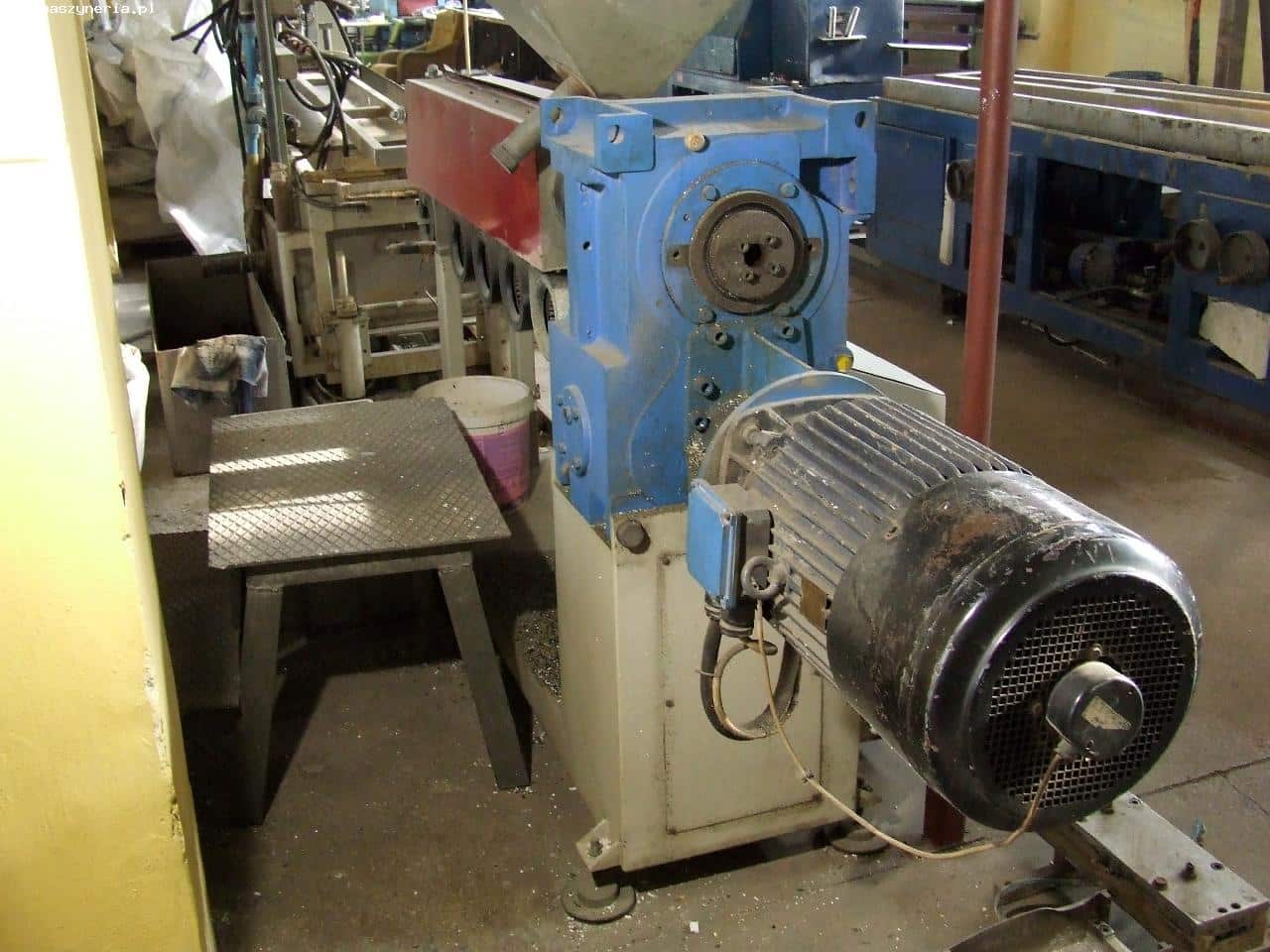

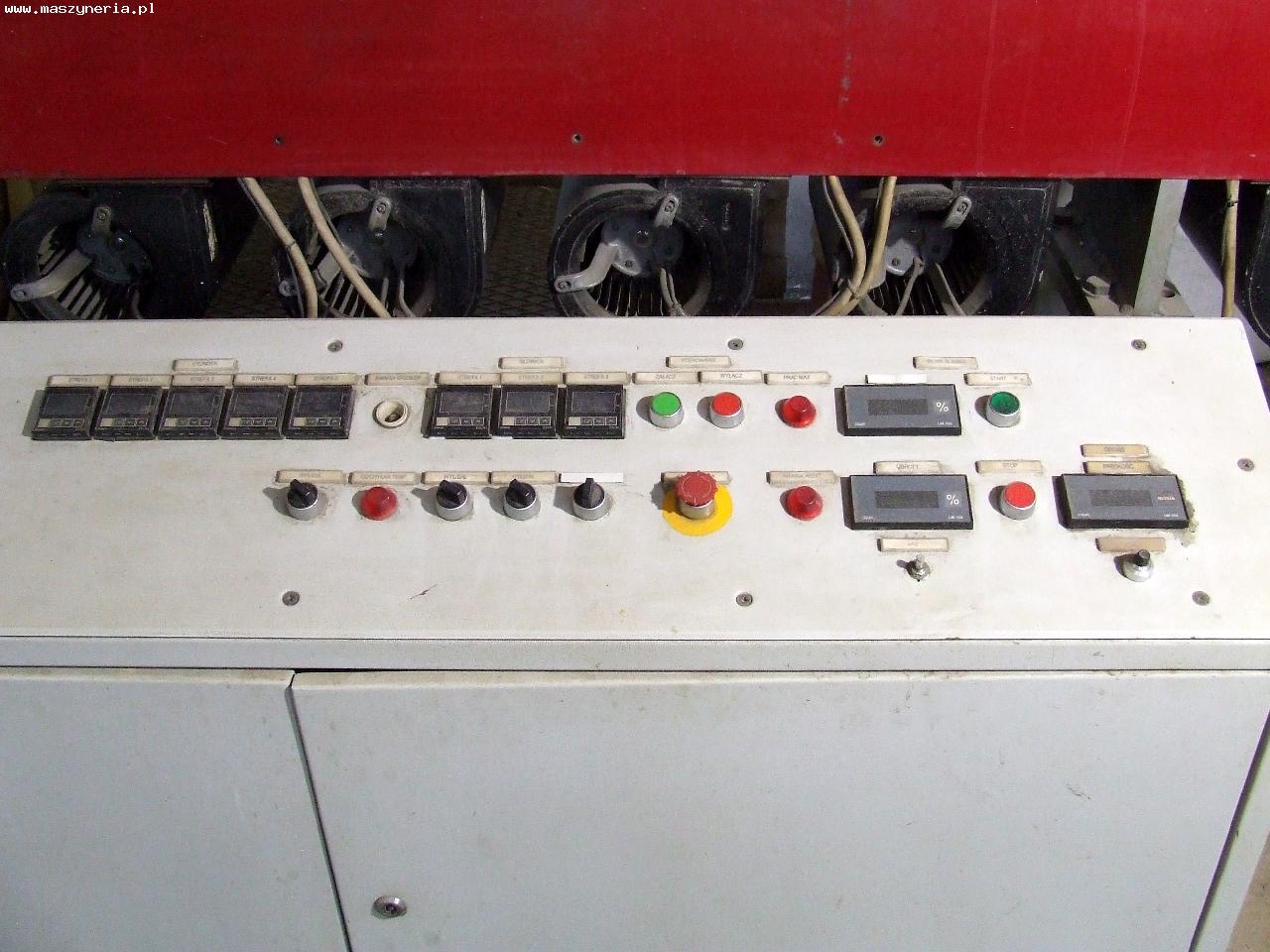

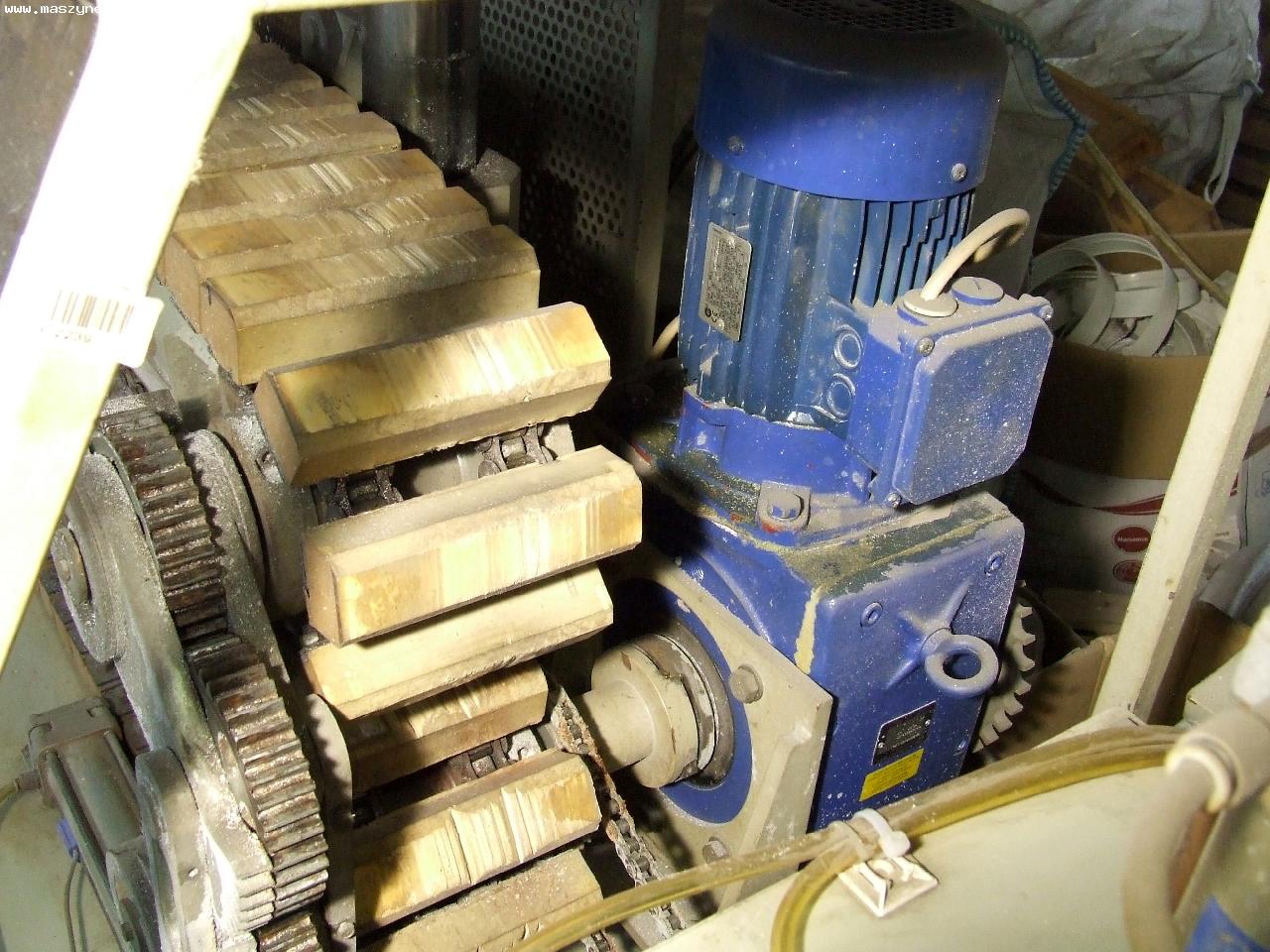

REDOR M-2E extruder for PVC profiles was produced in 2003 by the Polish company OBR REDOR Bielsko-Biała. The line is used for the production of plastic profiles. The line includes: an extruder REDOR M-2E 180-9-18, a calibrating device Reifenhauser KG KKP 301-2 and a extraction and cutting device ZMP Gliwice MCT 7V5 or MCT 7/V1-V5. We sell additional equipment for the line for the production of PVC profiles, i.e. the SK 3282AX2-100 L4 coestruder, the PVC angle perforator and the edge banding machine for covering the PVC angle with mesh.

Technical data of the REDOR M-2E extruder for PVC profiles

REDOR M-2E 180-9-18 extruder

– gear ratios: 18

– work pattern: 06A – L

– dimensions (length x width x height): 320 (including 70 engine) / 80/136 cm after disassembling the hopper

– power kW: 70 for 1500 min-1/47 for 1000 min-1/35 for 750 min-1

– line connection power: approx. 27 kW

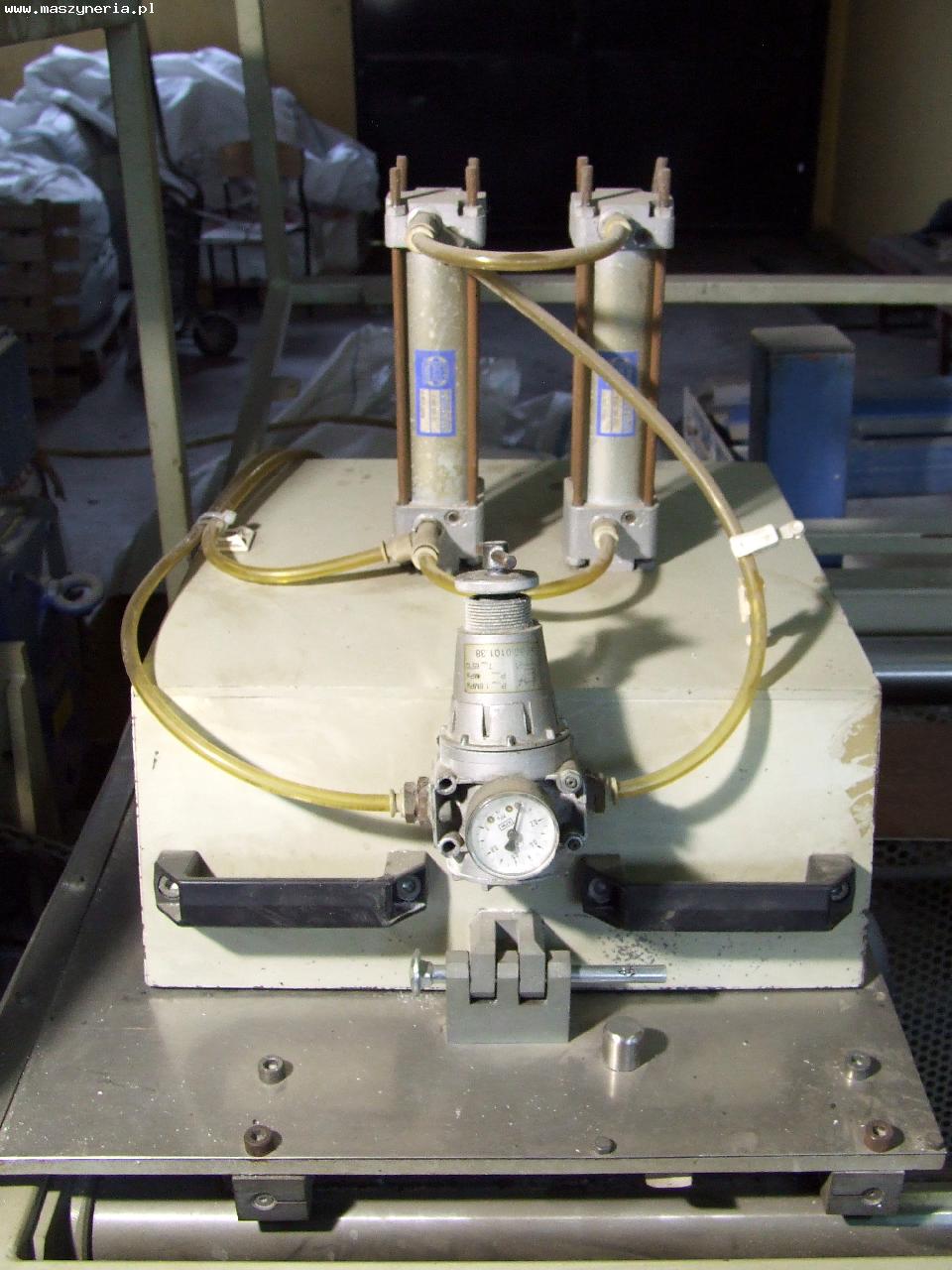

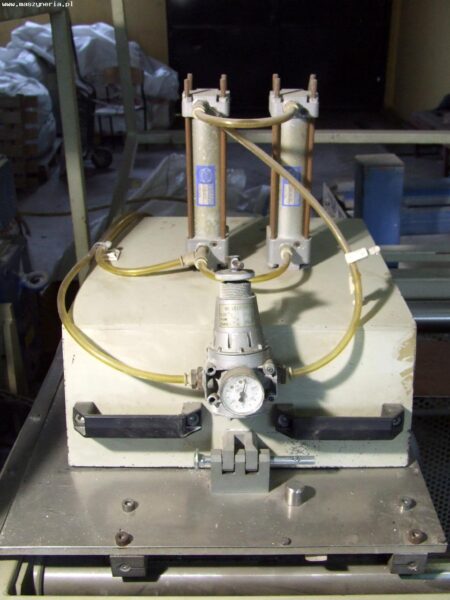

Calibration device Reifenhauser KG KKP 301-2

– year of construction: 1980

– dimensions (L x W x H): 220/105/225 cm with the mast, 165 without the mast

– channel dimensions (length x width x height): 305/60/10 cm

Extraction-cutting device ZMP Gliwice MCT 7V5 or MCT 7/V1-V5

– year of construction: 2003

– dimensions (L x W x H): 270/92/160 cm

– weight: 960 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe