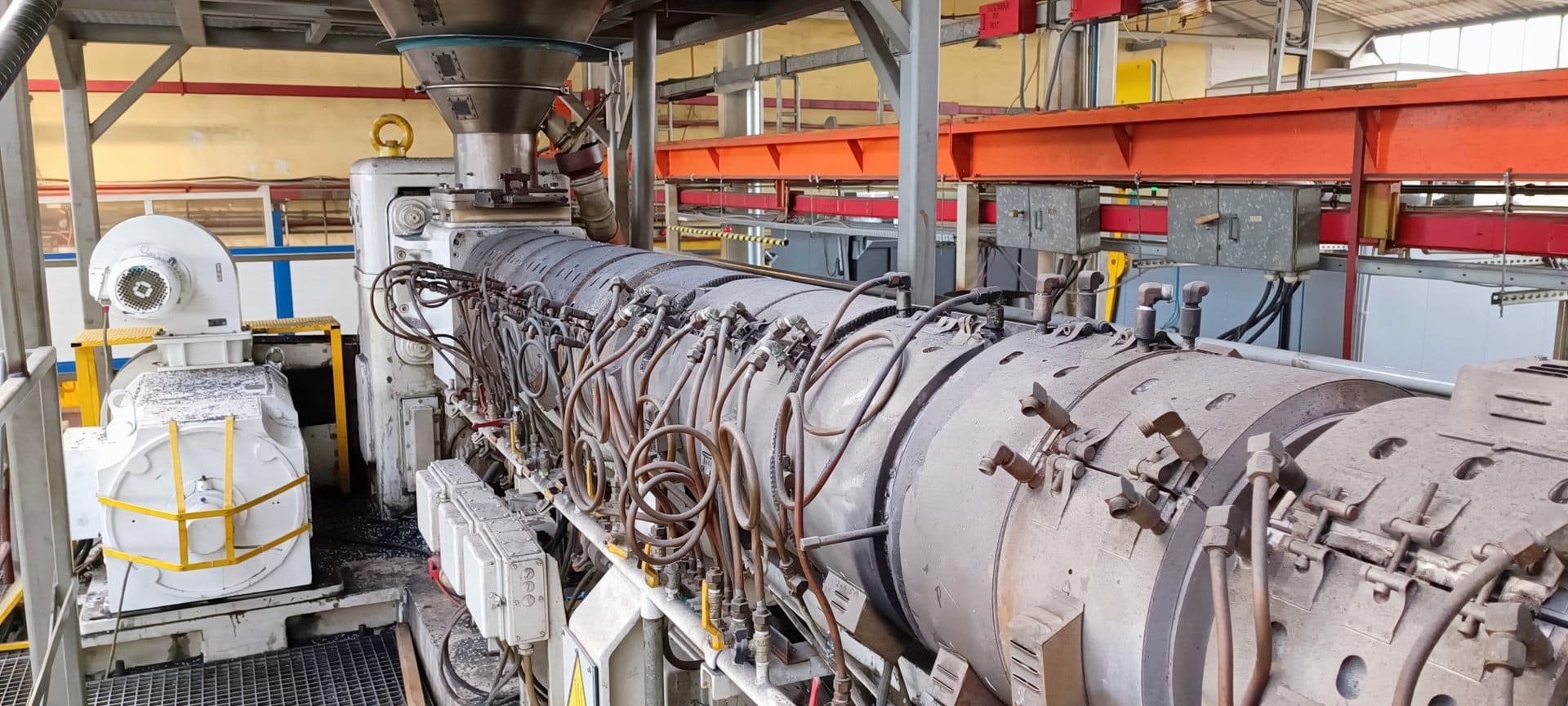

REIFENHÄUSER EH 2400-1-150-30 extruder was built in Germany in 1995 and is used to produce parts made of plastic. The materials produced by the machine, such as PMMA, PC, PE, PP, PS, ABS, consist of a single layer and have a maximum thickness between 1.2 and 9 mm

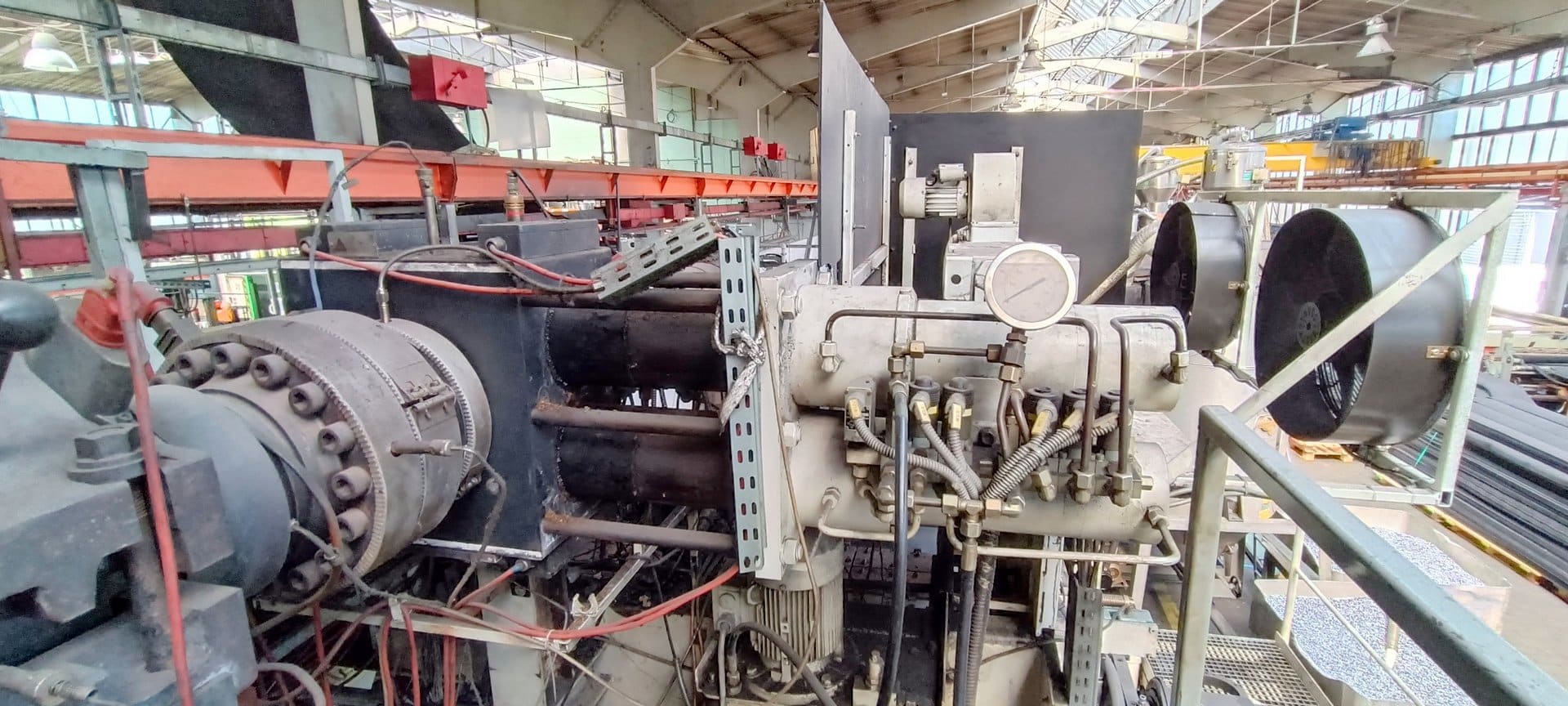

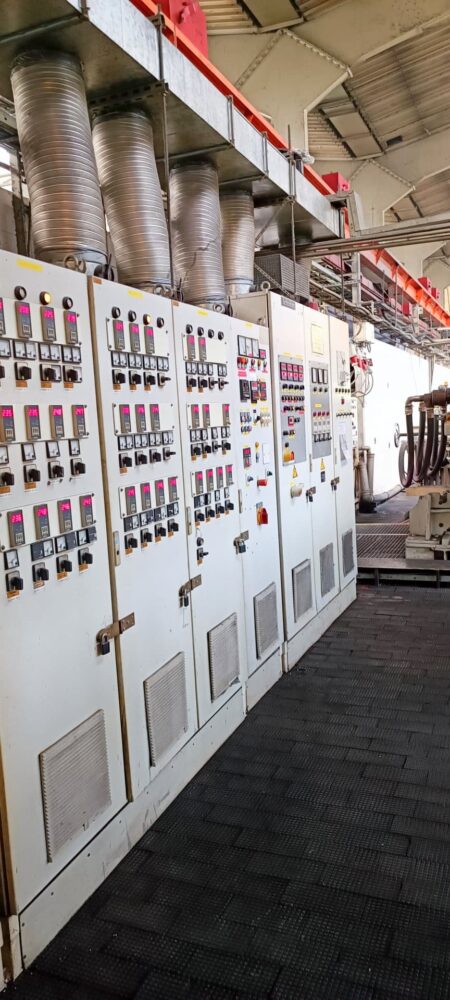

The sheet extrusion line heats the plastic to the right temperature in heating zones to achieve the desired plasticity and presses it through a 150 mm diameter screw and then cools it in a cooling track. The temperature in the heating zones can reach a maximum of 350°C, allowing for the production of 300 to 500 kg of material in one hour of machine operation. The film extrusion line is equipped with, among other things, a KREYENBORG K-SWE-160-88/PC hydraulic screen changer, a film laminating unit and three calanders with a width of 2300 mm and a diameter of 450 mm.

Technical specifications of the REIFENHÄUSER EH 2400-1-150-30 film extrusion line

- produced materials: PMMA, PC, PE, PP, PS, ABS

- machine capacity (depending on material): 300-500 kg/h

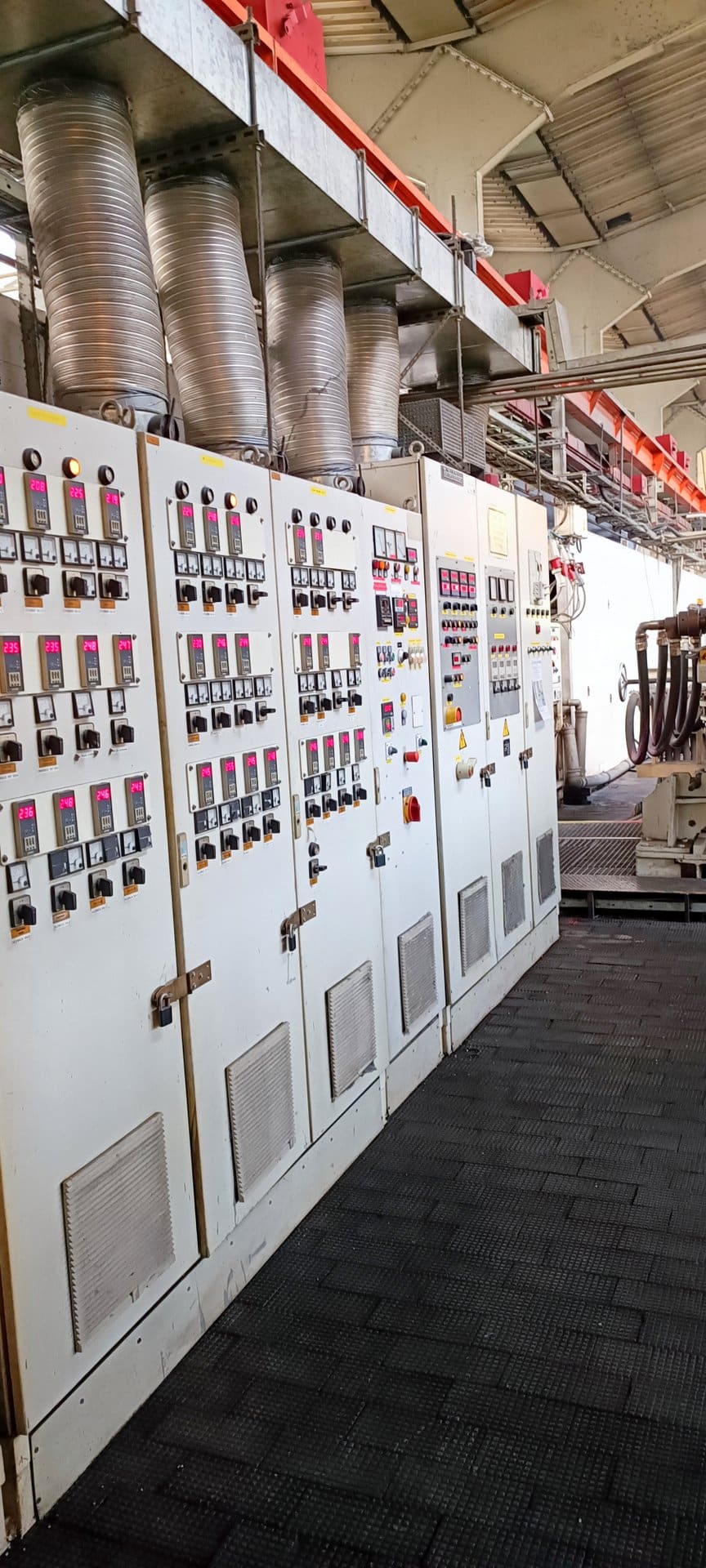

- control: analogue relay control system

- maximum length of material: unlimited

- material thickness: 1.2-9 mm

- number of material layers: 1

- screw diameter: 150 mm

- number of calanders: 3

- width of calanders: 2300 mm

- diameter of calanders: 450 mm

- maximum operating temperature: 350°C

- number of heating zones:

- length of cooling track: 8 m

- width of cooling track: 2300 mm

- number of polishing stack rollers: 3

- width of polishing stack rollers: 2200 mm

- diameter of polishing stack rollers: 400 mm

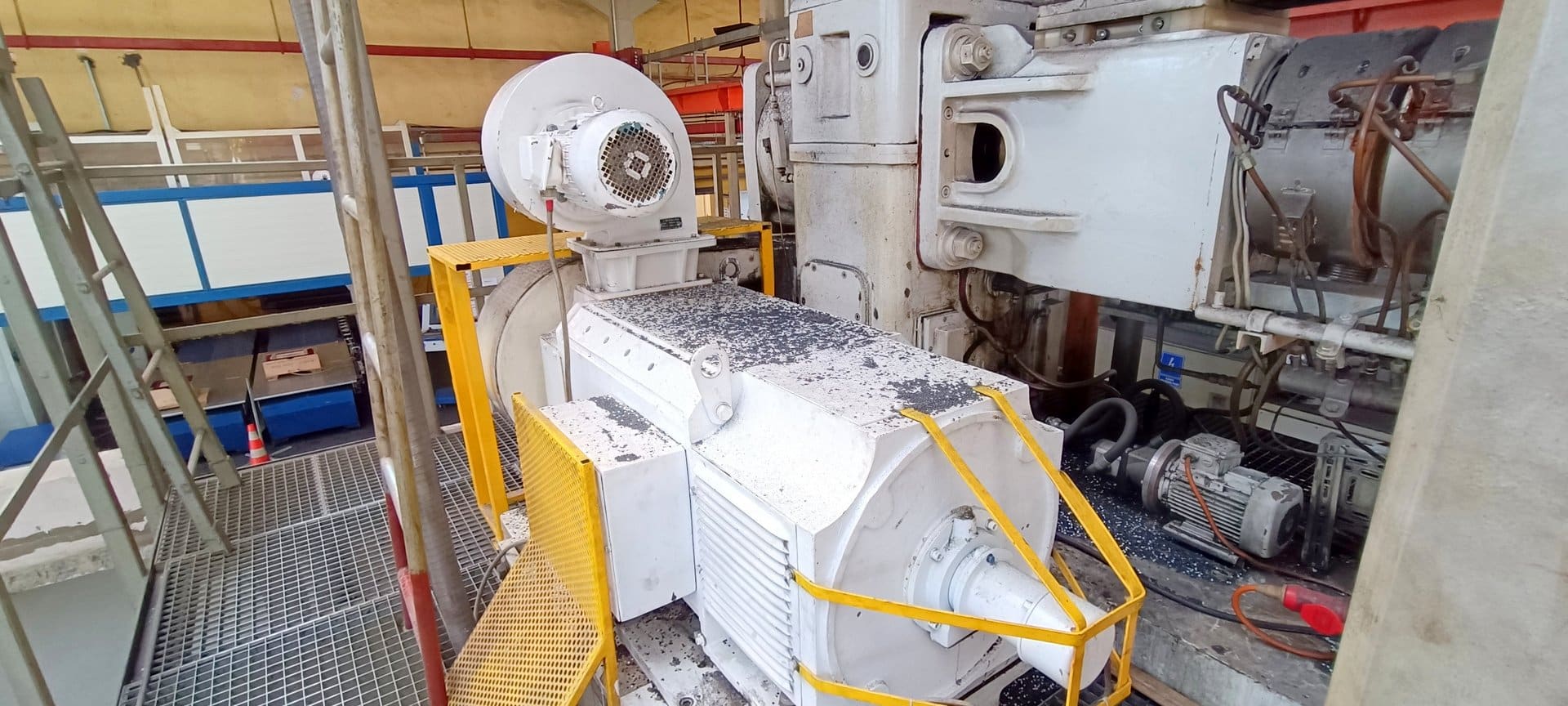

- drive: 315 kW

- voltage: 5x 230 V; 50 Hz

cylinder: 7 pcs.

melt pump: 9 pcs.

head: 11 pcs.

Equipment of the plastic sheet extruder EH 2400-1-150

- hydraulic screen changer: KREYENBORG K-SWE-160-88/PC

- horizontal polishing stack: REIFENHÄUSER RH GKT-2203-79×61

- melt pump: MAAG Extrex 70/70

- machine multi-roll cooling track: REIFENHÄUSER

- sheet extrusion die: VERBRUGGEN

- 12 m long REIFENHÄUSER sheet stacking device

- vacuum pump

- venting pump

- length cutting device with 3 adjustable heating knives

- cross cutting device with swarf extraction unit

- film laminating unit

- aggregate with degassing system and mixing unit

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe