REIS RV 30-26 robotic welding machine, built in 2010 in Germany, is designed for performing welding processes using the MIG/MAG method with the highest quality and precision. The welding cell is powered by an extremely efficient and reliable 2 kW FRONIUS TransPuls Synergic 4000 welding source, ensuring low operating costs.

The robot located in the welding cell has a robust arm with a reach of 1850 mm and six high-speed axes, thanks to which production cycles are significantly reduced. The high positioning repeatability and stability of the industrial robot guarantees the highest welding quality and precision.

Robotic welding cell composition:

– robot: REIS RV 30-26 – RSV

– FRONIUS TransPuls Synergic 4000 welding source with a capacity of 400 A (50%), 365 A (60%), 320 A (100%)

– positioner with two tables of 500 kg load capacity and dimensions of 1900 x 1000 mm each

– radiator: FRONIUS FK 4000-R FC

– control cabinet

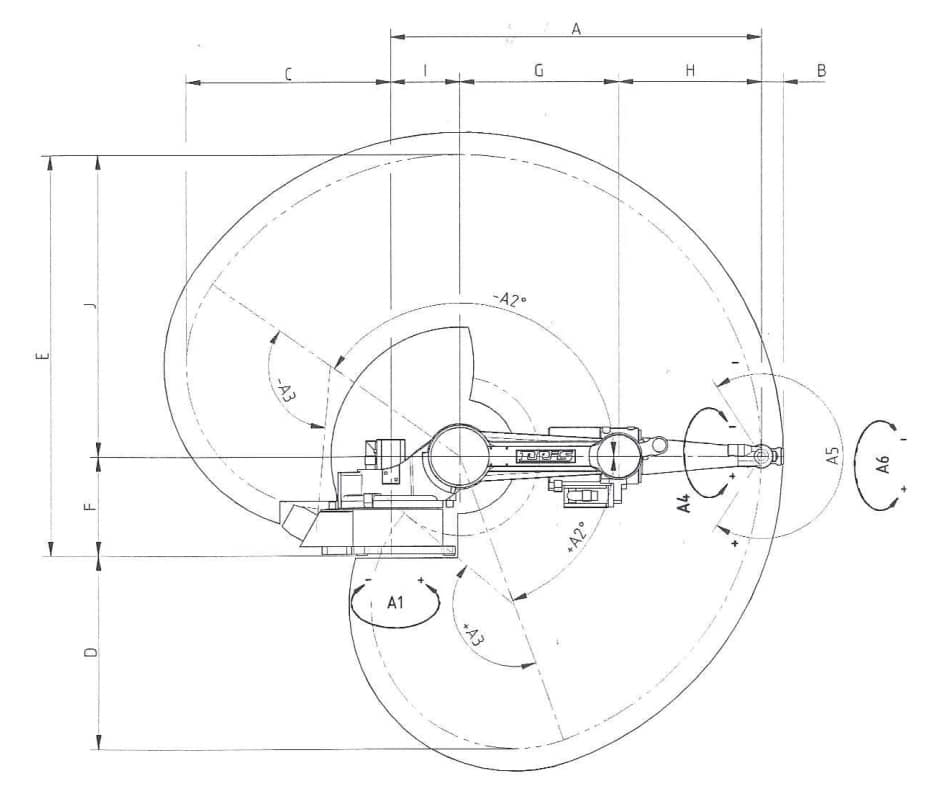

Technical data of the industrial robot REIS RV 30-26

- number of axes: 6

- maximum arm reach: 1850 mm

- maximum payload: 26 kg

- additional payload on second axis: 35 kg

- additional payload on third axis: 20 kg

- repeatability: ± 0,08 mm

- machine axis movement range

- machine axis motion speed

- average power consumption: 1.3 kVA

- rated current: 16 A

- power supply: 3×400 V; 50 Hz

- RV 30-26 machine weight: 511 kg

- welding cell dimensions (L x W): 6000 x 4000 mm

axis 1: ± 180°

axis 2: + 70°/ -140°

axis 3: + 150°/ -120°

axis 4: ± 210°

axis 5: ± 125°

axis 6: ± 360°

axis 1: 165 °/s

axis 2: 165 °/s

axis 3: 150 °/s

axis 4: 300 °/s

axis 5: 300 °/s

axis 6: 400 °/s

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe