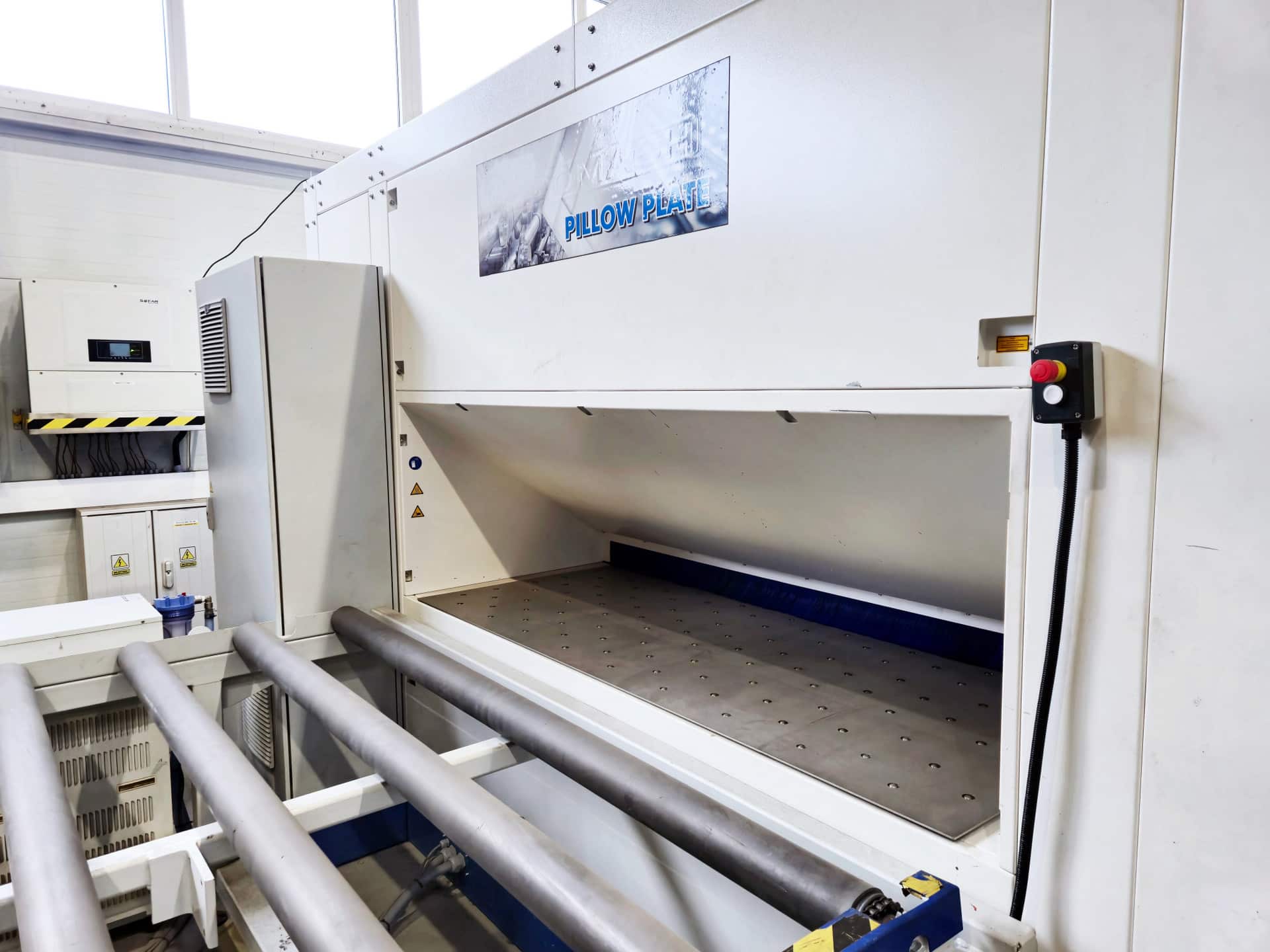

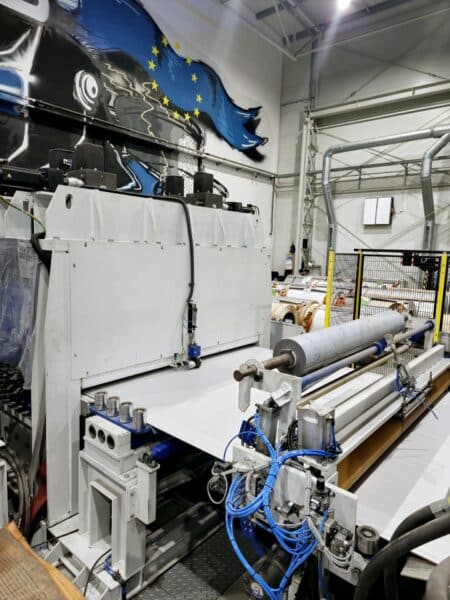

RODOMACH Pillow Plate production line was built in 2020. Pillow Plate heating and cooling coats are created by joining two sheets of stainless steel together using laser spot welding. Once a circular contour has been created, the sheet is pumped hydraulically resulting in so-called ‘pillows’. The large heat exchange and flow area increases heat/cold transfer and reduces the heating/cooling time of the product. Suitable thermohydraulic properties enable the design to be used under high pressure conditions and in a wide range of products, i.e. heat exchangers, filter housings and air-conditioning chambers.

The Pillow Plate heat exchangers production line consists of the following parts:

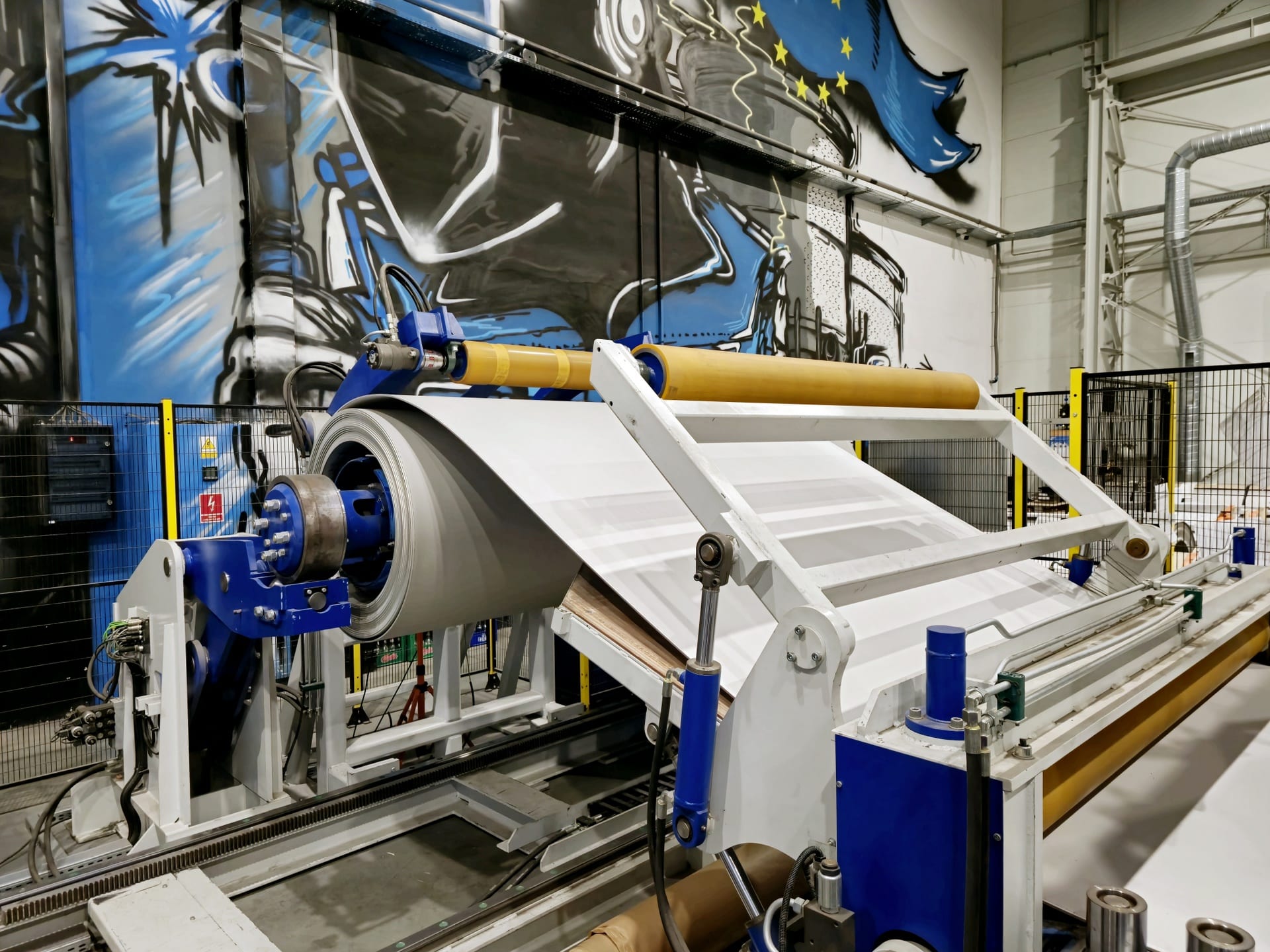

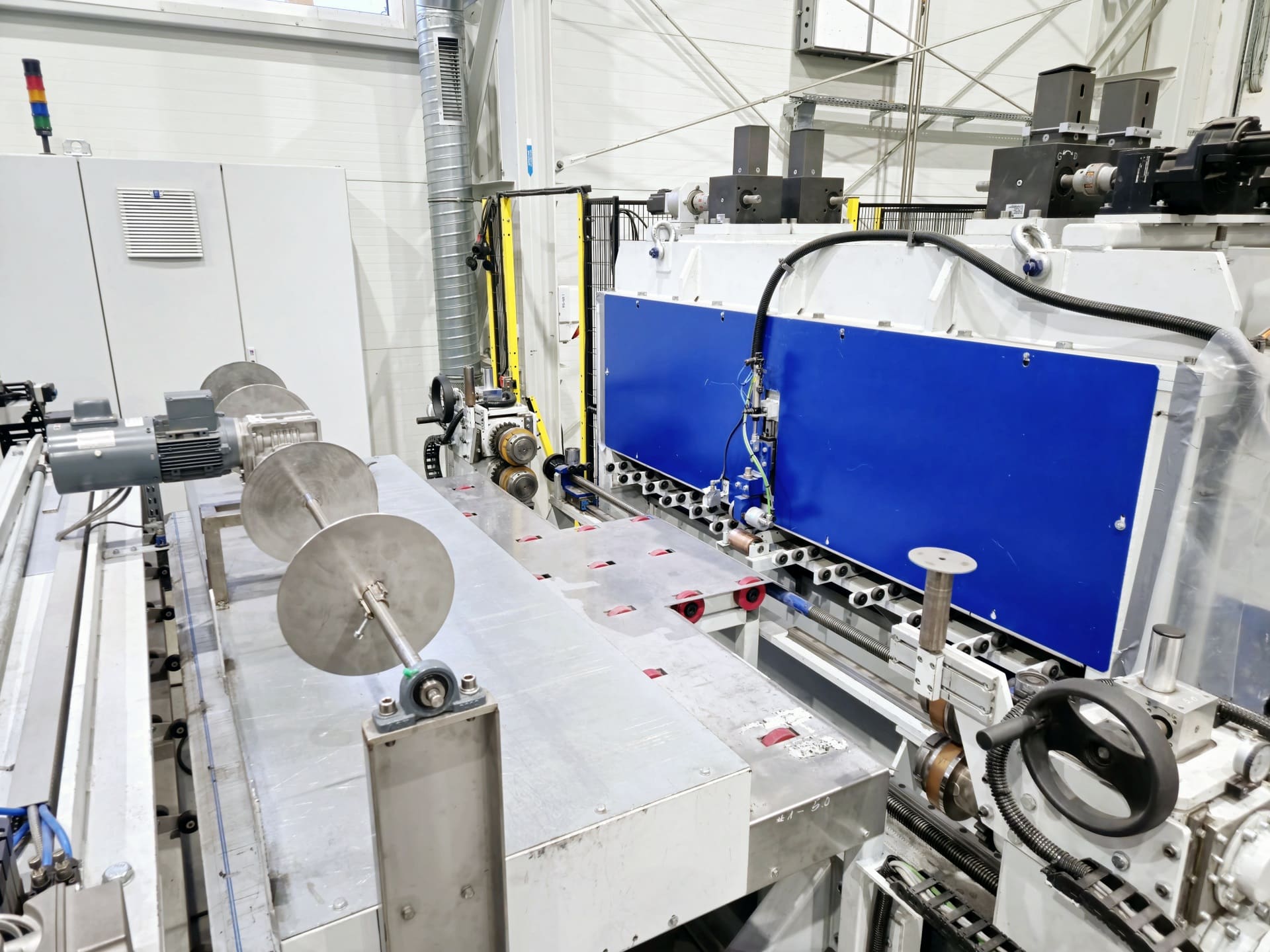

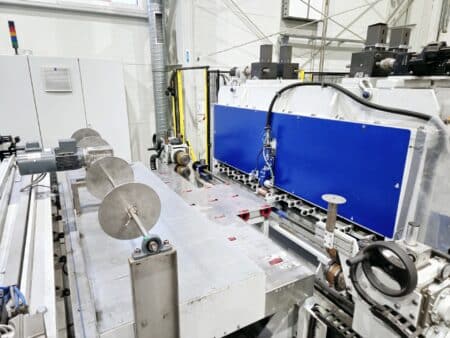

1. slitting line for sheet metal with a maximum thickness of 1.5 mm

– sheet metal decoiler

– infeed and guide system

– sheet metal straightener

– perforation unit

– guillotine

– roller conveyor

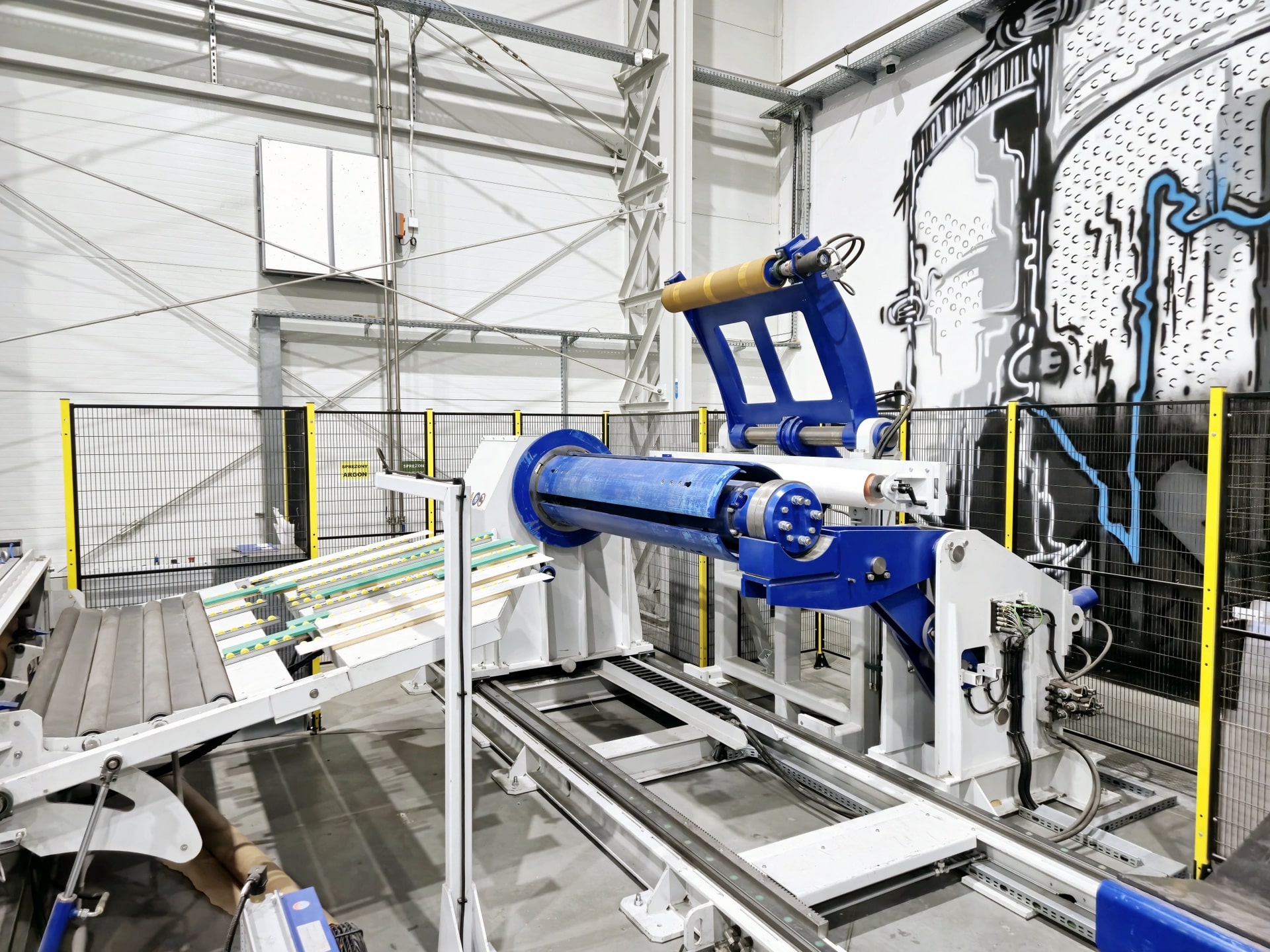

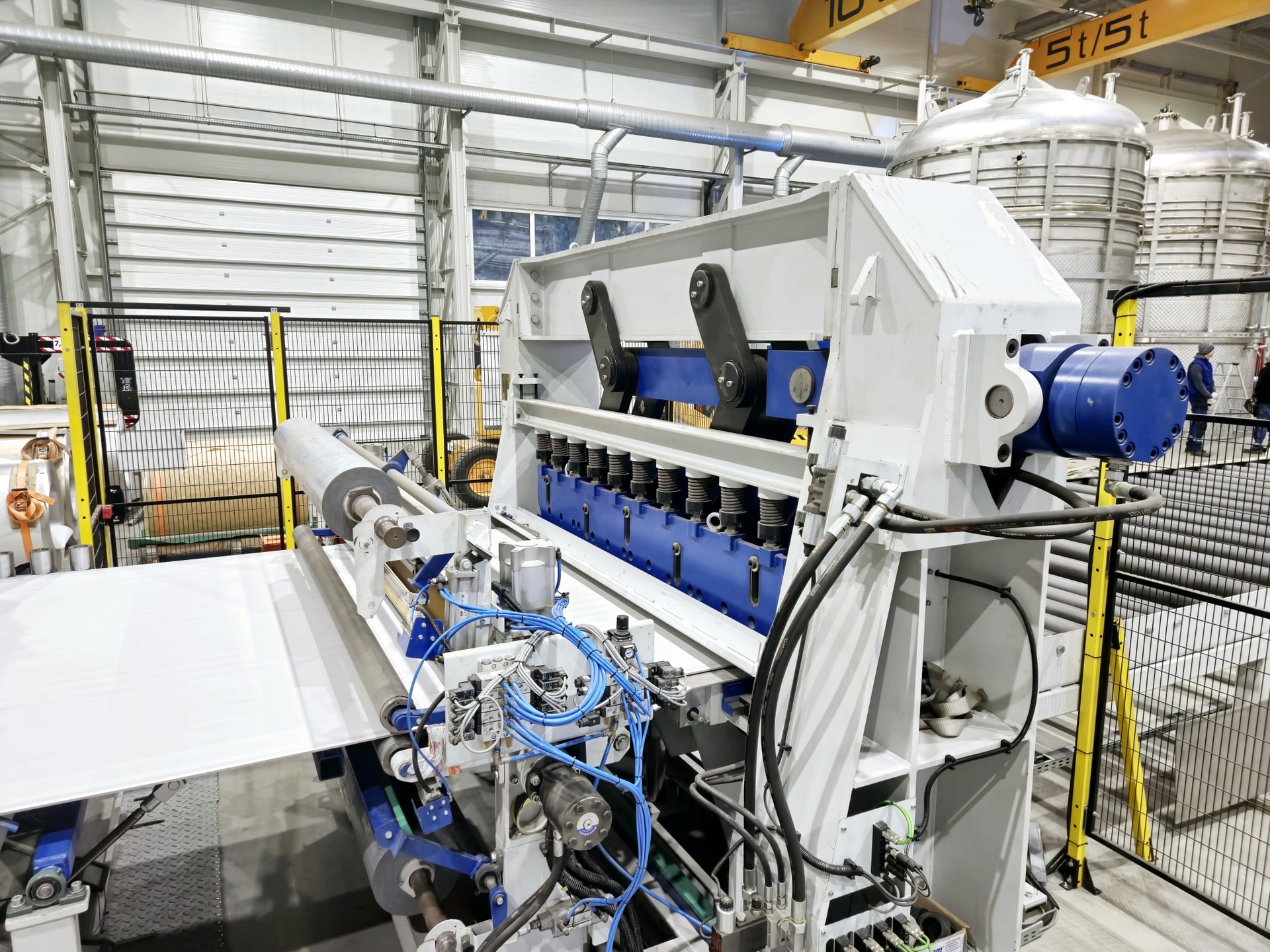

2. slitting line for sheet metal with maximum thickness of 6 mm

– sheet metal decoiler

– infeed and guide system

– sheet straightener

– sheet metal foiling system

– guillotine

– roller conveyor

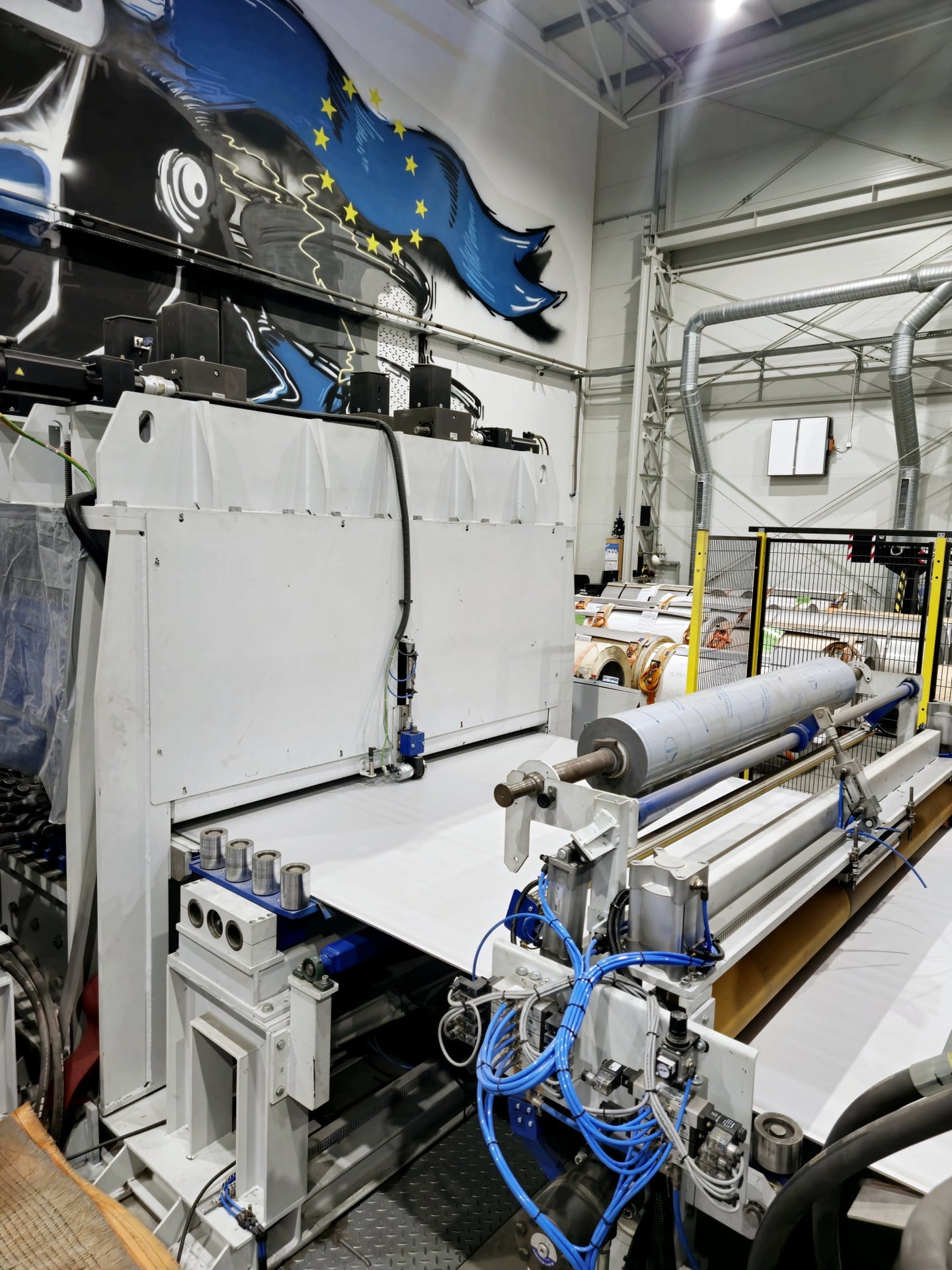

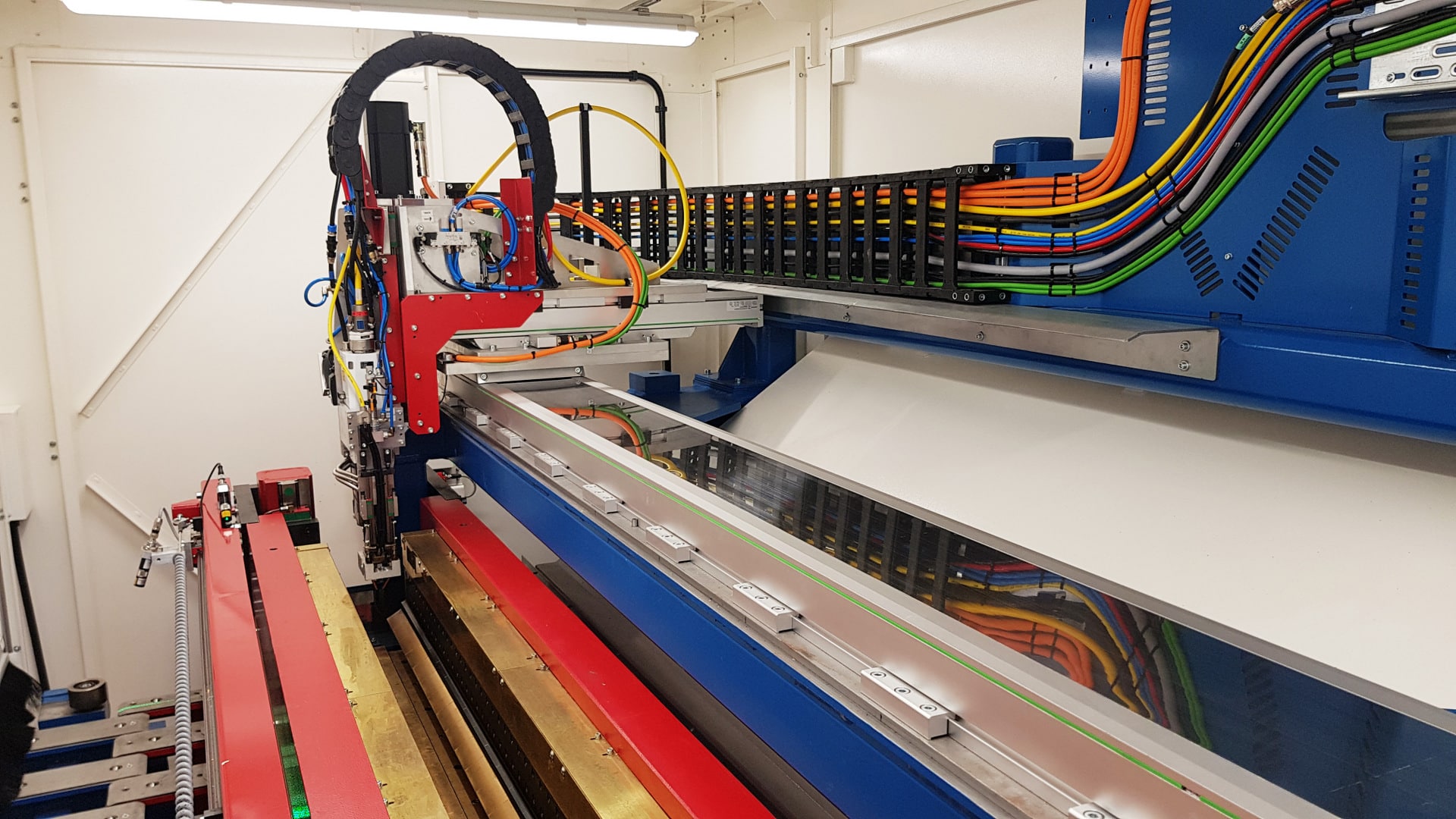

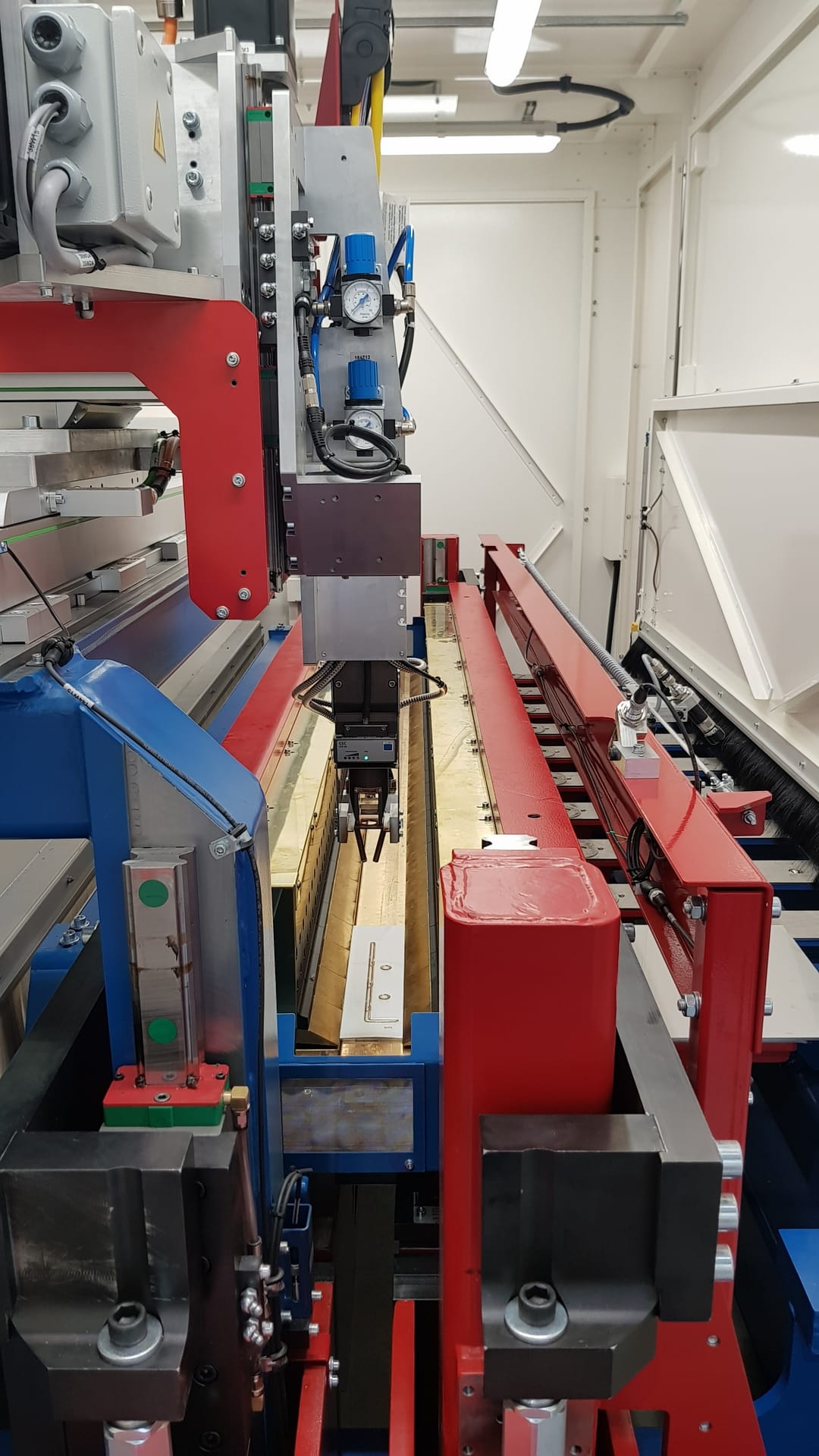

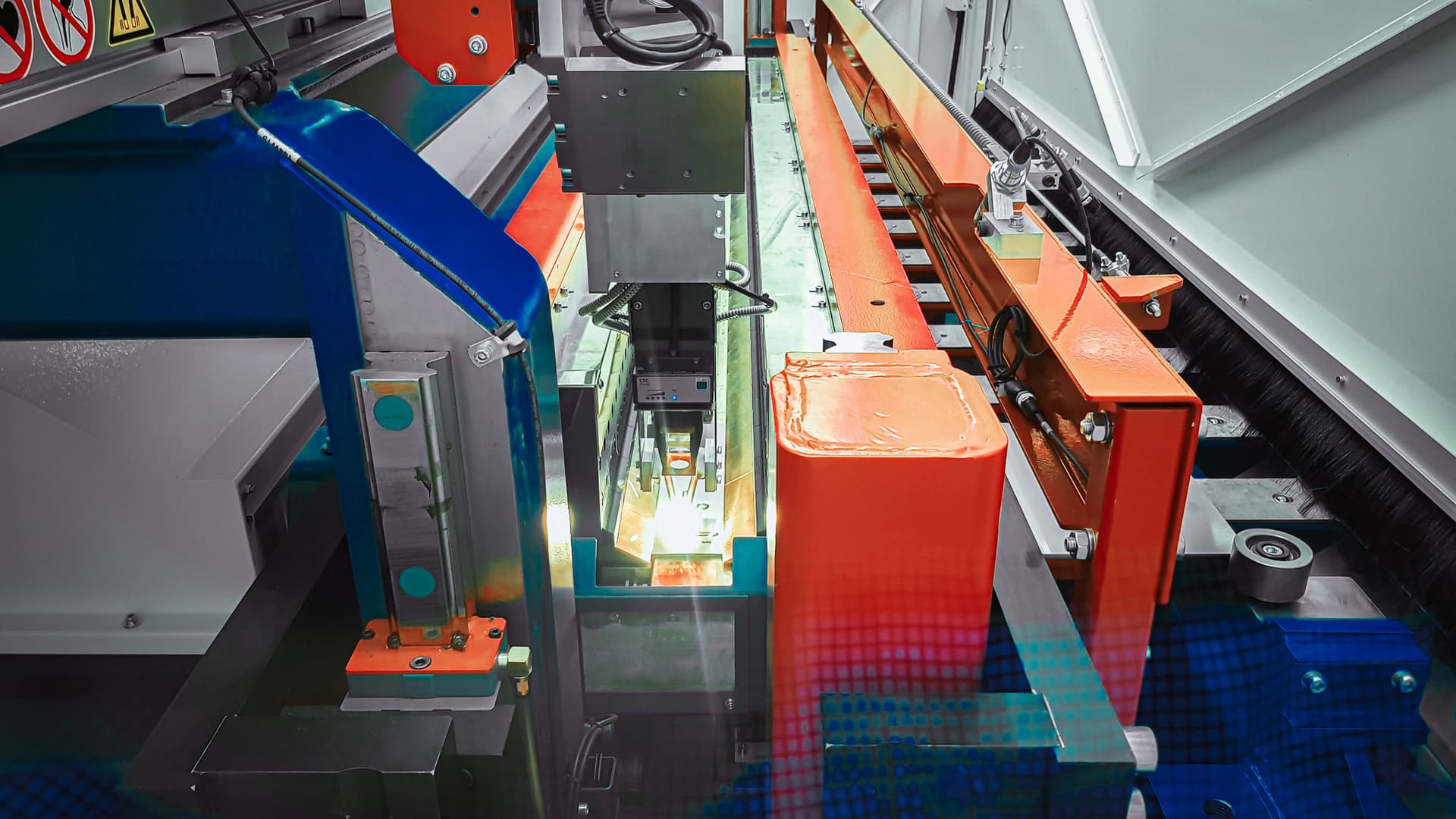

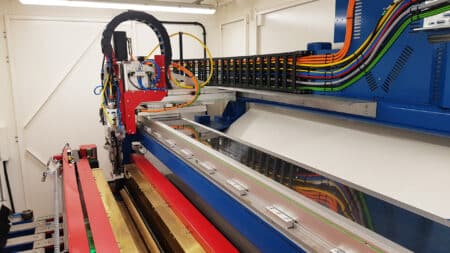

3. RODOMACH laser welding machine (2 pcs.)

Technical specifications of the RODOMACH laser welding machine

- material type: SS AISI 304 (L), SS AISI 316 (L)

- number of bands: 2

- range of upper (overlay) sheet metal thickness: 0.8-2 mm

- range of bottom (base) sheet metal thickness: 3-15 mm

- ability to combine sheets of the same thickness, e.g. 0.8 + 0.8 mm or 1.5 + 1.5 mm

- band dimensions (L x W): 16000 x 2000 mm

- disk laser: TRUMPF TruDisk 3001

- laser beam power: 3 kW/ 1 band

- gas type: Argon / Nitrogen (N2)

- CAD/CAM software

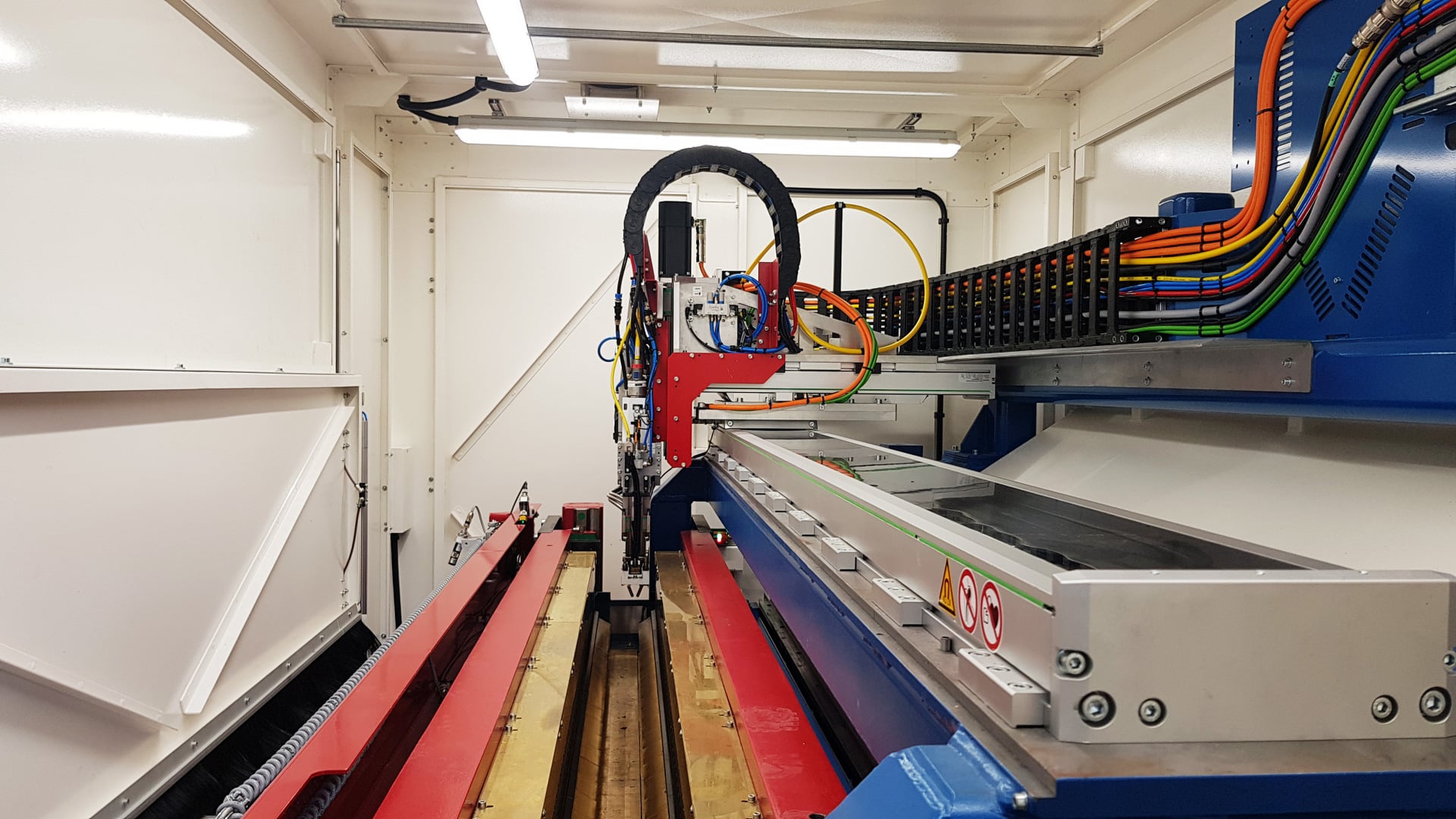

- control panel

- welding height adjustment

- anti-collision system

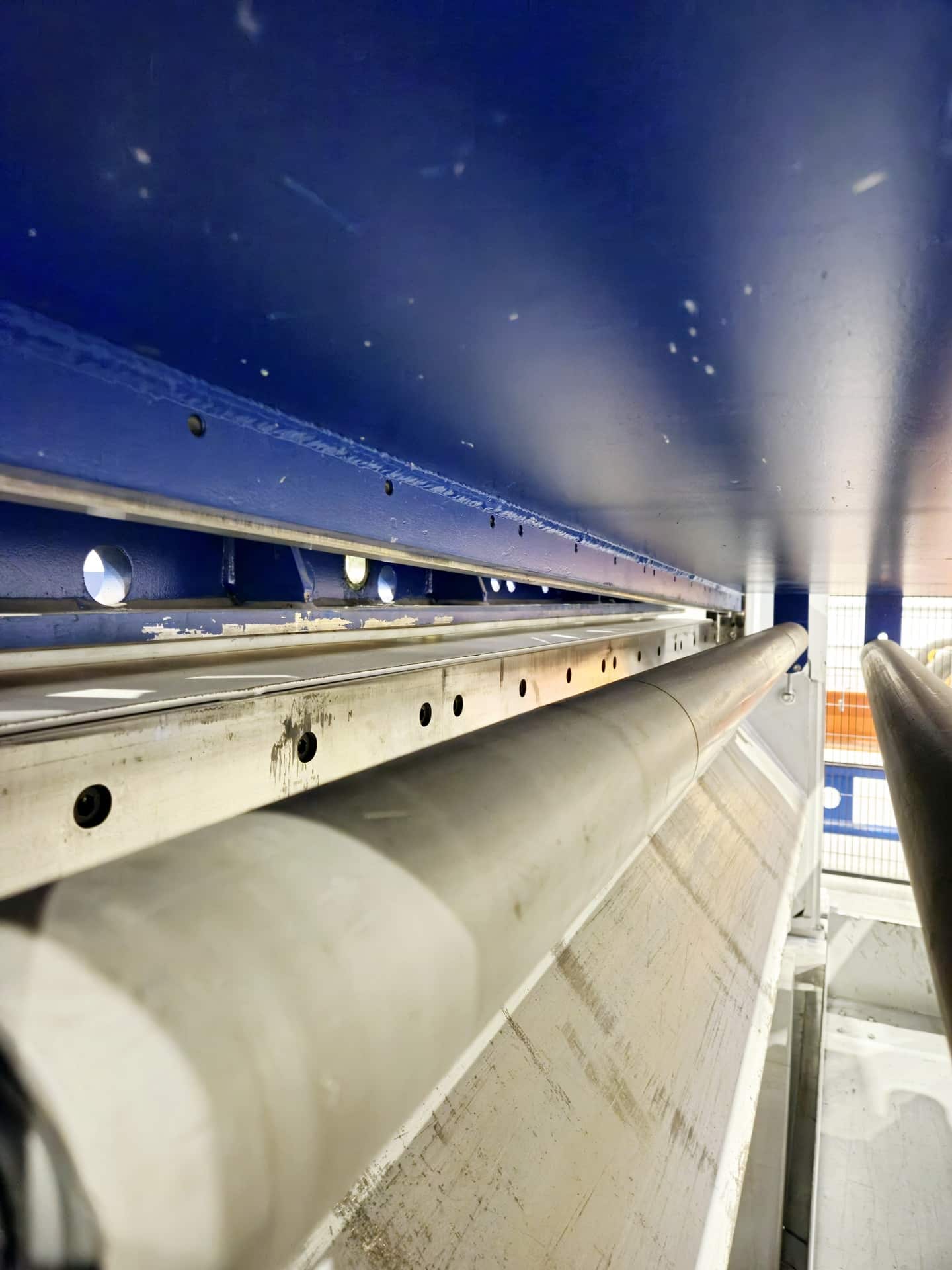

- precision workpiece support system

- workpiece marking device

- bottom band cooling system

- system protecting the bottom band from scratches during feeding

- fume extraction system

- gas flow measurement

- remote control

- weight of the RODOMACH machine: 8000 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe