RUIAN QUEENSENSE MACHINE DHB-500 film glove production line manufactured in 2020 by Chinese company RUIAN QUEENSENSE MACHINE CO.LTD. is used to produce double-layer foil gloves. The produced gloves, used for example in grocery shops or in production, guarantee effective protection against viruses and bacteria.

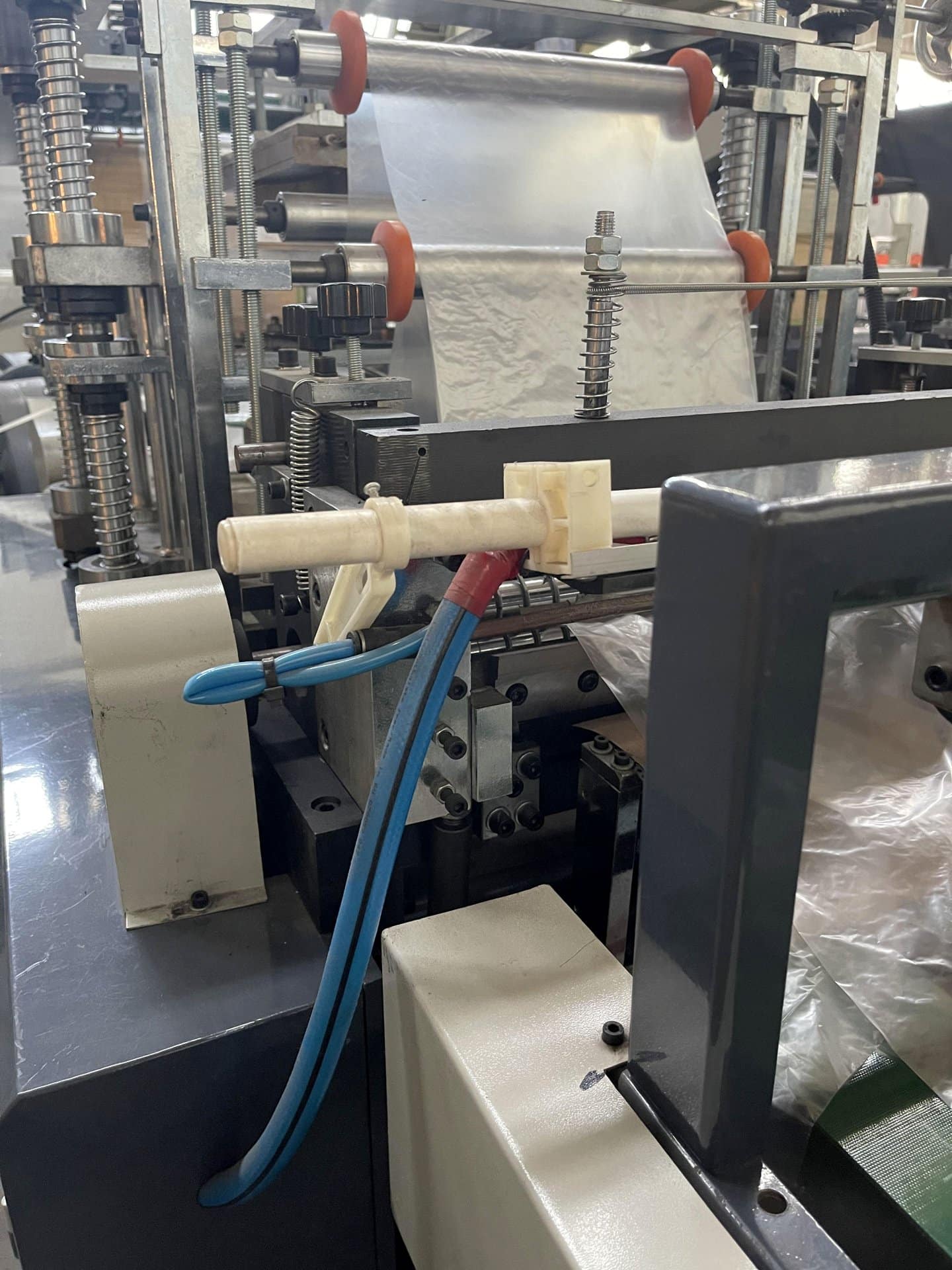

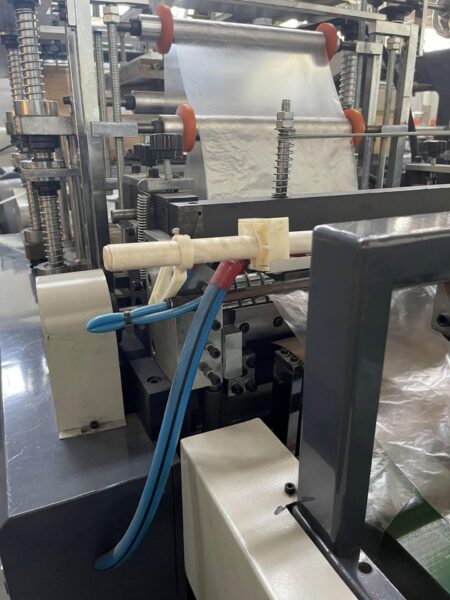

The QUEENSENSE DHB-500 automatic disposable gloves production line consists of two identical machines, both of which feature a central drive to control all glove-forming mechanisms. The dual unwinding station is equipped with a clutch, which allows infinite adjustment of the film tension and dual inverters for unwinding control. High-precision feeding of HDPE or LDPE material to the sealing position and the final product sorting point is ensured by the installed servo drives controlling the entire process.

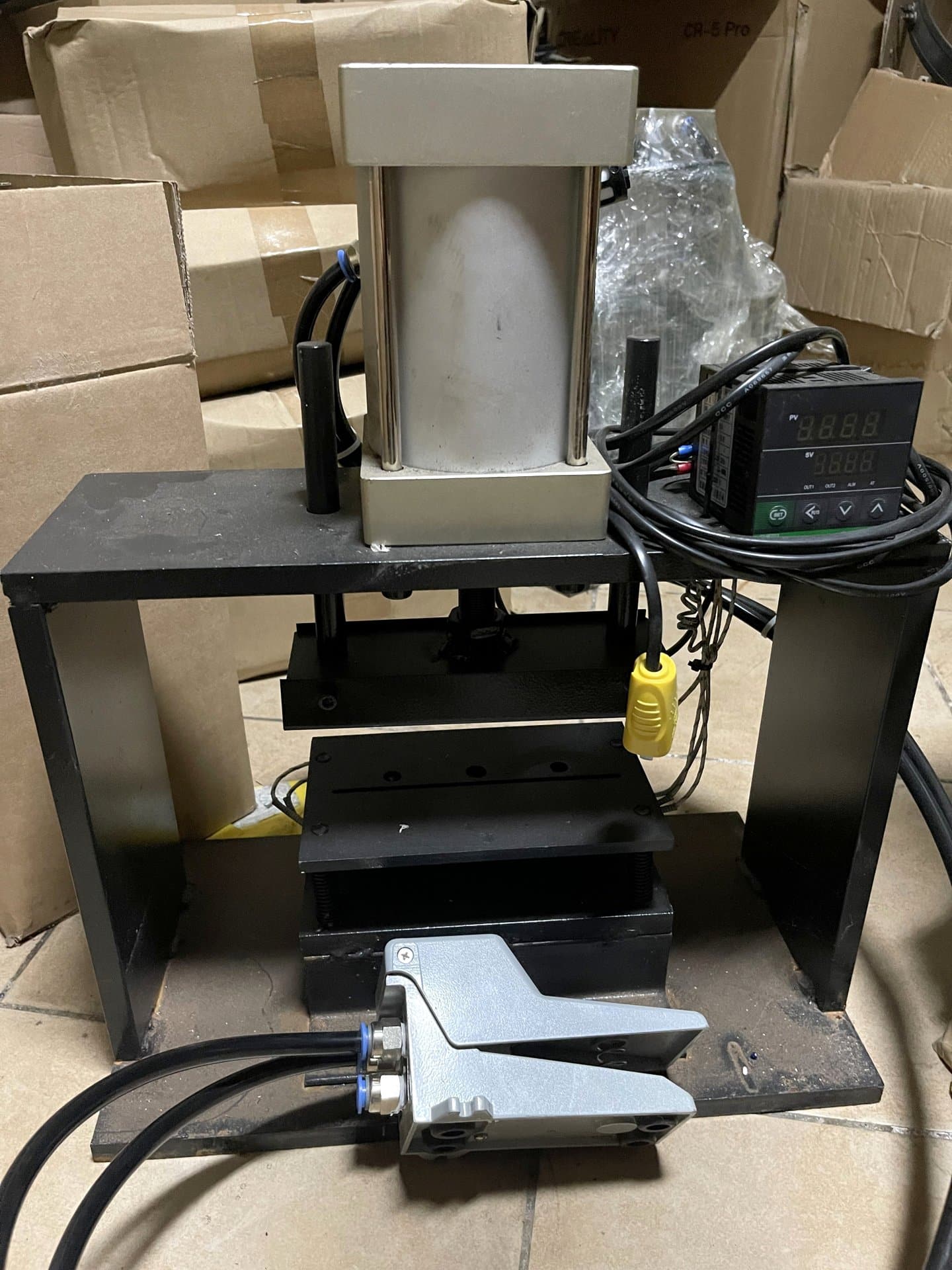

After changing the heat sealing dies, the RUIAN QUEENSENSE MACHINE DHB-500 film glove production machine is also capable of producing other film products, such as breakfast bags. The automatic film glove production line is equipped with, among others: four heat sealing dies (2 per machine), two new pneumatic presses, a stand-up press and a DC3003A temperature controller. The total weight of the machine is 1400 kg.

Parameters of the RUIAN QUEENSENSE MACHINE DHB-500 automatic glove making machine

- number of produced gloves: 50-200 pcs/min

- number of layers of produced gloves: 2

- minimum glove length: 200 mm

- maximum glove length: 350 mm

- minimum glove width: 240 mm

- maximum glove width: 300 mm

- motor power: 1.5 kW

- total power requirement: 8.3 kW

- total compressed air requirement: 8 bar

- power supply: 220 V; 50 Hz

- overall dimensions (L x W x H): 4000 x 1015 x 1850 mm

- weight of foil glove making machine: 1400 kg

Equipment of the foil glove making machine

- temperature controller: DC3003A

- HMI panel: TouchWin

- pneumatic press (2 units)

- stand-up press (1 unit)

- heat sealing dies (4 units)

- servo drive

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe