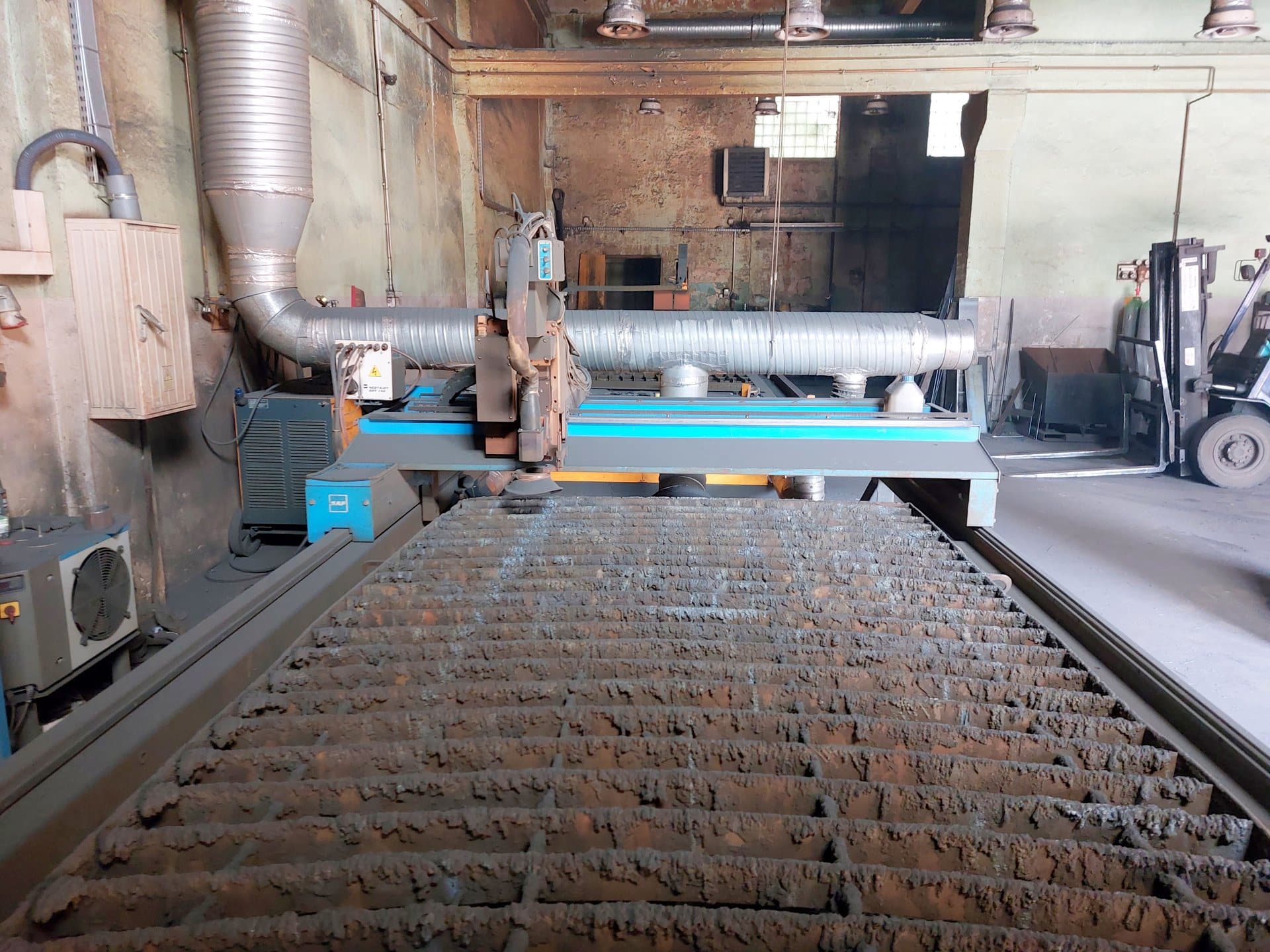

SAF OPTITOME 15 CNC plasma cutting machine was built in France in 2003. The machine is used to cut shapes in workpieces made of stainless steel, mild steel or aluminium. Depending on the previously selected nozzle, workpieces can have a thickness from 2 or 3 mm up to 18 mm.

The high cutting quality is achieved thanks to the use of a lightweight and rigid transverse beam with efficient drive, mounted on an extremely rigid and robust machine frame. The installed working table with dimensions (L x W) of 3000 x 1500 mm allows the reduction of mechanical stresses arising during thermal cutting or sheet loading/unloading. The plasma cutting machine is supplied with equipment consisting of among others: a NERTAJET HP 125 plasma source with a power of 125 A and a DIGISAF 100 CNC control.

Technical data of the SAF OPTITOME 15 plasma

- materials to be cut: stainless steel, mild steel, aluminium

- working table dimensions (L x W): 3000 x 1500 mm

- working table height: 800 mm

- minimum thickness of sheet metal: 2 mm

- maximum thickness of sheet metal: 18 mm

- maximum cutting speed: 10 m/min

- maximum feed speed: 15 m/min

- positioning accuracy: ± 0.4 mm

- power of plasma source: 125 A

- dimensions of the OPTITOME 1530 machine (L x W x H): 4920 x 2376 x 1714 mm

Equipment of the plasma cutting machine

- CNC control: DIGISAF 100

- plasma source: NERTAJET HP 125

- extraction table

- plasma torch

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe