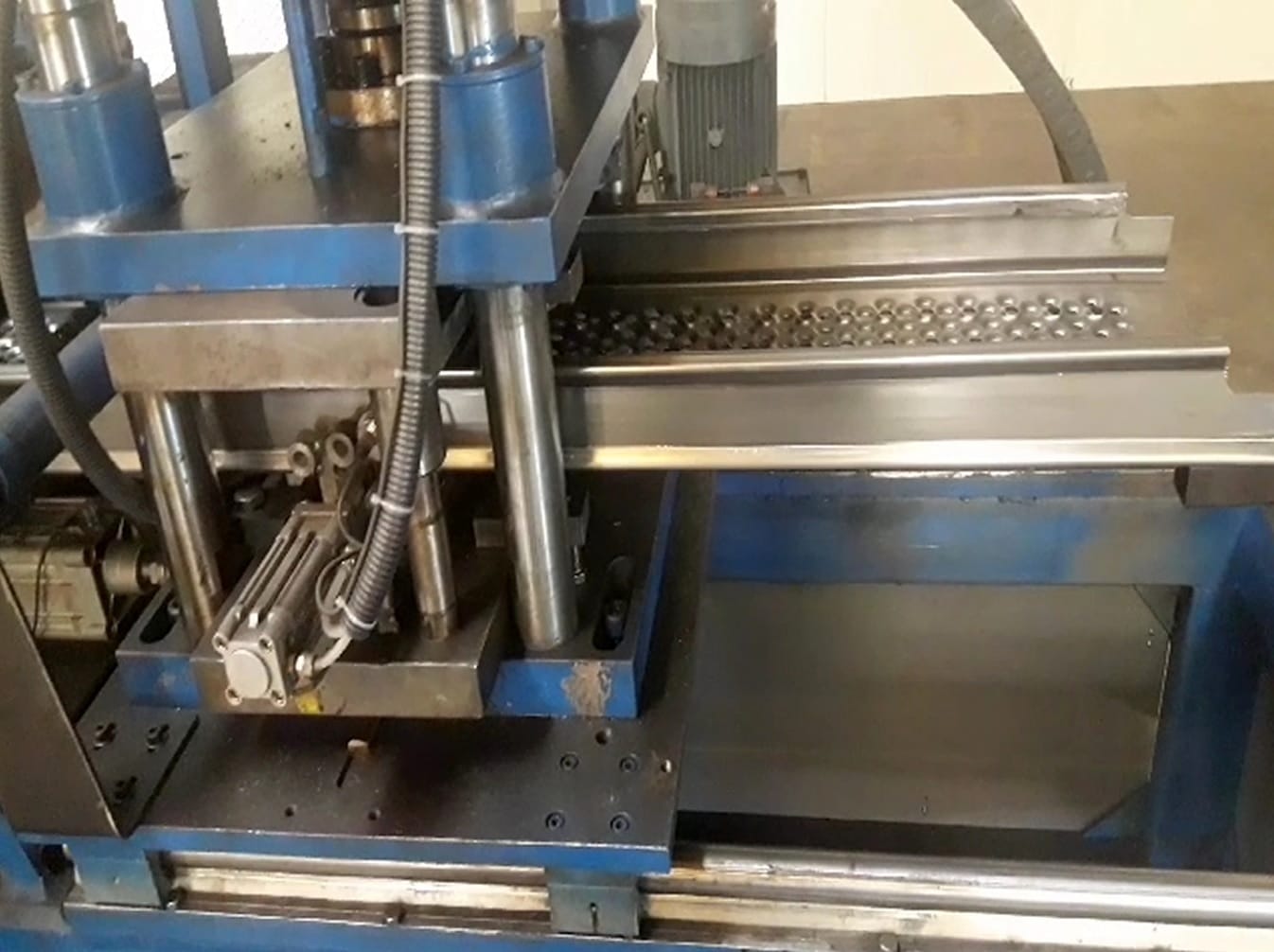

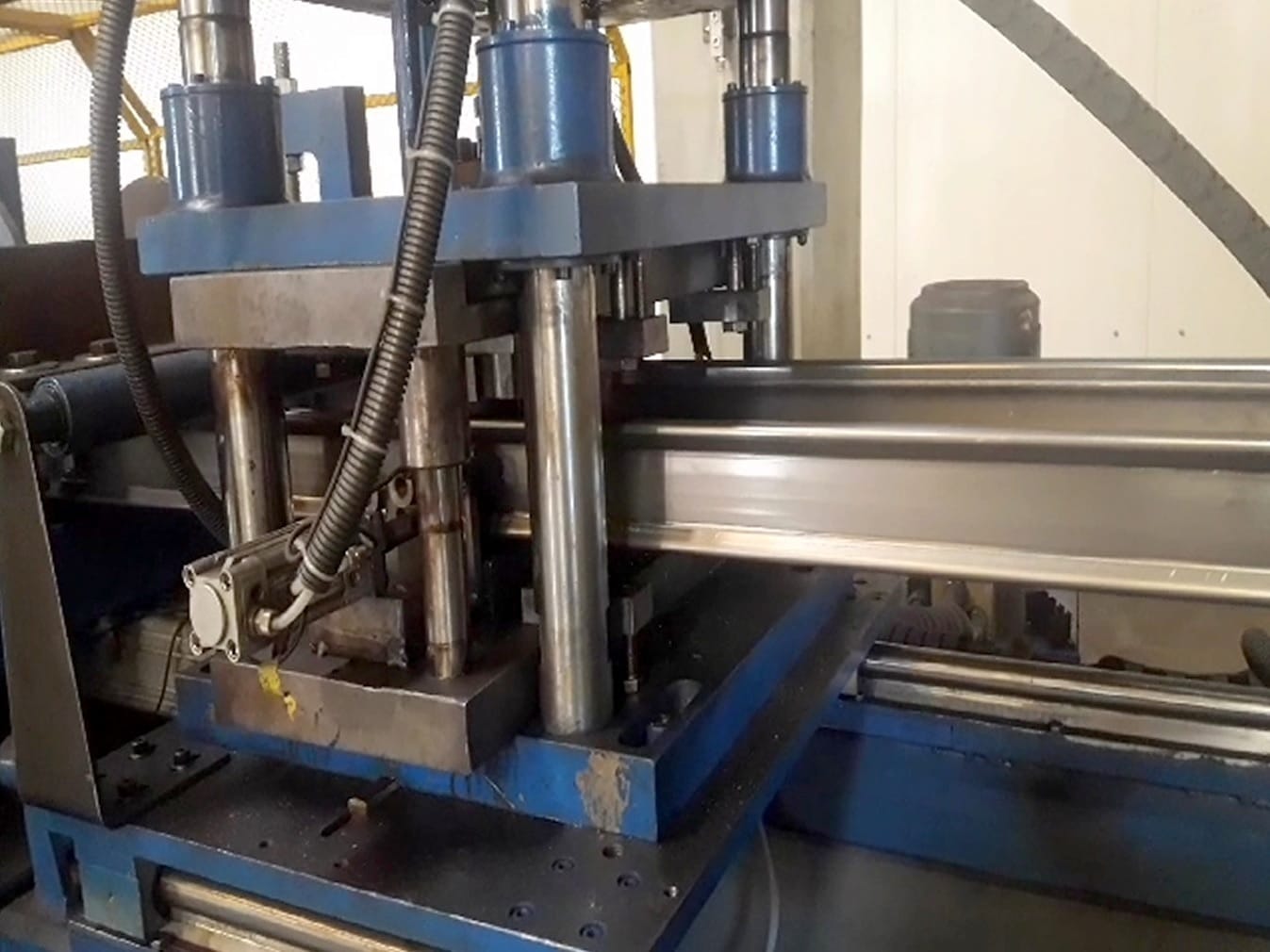

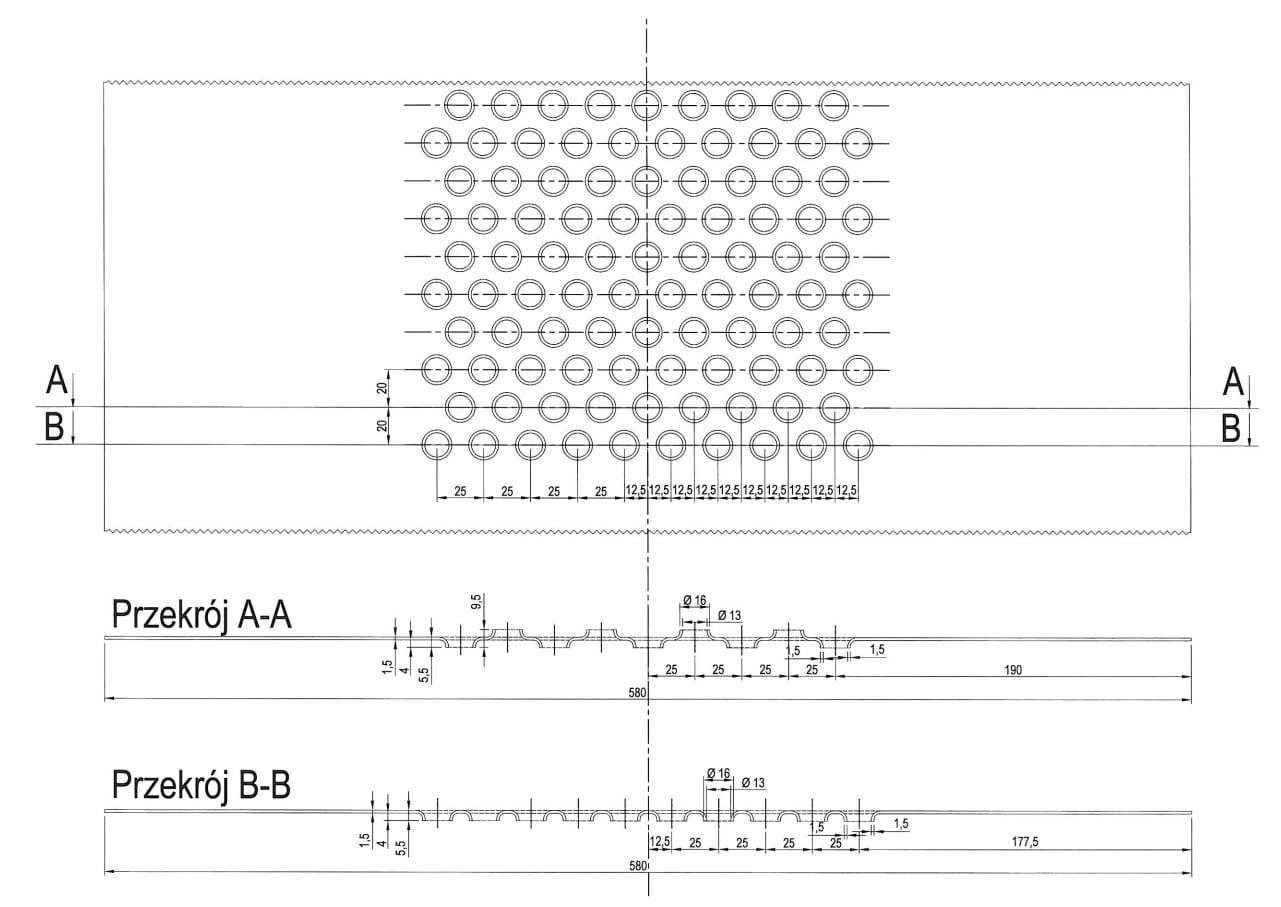

Scaffolding production line built in 2015 is designed for the efficient production of steel boards used in construction scaffolding. The sheet metal unrolled from the coil goes through a straightening machine and is then subjected to the relevant machining stages. At the beginning of the machining process, the appropriate side holes are punched and the sheet is perforated to ensure adequate slip resistance. In a further stage, the sheet goes through a rollforming line, which gives the final shape of the board. The installed software of the machine allows to choose from 8 different steel scaffolding board lengths ranging from 0.73 m to 3.07 m. A complete steel scaffolding boards production line with tooling performs the entire process fully automatically.

The automated production line for construction scaffolding boards consists of the following components:

– software

– B&R PP41 controller

– sheet metal feeder

– straightening machine

– press for cutting the sides of the platform to the correct height/length

– bottom drive press for sheet metal perforation

– punching and stamping dies

– rollers to bend the shape of the platform

– guillotine to cut the finished platform

– table for collecting the finished platform

Technical specifications of the steel platform production line for scaffolding

- board lengths: 0.73 m, 1.09 m, 1.57 m, 2.07 m, 2.57 m, 3.07 m, 2 m, 3 m

- bottom drive press force: 50 t (500 kN)

- bottom drive press work table dimensions (L x W): 1200 x 800 mm

- bottom drive press drive power: 11 kW

- feed rollers diameter: 120 mm

- feed rollers length: 650 mm

- punching unit for holes (4 rows, 20 holes)

- stamping unit for holes (4 rows, 20 holes)

- contour punching unit

- feed roller drive: servo drive

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe