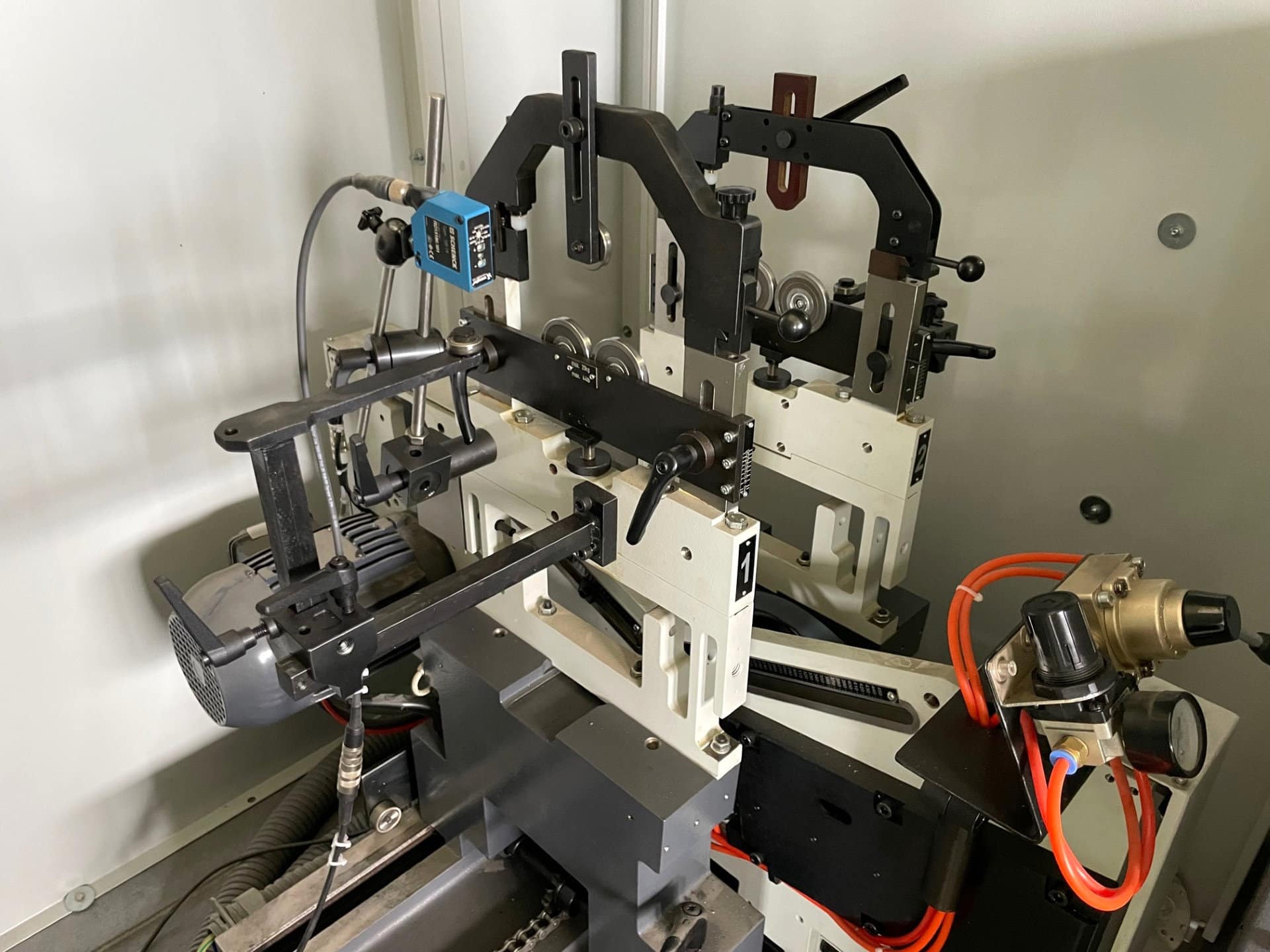

SCHENCK HE2BU balancing machine manufactured in Germany in 2014, is used during the final production stage to increase the service life of rotating components by balancing them properly. Balanced rotors are characterised by lower forces on the bearings and quiet operation without any vibration. The SCHENCK rotor balancing machine has been practically unused since its purchase and its configuration allows the machine to be used in high volume production.

The HE2BU electric motor rotor balancing machine is equipped with a state-of-the-art SCHENCK CAB 820 measuring system with intuitive and easy-to-use software, which with the use of a microprocessor guarantees the best machining results. During machining, the software accurately measures unbalance in two dimensions – static unbalance and moment unbalance and also supports various correction methods including milling, drilling, grinding, punching, welding and adding weights. Post-process results are stored in the measuring module’s database for further use in subsequent machining.

In addition to balancing rotors, the extremely versatile and universal machine also allows the machining of shafts, pulleys and other components, as well as the reading and printing of data in the form of barcodes.

Technical parameters of the SCHENCK HE2BU electric motor rotor balancing machine

- measuring system: SCHENCK CAB 820

- power supply: 3x 400 ± 10% V; 50/60 Hz

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe