SCHLICK RB 1500 SMARTLINE shot blasting machine was built in 2004 in Germany. The blastroom uses highly pressurised ejected shot to thoroughly clean the surface of sheet metal and steel profiles with a maximum height of 800 mm and a thickness of 50 mm. Workpieces enter the chamber of the SCHLICK-ROTO-JET RB 1500 – SL machine made of hardenable manganese steel by means of a roller conveyor, in which they are then processed with the blasting shot ejected by four highly efficient twin-disc turbines of 7.5 kW each.

The SCHLICK RB 1500 SmartLine blastroom machine is characterised by its compact and robust design, ensuring extremely economical and efficient processing of workpiece surfaces. The machine uses the SCHLICK Air-Shoc filter unit, which automatically and effectively separates dust from the air stream in order to eliminate contamination.

Technical data of the SCHLICK RB 1500 SMARTLINE shot blasting machine

- blasting chamber working dimensions (W x H x L): 1500 x 800 x 2000 mm

- maximum workpiece thickness: 50 mm

- minimum workpiece thickness: 6 mm

- number of turbines: 4

- turbine power: 7.5 kW

- roller conveyor speed: 0.5-2.5 m/min

- rollers spacing of roller conveyor: 650 mm

- man-hours: 35799,86 h

- height to top edge of roller conveyor: 950 mm

- compressed air consumption (at 5-7 bar): approx. 23 m3/h

- dust content of the outgoing air: <1 mg/m3

- total power consumption: 56 kW

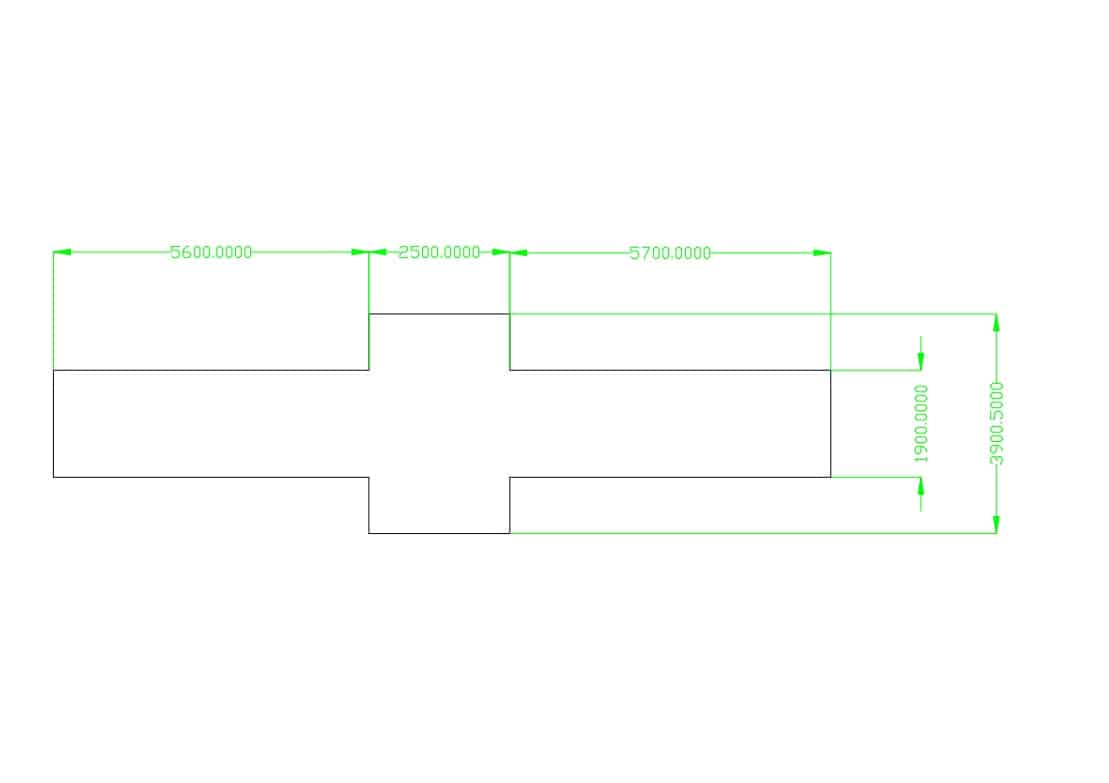

- dimensions of the RB 1500 SMARTLINE machine (L x W x H): 13800 x 3900 x 5500 mm

Equipment of the shot blasting machine

- twin-disc turbines: SCHLICK-ROTO-JET

- filter unit: SCHLICK Air-Shoc

- roller conveyor

- automatic blasting medium removal system

- DTR – technical and propulsory documentation in Polish language

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe