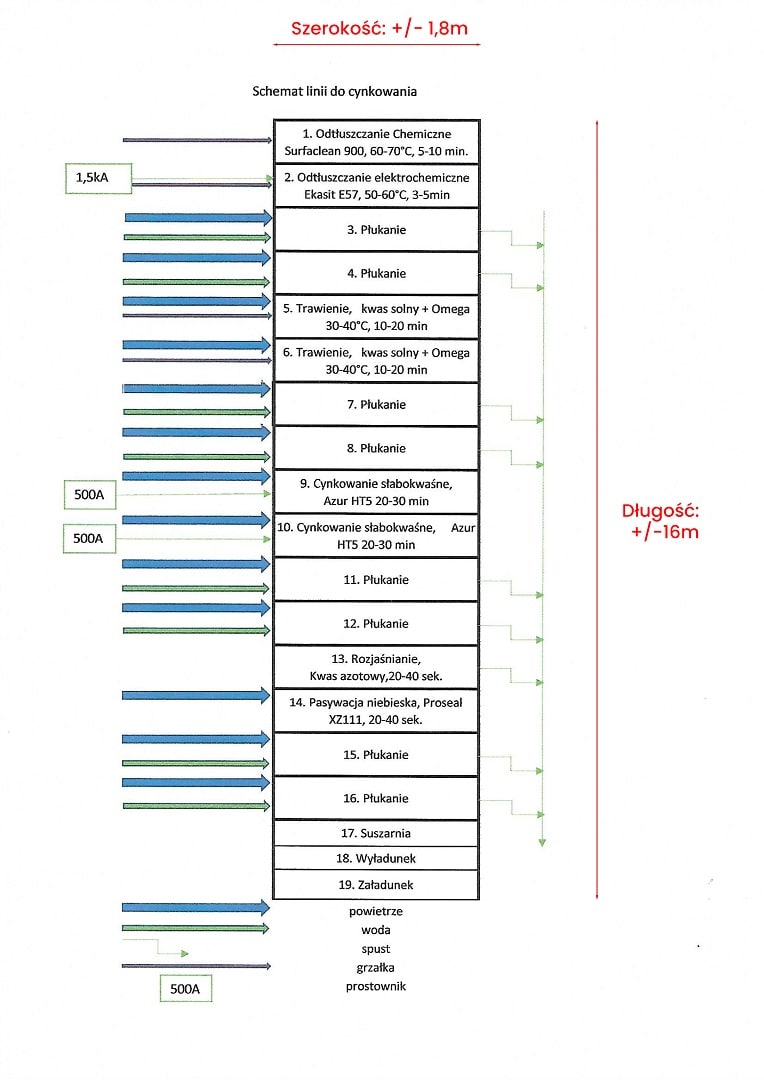

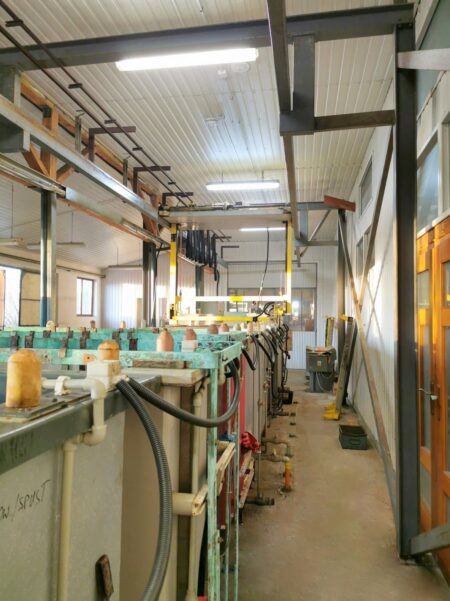

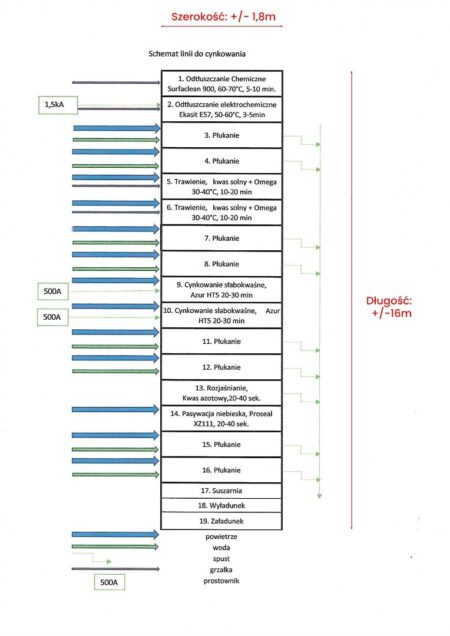

SCHLOTTER Galvanotechnik galvanising line, manufactured in 1994 in Austria, is designed for professional electrochemical treatment on various types of workpieces. During the treatment, a special coating is produced which protects the workpieces from mechanical damage and corrosion.

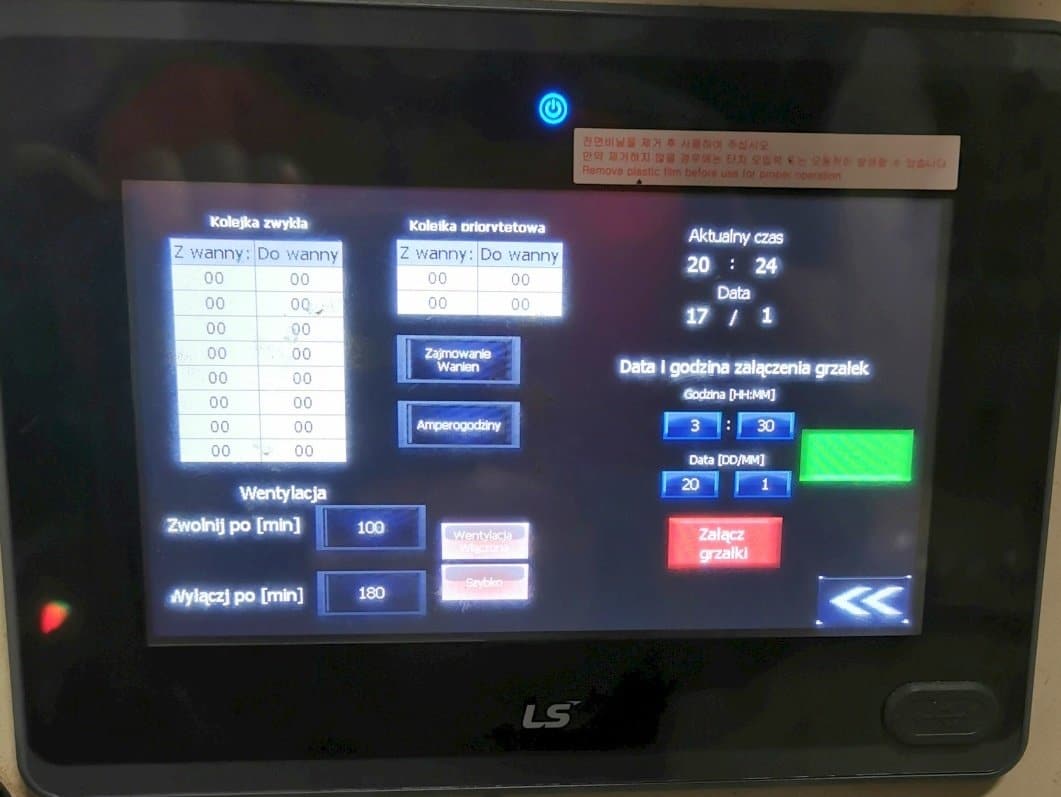

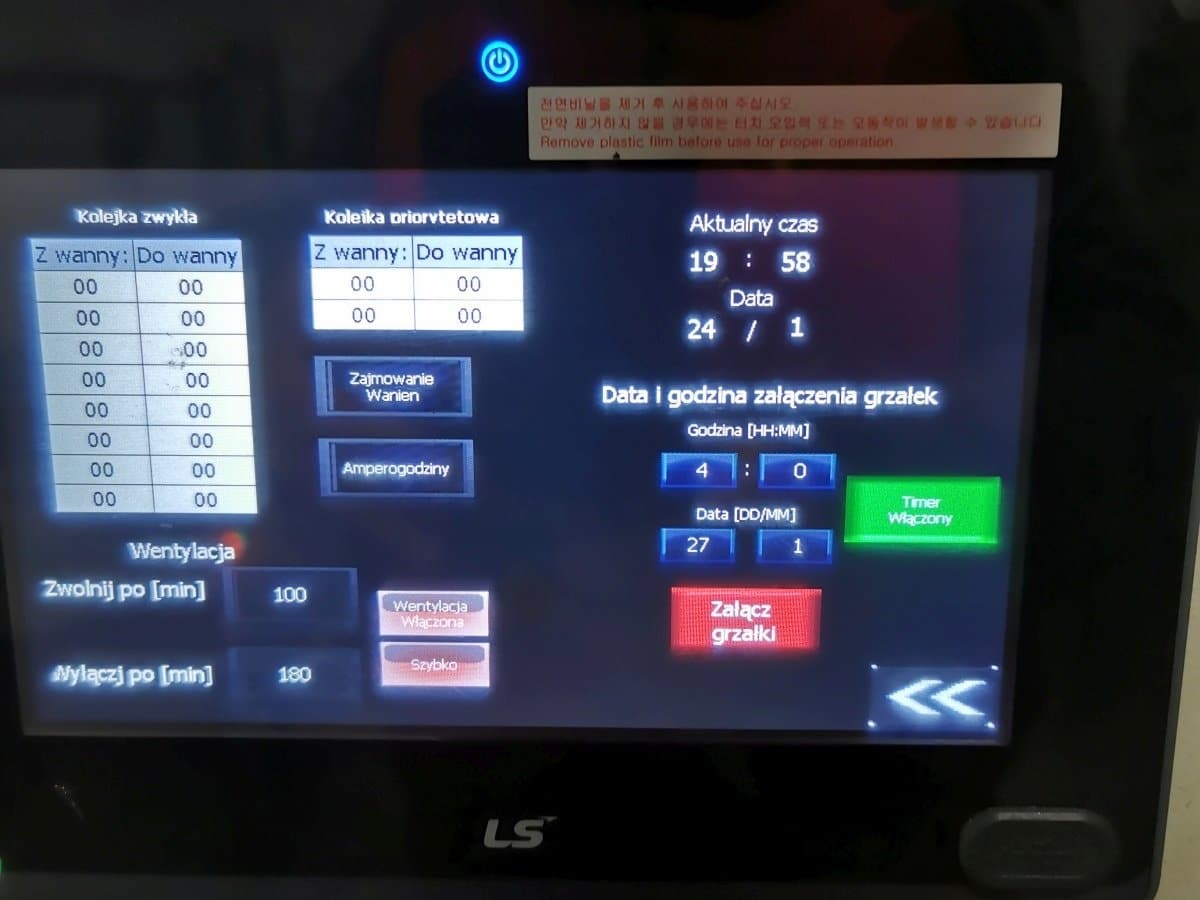

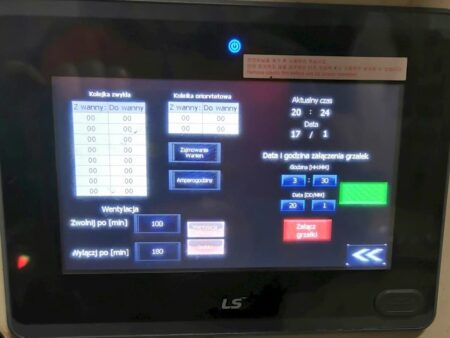

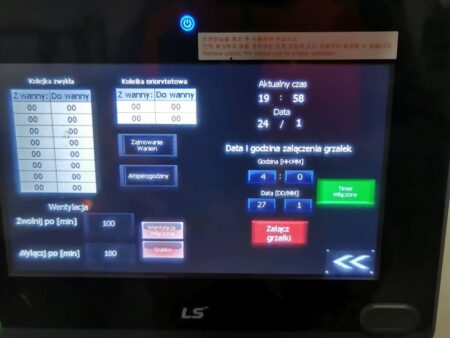

The SCHLOETTER Galvanotechnik galvanising line, characterised by its high reliability and low operating costs, is equipped with a modern control system, which makes it possible to control the ventilation system and to adjust parameters such as process time in the galvanising baths and heater on/off times. The galvanising and phosphating line is fully complete and ready for operation.

Equipment of the SCHLOTTER Galvanotechnik automatic galvanising plant

- tumbler trolleys (6 sets)

- trolleys for suspension system (5 sets)

- centrifuges (2 pcs.)

- rectifiers (3 pcs.)

- workpiece dryer

- ventilation system

- electronics and control system

- control cabinet

Galvanising machine dimensions

- crane travel track (L x W x H): 20 x 2.5 x 4 m

- spacing of columns supporting the crane runway: 4 m

- internal dimensions of tubs (L x W x H): 120 x 60 cm

- dimensions of the machine (L x W): ± 16 x 1.8 m

The machine was continuously upgraded during its operation – in 2019 the galvanising plant was equipped with a new electronics and control system.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe