SERON 0609 EXPERT CNC milling machine was manufactured in 2020 in Poland and allows for highly efficient machining of soft metals, plastics and composites. The versatile machine, which is a combination of state-of-the-art technology and high precision, has a ribbed construction made of the highest quality steel, which eliminates any vibration and deformation during the process. The excellent precision and process stability achieved by the machine can satisfy even the most demanding customers.

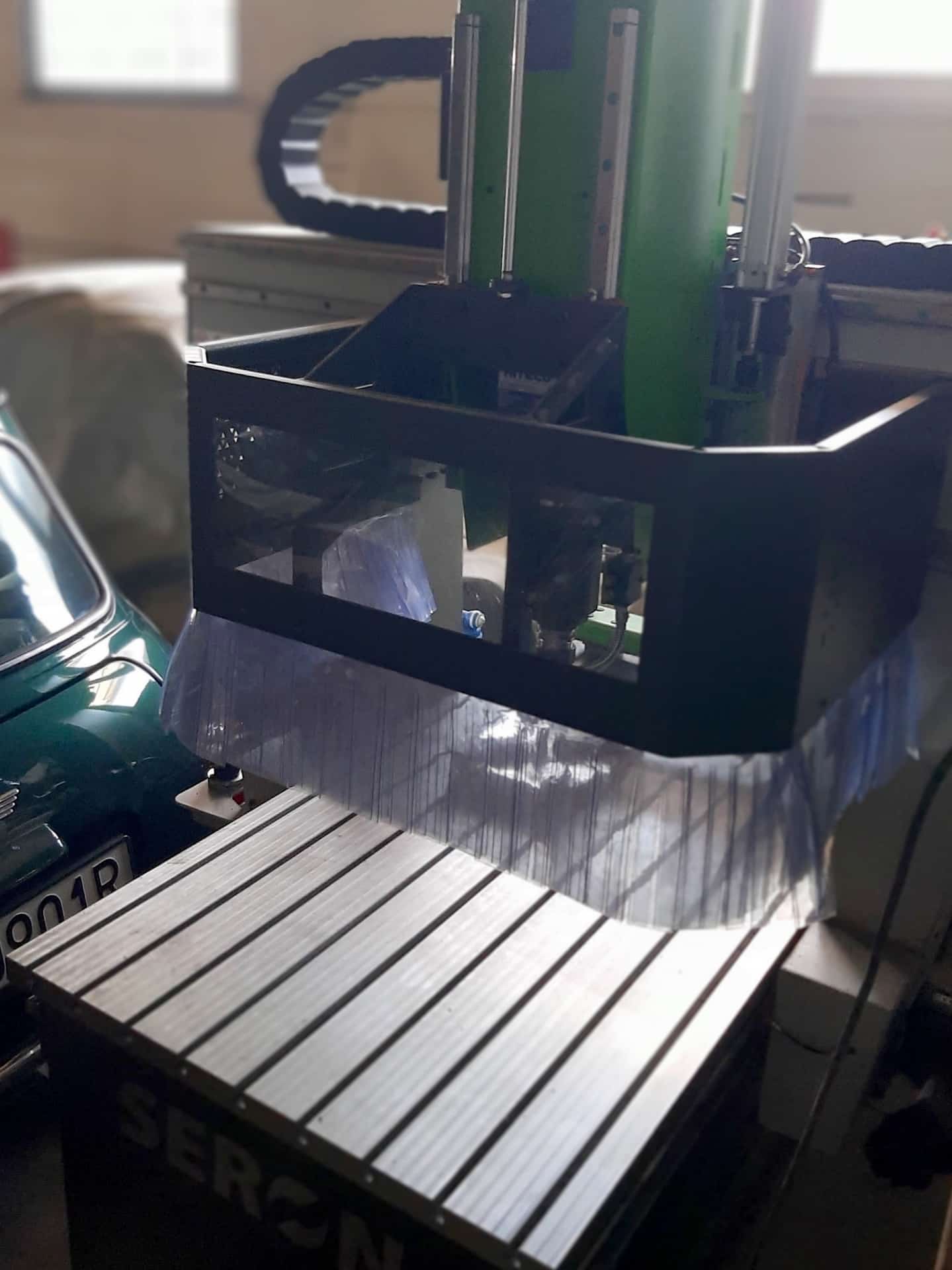

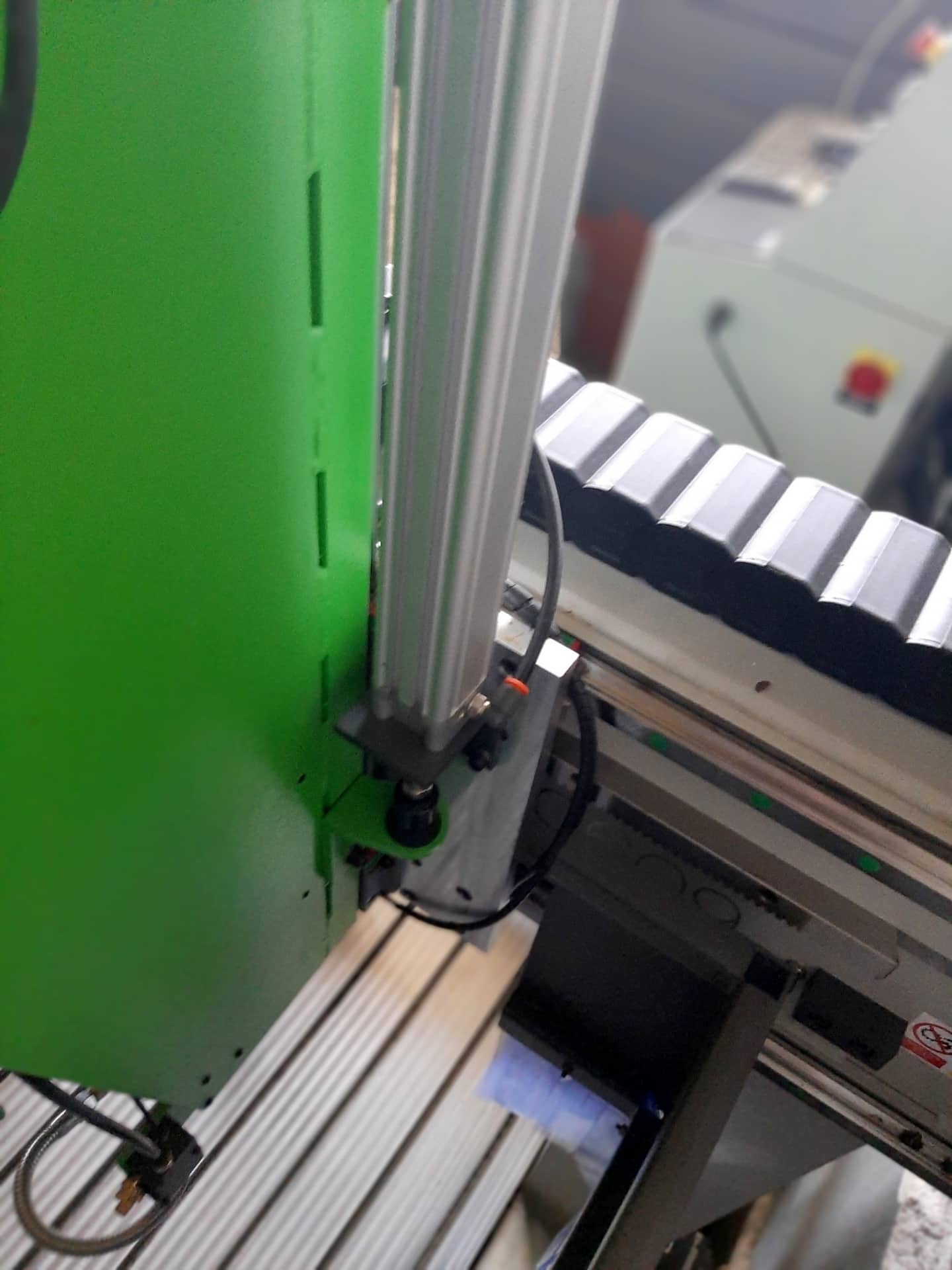

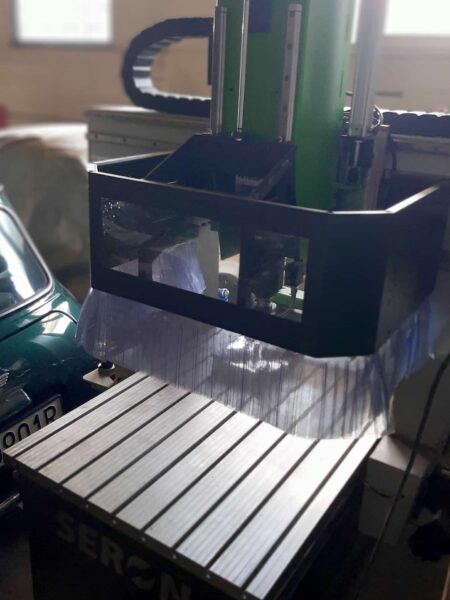

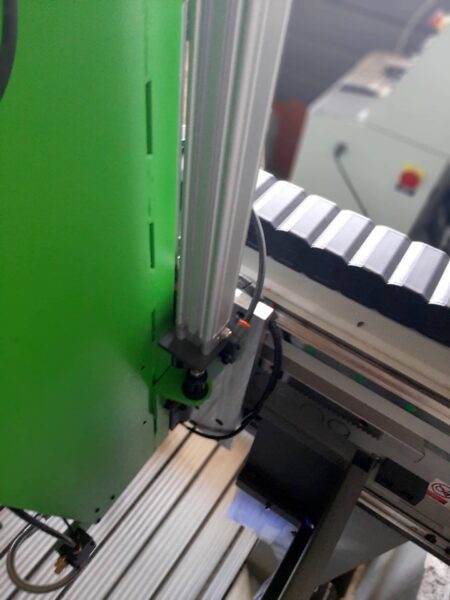

The SERON CNC milling machine has a 600 mm long and 900 mm wide T-slot table made of solid aluminium. The table ensures easy clamping of materials using, e.g. special clamps, and allows the installation of additional equipment such as vices. In order to achieve very high dynamics, axis accelerations and travel speeds even during the most demanding challenges, all machine axes (X,Y,Z) are equipped with powerful OMRON brushless AC servomotors with return compression. The special servo amplifier used on the devices continuously controls the motor parameters, guaranteeing that there is no operating deviation.

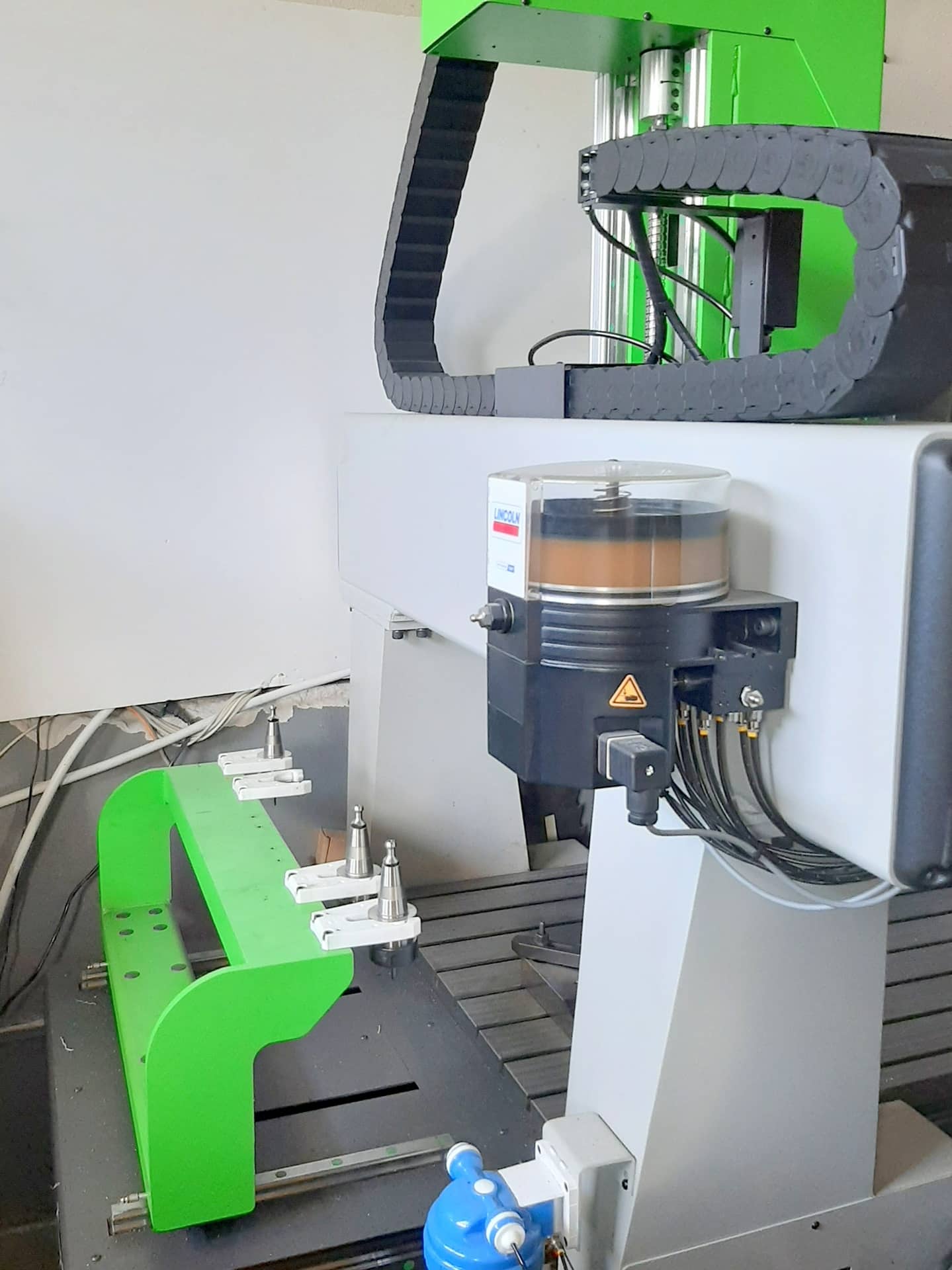

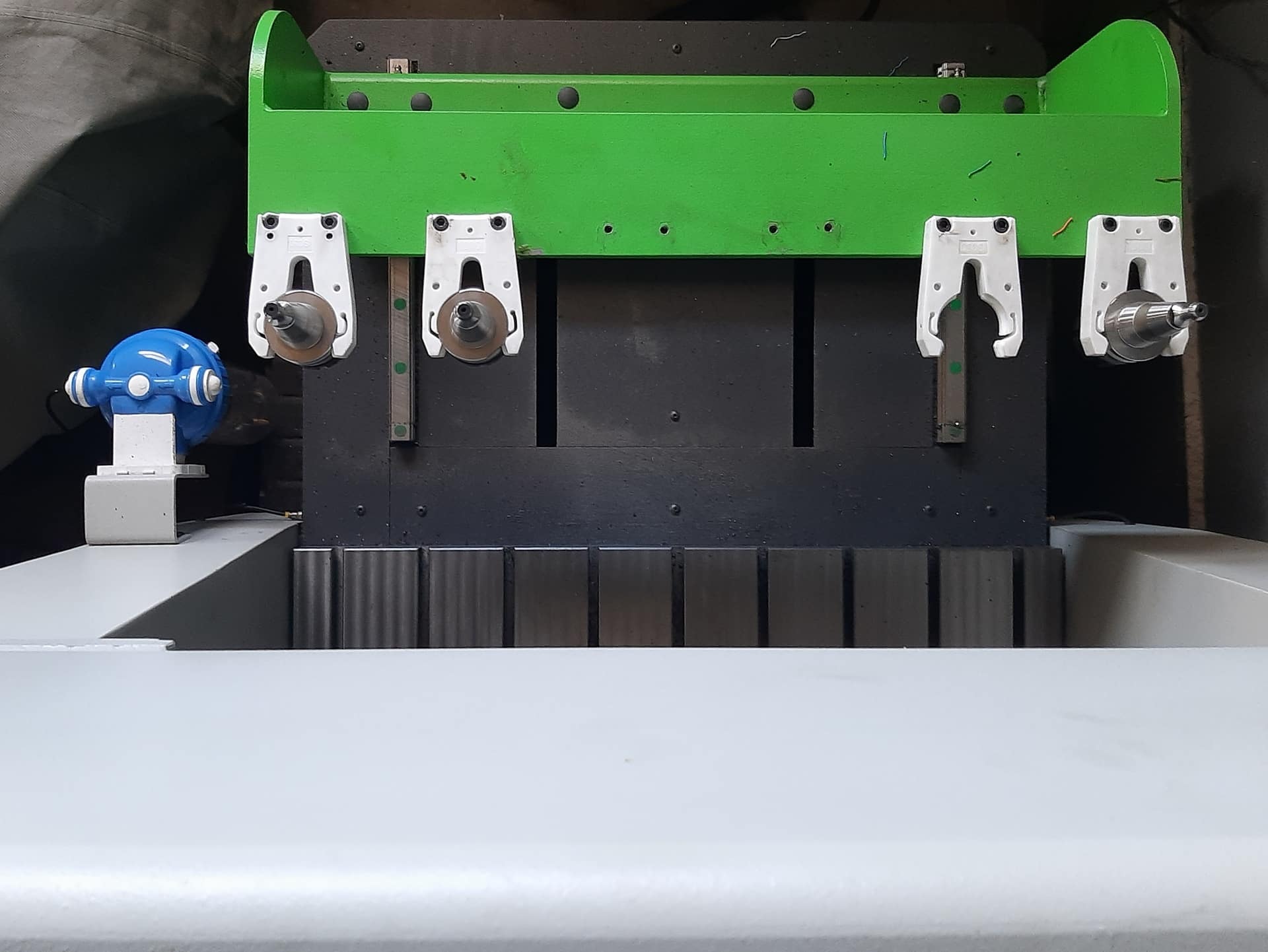

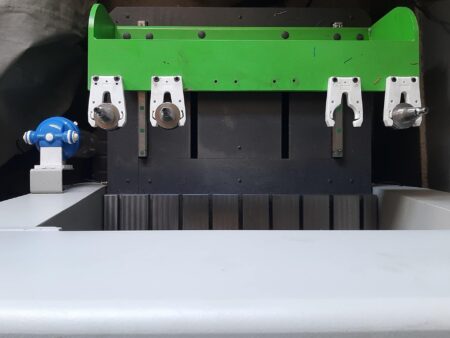

Workpieces are machined by a powerful HITECO electro-spindle with ATC system support (automatic tool changing), which allows the use of multiple tools in the production process without the need to calibrate them and without stopping the process. Tools taken from the 6-position linear magazine are cooled each time by compressed air with a small admixture of cutting fluids to increase the cutting speed and significantly extend tool life. The 0609 EXPERT CNC milling machine is also offered with, among others, an OSAI control system, a manual manipulator and a RENISHAW TS27R tool setting probe.

Technical data of the CNC milling machine SERON 0609 EXPERT

- number of axes: 3

- machined materials: soft metals, plastics, carbon, alucobond, dibond, wood, OSB and MDF, PVC, HPL, glass, etc.

- working area (L x W): 600 x 900 mm

- Z-axis range: 300 mm

- feed rate in one axis: up to 50 m/min

- feed rates with simultaneous X,Y axis drives: up to 70 m/min

- axis acceleration: 0.25-4 g

- electro-spindle maximum rotational speed: 24000 rpm

- electro-spindle drive power: 7.5 kW

- tool holder standard: ISO 30

- tool chuck standard: ISO 30 / HSKF63

- motor power: 10 kW

- power supply: 400 V; 50 Hz

Equipment of the milling machine

- control system: OSAI

- electro-spindle: HITECO QE-1F 6.6/12 24 I30 NL CB

- tool setting probe: RENISHAW TS27R

- linear magazine (6 positions)

- double-sided brushless AC servo motors: OMRON

- T-slot table made of solid aluminium (M8 clamping)

- manual manipulator

- mist cooling system

- automatic central lubrication with TIMKEN/SKF grease

- trapezoidal rails 25 mm: BOSCH REXROTH

- hardened ground helical bars

- ER32 collets (range 3-20 mm, 18 pcs.)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe