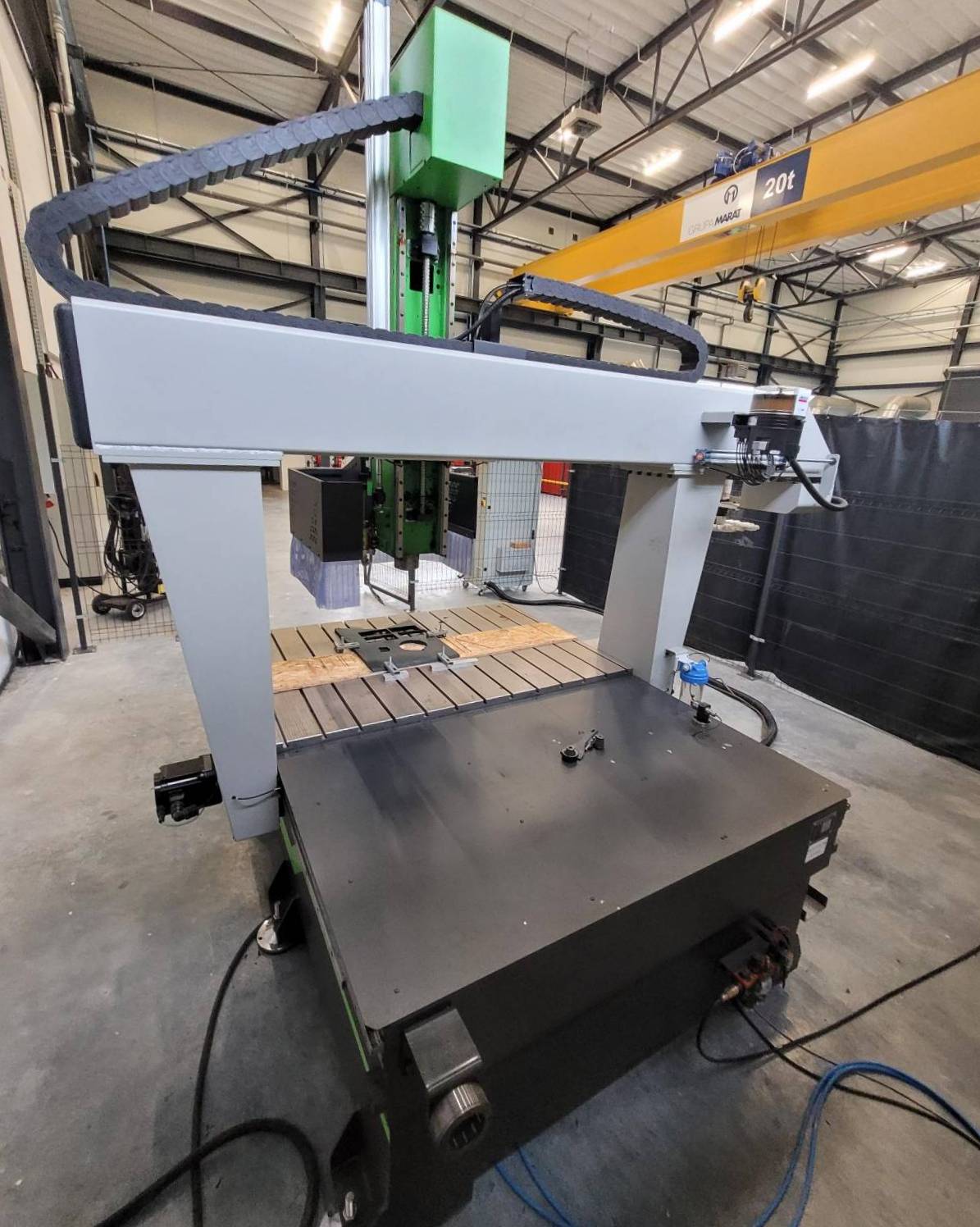

SERON 1310 PRO CNC router was built in 2020 in Poland by SERON Sp. z o.o. Sp.k. The machine, designed for precision machining of a wide range of materials, is distinguished by a number of modern, carefully selected components with the best technical parameters. Materials such as mild metals, composites, plastics and solid wood are machined by means of a high-speed brushless spindle. The design, made entirely of stress-relieved steel profiles and sheets, in turn, ensures the long-term stability and dimensional precision of the machine.

The operator has at his disposal an industrial, professional CNC control with many useful functions. Among them, there is for example the smooth vector analysis function, which ensures that the machine runs smoothly even with dynamic changes in direction and complex shapes. All equipment is integrated inside the security fence. The 1310 PRO CNC milling machine weighs 1300 kg.

Technical specifications of the SERON 1310 PRO milling machine

- machinable materials: steel, mild metals, composites, plastics, solid wood, wood-based materials, cardboard, foam, leather, textiles, etc.

- feed in the X/Y/Z axis: 1300/1000/200 mm

- spindle power: 4 kW

- power: 24 kW

- power supply: 400 V; 50 Hz

- dimensions (L x W): 2400 x 1700 mm

- weight of the SERON 1310 PRO machine: 1300 kg

Equipment of the SERON CNC router

- steering cabinet with professional CNC controller

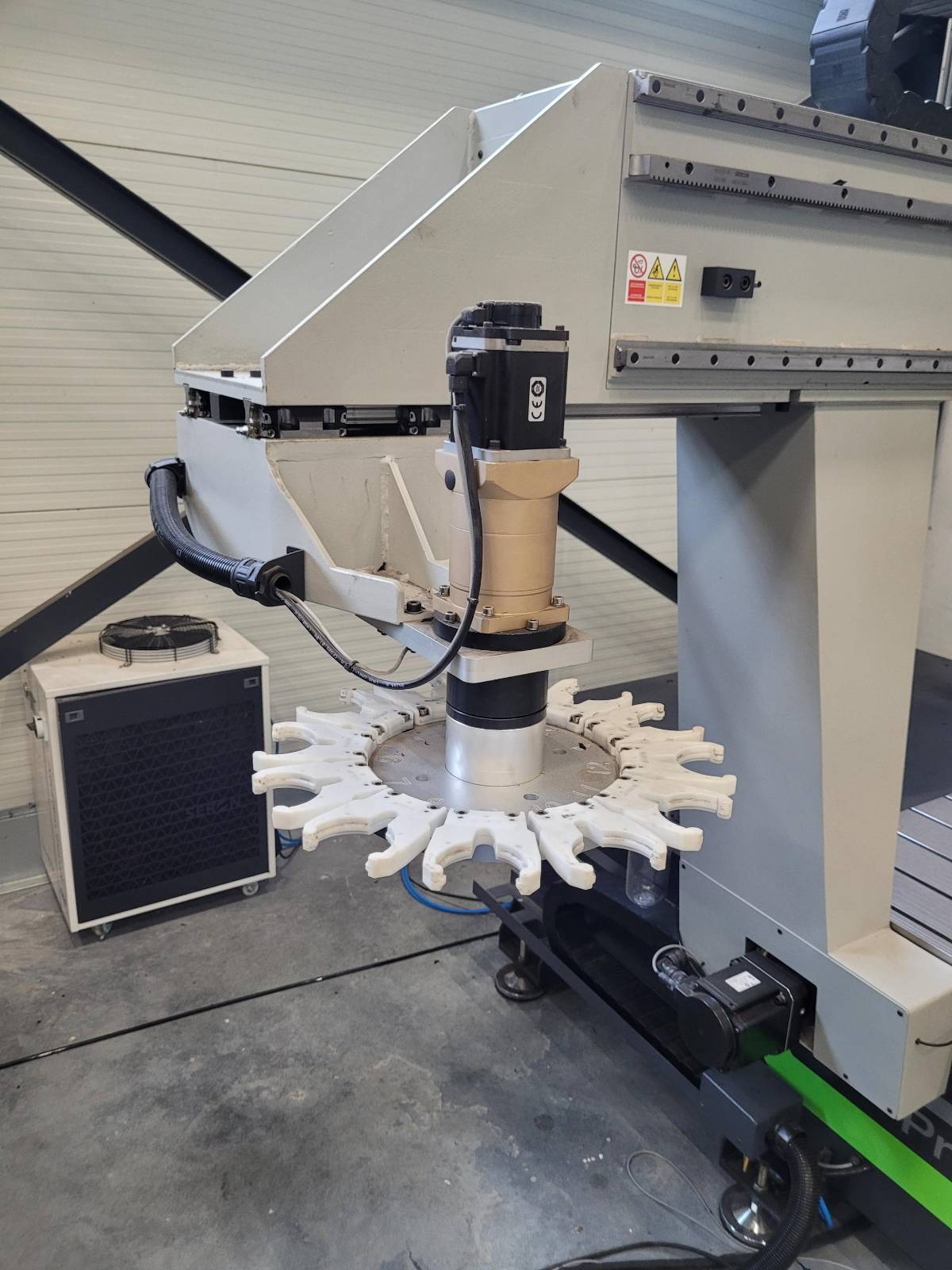

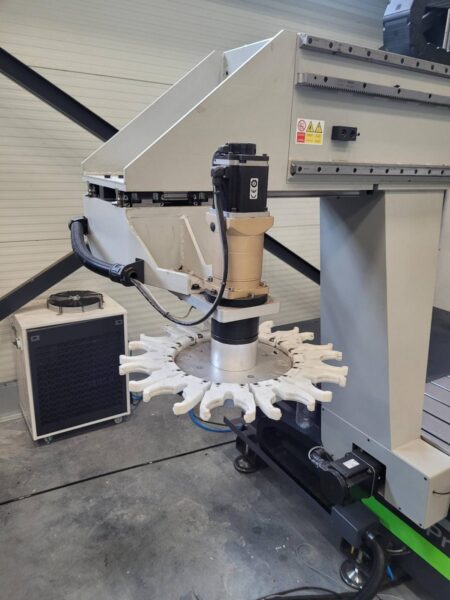

- brushless spindle with overload protection

- 12-position turret magazine

- hand-held pendant

- chiller: CW-6000AN

- security fence

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe