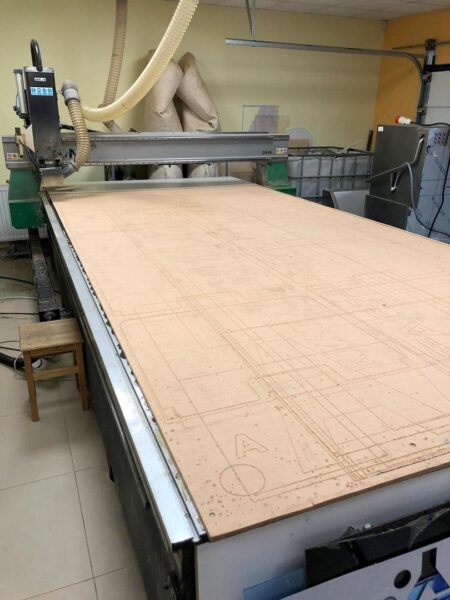

Seron 2040 Expert CNC milling plotter was manufactured in 2015 in Poland by the SERON company. The milling machine is designed for processing such materials as: soft metals (aluminum, brass, copper), plastics, plexiglass, composites, PVC and HPL as well as solid wood. The device has a work table (L x W) 2100 x 4000 mm, and the X / Y / Z axis travel is 2100, 4000 and 200 mm, respectively. The machining center is equipped with a 5.5 kW liquid cooled spindle with a maximum speed of 24,000 rpm. Additional equipment includes MACH3MILL control system, Omron servo drives with EtherCat protocol and chip extraction system.

Technical data of the Seron 2040 Expert CNC milling machine

– working area: 2100x4000mm

– X / Y / Z axis travel: 2100/4000/200 mm

– gate clearance and the range of the Z axis: 200mm

– travel speed: up to 90 m / min

– raster table

– maximum speed of the electro-spindle: 24,000 rpm

– spindle power: 5.5 kW

– accelerations: up to 1G

– software resolution: up to 0.0001mm

– positioning accuracy: 0.01 mm

– linear bearing: trapezoidal rails, Bosch Rexroth 25

– supply voltage: 400V; 50Hz; +/- 10%

– maximum power of the device: 9kW

Equipment for the Seron 2040 Expert CNC milling plotter

– control system: MACH3MILL

– chip extraction installation

– Omron servo drives with EtherCat protocol

– liquid-cooled spindle

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano