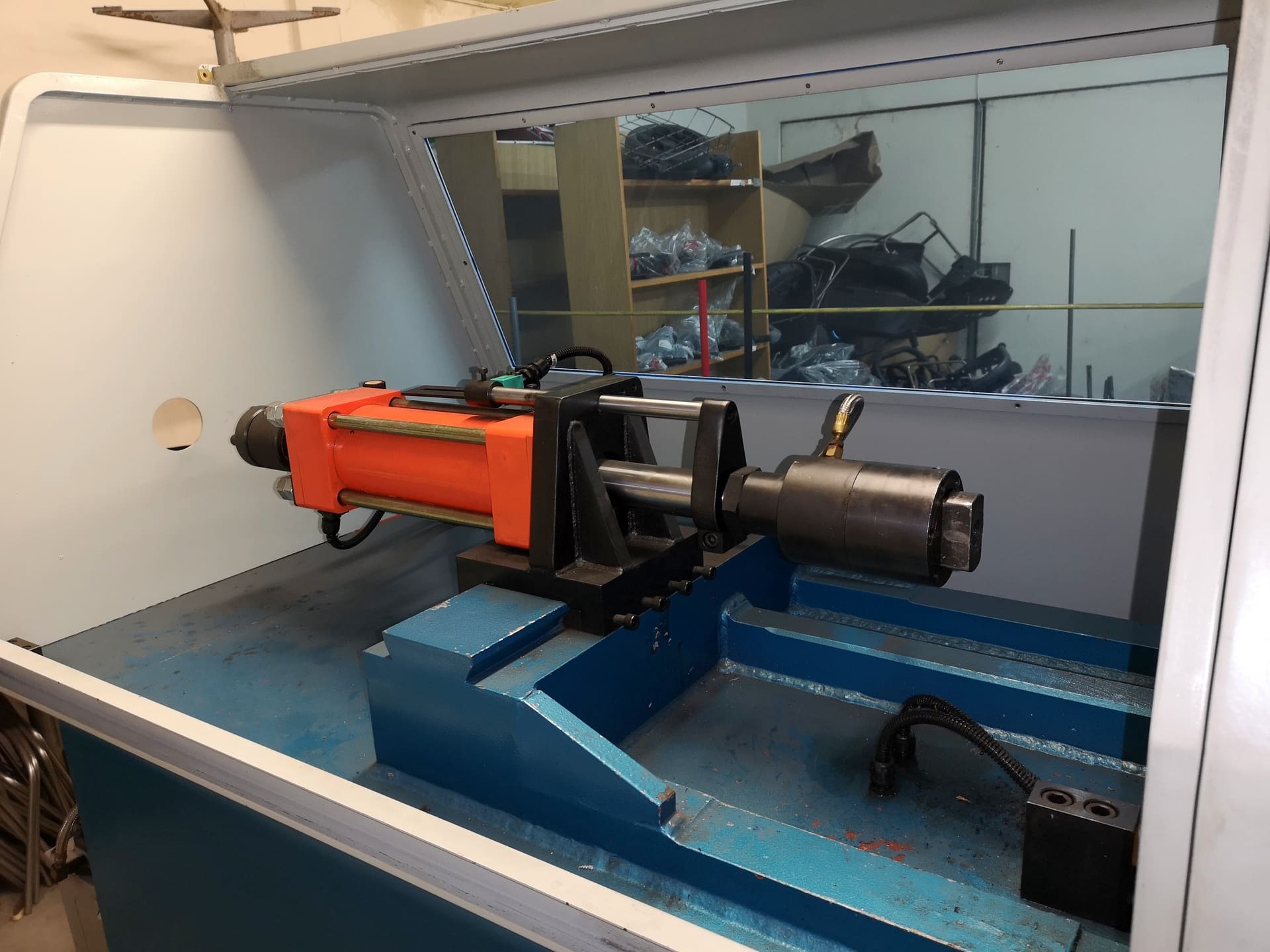

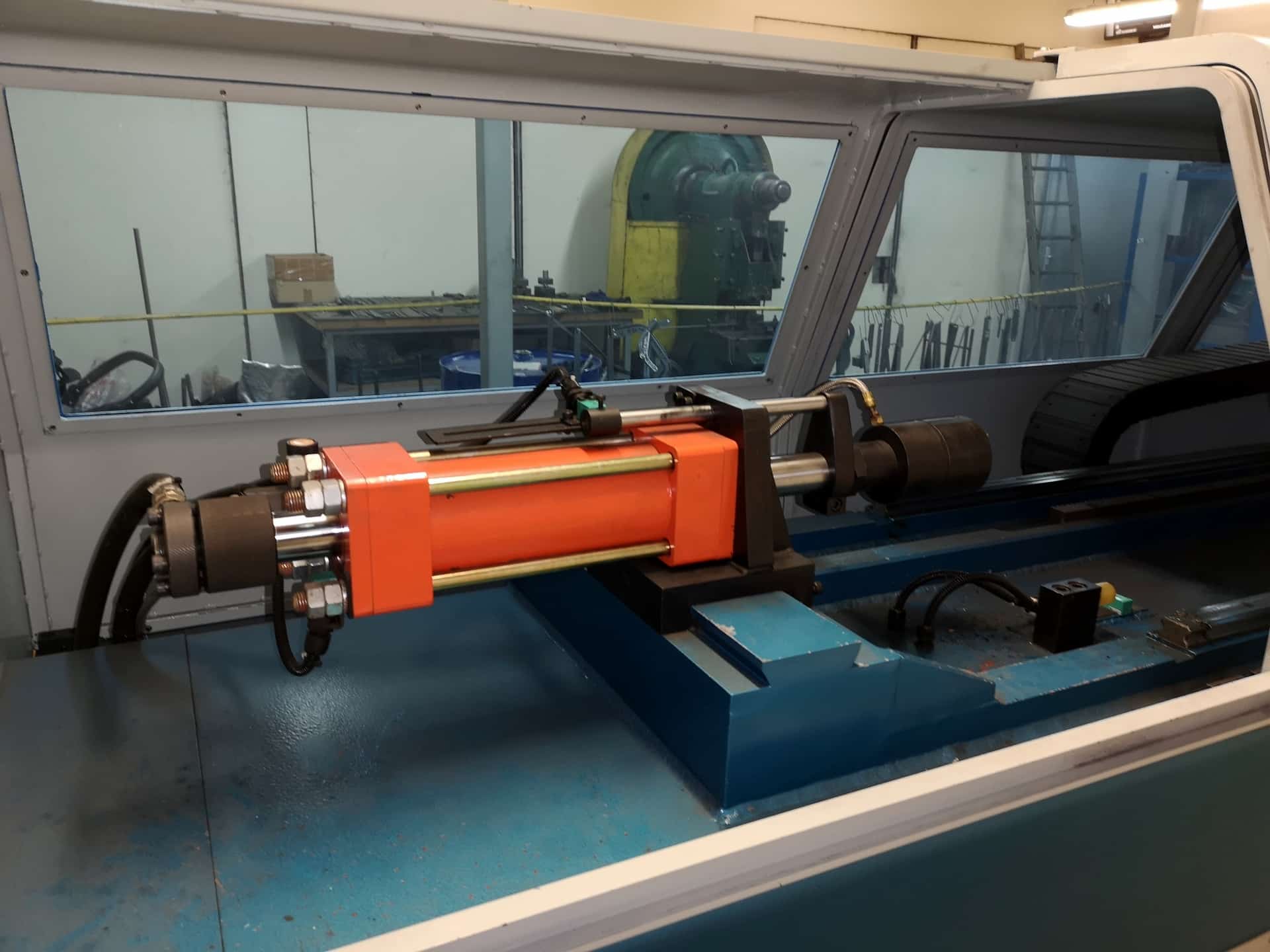

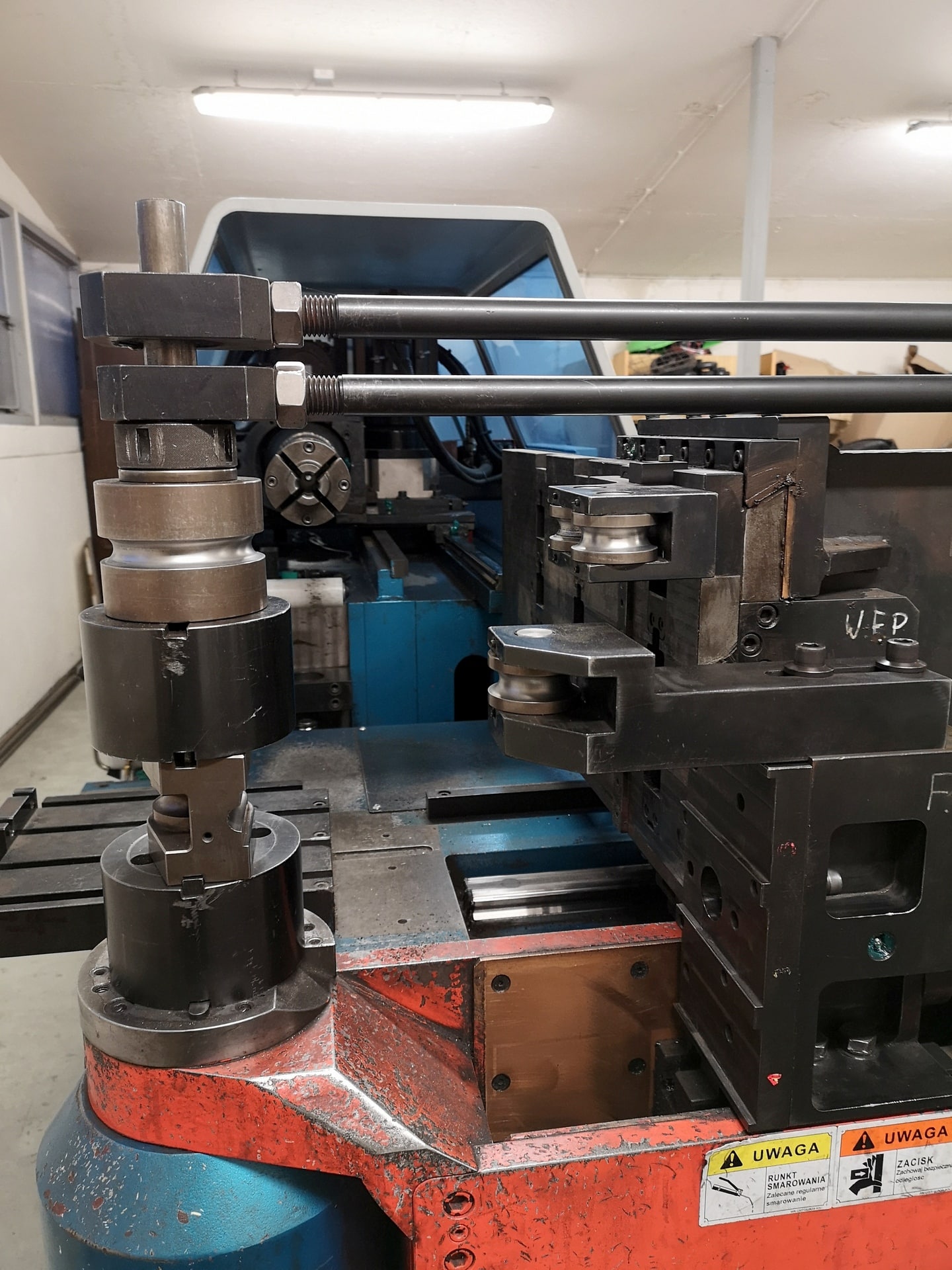

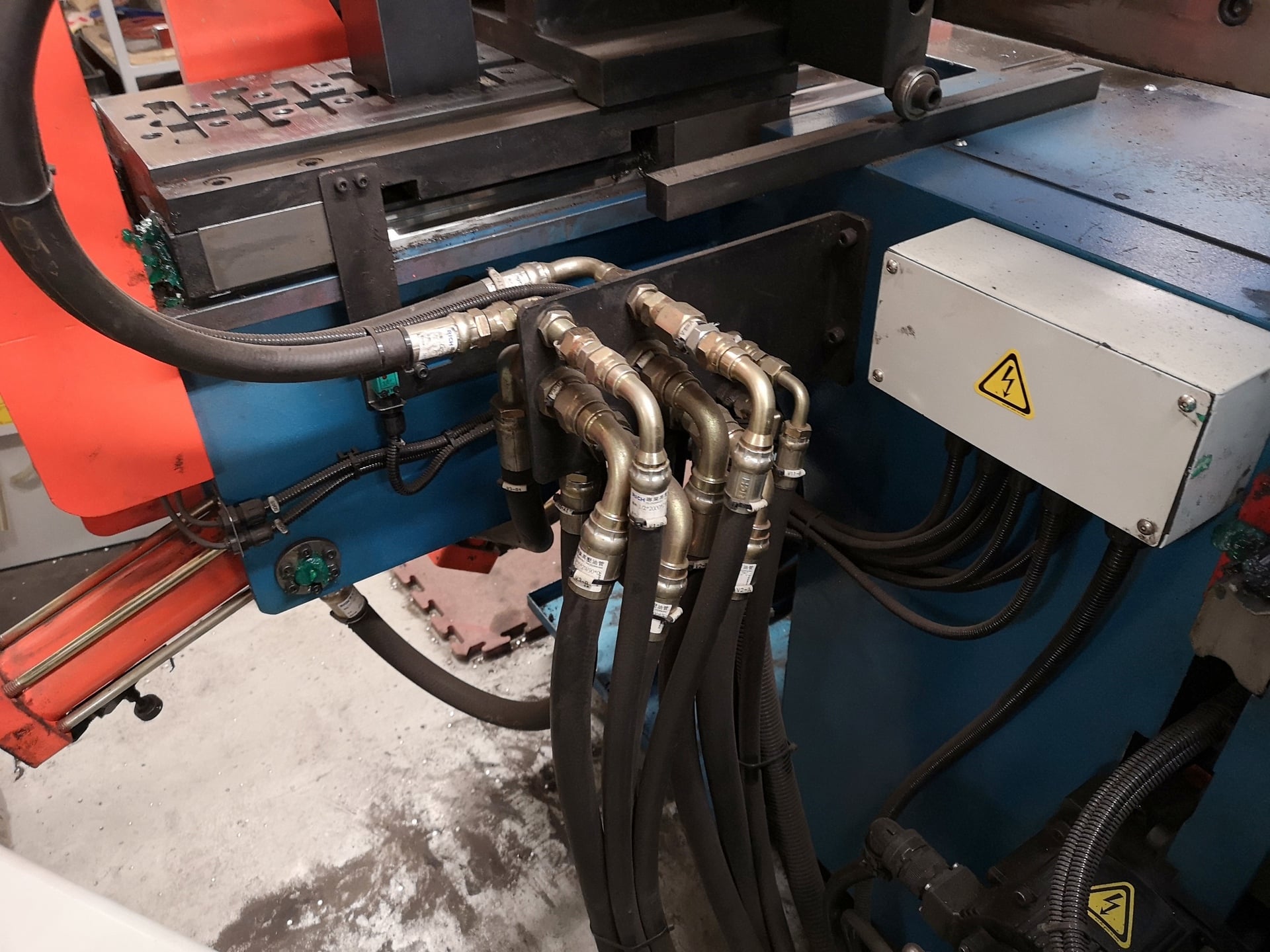

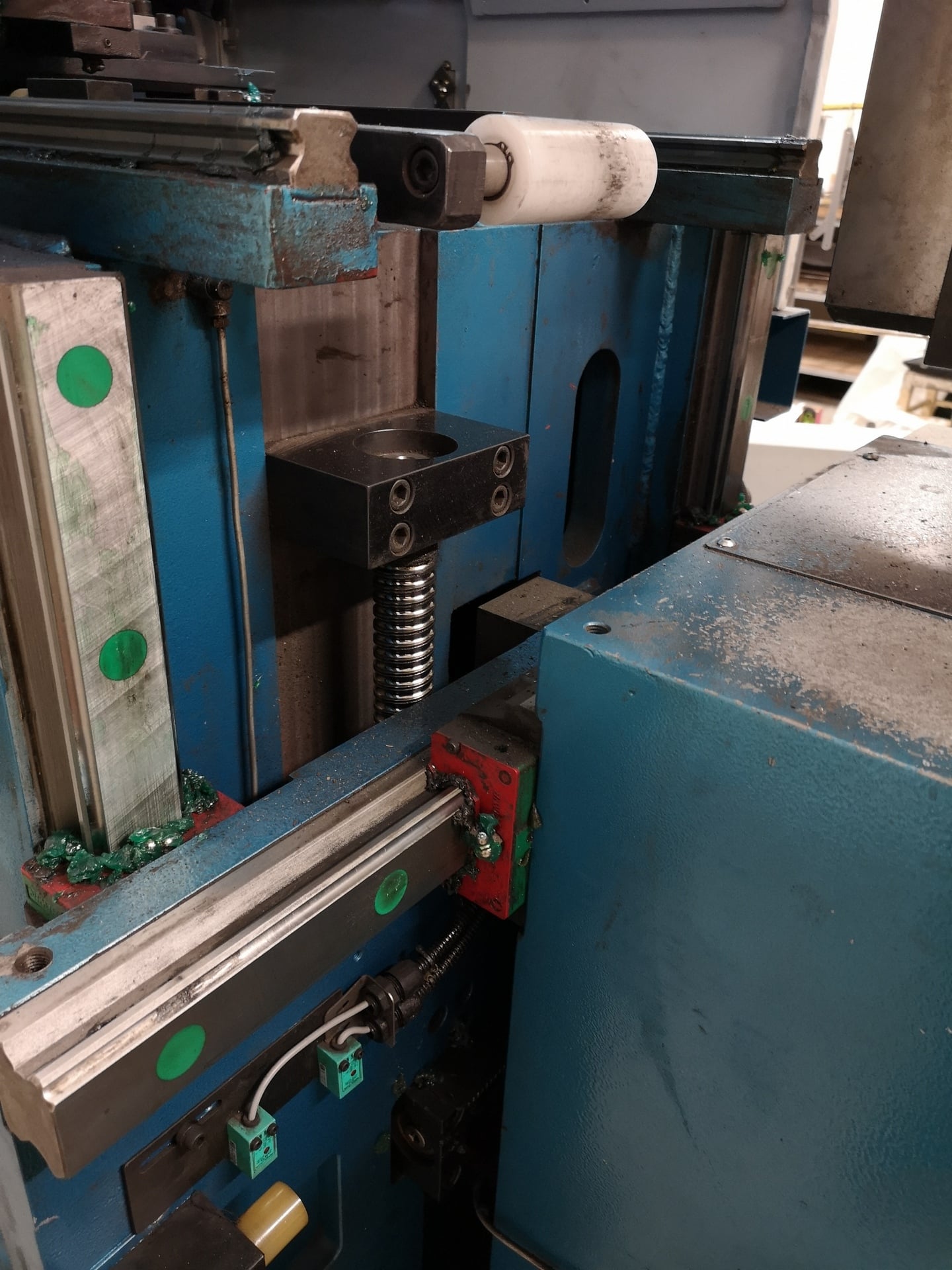

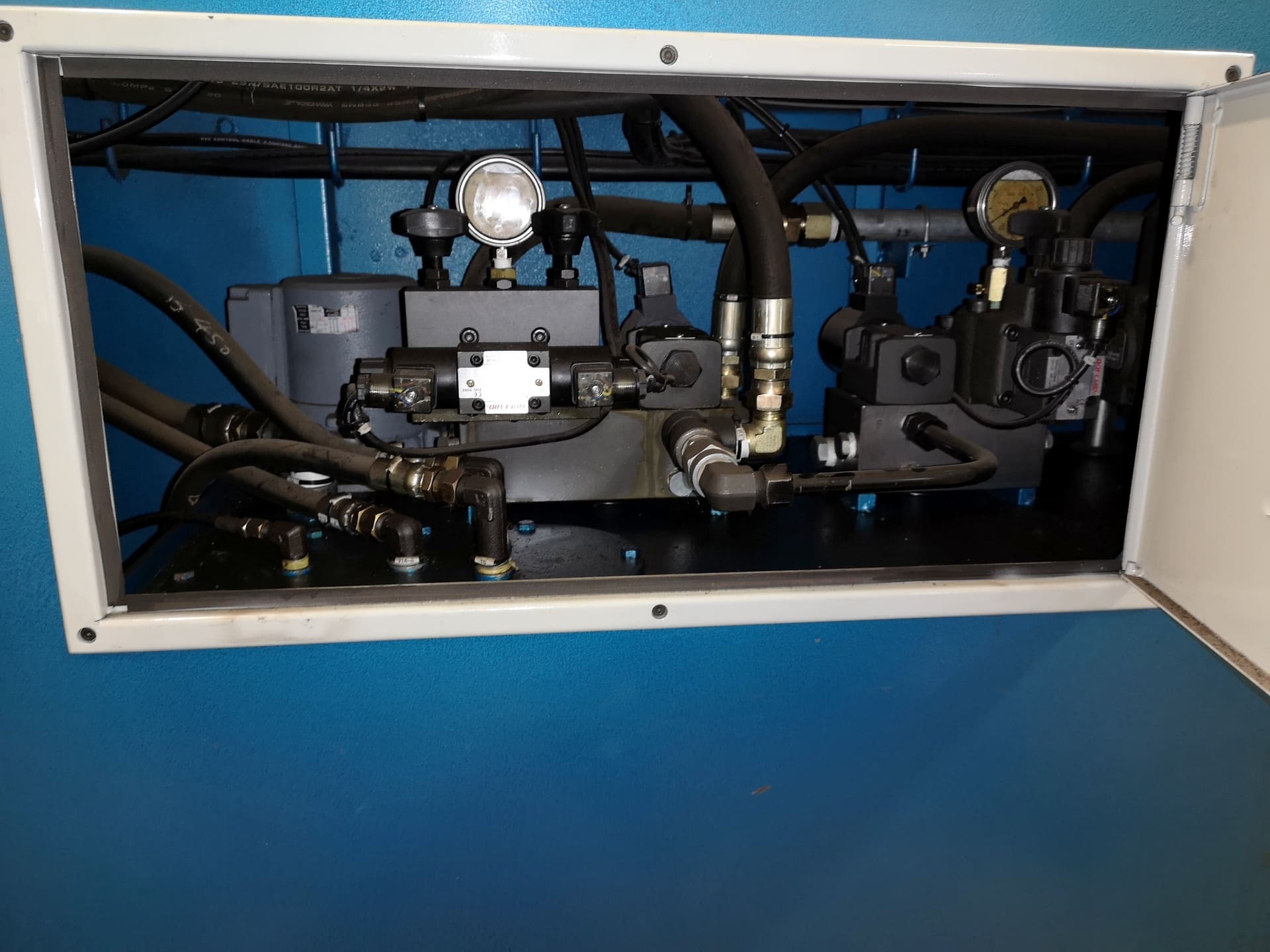

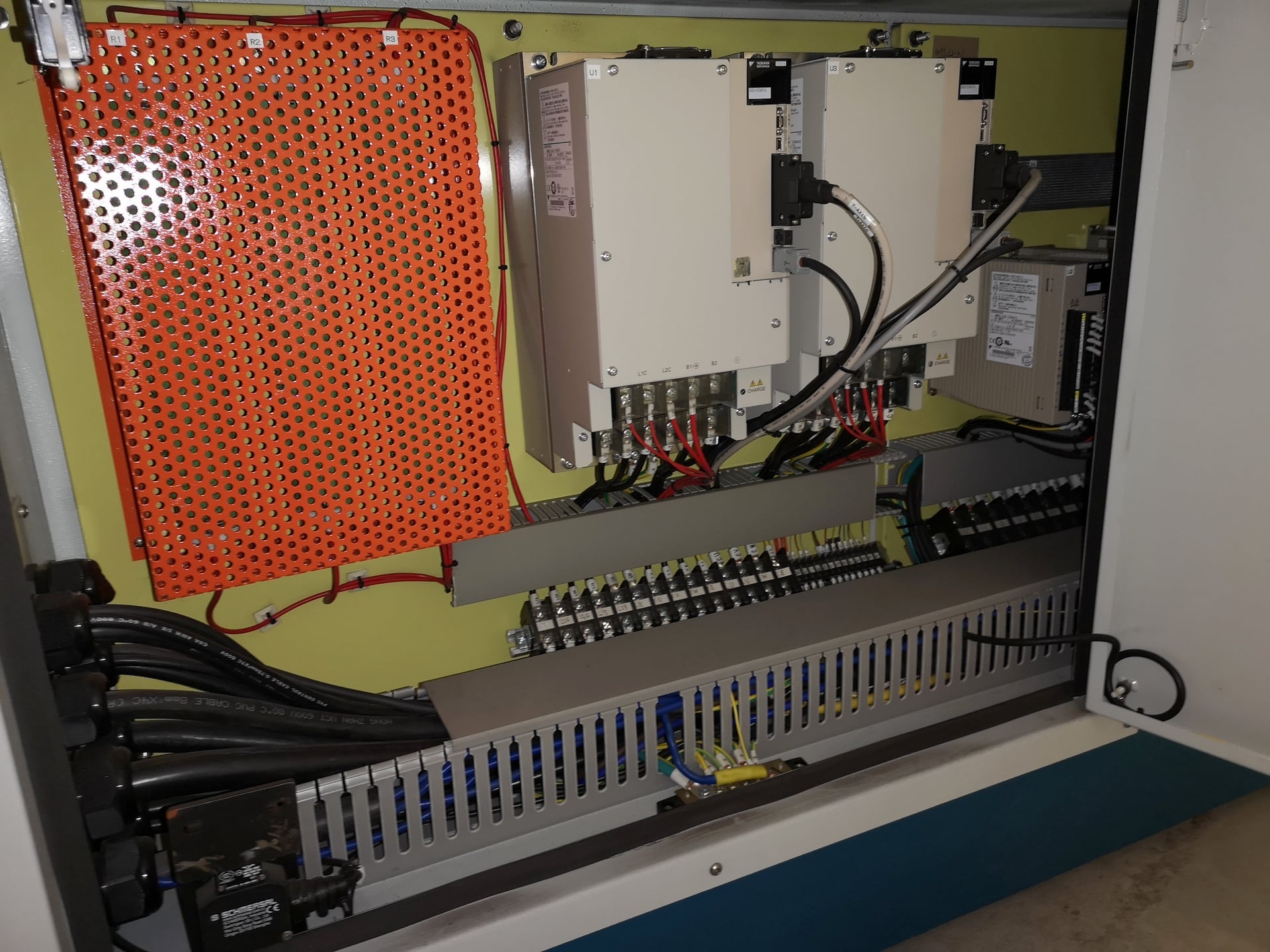

SHUZ TUNG CNC 50 BRM CNC tube and profile bending machine built in 2014 in Taiwan allows for fully automatic, serial production of complex spatial workpieces in 5 axes with simultaneous hole punching. Excellent precision and accuracy of bending are guaranteed by the reliable servo motors used in the machine, which are responsible for realising the main working movements, i.e. bending, rotation and material feed. The rest of the movements are driven by a central hydraulic system with electronic lubrication.

The SHUZ TUNG CNC mandrel bending machine is operated via a control panel with an installed CNC controller with the option of saving an unlimited number of programmes. In addition, the automatic servo bending machine is equipped with several bending rolls, a high-quality mandrel and an actuator to support material feed. The 50 BRM automatic CNC mandrel bending machine weighs 3500 kg.

Technical specifications of the SHUZ TUNG CNC 50 BRM CNC 3D mandrel bending machine

- number of axes: 5

- maximum tube bending capacity: 50×2 mm

- maximum bending angle: 190°

- maximum bending radius: 220 mm

- feeding speed: 1-1000 mm/s

- feeding accuracy (ball screw): ± 0.01 mm

- maximum feed length: 2500 mm

- maximum feed length with mandrel: 3500 mm

- bending speed: 120°/s

- bending accuracy: ± 0,05°

- rotational speed: 200°/s

- number of programmes: unlimited

- number of bends per programme: unlimited

- motor power: 50 HP

- oil tank capacity: 4,6 l

- maximum oil pressure: 5 kg/cm2

- oil flow: 300 CC/min

- dimensions (L x W x H): 5200 x 1150 x 1400 mm

- weight of machine: 3500 kg

Equipment of the CNC50BRM tube bending machine

- CNC control

- workpiece punching function (punching holes)

- electric lubrication

- tooling

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe