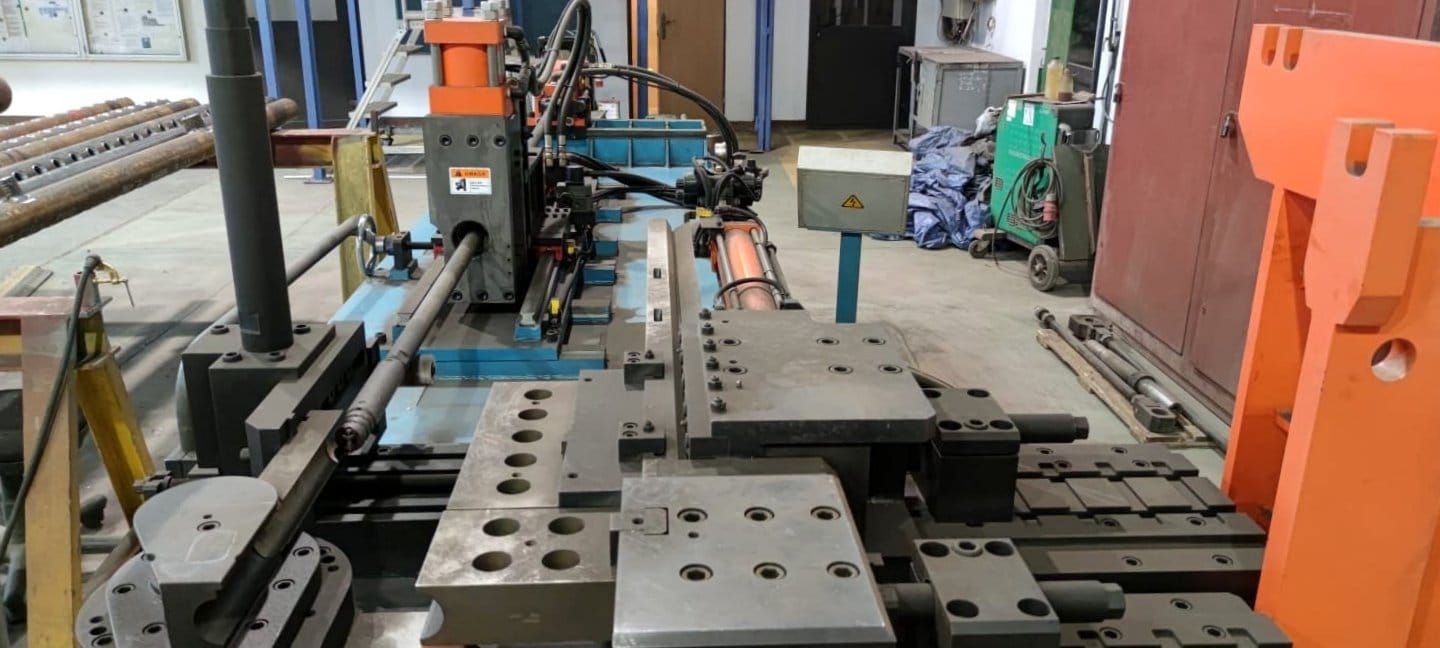

SHUZ TUNG NCB100 tube bending machine was manufactured in 2017 in Taiwan. The machine is designed for bending tubes and profiles and operates in two modes – manual and semi-automatic. In manual mode, individual movements, such as bending or mandrel withdrawal, are initiated by unambiguous commands from the control panel. On the other hand, in the semi-automatic mode, the operator initiates the bending process by pressing the start buttons on the portable control column.

The SHUZ TUNG NCB100 tube and profile bending machine is controlled by an NC control with a touch screen LCD panel allowing storage of up to 99 programs, each of which enables the execution of 20 bending processes with different angles. The semi-automatic mandrel bending machine has functions of controlled mandrel return and reverse bending, significantly affecting the quality of bending and ease of operation.

The machine can bend tubes and profiles up to an angle of 190° and a bending radius of 500 mm at speeds up to 20° per second. Its capacity when bending steel tube is 100 x 6.0 mm. The total weight of the mandrel bending machine is 6500 kg.

Technical data of SHUZ TUNG NC B100 bending machine

- NC control

- bending capacity (steel pipe): 100 x 6.0 mm

- range of bending radius: up to 500 mm

- minimum bending radius CLR: 1,5D

- bending angle range: up to 190°

- mandrel length: 3000 mm

- bending speed: up to 20°/sec.

- bending accuracy: ±0.1°

- number of bending programs: 99

- number of bends: 20/program

- motor power: 25 HP

- machine dimensions (L x W x H): 490 x 170 x 145 cm

- machine weight: 6500 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe