SINO NCP 45 eccentric press used for precision machining of workpieces was manufactured in 2018 by the Chinese company Sino Machinery & Tools (Dongguan) Co., LTD. Stability during the metalworking process, is maintained thanks to the machine’s rigid construction made of high-quality steel. The best components used in the press, including, among others, a 60 mm adjustable slider making from 50 to 100 strokes per minute over a distance of 80 mm, guarantee the most accurate metal machinig results.

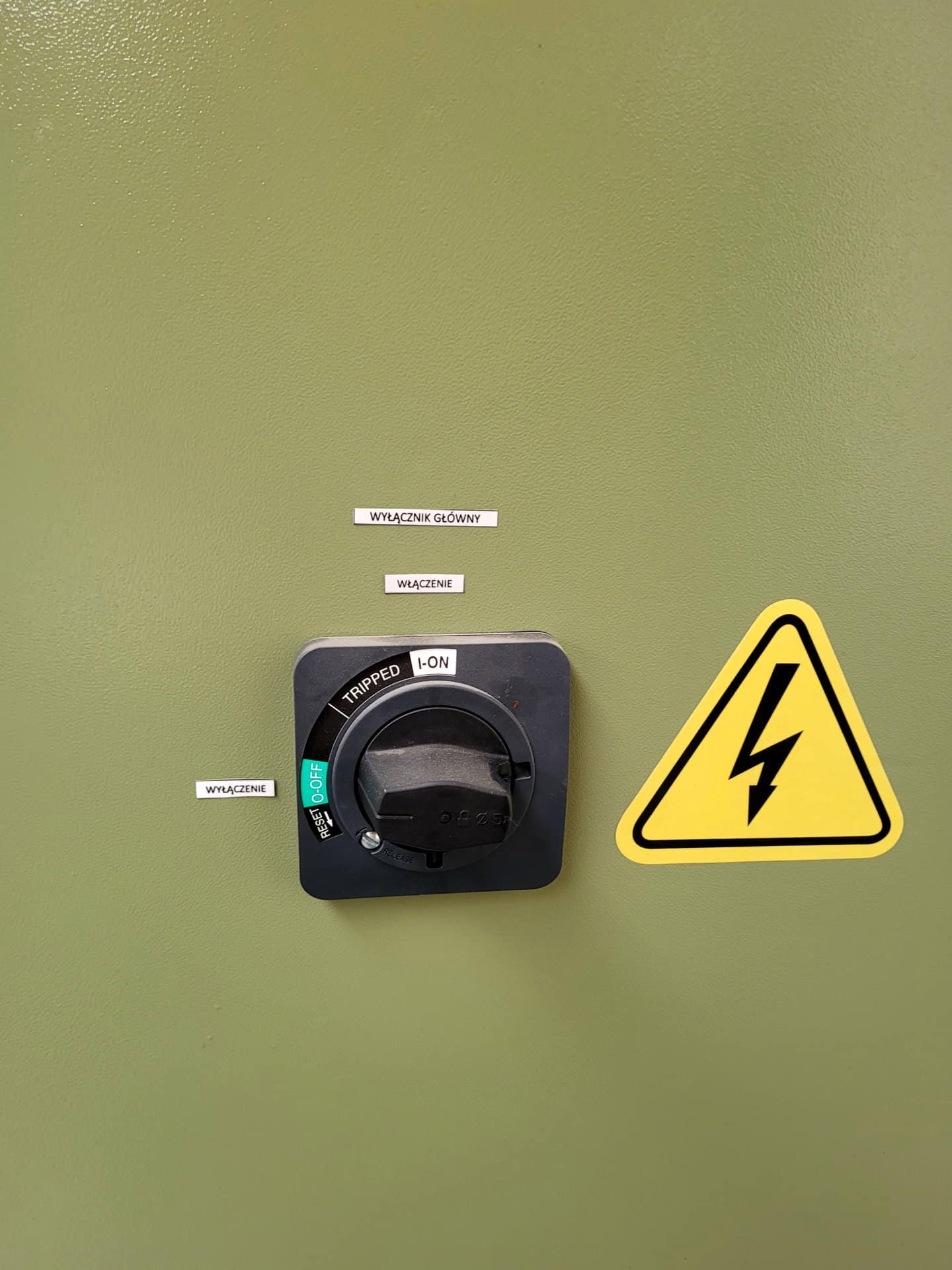

High operating safety is maintained thanks to the used light curtains, effectively protecting the operator from unwanted entry into the machine’s working area. The crank press has 45 tonnes of press force and extensive equipment consisting of, among others, a WAKO SEIKI MTS35 die height indicator, pneumatic counterbalances and a TECO A510s inverter. The total weight of the machine is 3600 kg.

Technical data of the SINO NCP 45 crank press

- maximum press force: 45 t

- stroke of the slider: 80 mm

- number of slider strokes: 50-100/min

- slider adjustment range: 60 mm

- work area of the slider: 440 x 320 mm

- die height: 180-240 mm

- work area dimensions (L x W x H): 750 x 380 x 225 mm

- bolster dimensions (L x W x H): 850 x 440 mm

- thickness of bolster: 85 mm

- hole of bolster (L x W): 300 x 150 mm

- frame width: 720 mm

- maximum die weight: 412 kg

- motor power: 5 HP

- maximum pressure: 5 kg/cm2

- power supply: 380 V

- floor space requirement (L x W): 930 x 1370 mm

- overall dimensions (L x W x H): 1000 x 1516 x 2373 mm

- total weight of NCP45 machine: 3600 kg

Equipment of the press

- light curtains

- inverter: TECO A510s

- die height indicator: WAKO SEIKI MTS35

- stepless adjustment of the machine motor speed

- crankshaft angle indicator

- magnetic stroke counter

- pneumatic counterbalances

- hydraulic overload protection

- lubrication system

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe