SODICK AQ327L PREMIUM wire EDM was produced in 2006. It is equipped with a work table with an area of 396 x 606 mm. The machine allows the processing of a detail with a maximum weight of 500 kg and a height of 240 mm. The Sodick bead core enables machining in five axes (X, Y, Z, U, V), thanks to which it is possible to make cones and elements of a different shape at the bottom and top of the workpiece. EDM treatment of the EDM machine enables the processing of materials after previously performed heat treatment, e.g. hardening, which has a significant impact on improving the dimensional and shape accuracy of the final product. In addition, the machine is equipped with an automatic wire threading system AWT.

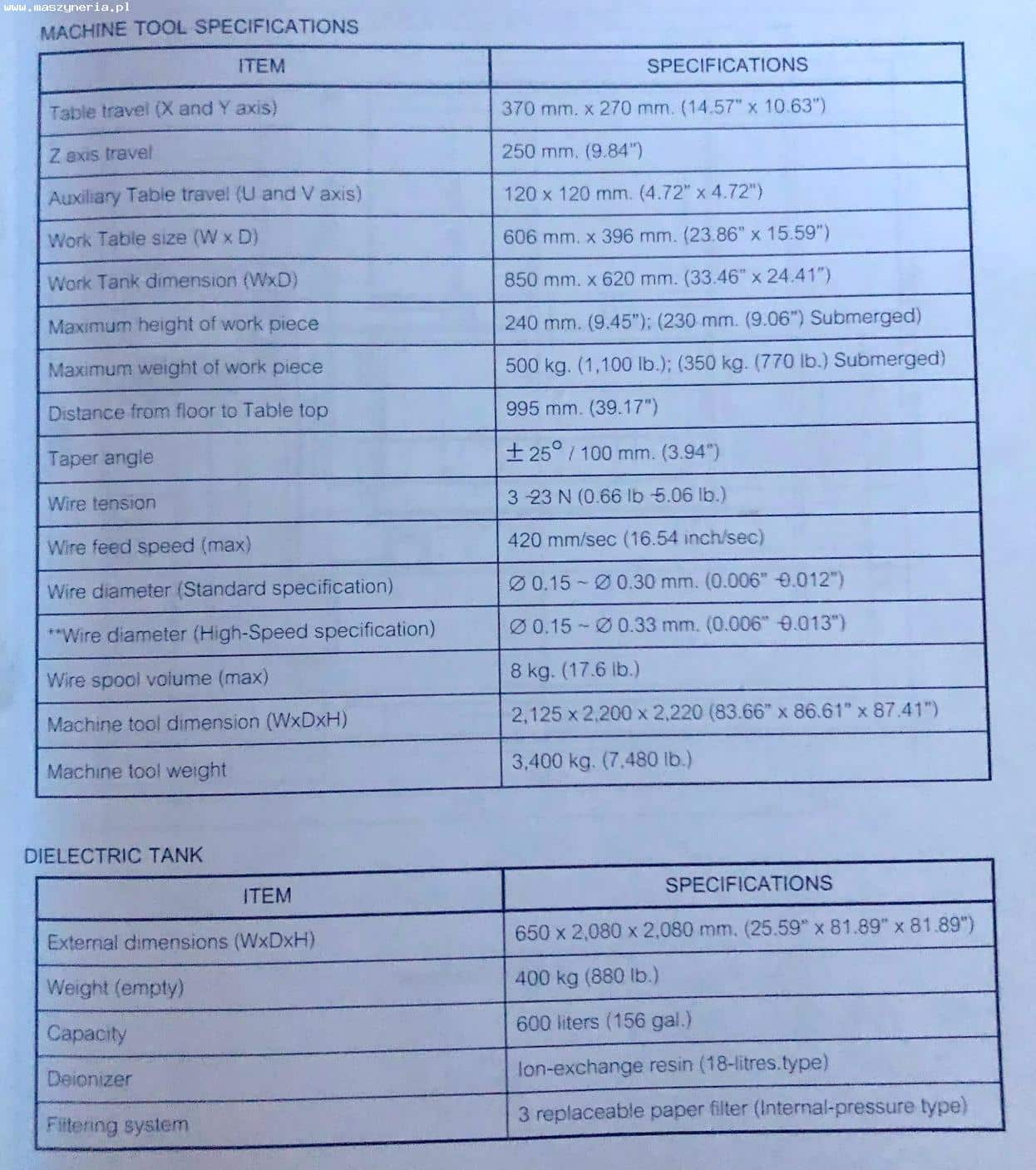

Technical data of the SODICK AQ327L PREMIUM EDM machine

– man-hours: 14528 h

– number of axes: 5 (X, Y, Z, U, V)

– axis travel (X x Y x Z): 370 x 270 x 250 mm

– axis travel (U x V): 120 x 120 mm

– working table surface: 606 mm x 396 mm

– maximum weight of the processed detail: 500 kg

– working tank dimensions: 850 x 620 mm

– maximum height of the workpiece: 240 mm

– maximum cone angle: + – 25 degrees / 100 mm

– the best surface smoothness: 0.1um Ra

– wire diameter (standard): 0.15 – 0.30 mm

– wire diameter (high speed): 0.15 – 0.33 mm

– wire tension: 3-23 N

– wire spool weight: 8 kg

– distance from the floor to the machine table: 995 mm

– device weight: 3400 kg

– Technical Documentation

Dielectric reservoir:

– dimensions of the dielectric tank: 650 x 2080 x 2080 mm

– weight of the dielectric tank (empty): 400 kg

– dielectric tank capacity: 600 liters

– dielectric filtering system: 3 replaceable filters

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano