SOLO 202 30/30/60 quenching machine built in 2001 in Switzerland, is a multifunctional machine used in the process of workpiece quenching. The quenching process improves the mechanical properties of the workpiece by increasing its strength and wear resistance. The machine’s extensive machining capabilities and high performance allow the following types of metal heat treatment to be performed:

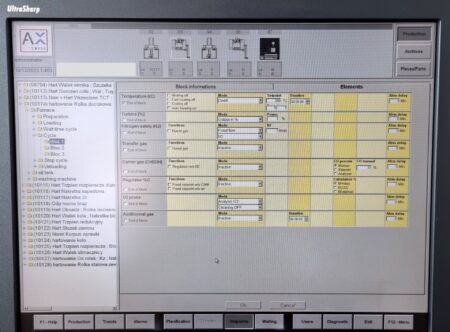

– austenitizing (in atmosphere, protective gas or nitrogen)

– carburizing

– carbonitriding

– water quenching

– tempering (without protective gas)

– alkaline spray washing

– annealing

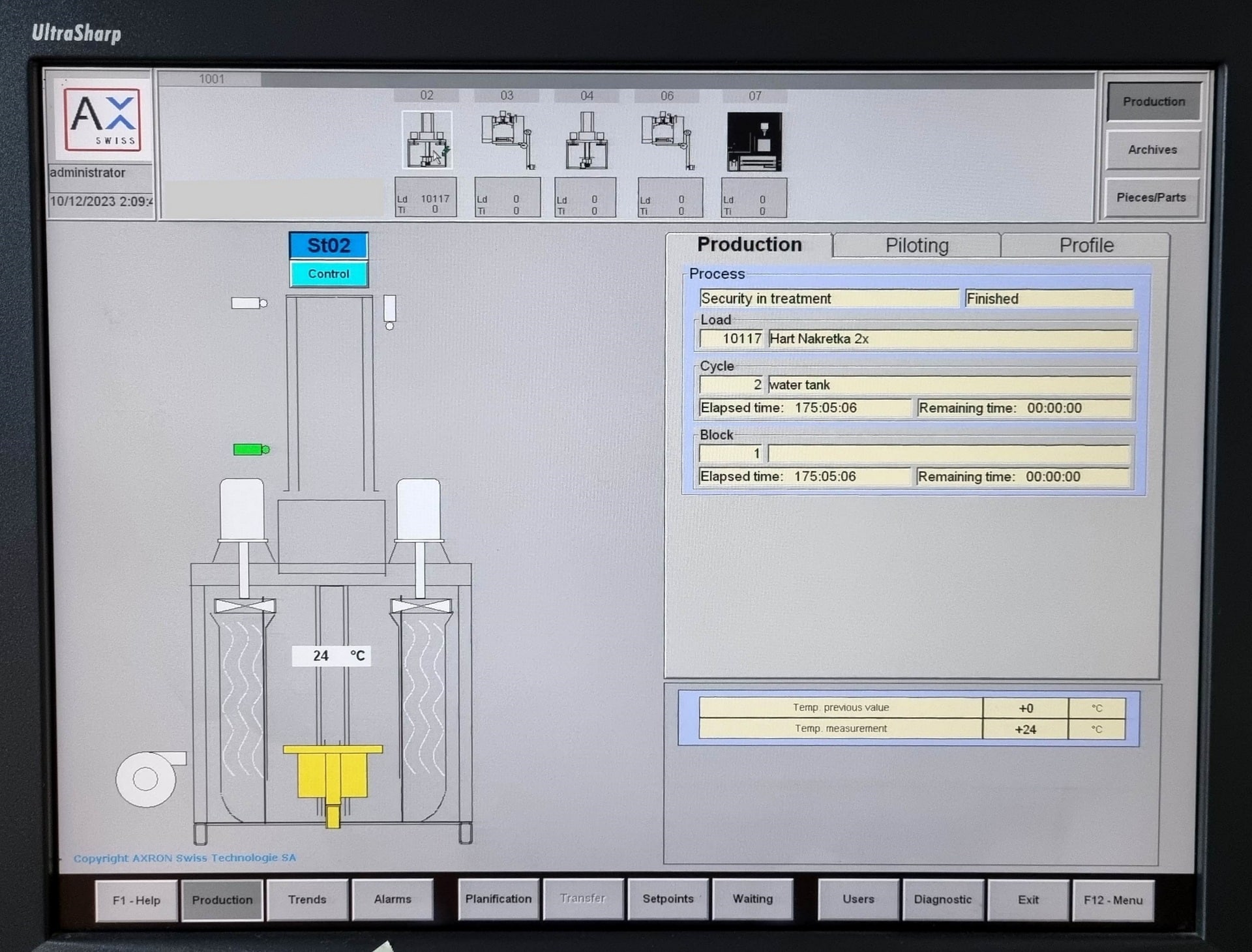

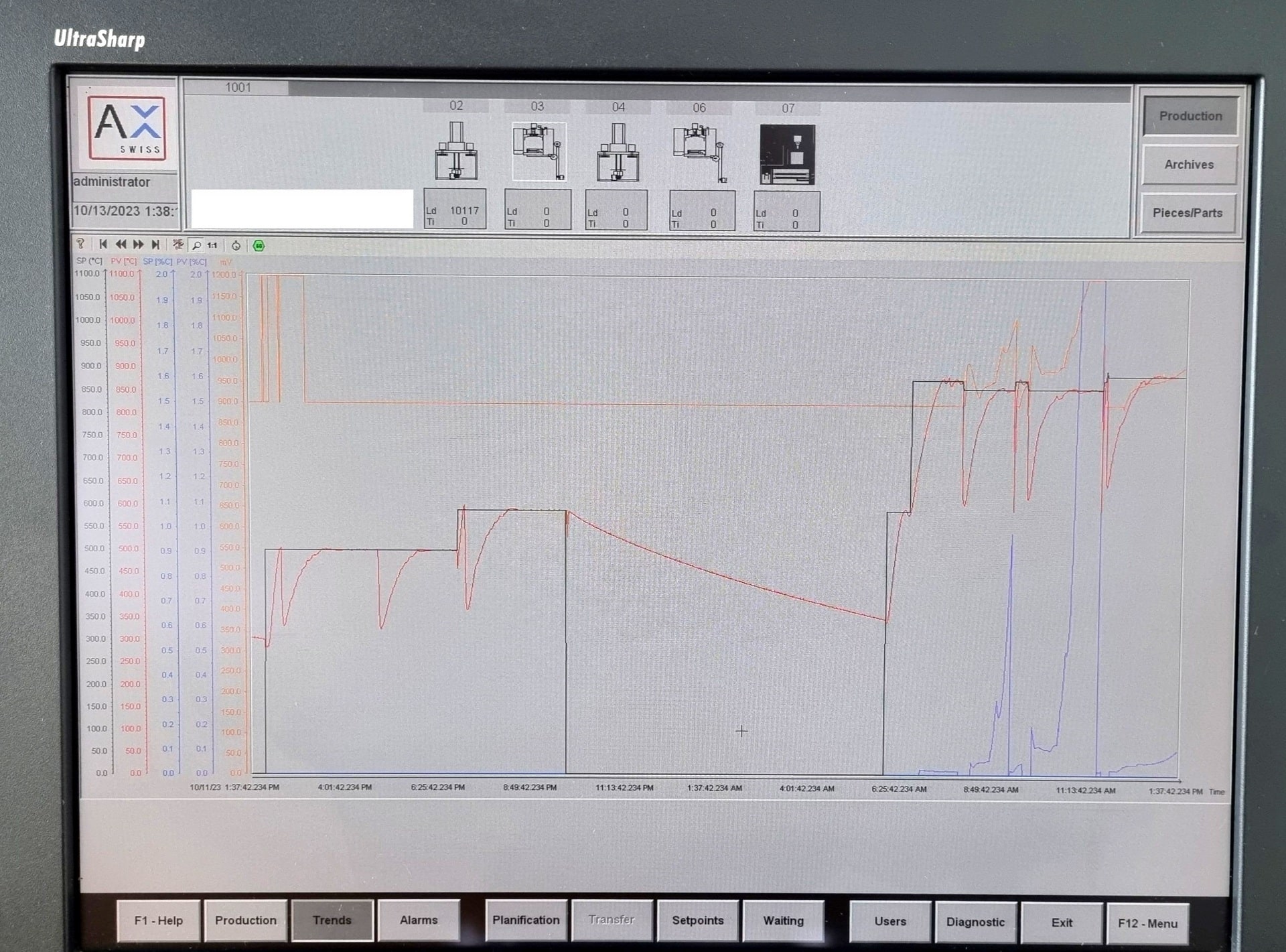

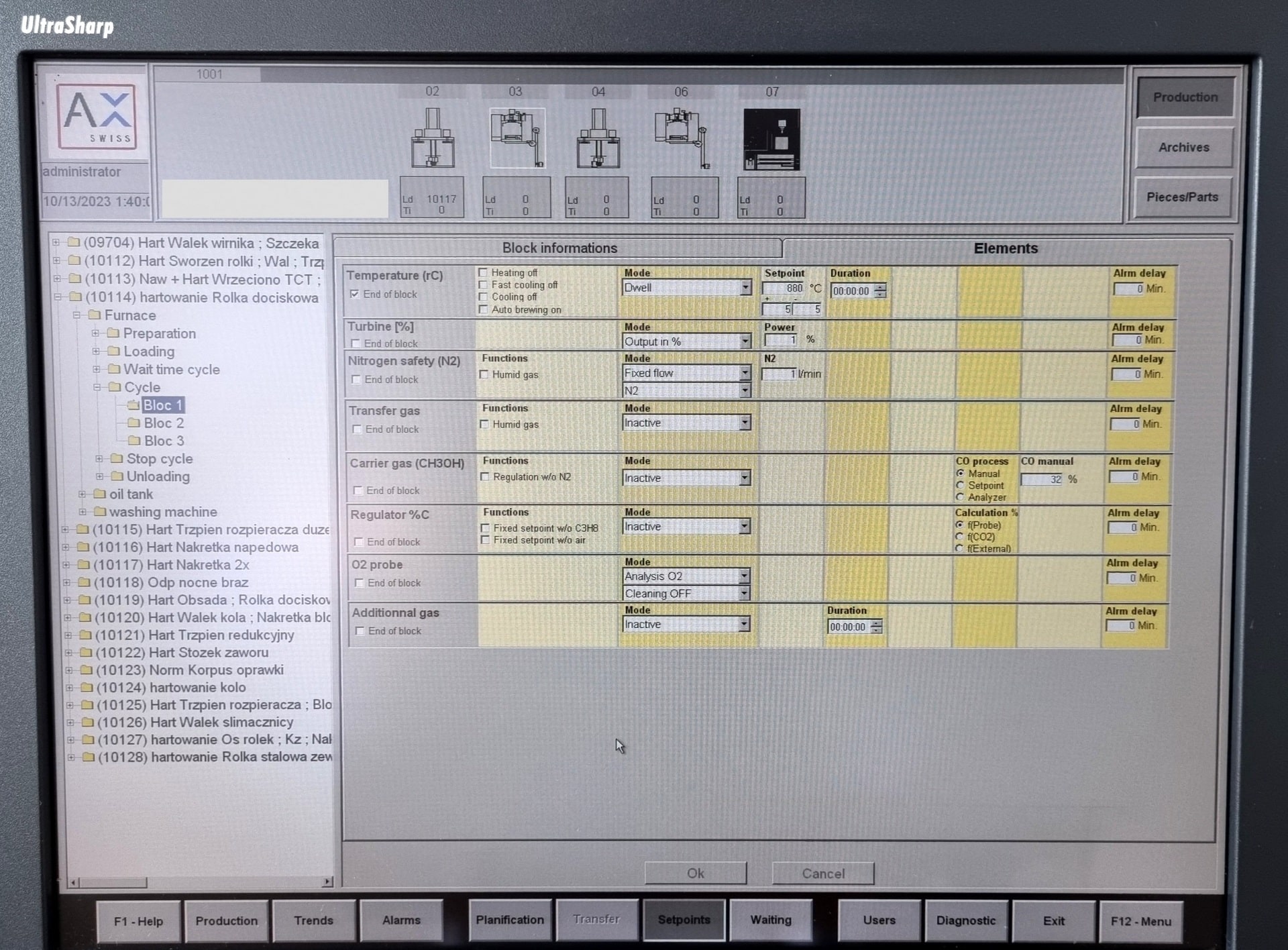

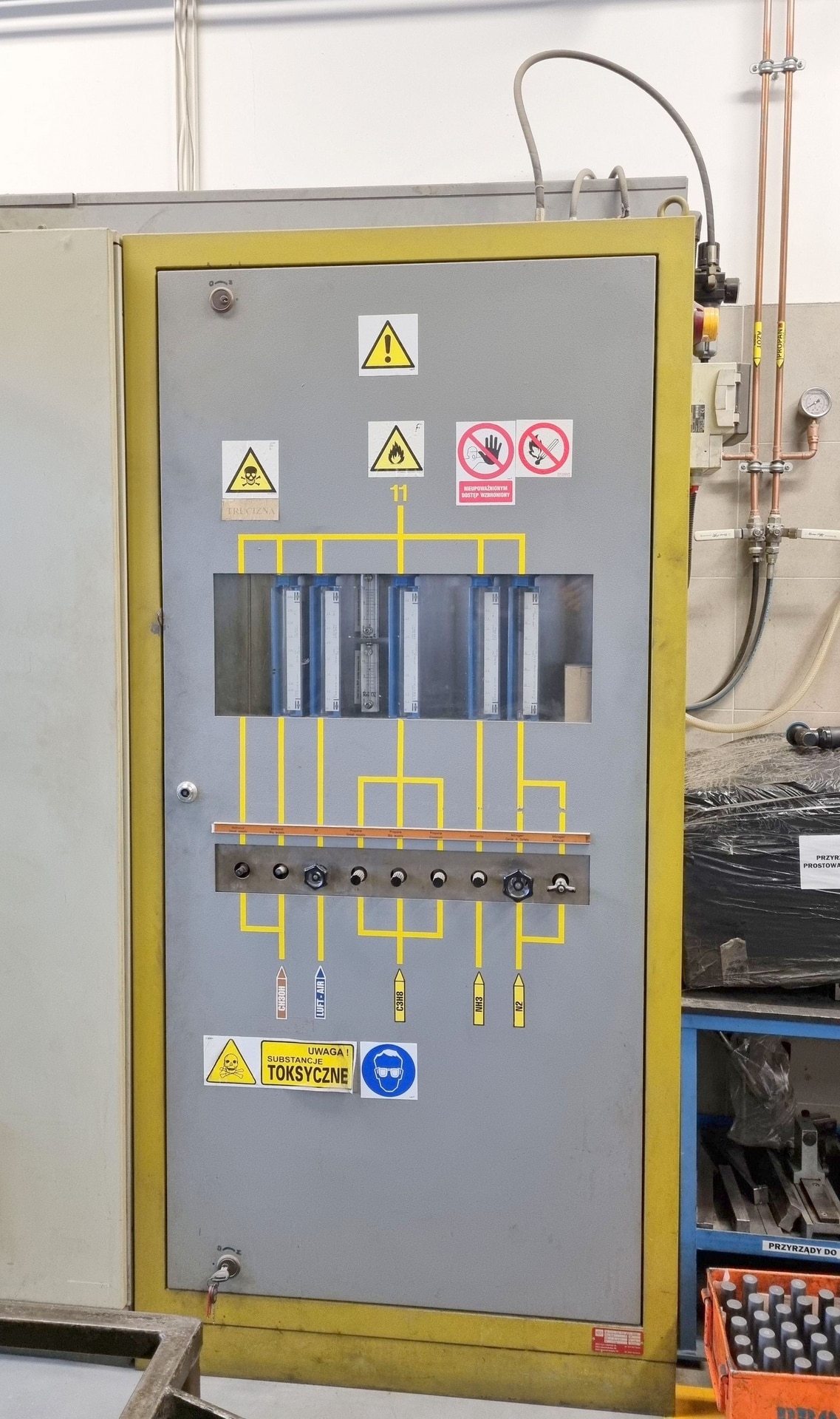

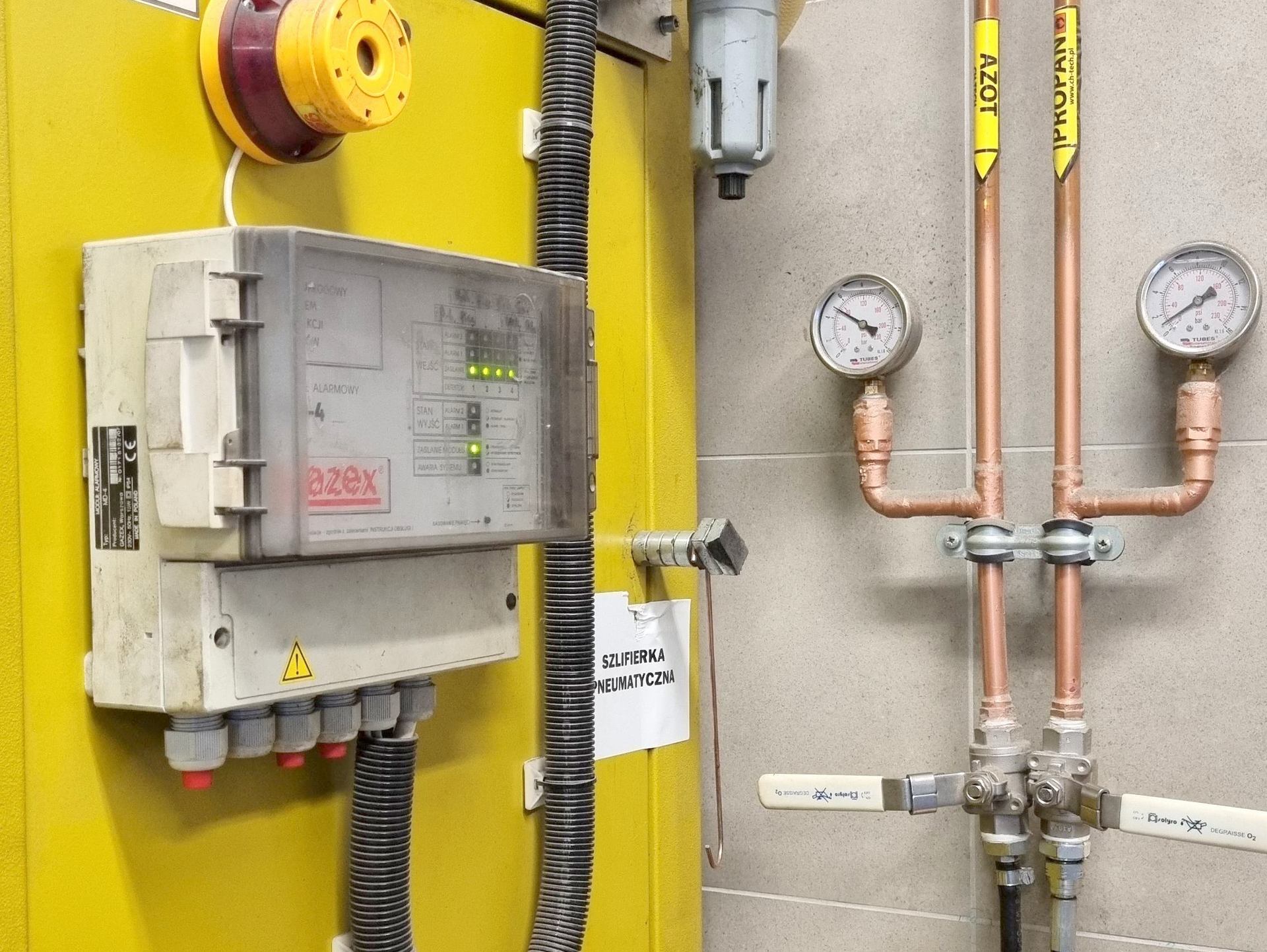

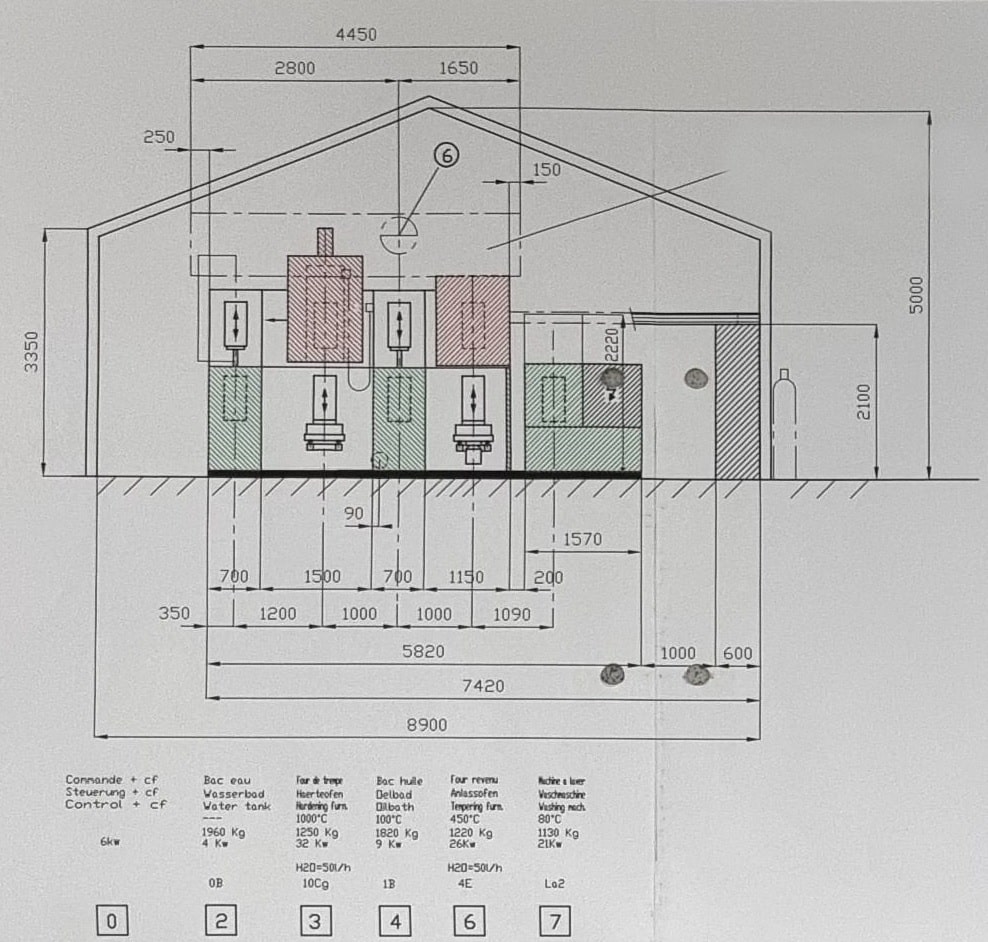

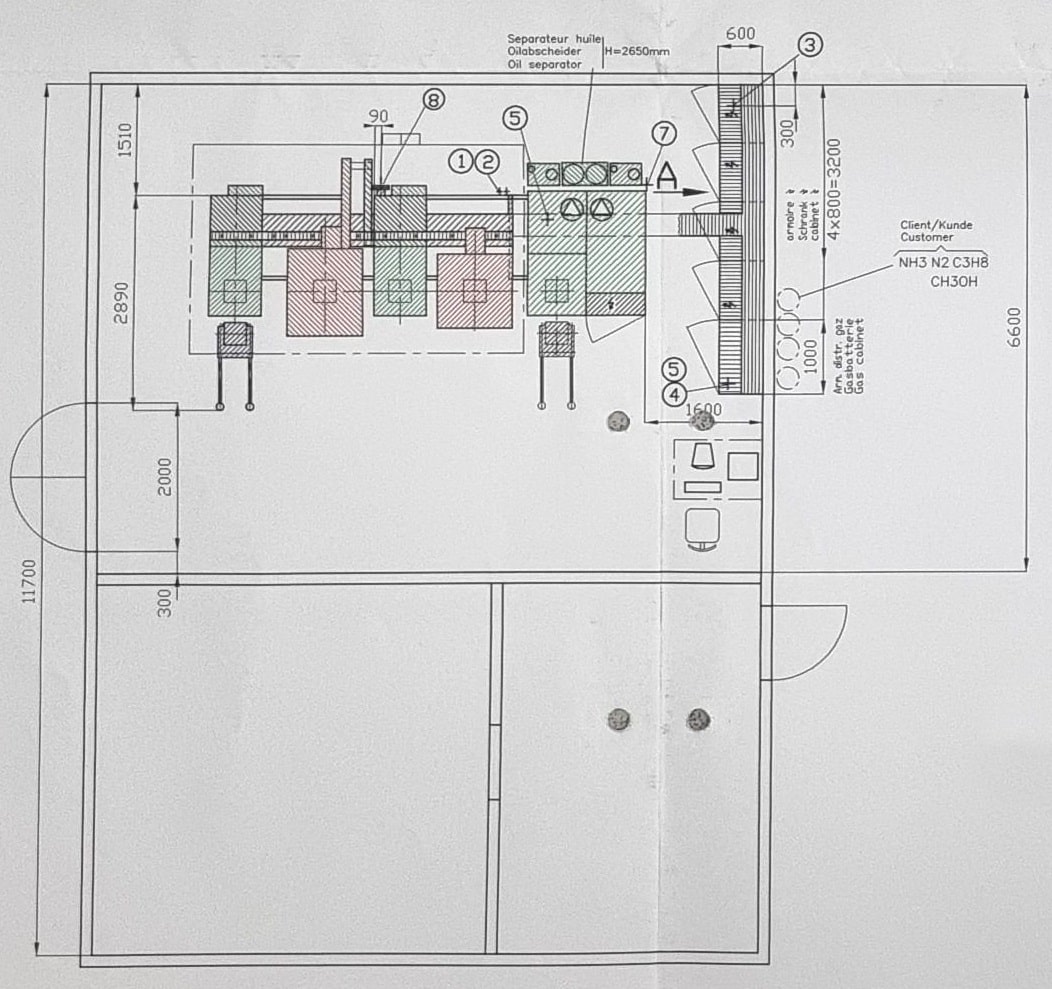

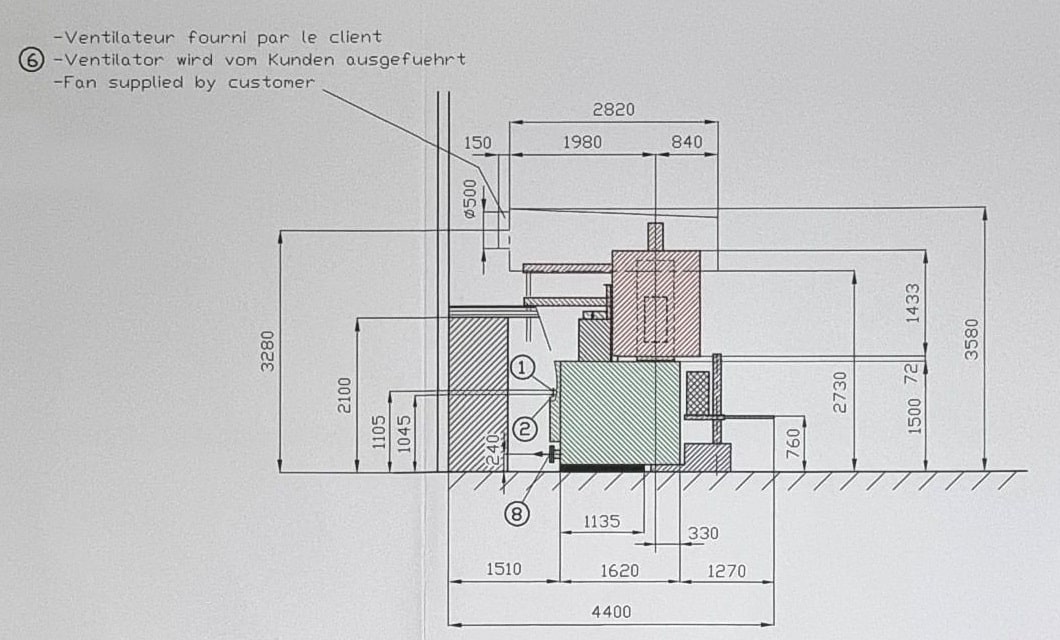

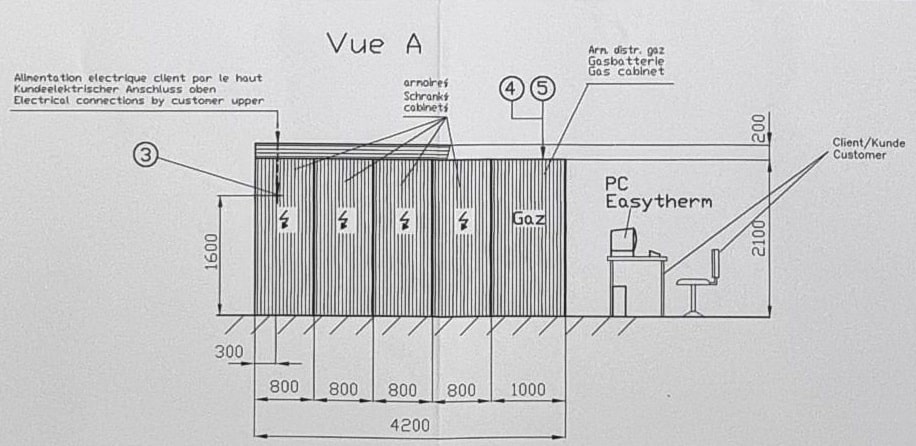

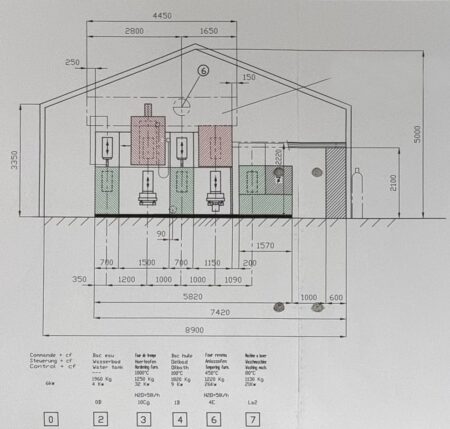

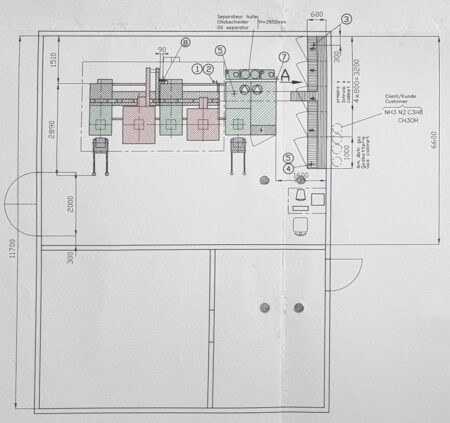

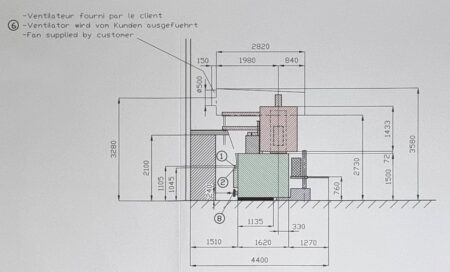

The SOLO quenching machine of multi-module construction is equipped with two quenching furnaces (a bell furnace and a tempering furnace), two tanks (an oil bath and a water tank) and a spray washing machine with a two-section oil separator for load washing. The furnaces, made of top-quality sheet metal and cast iron sections, are distinguished by good tightness, low heat loss and high thermal efficiency. In addition, they are equipped with lightweight insulation and easily replaceable ceramic resistance heating supports, which provide effective overheating protection.

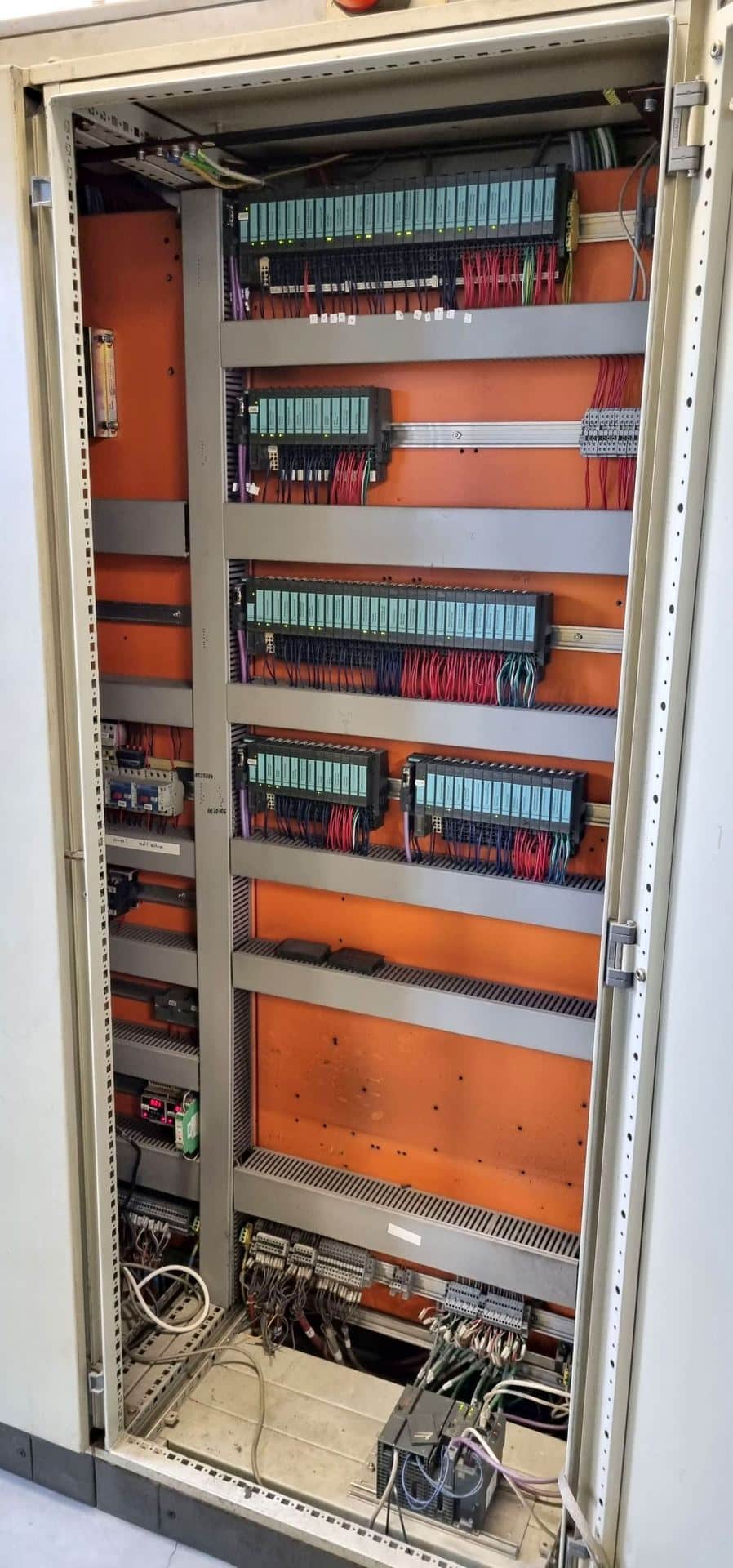

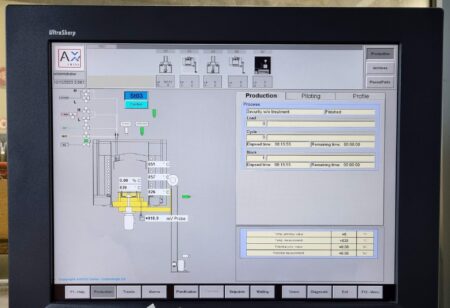

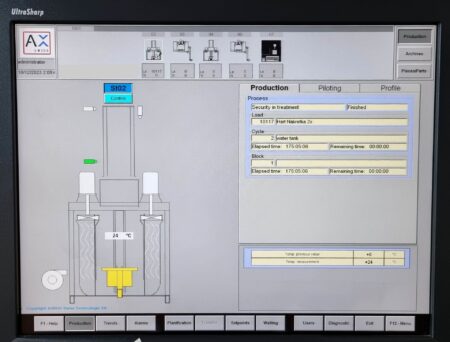

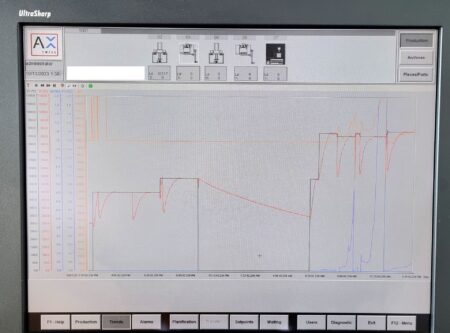

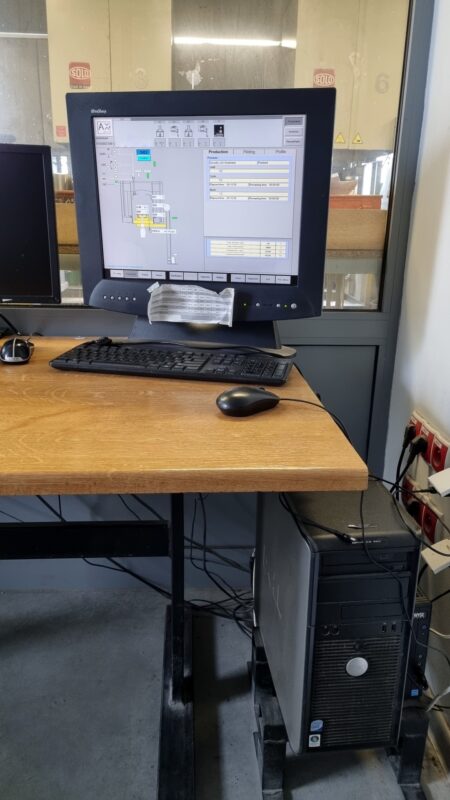

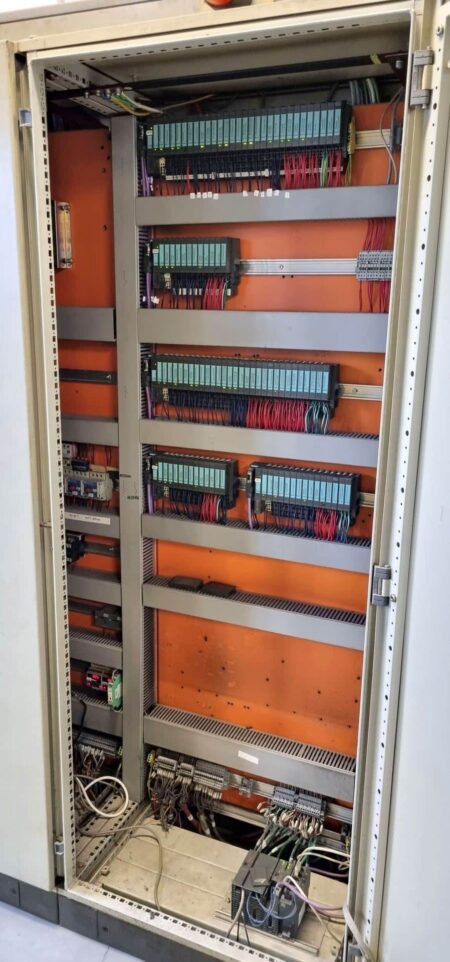

Loads with a maximum height of 600 mm are transported between the individual machining stages by a manipulator made of welded steel plates. The manipulator performs longitudinal movement on guide rails and vertical movement using an electrically controlled hydraulic cylinder and pedal. To ensure that the machine is convenient and easy to operate, all process parameters are programmed in the control system in the form of a computer and a SIEMENS SINUMERIK S7 CNC controller, which allows, for example, the creation of a programme database or process history. The SOLO 202 quenching machine weighs approximately 5570 kg.

Technical specifications of the quenching machine SOLO 202 30/30/60

General data

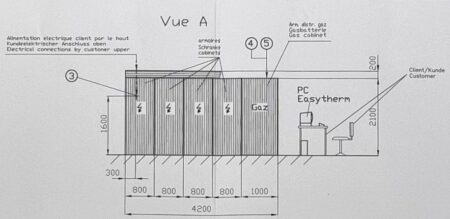

- CNC control: SIEMENS SINUMERIK S7

- computer with Windows XP

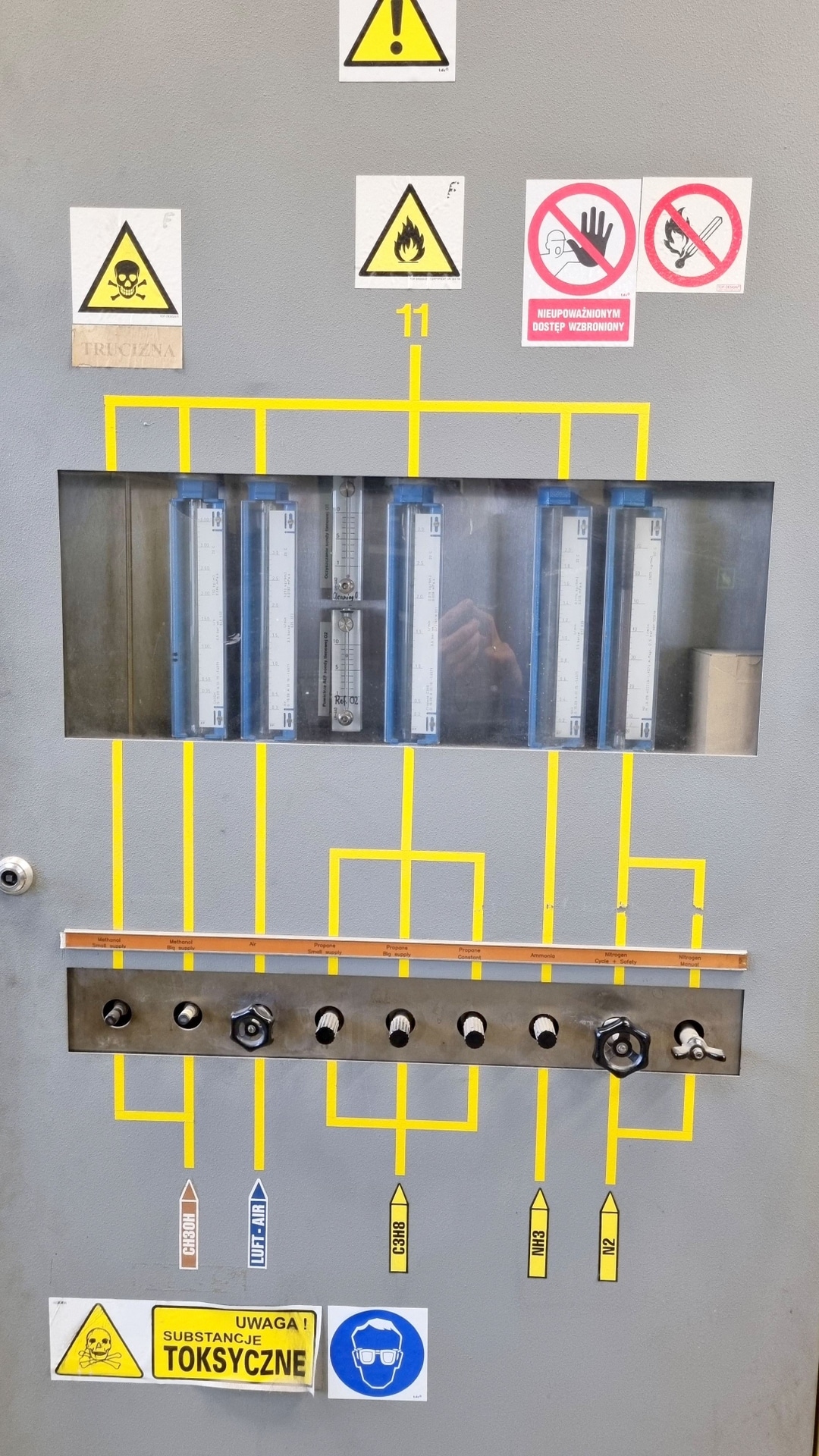

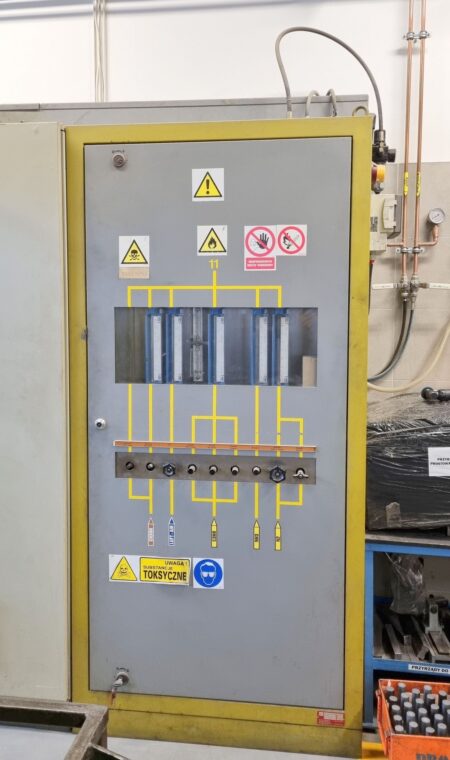

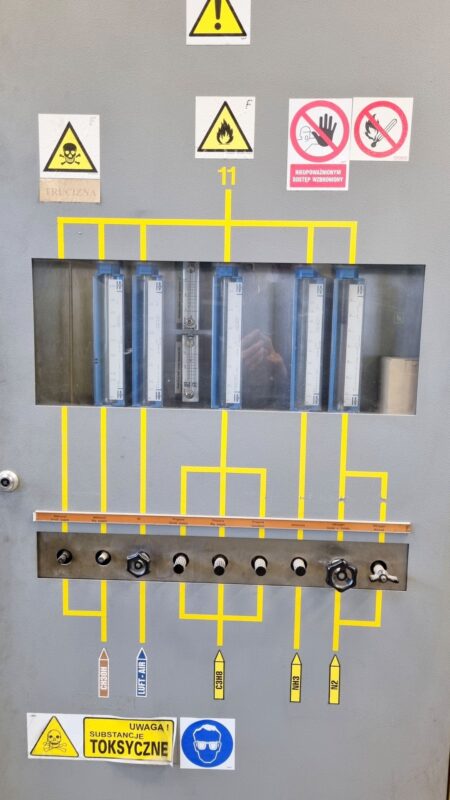

- gas types used: methanol, air, propane, ammonia, nitrogen

- maximum load dimensions (L x W x H): 300 x 300 x 600 mm

- load area: 0,09 m2

- load volume: 0,054 m3

- maximum load gross weight: 80 kg

- gas-tightness safety system

- minimum water pressure: approx. 2-3 bar

- water temperature: +15/+25°C

- minimum compressed air pressure: 7 bar

- DTR – Technical and Operating Documentation in English

- input power: 98 kW

- power supply: 3x 400 V; 50 Hz

- dimensions (L x W x H): 7500 x 4400 x 3600 mm

- weight of machine: approx. 5570 kg

Bell type furnace

- maximum temperature: 1000°C

- temperature management by thermocouples

- cylindrical bell made of refractory steel (new)

- safety device to avoid entry of gas with a temperature below 750°C

- number of heating zones: 3

- heating power: 30 kW

- input power: 32 kW

- gas consumption: 0.6-0.8 Nm3/h

- closed cooling water circuit (two 300 l tanks + radiator for cooling water)

- cooling water inlet pressure: 5 bar

- weight: 1250 kg

Tempering furnace

- maximum temperature: 450°C

- number of heating zones: 1

- heating power: 24 kW

- input power: 26 kW

- closed circuit cooling water (two 300 l tanks + radiator for cooling water)

- cooling water inlet pressure: 5 bar

- weight: 1220 kg

Oil quenching tank

- maximum tank capacity: 1200 l

- maximum temperature: 100°C

- working temperature: ambient temperature

- resistance heating with electronic regulation

- water circulation turbines with guide channels (2 speeds)

- load sensor

- heating power: 6 kW

- input power: 9 kW

- empty tank weight: 760 kg

- full tank weight: approx. 1820 kg

Water quenching tank

- maximum tank capacity: 1200 l

- load sensor

- water circulation turbines with guide channels (2 speeds)

- lift for immersion and withdrawal of the load

- input power: 4 kW

- empty tank weight: 760 kg

- full tank weight: approx. 1960 kg

Spray washing machine

- maximum temperature: 80°C

- tank temperature regulation: +10°C

- electrically heated tanks (2 units)

- thermal and acoustic insulation of washing chamber

- thermal insulation of tanks

- pneumatically opened door

- heating power 12 kW

- input power: 21 kW

- weight with full tank: 1130 kg

Manipulator

- vertical movement speed: approx. 3 m/min

- arm rotation: up to 90°

- electric control panel integrated in the frame

- input power: 0.5 kW

- weight: 150 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe