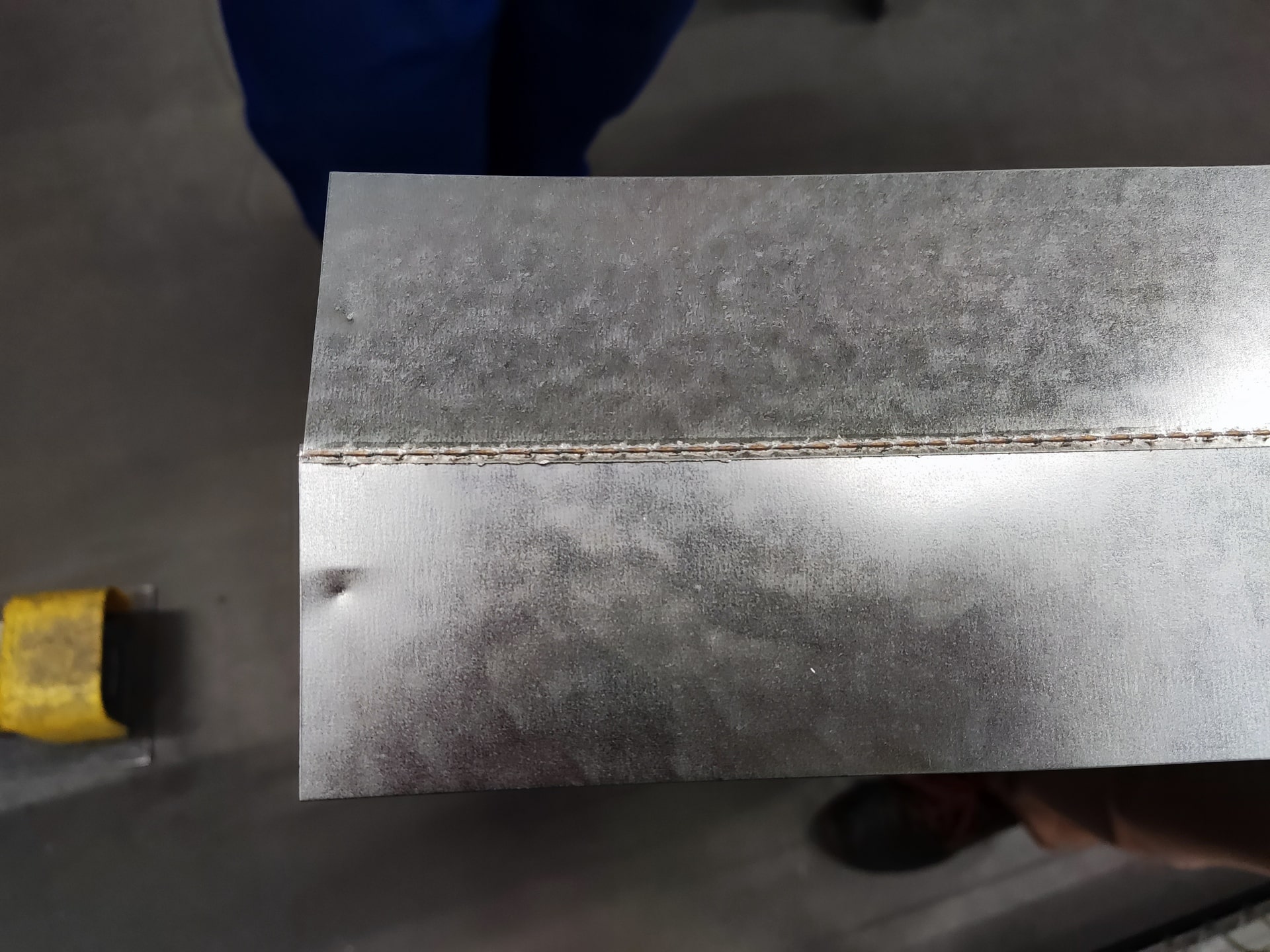

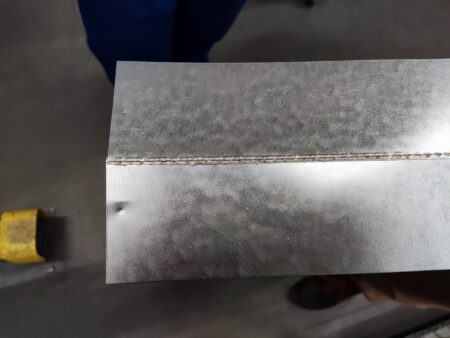

SPIRO CSTW 2D HG 1500 seam welding machine built in Switzerland in 2008, is designed for welding workpieces made of, among others, stainless steel or galvanised steel that are overlapped. The completed seam requires no additional sealing, cleaning or painting, and the channels are perfectly tight along the entire length of the workpiece. The versatile CTSW-2D HG welding machine uses welding rolers to precisely and accurately join materials, making it ideal for a variety of industrial production applications.

Technical data of the SPIRO CSTW 2D HG 1500 welding machine

- machinable materials: stainless steel, galvanised steel, black steel, tubes

- welding length (seam): 60-1524 mm

- maximum workpiece diameter: 1000 mm

- minimum workpiece diameter: 10 mm

- maximum workpiece thickness: 1.25 mm

- minimum workpiece thickness: 0.3 mm

- maximum welding speed: 12 m/min

- seam overlap: 8 mm

- chiller: MARKSA CH 2400 LE LOCLE

- cooling capacity: approx. 3.5 kW

- cooling water pressure: 4-6 bar

- cooling water consumption: 15 l/min

- cooling water inlet temperature: 15-18°C

- compressed air operating pressure: 6 bar

- compressed air consumption: approx. 150 l/min

- transformer power: 60 kVA

- power supply: 3x 400 V; 50 Hz

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe