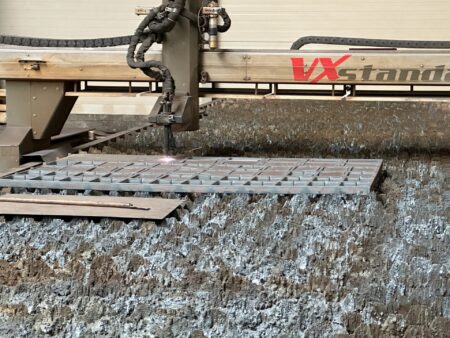

STIGAL VX STANDARD plasma cutting machine manufactured in Poland in 2014 is used for precise cutting of larger sized metal sheets. Excellent cutting quality and precision are ensured by a gantry made of highly durable aluminium alloys, together with a lubrication-free driving system and three torches powered by the reliable CEBORA PLASMA PROF 254 HQC source.

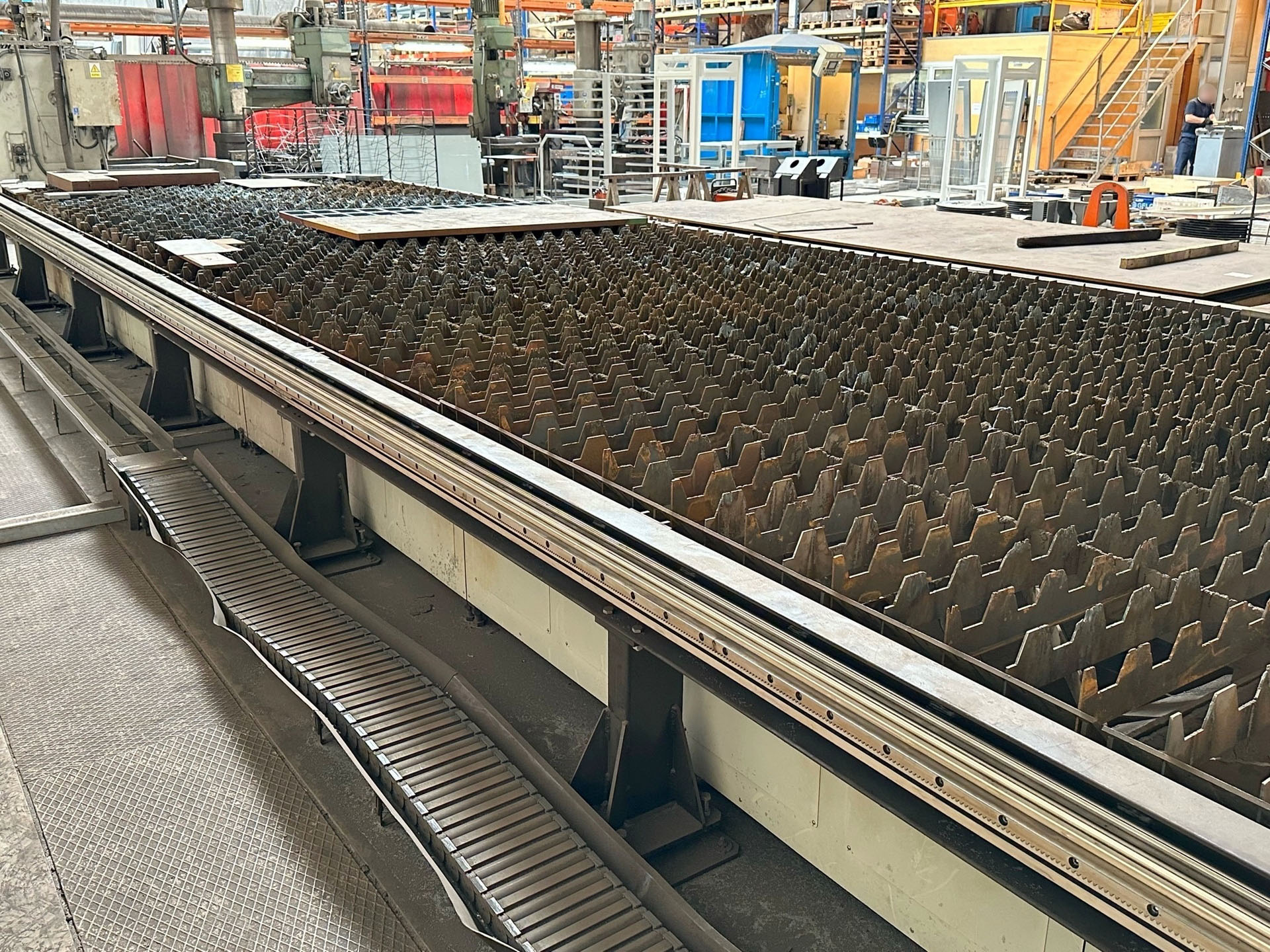

The large working table of the STIGAL VXSTANDARD plasma-gas cutting machine, with a length of 12000 mm and a width of 3000 mm provides easy loading and unloading of workpieces from either side of the machine. The plasma cutting machine is offered with equipment consisting of, among others, the CEBORA PGC-3 semi-automatic synergy gas console and CAD/CAM software with NESTING function. The total weight of the machine is approximately 9000 kg.

Technical parameters of the plasma-gas cutting machine STIGAL VX STANDARD

- work table surface (L x W): 12000 x 3000 mm

- maximum workpiece thickness: 150 mm

- maximum workpiece length: 12000 mm

- maximum workpiece width: 3000 mm

- maximum workpiece weight: 1200 kg/m2

- plasma source power: 250 A

- maximum travel speed: 22 m/min

- torch up/down movement speed: 330 mm/s

- torch positioning accuracy: ± 0.05 mm

- type of torch height adjustment: voltage

- suction nozzle: ∅ 315 mm

- power consumption: 11500 W

- operating temperature: +5 °C / +40 °C

- maximum humidity (non-condensing): 90 %

- power supply: 400 V; 50 Hz

- weight of machine VX-STANDARD: approx. 9000 kg

Equipment on the plasma cutting machine

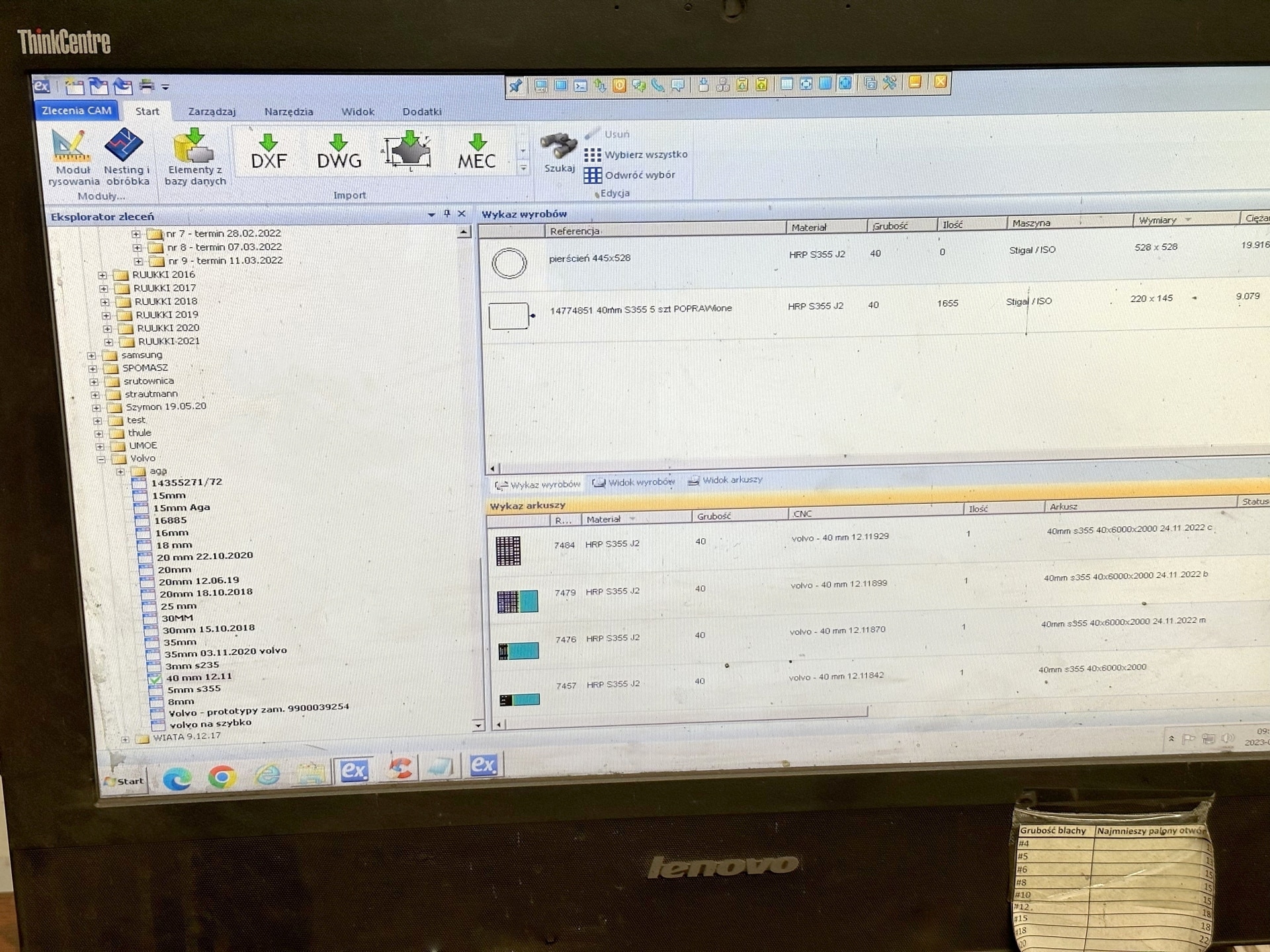

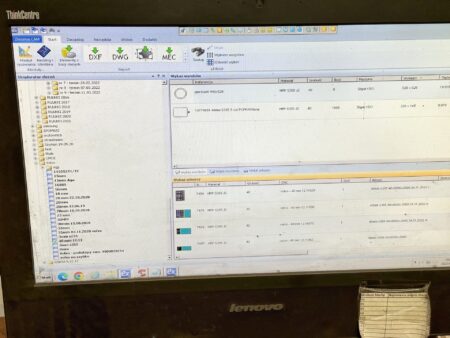

- operator panel with CNC controller

- CAD/CAM software with NESTING function

- plasma source: CEBORA PLASMA PROF 254 HQC

- plasma and gas torches

- semi-automatic gas console: CEBORA PGC-3

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe