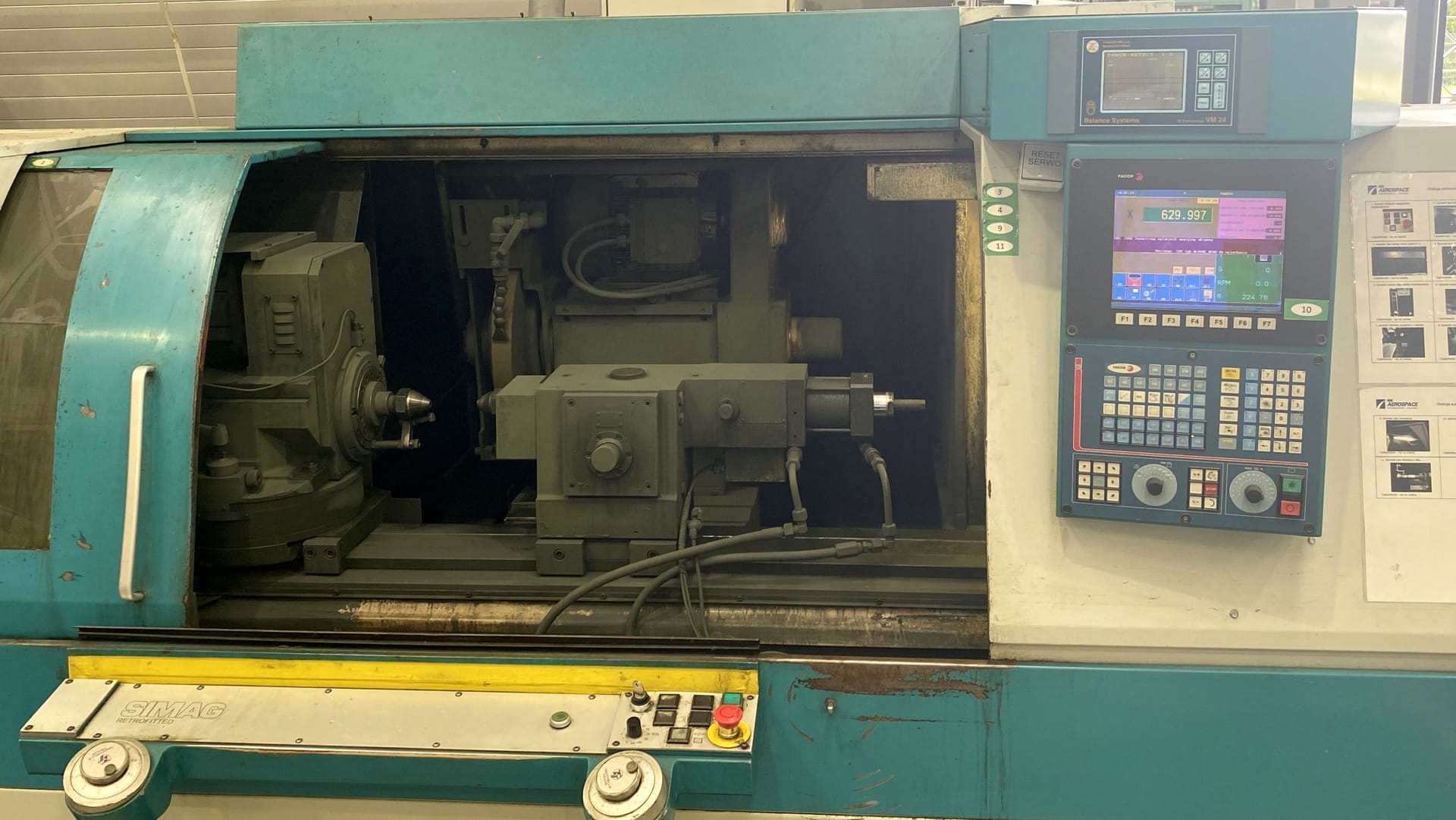

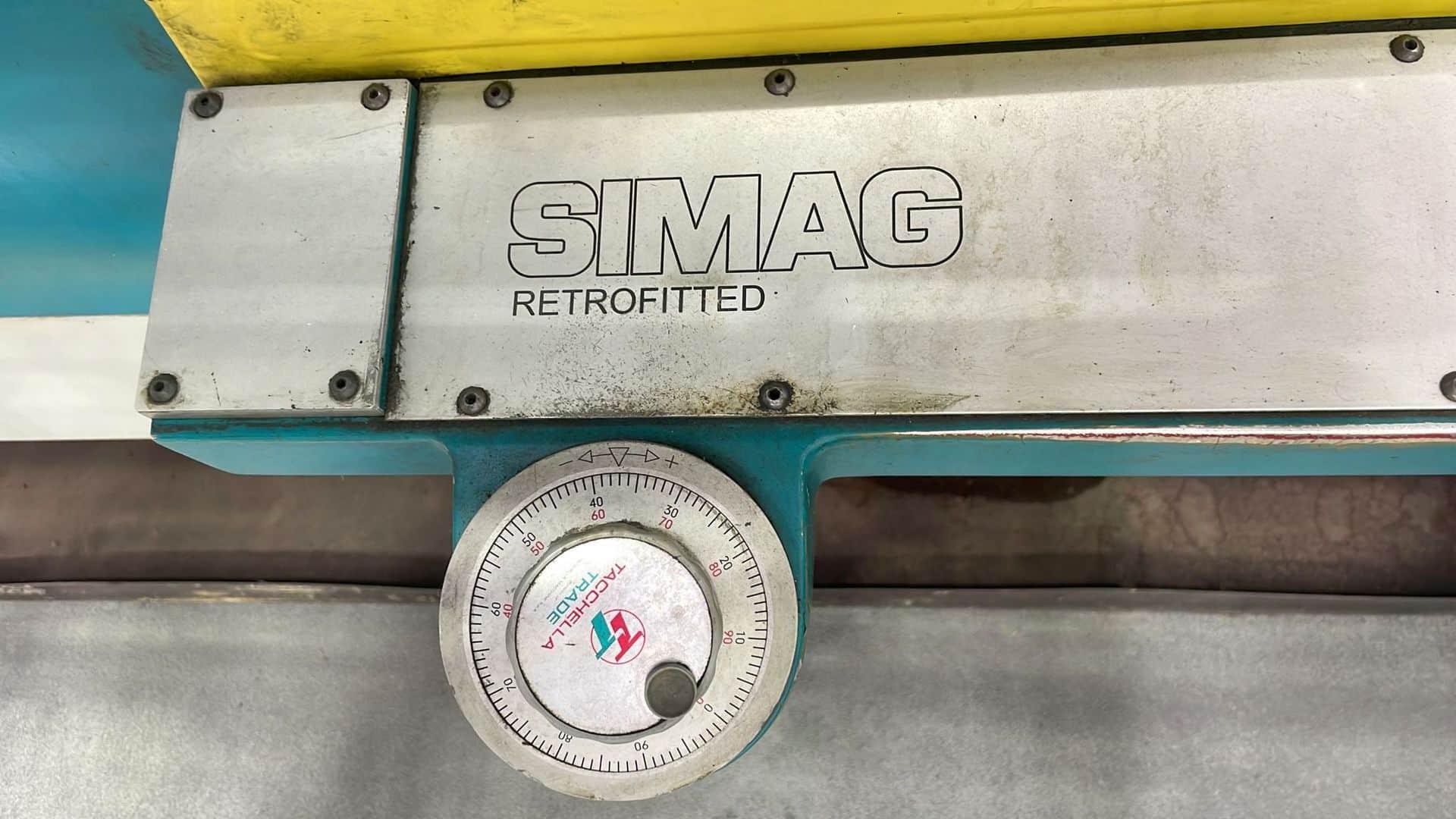

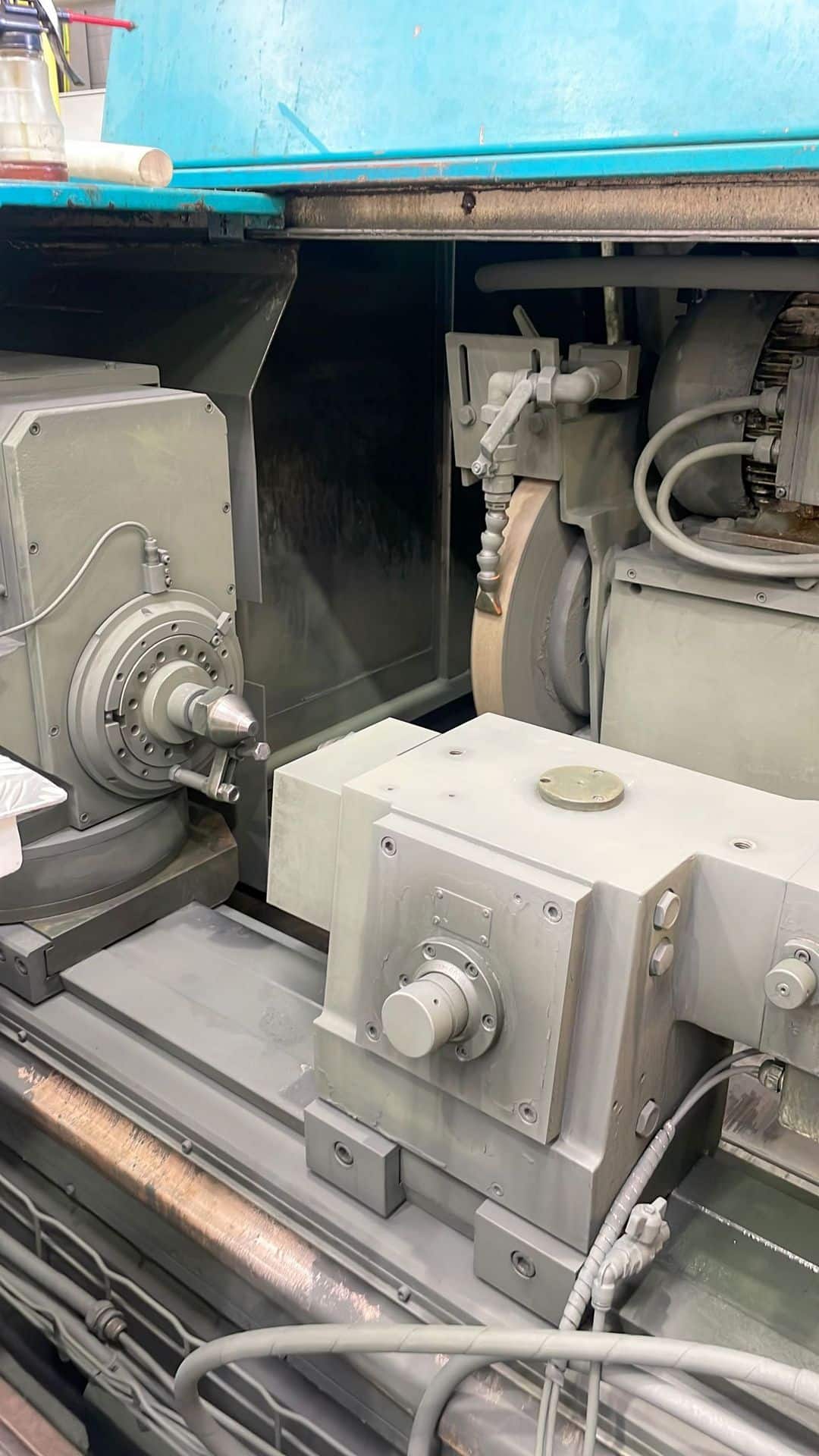

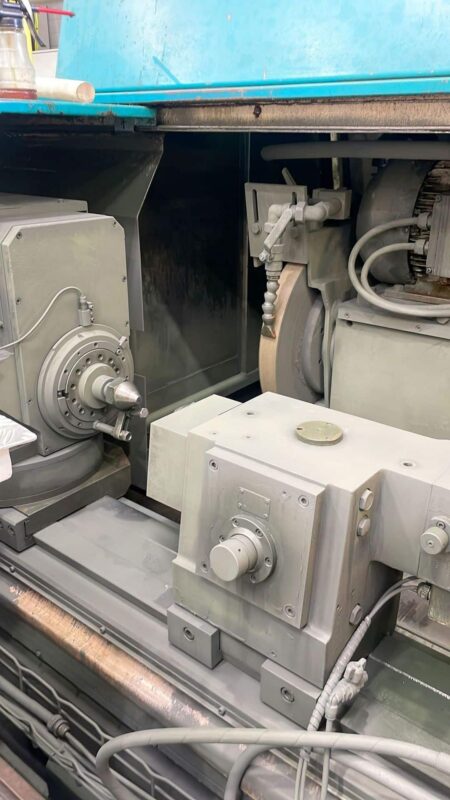

TACCHELLA ELEKTRA 1518 MPC CNC grinding machine was built in Italy in 1999. Characterised by high reliability and performance, the machine is used in the process of highly accurate grinding of the external rotating surfaces of workpieces with a maximum length of 1500 mm and a diameter of 350 mm. The TACCHELLA CNC shaft grinding machine has a large workspace with tailstock, grinding wheel spindle and workpiece spindle.

After placing a shaft with a maximum weight of 50 kg in the spindle holder, the workpiece is ground at high speed by an incremental encoder driven grinding wheel with a maximum diameter of 450 mm. In order to simplify the machining process, the ELEKTRA 1518 MPC CNC grinding machine is equipped with state-of-the-art features, such as the HOFLER BALANCE SYSTEMS VM 24 operator panel and a functional and user-friendly FAGOR CNC controller, which allows full control of the machine. The total weight of the machine is 6500 kg.

Technical specifications of the TACCHELLA ELEKTRA 1518 MPC grinding machine

General data

- CNC control: FAGOR

- operator panel: HOFLER BALANCE SYSTEMS VM 24

- maximum workpiece length at 0° (grinding wheel diameter 450 mm): 1500 mm

- maximum workpiece diameter at 0° (grinding wheel diameter 450 mm): 350 mm

- maximum workpiece weight in tusks: 120 kg

- tusk rise: 180 mm

- distance between tusks: 1500 mm

- relative angle between axis guideways: 90°

- power: 15 kW

- machine weight: 6500 kg

X axis

- X axis feed rate: 350 mm

- X axis feed speed: 10000 mm/min

- X axis accuracy: 0,0005 mm

- drive: brushless AC servo motor

- axis control system: rotary encoder (linear)

Z axis

- Z axis feed rate: 1680 mm

- Z axis feed speed: 10000 mm/min

- Z axis accuracy: 0.001 mm

- table adjustment: 0° / +7°

- drive: brushless AC servo motor

- axis control system: rotary encoder (linear)

Grinding wheel spindle

- maximum grinding wheel dimensions (diameter x width x bore): 450 x 80 x 203 mm

- grinding wheel peripheral speed (diameter 300 mm): 33 m/s

- angle setting: 0° / +180°

- adjustment system: manual

- adjustment control system: incremental encoder

- locking/unlocking system: semi-automatic

- motor power: 7.5 kW

Workpiece spindle

- spindle rotational speed range: 10-800 rpm

- internal/external spindle taper: Morse 5/ ASA 4

- spindle bore: 36 mm

- manual adjustment of spindle base: 0° / +30°

- micrometer positioning accuracy: ± 1°

- maximum weight of workpiece mounted in the holder at a distance of 100 mm from the spindle front: 50 kg

- spindle torque: 22 Nm

Tailstock

- tailstock quill taper: Morse 4

- tailstock quill extension: 35 mm

- micrometric side adjustment of tailstock (cylindricality correction): ± 0.10 mm

In 2016 the ELEKTRA 1518 grinding machine underwent an overhaul with a value equivalent to EUR 95000.

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe