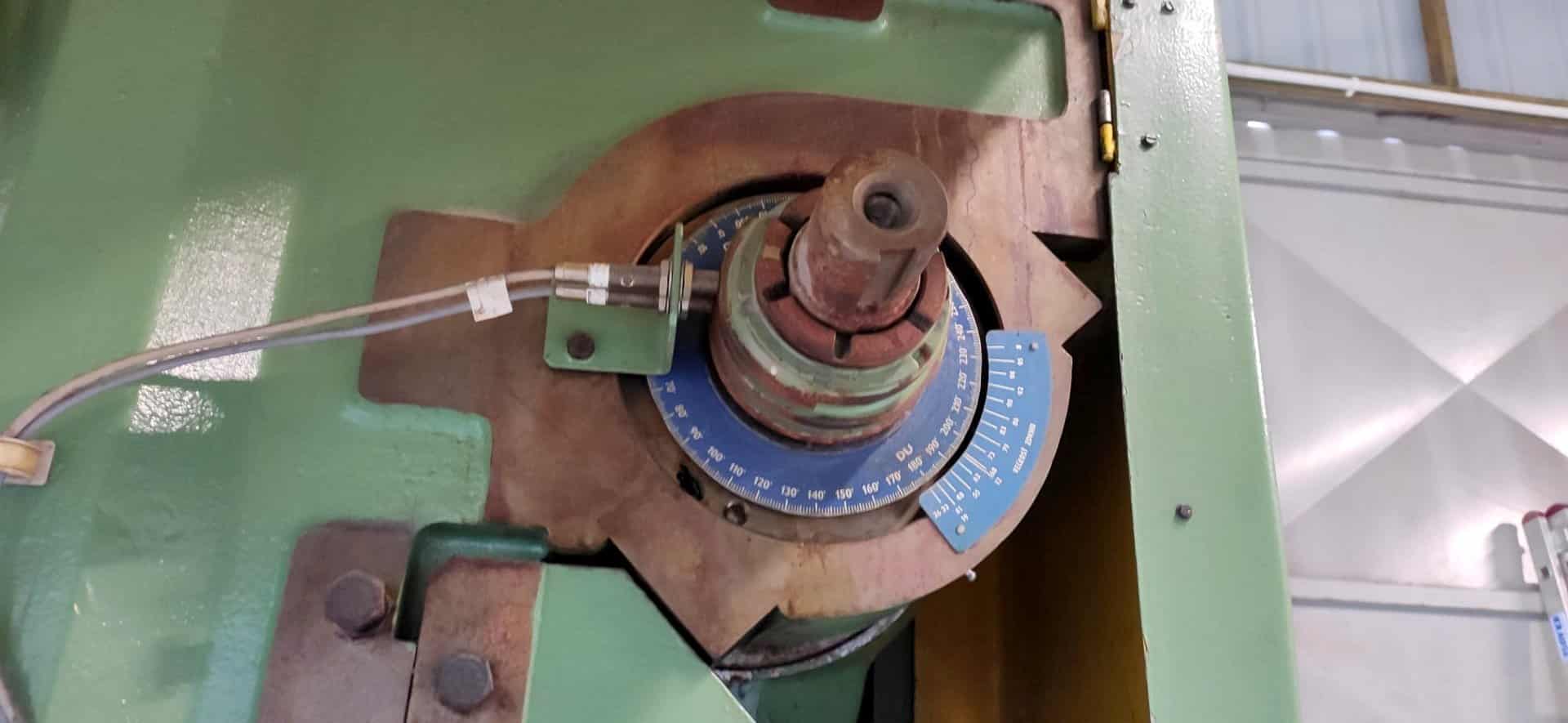

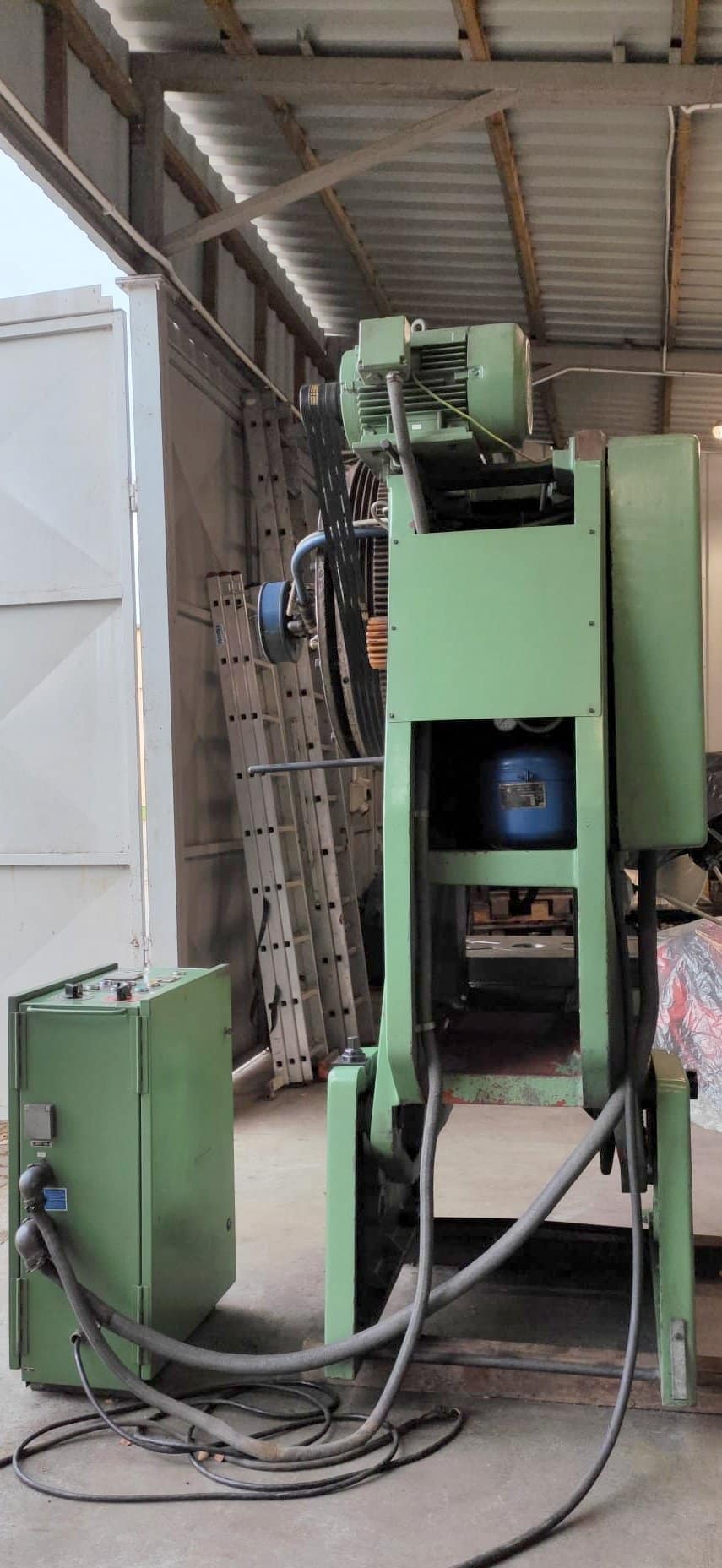

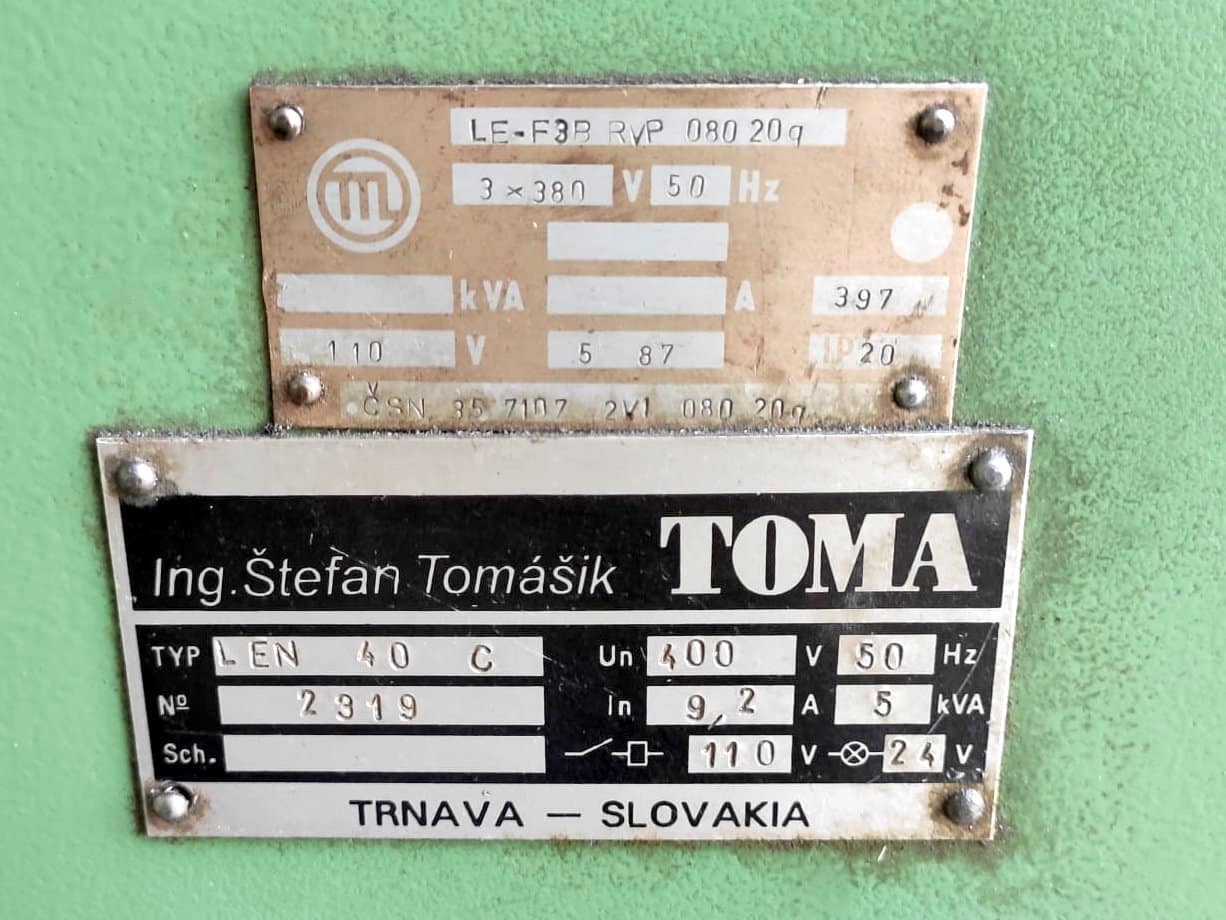

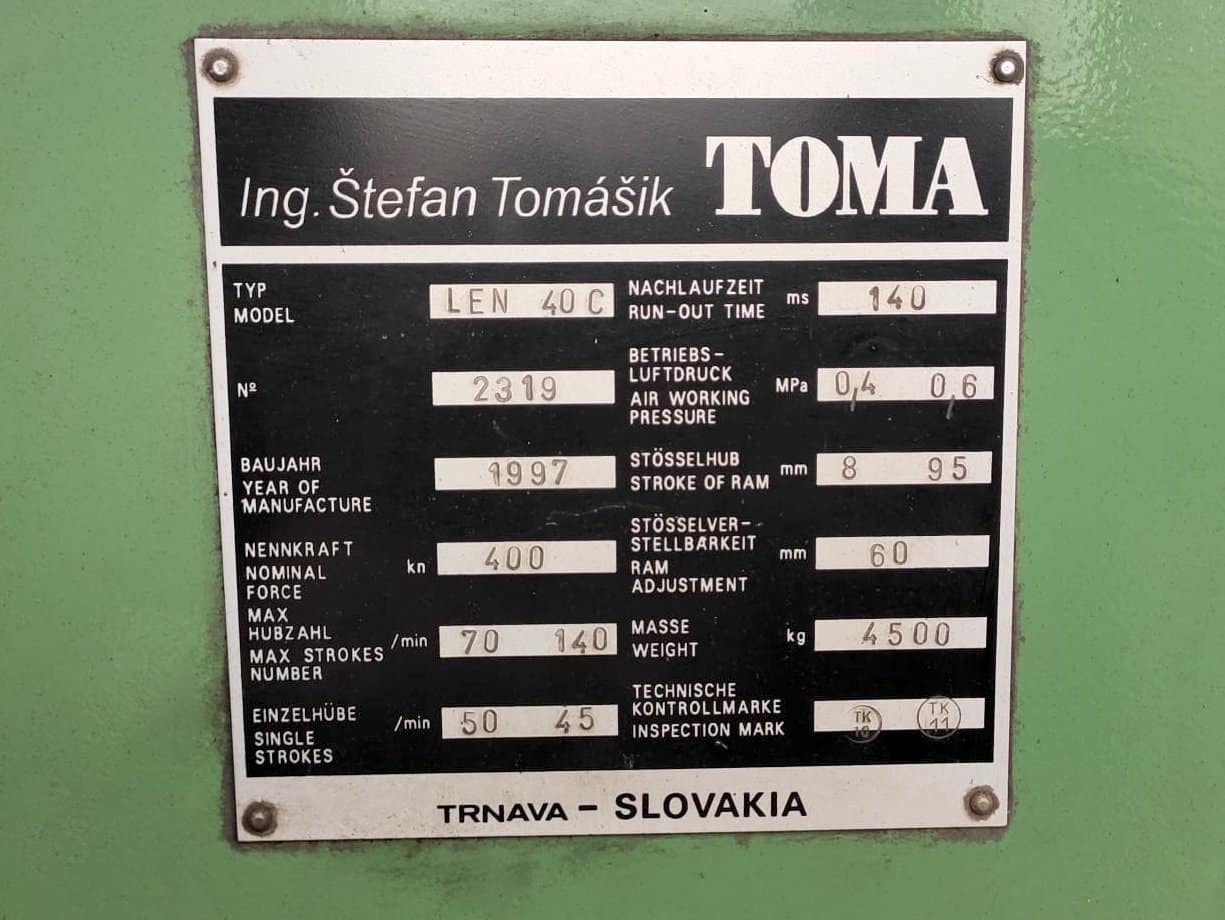

TOMA LEN 40C eccentric press, built in 1997 in Slovakia, is used for cutting, shearing, punching and stamping of metals. The machine with two gears, offers the possibility to work at two different processing speeds – 70 or 140 strokes per minute. The motor gears are changed using a switch located on the control cabinet of the press. To ensure that the power of the machine remains the same when the machining speed and motor speed are reduced, an additional flywheel must be engaged.

First gear:

– number of slider strokes in automatic mode: 70 1/min

– number of slider strokes in single mode: 45 1/min

Second gear:

– number of slider strokes in automatic mode: 140 1/min

– number of slider strokes in single mode: 50 1/min

Operating with a force of 40 tonnes the TOMA LEN 40 C press has an adjustable slider between 8 and 95 mm, guaranteeing excellent results in the machining of workpieces. The working area with a 660 mm long and 530 mm wide table is fully illuminated by a lamp mounted on the body of the machine. The eccentric press is equipped with a pedal for foot control, 4 anti-vibration pads and an bolster. The total weight of the press is 4500 kg.

Characteristics of the TOMA LEN 40C press

- maximum press force: 40 t (400 kN)

- working table surface (L x W): 660 x 530 mm

- slider area: 400 x 250 mm

- minimum stroke length of slider: 8 mm

- maximum stroke length of slider: 95 mm

- maximum distance between table and slider: 295 mm

- adjustment of distance between table and slider: 60 mm

- reach: 265 mm

- run-out time: 140 ms

- number of motor gears: 2

- compressed air pressure: 0.4 MPa

- power supply: 400 V; 50 Hz

- overall dimensions (L x W x H): 1585 x 1245 x 2370 mm

- total weight of LEN 40C machine: 4500 kg

Equipment of the eccentric press

- bolster

- illumination of the workspace

- anti-vibration pads (4 pcs.)

- pedal for foot control

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe