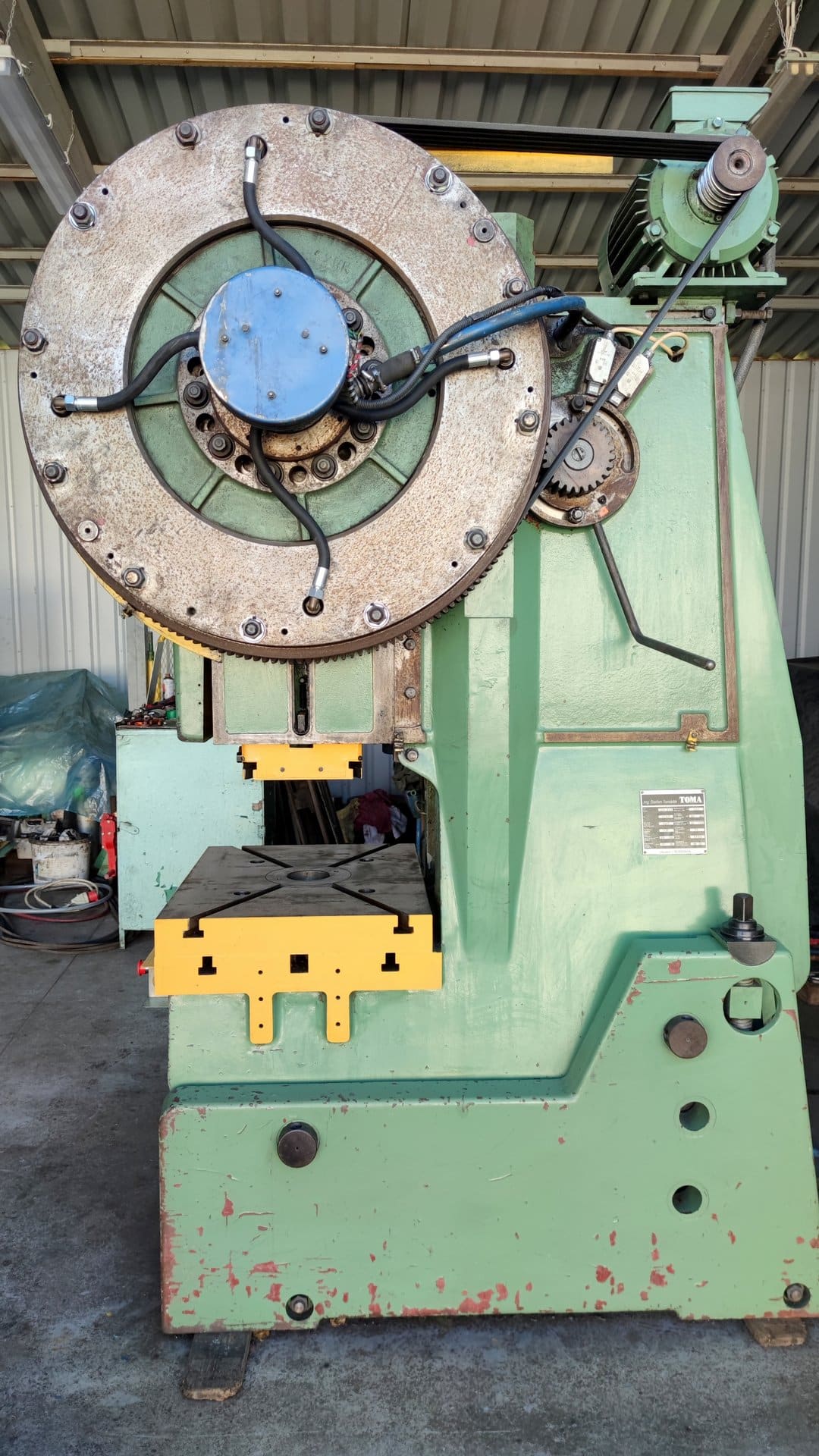

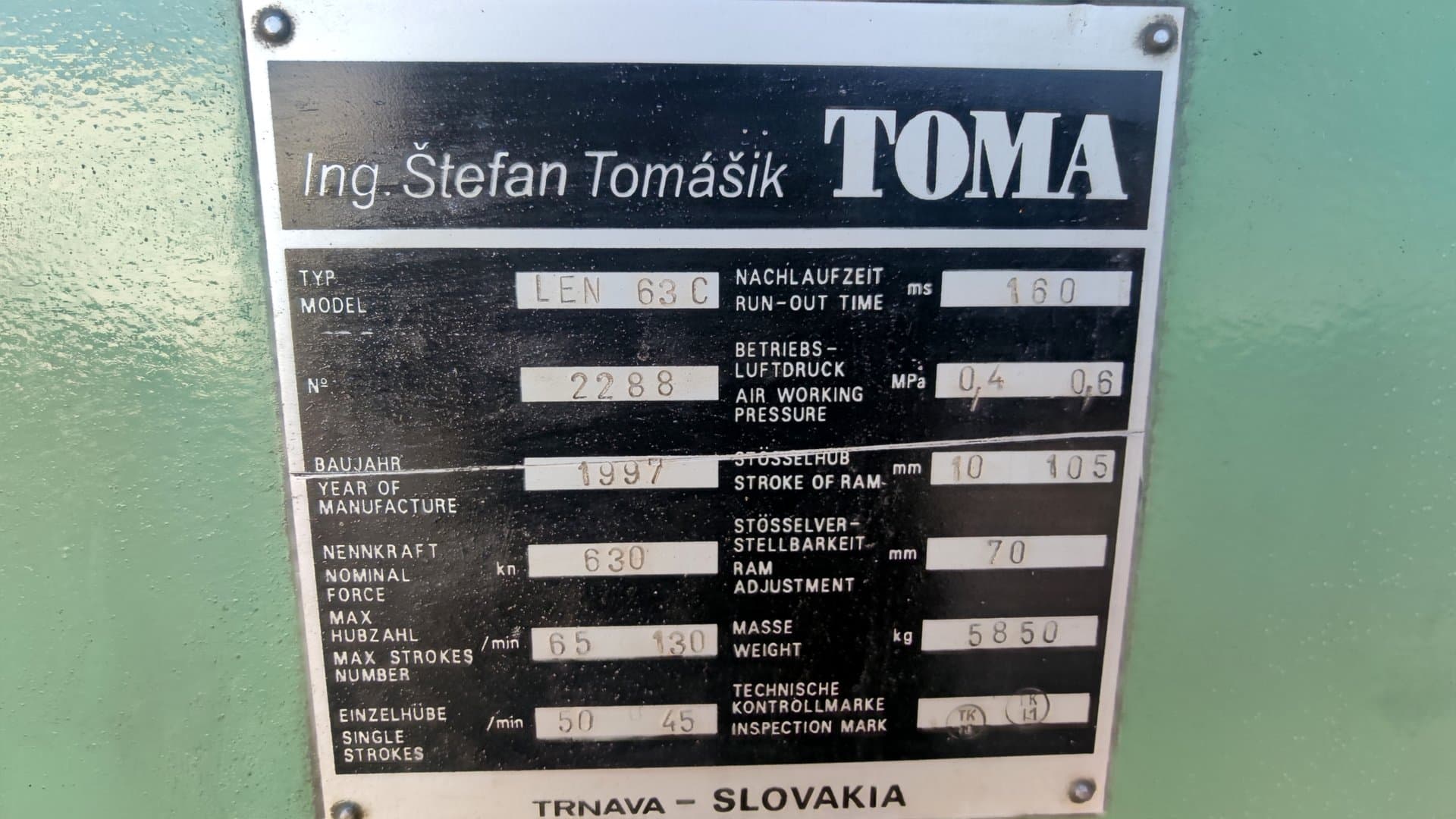

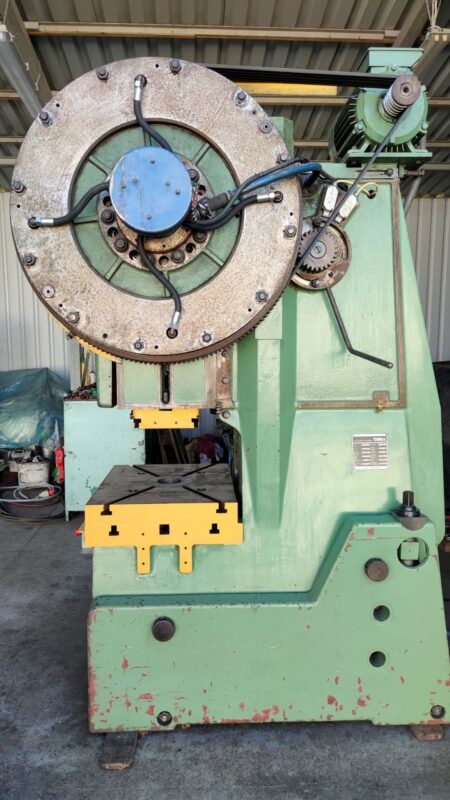

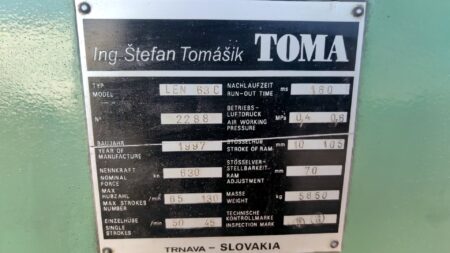

TOMA LEN 63C eccentric press manufactured in Slovakia in 1997 is designed for precision punching, cutting and punching of metals with a force of 63 tonnes. The machine processes workpieces at two different speeds – the motor gears with different speeds are changed by a switch located in the control cabinet.

First gear of the machine (730 rpm):

– number of slider strokes in automatic mode: 65 1/min

– number of slider strokes in single mode: 50 1/min

Second gear of the machine (1440 rpm):

– number of slider strokes in automatic mode: 130 1/min

– number of slider strokes in single mode: 45 1/min

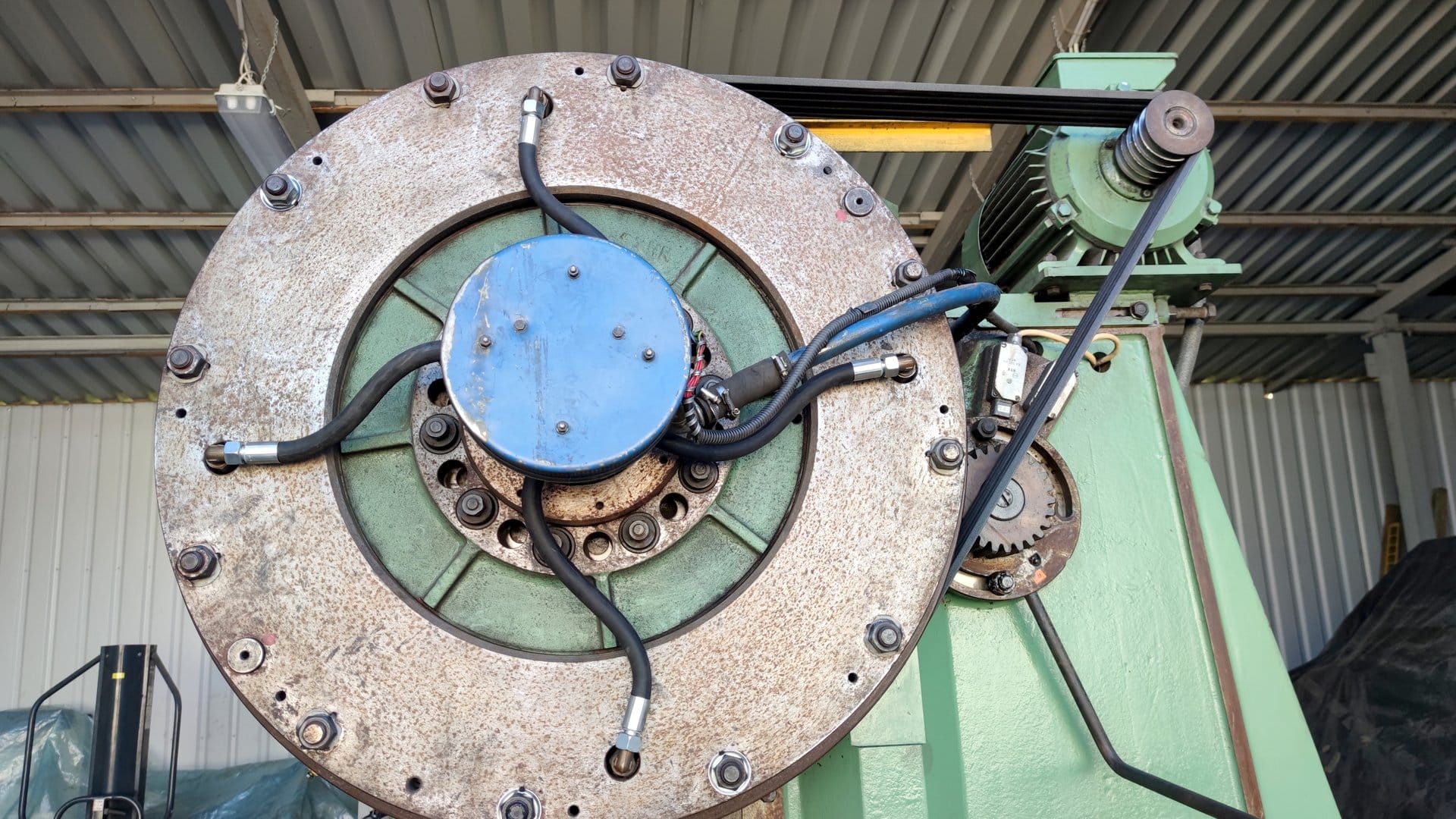

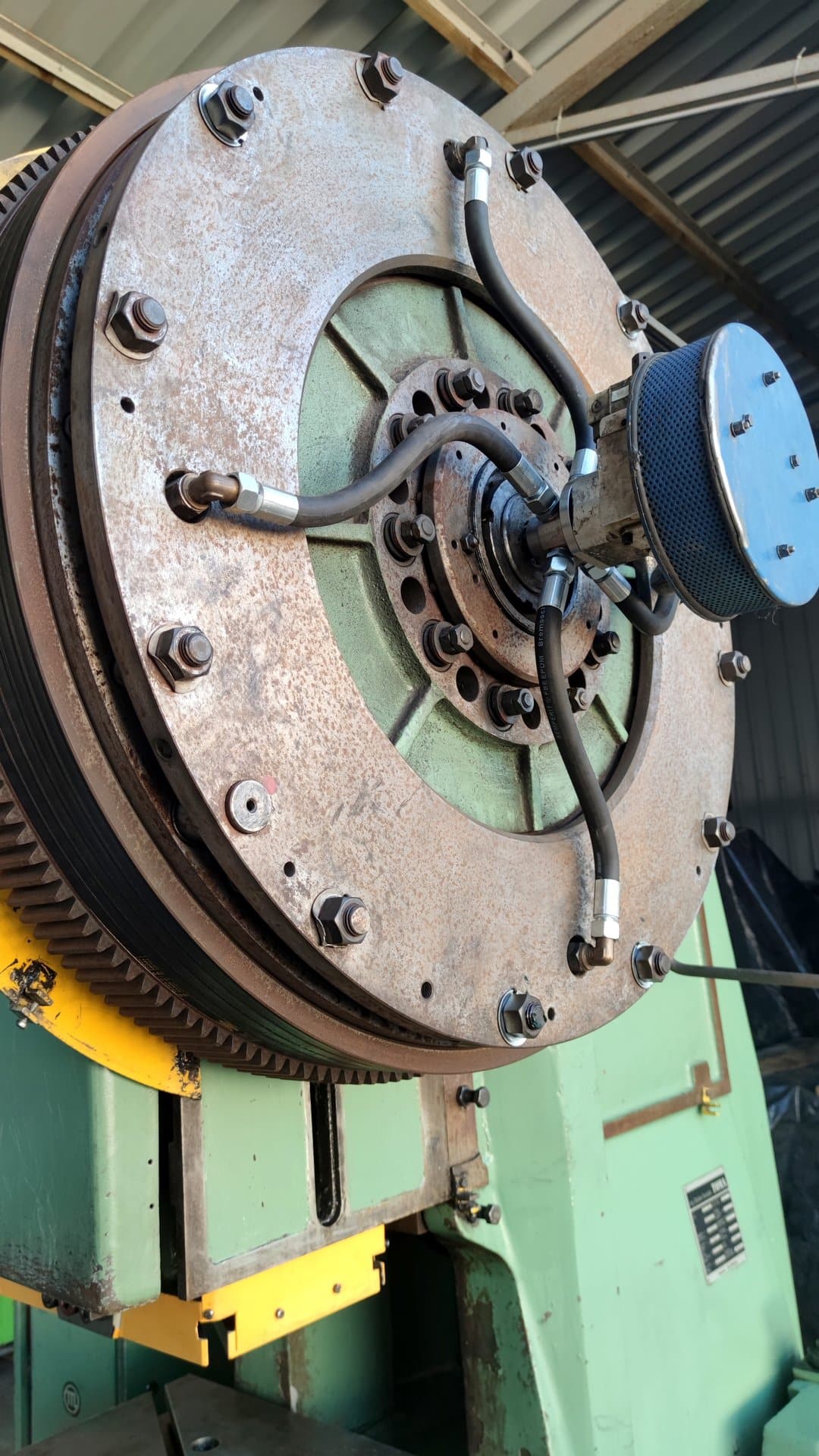

The press has an adjustable slider from 10 to 105 mm, guaranteeing excellent machining results and a fully illuminated workspace by a lamp mounted on the body of the machine with a 800 mm long and 630 mm wide table. The eccentric press went through regular servicing, the following components were replaced with new ones:

– pneumatic hoses (4 pieces)

– clutch connector with electrovalve

– V-belts (5 pcs.)

– bending washers (12 pcs.)

– bearings (4 pcs.)

– connectors (4 pcs.)

The press is offered with equipment including an bolster, 4 anti-vibration pads and a foot control pedal. The total weight of the machine is 5850 kg.

Characteristics of the TOMA LEN 63C press

- maximum press force: 63 t (630 kN)

- work table dimensions (L x W): 800 x 630 mm

- slider area (L x W): 450 x 280 mm

- minimum stroke length of slider: 10 mm

- maximum stroke length of slider: 105 mm

- maximum distance between table and slider: 335 mm

- adjustment of distance between table and slider: 70 mm

- reach: 315 mm

- distance between columns: 355 mm

- number of motor gears: 2

- run-out time: 160 ms

- motor power: 4/7.5 kW

- air pressure: 0.4-0.6 MPa

- overall dimensions (L x W x H): 1425 x 1790 x 2550 mm

- total weight of LEN 63 C machine: 5850 kg

Equipment of the eccentric press

- bolster

- Illumination of the workspace

- pedal for foot control

- anti-vibration pads (4 pcs.)

- DTR – technical and propulsory documentation

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe