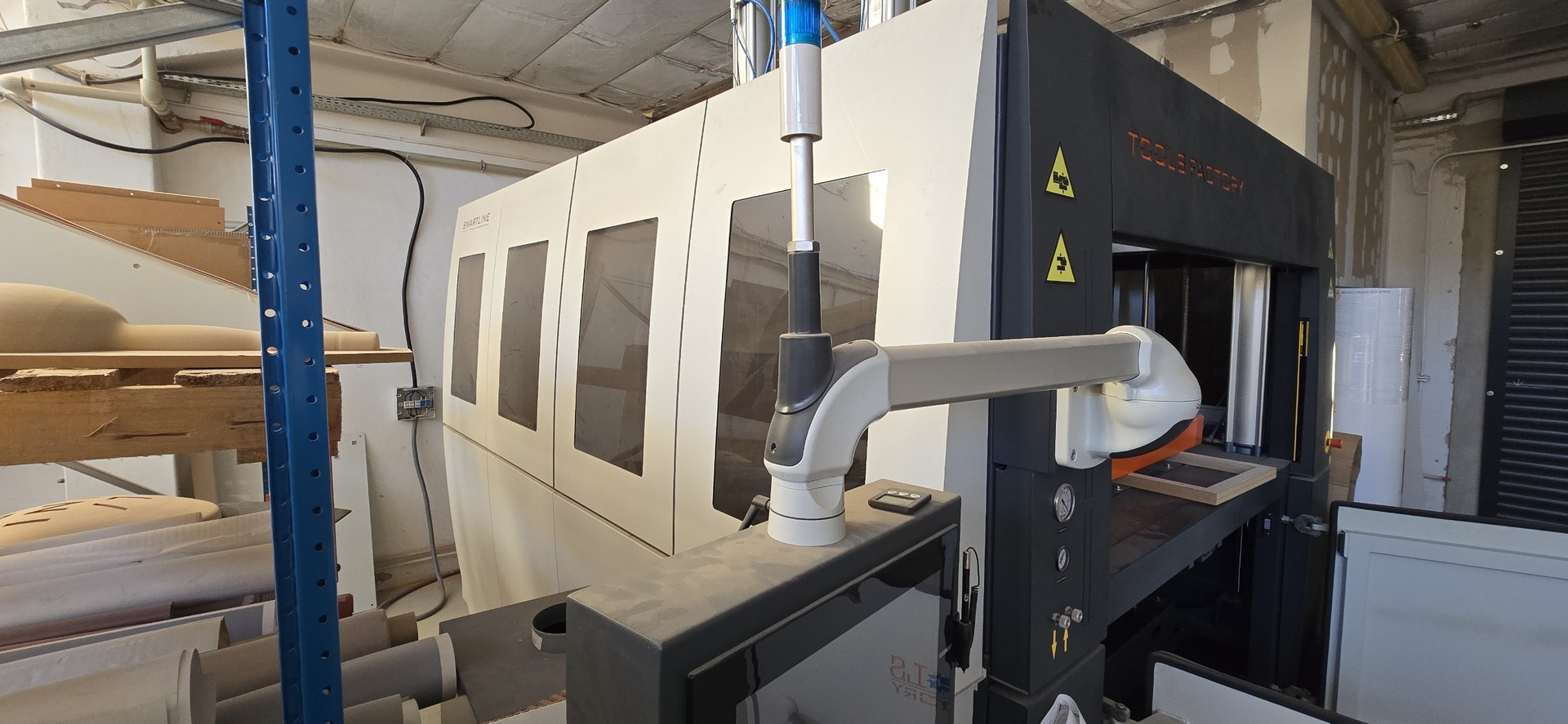

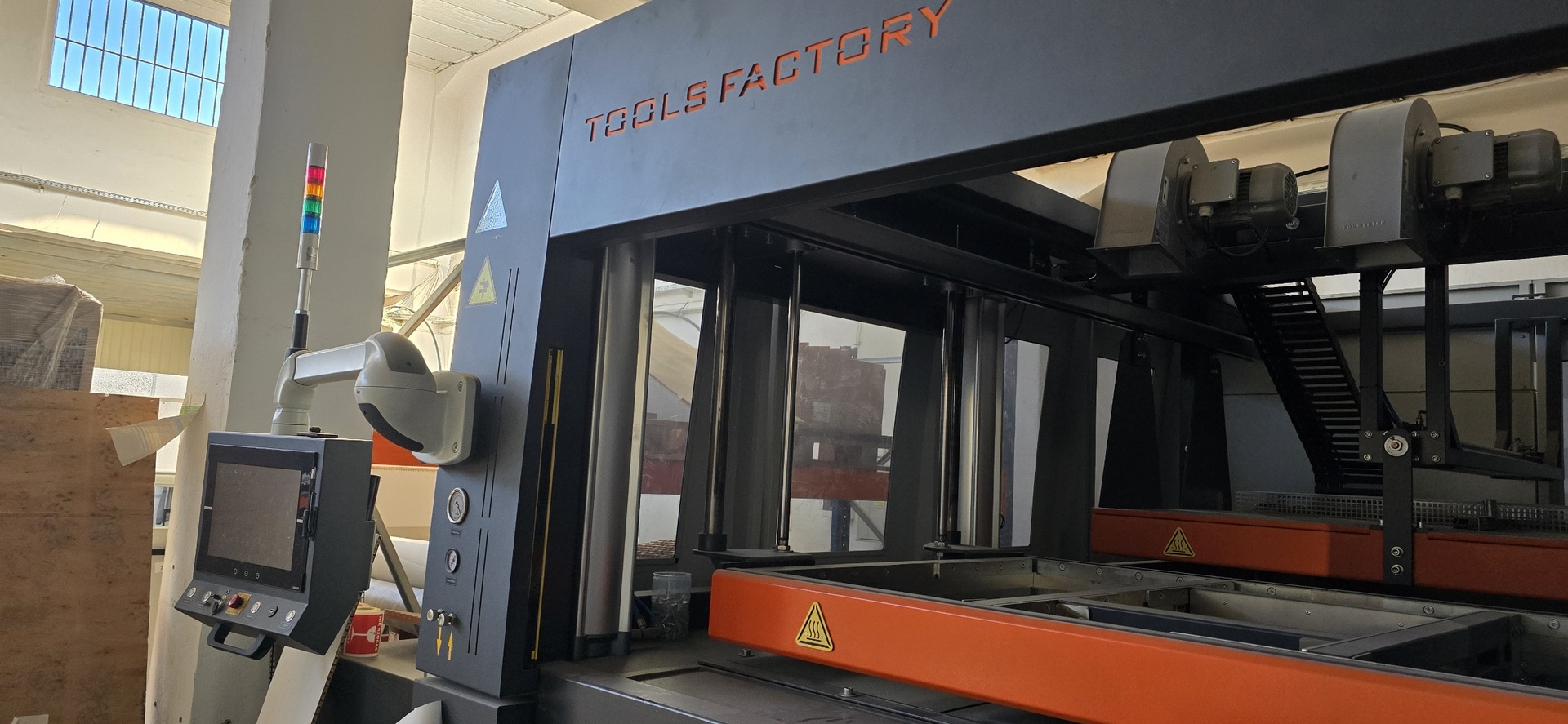

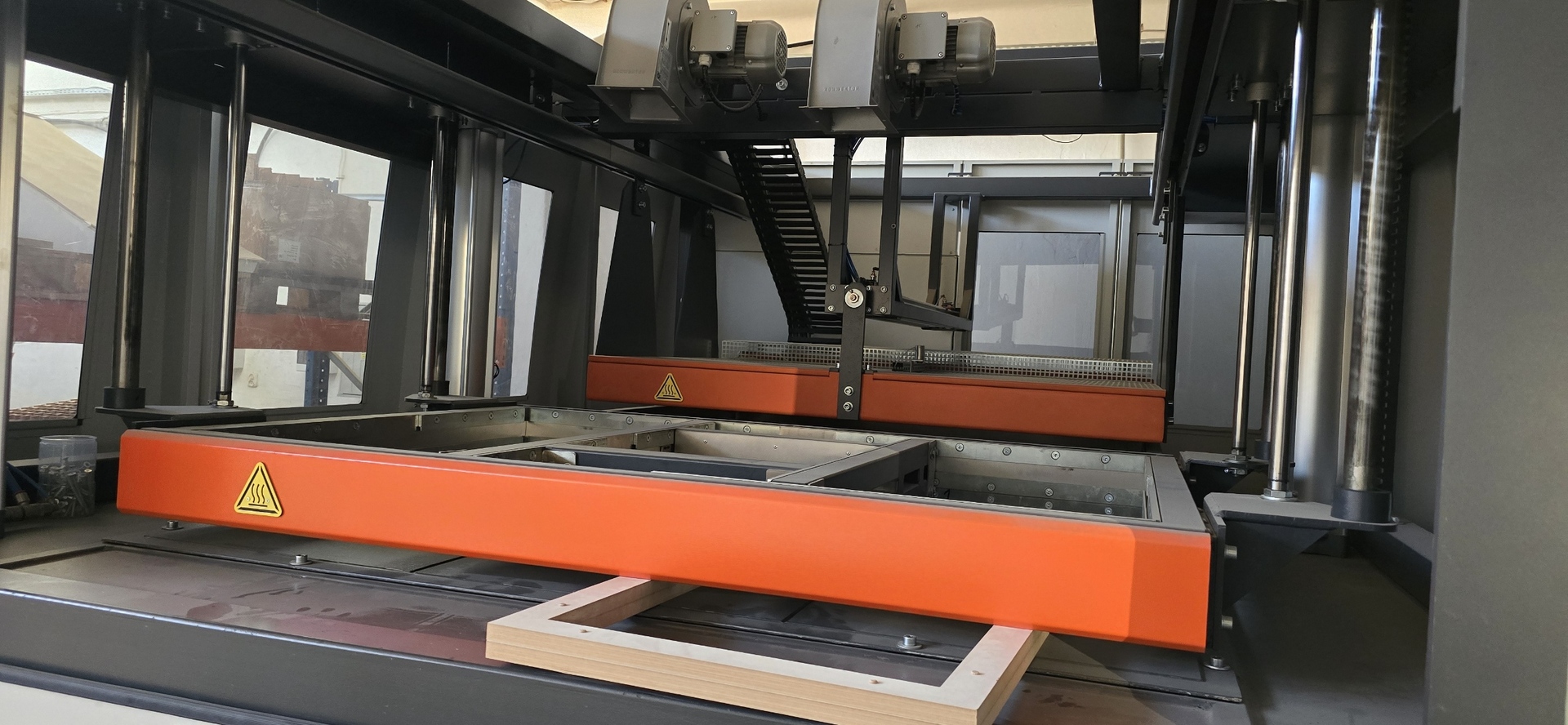

TOOLS FACTORY TF SMARTLINE 150 PLUS vacuum thermoforming machine was built in 2019 in Poland by Tools Factory Sp. j. The machine enables fully automatic production of high-quality plastic products, i.e. bathtubs, containers and automotive parts. The thermoforming process is performed using a vacuum, which precisely reproduces the plasticised material on the mould. The offer also includes extensive equipment, consisting of, among others, a modern control system and ceramic heaters. The TF SMARTLINE 150 PLUS vacuum thermoforming machine weighs approximately 5500 kg.

Technical specifications of the TOOLS FACTORY TF SMARTLINE 150 PLUS thermoforming machine

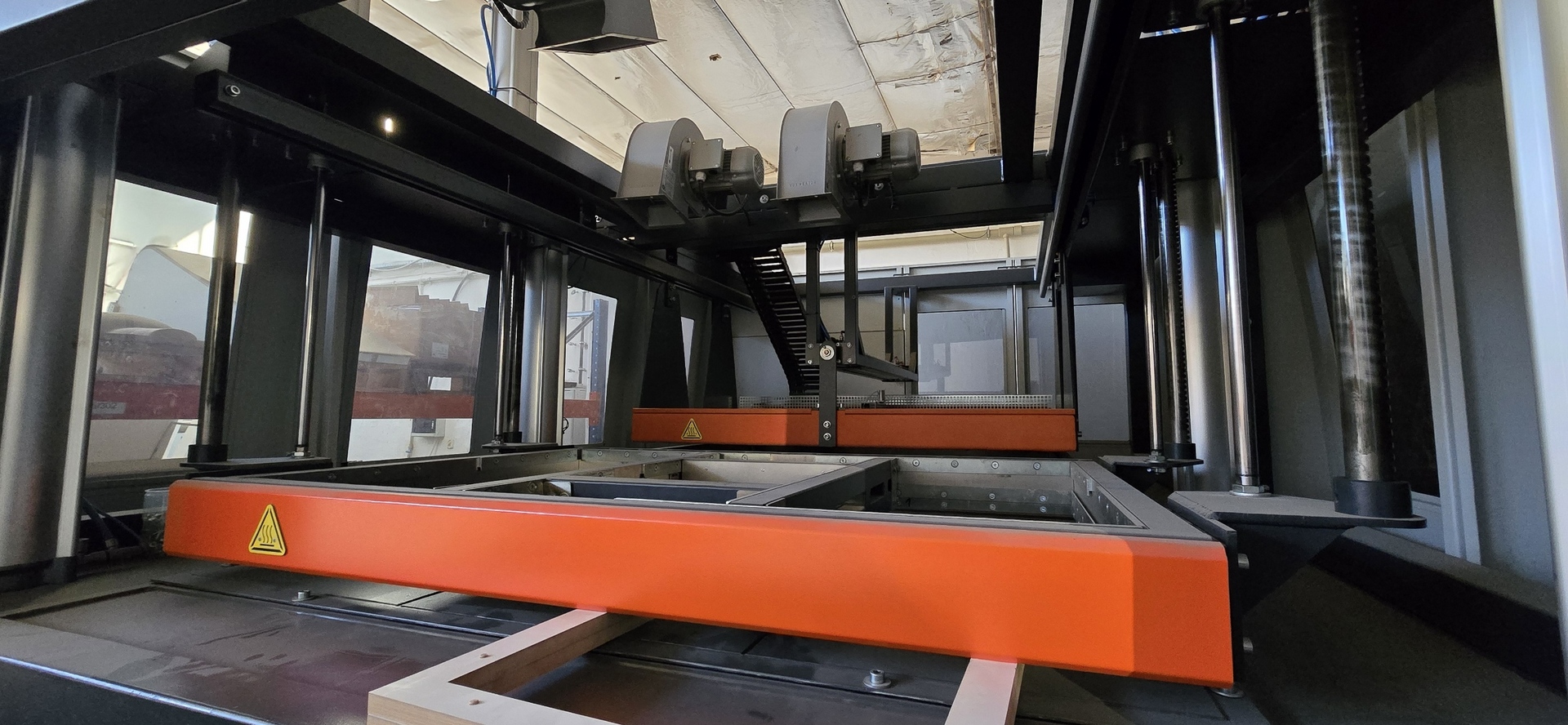

- work area (L x W): 1450 x 950 mm

- maximum plate dimensions (L x W): 1500 x 1000 mm

- maximum mould height: 500 mm

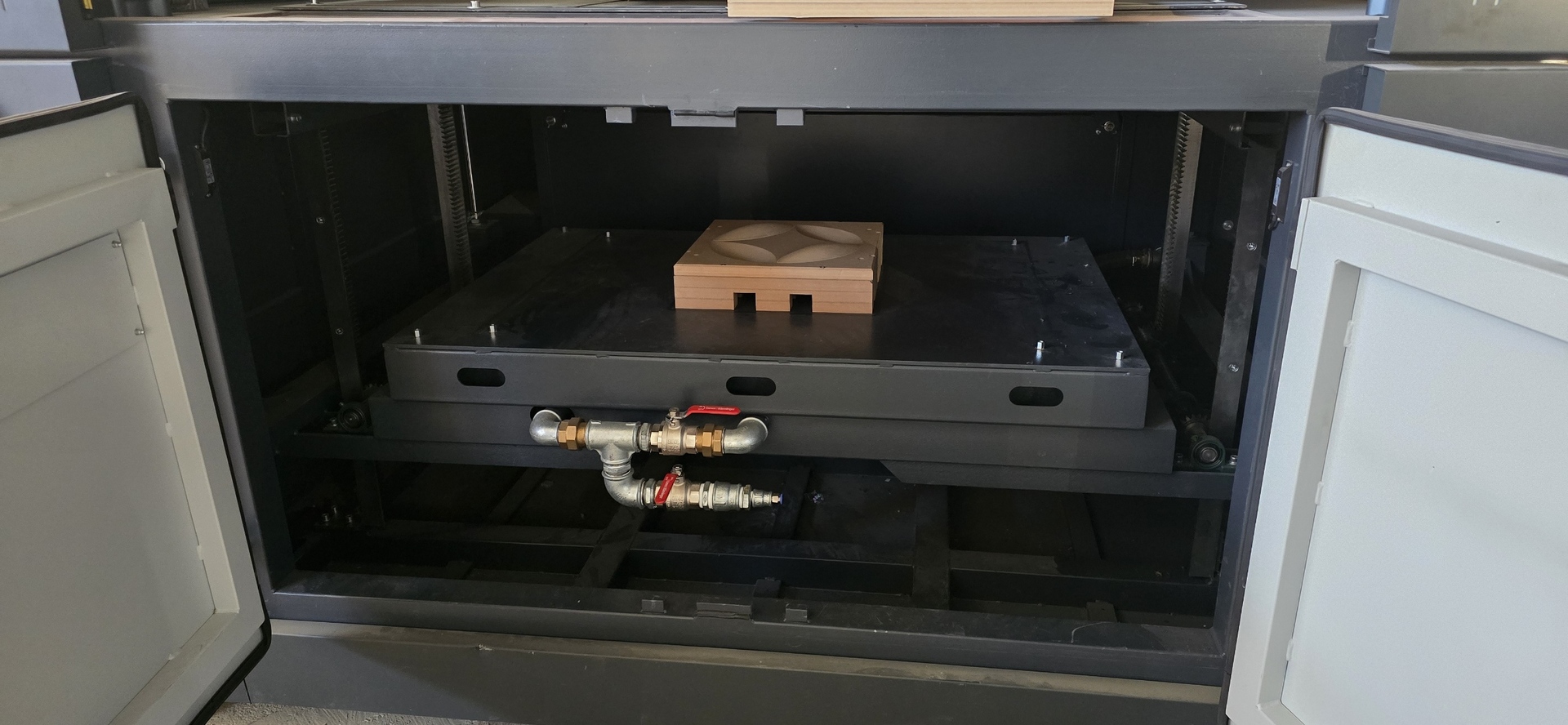

- clamping force (work table): 6.7 t (67 kN)

- clamping force (clamping frame): 1.9 t (19 kN)

- work table drive: pneumatic

- clamping frame drive: pneumatic

- furnace drive: pneumatic

- vacuum pump capacity: 100 m3/h

- compressed air pressure: 6 bar

- noise level: 85 dB

- power consumption: 60 kW

- power supply: 3x 400 V

- dimensions (L x W x H): approx. 3700 x 4050 x 3400 mm

- weight of the TOOLS FACTORY TF SMARTLINE 150 machine: approx. 5500 kg

Equipment of the TOOLS FACTORY thermoforming machine

- ceramic heaters

- vacuum pump (2 pcs.)

- pyrometer control and real-time temperature monitoring

- fan for material cooling 1500 m3/h (4 pcs.)

- safety system

- remote access, diagnostics and service

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe