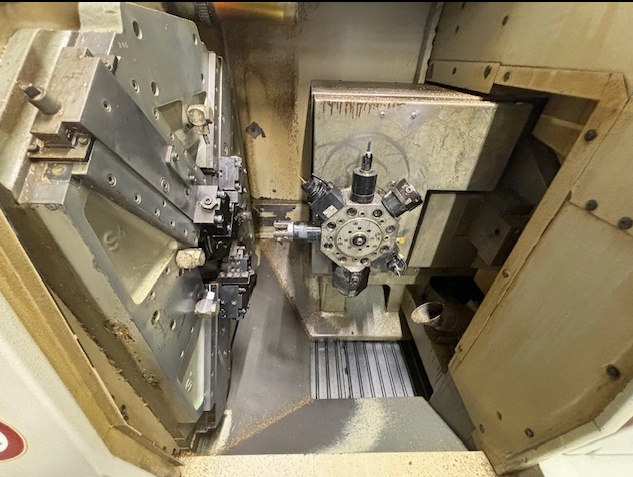

TRAUB TNM 28 sliding head lathe was built in Germany by TRAUB Drehmaschinen GmbH. The machine, which is distinguished by its high efficiency, is the perfect choice for precise, multi-axis machining of workpieces with a maximum length of 200 mm. All machining processes, i.e. drilling, threading and turning, are performed fully automatically inside a large work space. In order to obtain excellent repeatability of the manufactured parts, the TRAUB TNM is equipped with components of the best technical parameters, i.e. two reliable spindles and an 8-position turret. All this is complemented by an easy-to-use CNC controller with many useful functions. The TRAUB TNM 28 CNC automatic lathe weighs approximately 3000 kg.

Technical specifications of the TRAUB TNM 28 CNC turning center

- feed in the X/Z axis: 60/200 mm

- rapid traverse in the X/X2/Z axis: 15/15/30 m/min

- driven tool rotational speed: 300-6000 rpm

- guide sleeve travel: 63 mm

- weight of the TRAUB TNM 28 machine: approx. 3000 kg

Main spindle

- maximum turning length: 200 mm

- maximum rotational speed: 6300 rpm

- minimum rotational speed: 63 rpm

- bore diameter: 28 mm

- drive power: 4.6 kW

- torque: 40 Nm

Sub-spindle

- maximum turning length: 60 mm

- minimum turning length: 3 mm

- maximum rotational speed: 6300 rpm

- minimum rotational speed: 300 rpm

Equipment of TRAUB CNC lathe

- CNC controller: TRAUB SYSTEM TX 8H

- sub-spindle

- 8-position turret

- driven tools

- bar feeder

- chip conveyor: KNOLL 280 S-1

(The technical parameters given may differ slightly from reality. A verification with the actual capabilities of the offered machine is required.)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe