TRUMPF TruLaser 3030 BE laser cutting machine was built in 2012 in Germany. The machine machines sheets of structural steel, stainless steel and aluminium with a high-quality 3.2 kW laser beam, guaranteeing smooth and even edges of the cut workpiece. Among the extensive equipment of the TRUMPF TruLaser 3030 Basic Edition laser cutting machine are the reliable TRUMPF TruFlow 3200 laser source, the cooling unit and the SIEMENS SINUMERIK 840D CNC control for programming operating modes and controlling the cutting process. The total weight of the laser is 10500 kg.

Technical parameters of the TRUMPF TruLaser 3030 BE laser cutting machine

- maximum laser power: 3200 W (3.2 kW)

- laser type: CO2

- maximum workpiece thickness (structural steel): 20 mm

- maximum workpiece thickness (stainless steel): 12 mm

- maximum workpiece thickness (aluminium): 8 mm

- feed rates in the X/Y/Z axis: 3000/1500/115 mm

- positioning speed parallel to the axis: 60 m/min

- positioning speed with simultaneous operation of the X and Y axes drives: 85 m/min

- sheet metal maximum weight: 710 kg

- smallest programmable step: 0.001 mm

- positioning deviation: ± 0,10 mm

- average positioning deviation: ± 0.03 mm

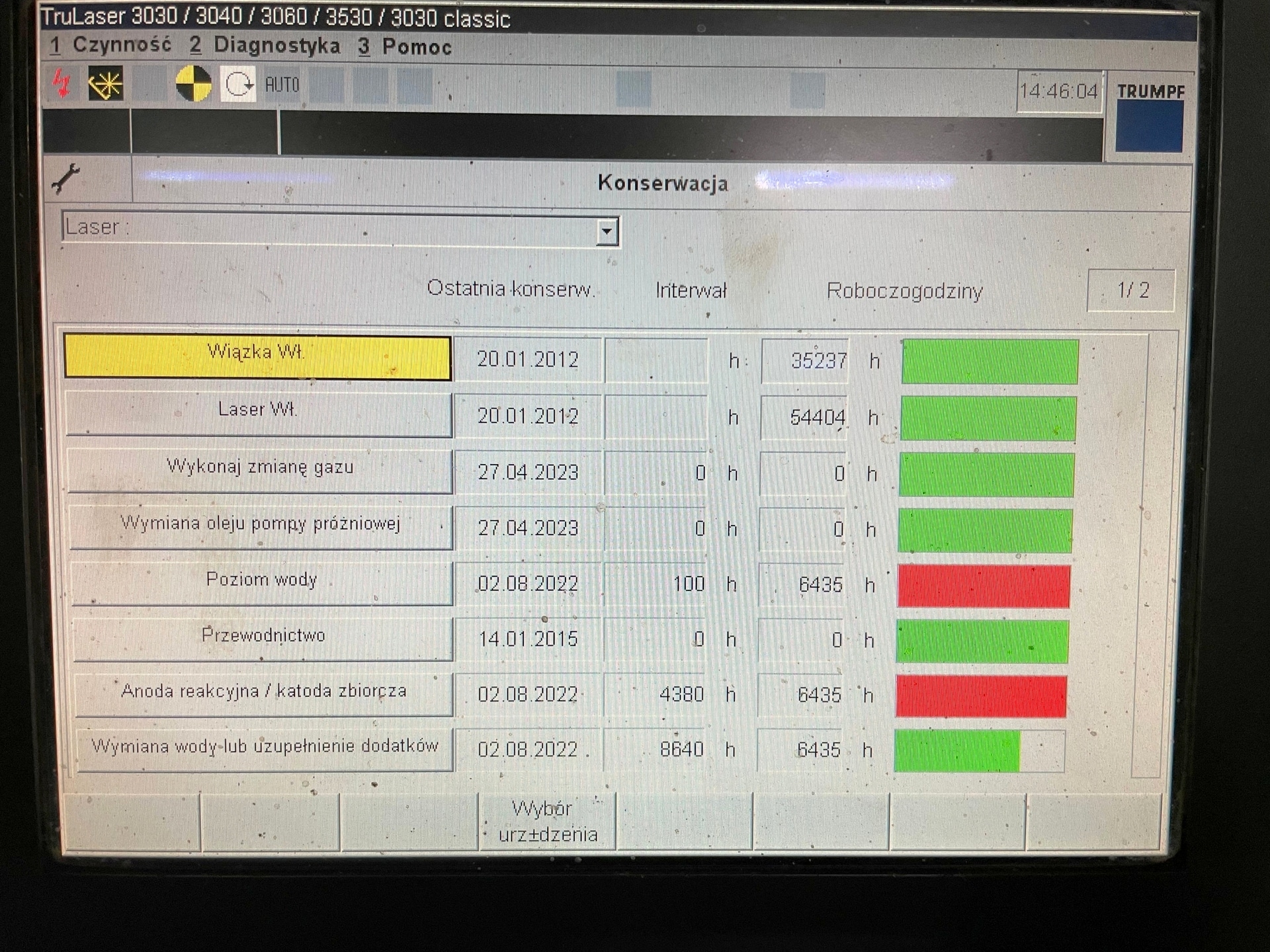

- switch-on time: 54404 h

- laser beam emission time: 35237 h

- coupled air connection: 7-10 bar

- nitrogen connection N2: 30 bar

- oxygen connection O2: 20 bar

- compressed air consumption with laser source: 4 Nm3/h

- laser gas consumption (CO2): 1 l/h

- laser gas consumption (N2): 6 l/h

- laser gas consumption (He): 13 l/h

- power consumption with laser source and cooling unit: 26-53 kW/h

- connection power: 68 kVA

- power supply: 400 V; 50 Hz

- dimensions (L x W x H): 9300 x 4600 x 2000 mm

- weight of machine TruLaser 3030 BE: 10500 kg

Equipment of the laser cutting machine

- CNC control: SIEMENS SINUMERIK 840D

- laser source: TRUMPF TruFlow 3200

- cooling unit

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe