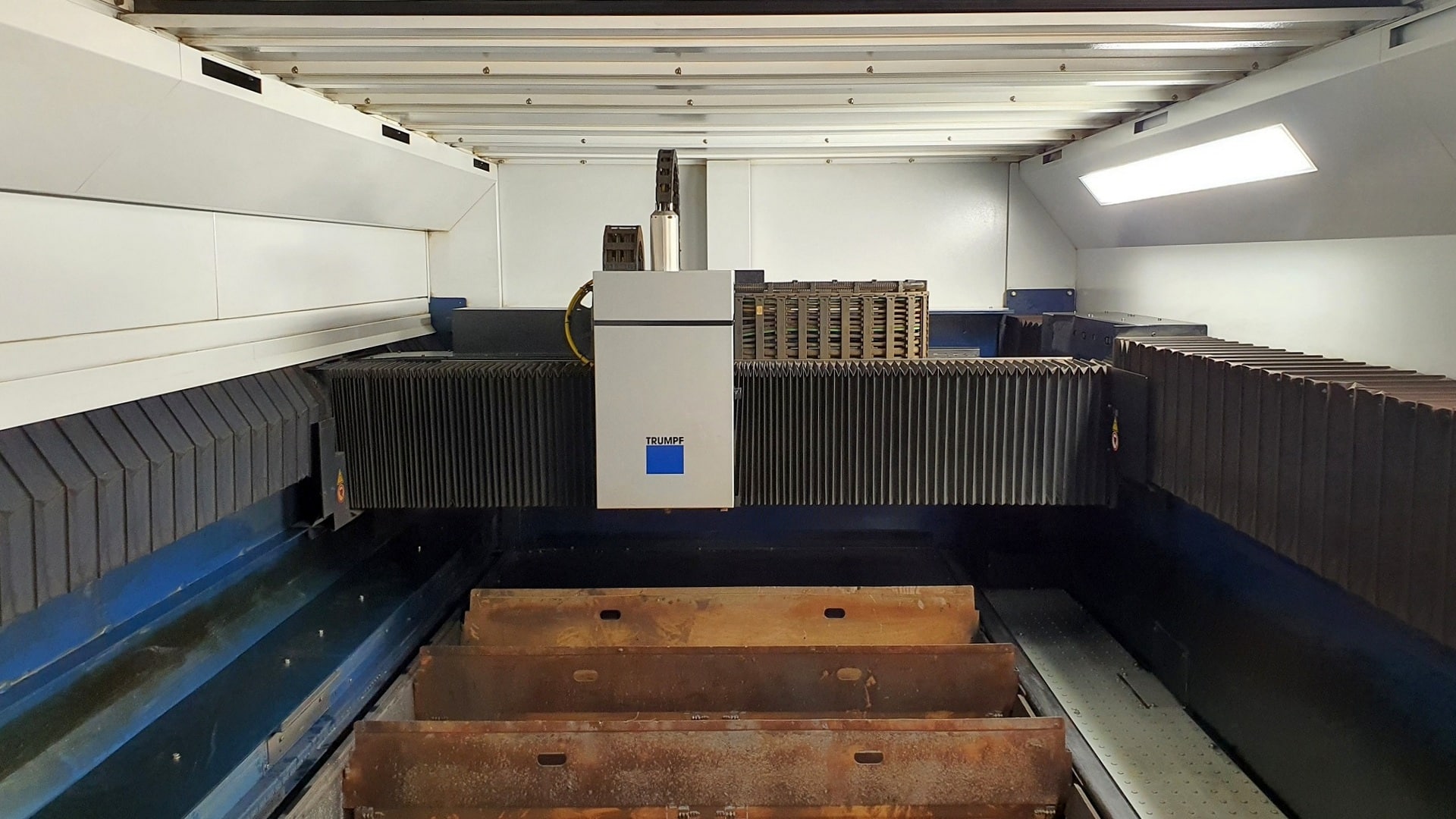

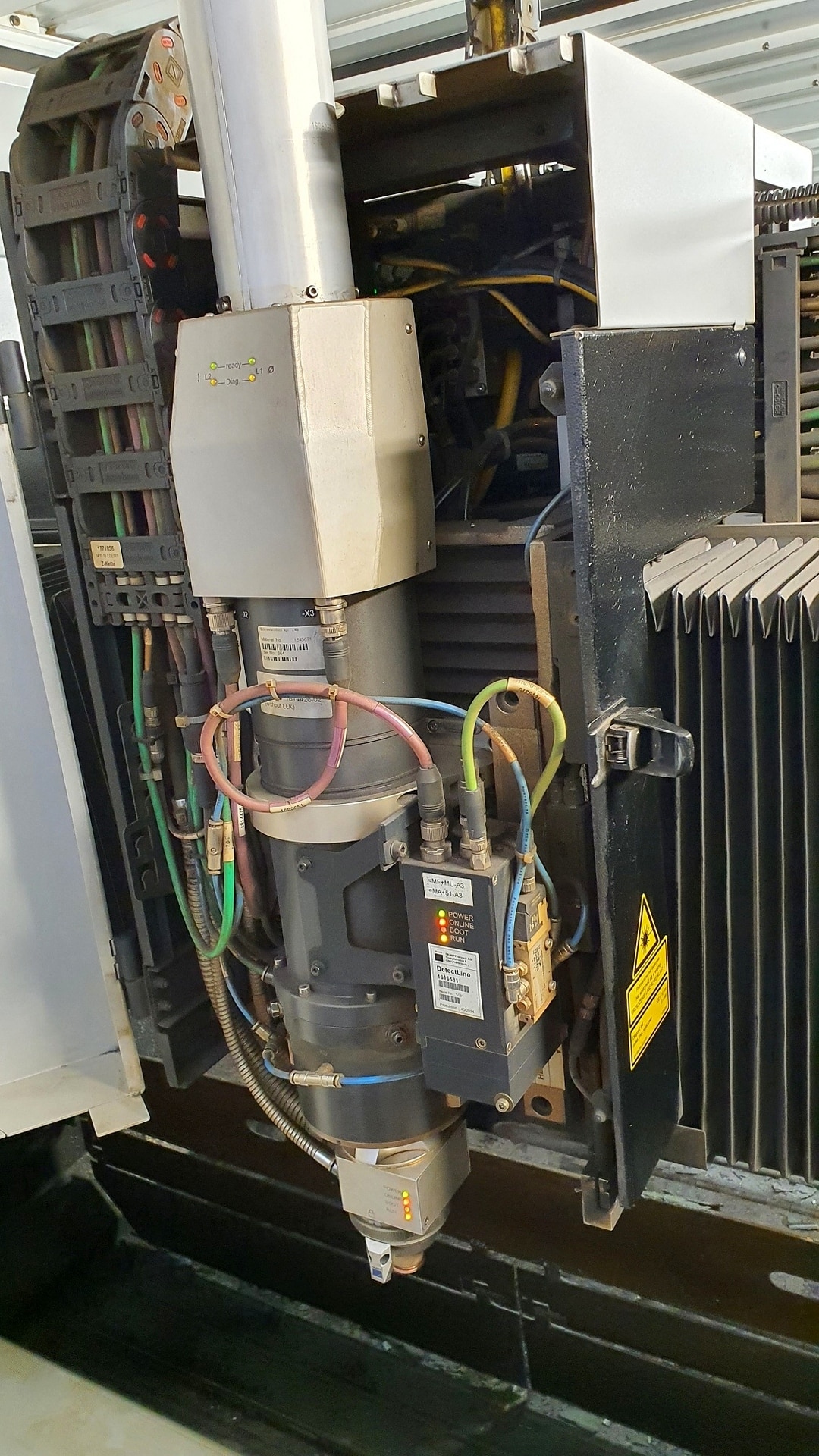

TRUMPF TruLaser 3030 FIBER laser cutting machine was manufactured in 2014 in Germany. The machine uses state-of-the-art fibre cutting technology for the precise machining of structural steel, stainless steel, aluminium and copper sheets, which guarantees smooth and even edges without any splintering. Thanks to the DetectLine package, which automatically measures the cut crest of the focal point and precisely determines the position of the focal point and the position of the sheet, it is also possible to perform very accurate additional processing of previously cut parts.

The TruLaser 3030 FIBER (L49) laser cutting machine is equipped with the reliable TRUMPF TruDisk 3001 disk laser with a power of 3000 W. The energy-saving pulse function and intelligent power management generate a high-quality beam with simultaneously low operating costs and reduced power requirements. Cutting of workpieces with a maximum weight of 900 kg is performed in three X,Y,Z axes with feed rates of 3000 mm (X axis), 1500 mm (Y axis) and 115 mm (Z axis).

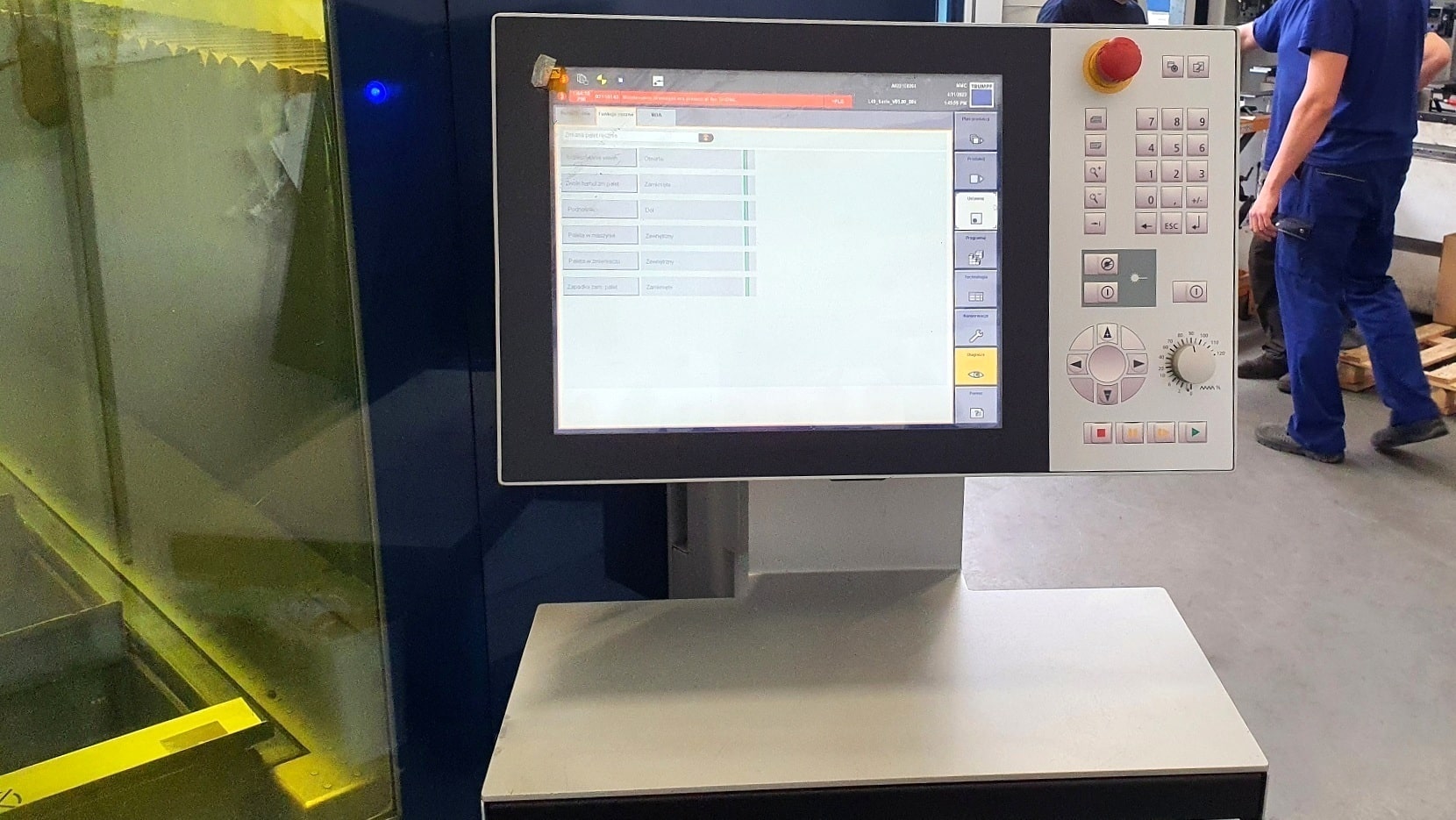

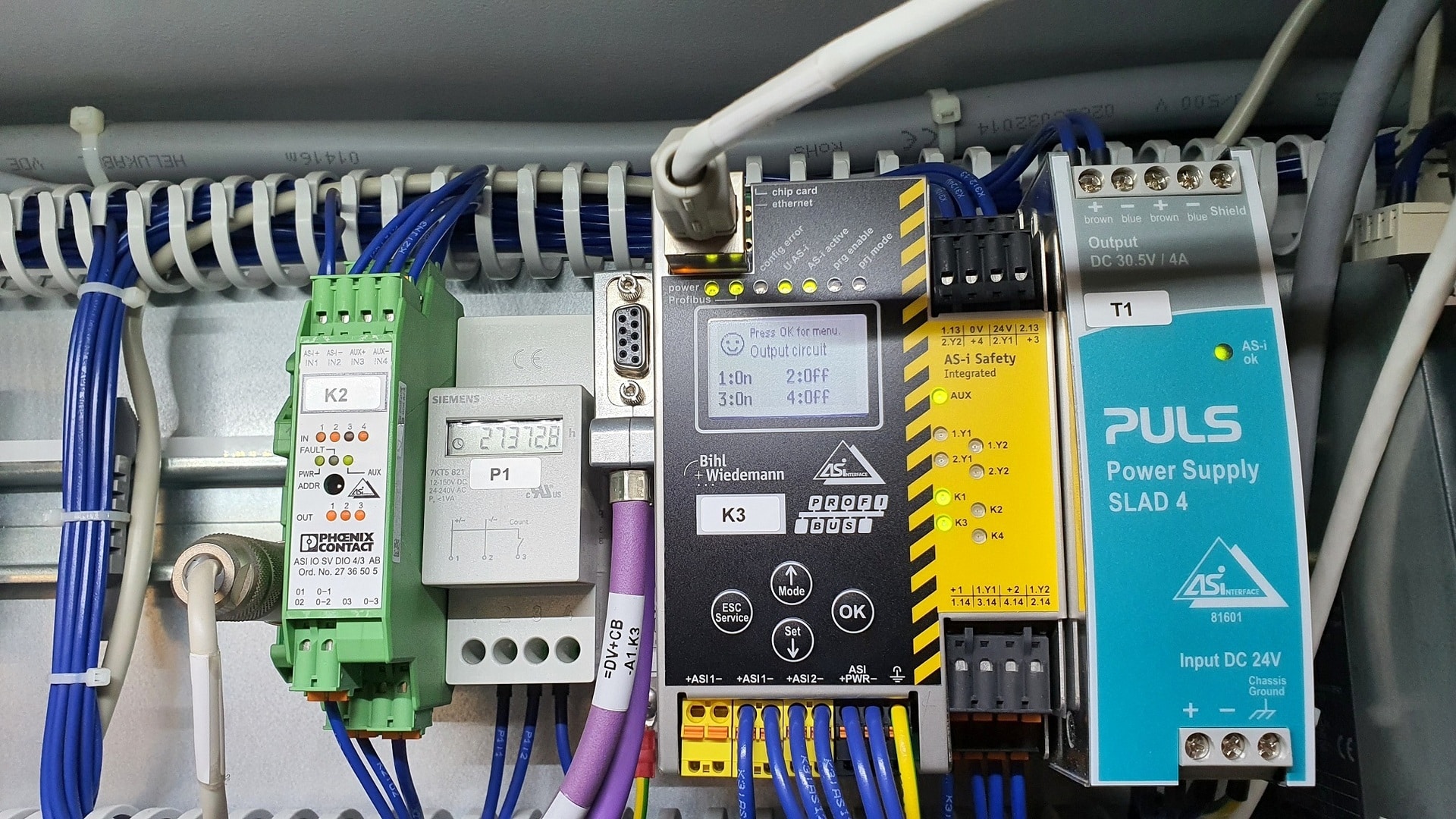

The TruLaser 3030 fiber laser is controlled both from the state-of-the-art SIEMENS SINUMERIK 840D SL CNC control with colour screen and via the application MobileControl App. The app transfers the control panel interface to a tablet screen, allowing the machine to be controlled and operated simply and flexibly from anywhere within the plant.

Technical specifications of the TRUMPF TruLaser 3030 FIBER laser cutting machine

- laser power: 3 kW

- feed rates in the X/Y/Z axis: 3000/1500/115 mm

- maximum workpiece weight: 900 kg

- maximum sheet thickness (structural steel): 20 mm

- maximum sheet thickness (stainless steel): 15 mm

- maximum sheet thickness (aluminium): 15 mm

- maximum sheet thickness (brass): 6 mm

- maximum sheet thickness (copper O2): 6 mm

- maximum sheet thickness (copper N2): 3 mm

- speed of positioning with simultaneous operation of the X and Y axes drives: 140 m/min

- smallest programmable step: 0.001 mm

- positioning deviation (PA): ± 0.05 mm

- average positioning deviation (PS): ± 0.03 mm

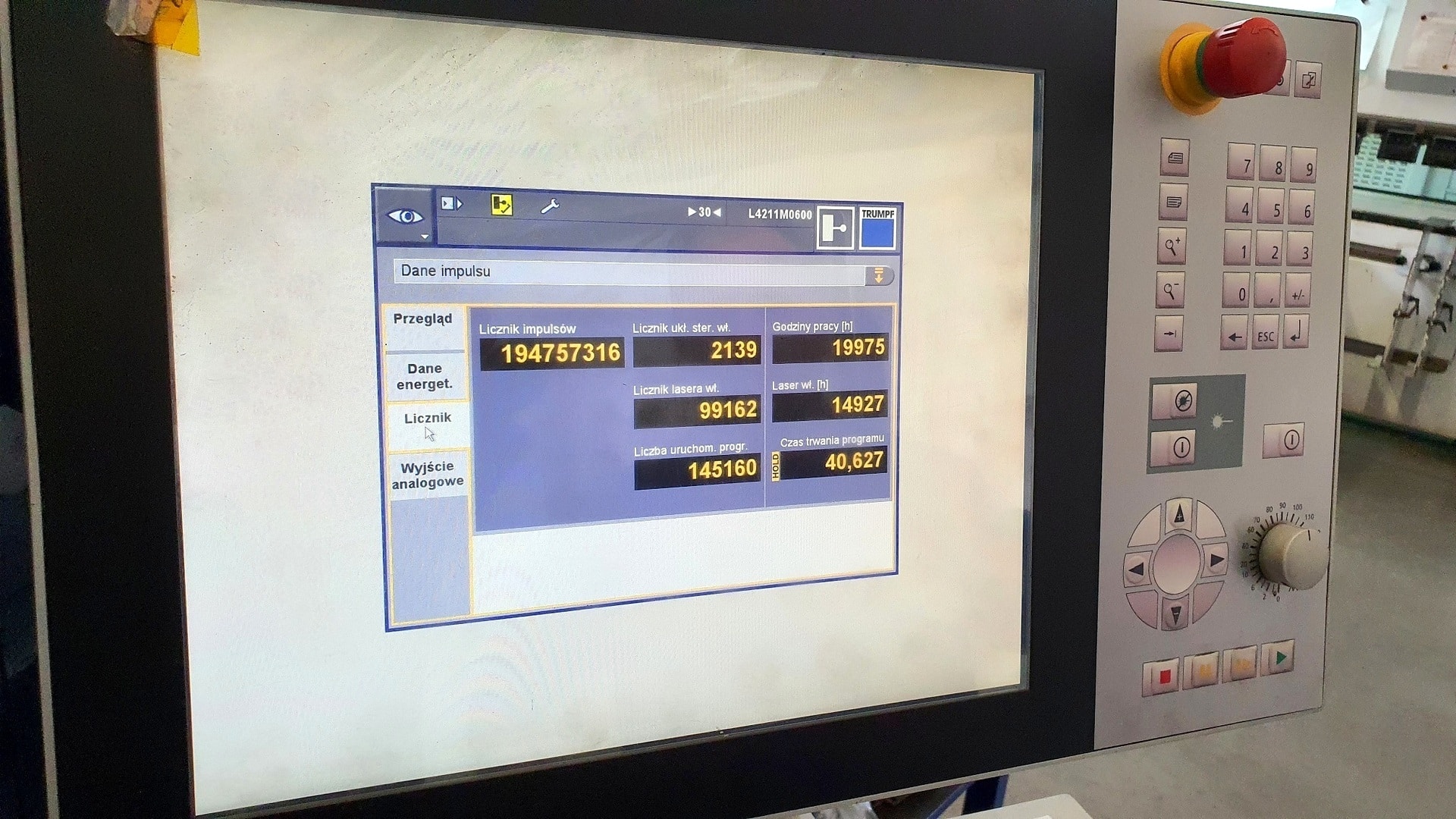

- working hours: 19975 h

- laser switch-on time: 14927 h

- average compressed air consumption: 35 Nm3/h

- compressed air connection: 7-10 bar

- N2 nitrogen connection: 30 bar

- O2 oxygen connection: 20 bar

- connection power: 35 kVA

- laser power consumption with cooling unit: 6-23 kW

- power supply of TruLaser 3030 FIBER machine: 400 V; 50 Hz

Equipment of the laser cutting machine

- CNC control: SIEMENS SINUMERIK 840D SL

- disk laser: TRUMPF TruDisk 3001

- copper cutting package

- DetectLine package

- MobileControl App application

- integrated FHD camera

- clamping clamps (2 per pallet)

- USB port

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe