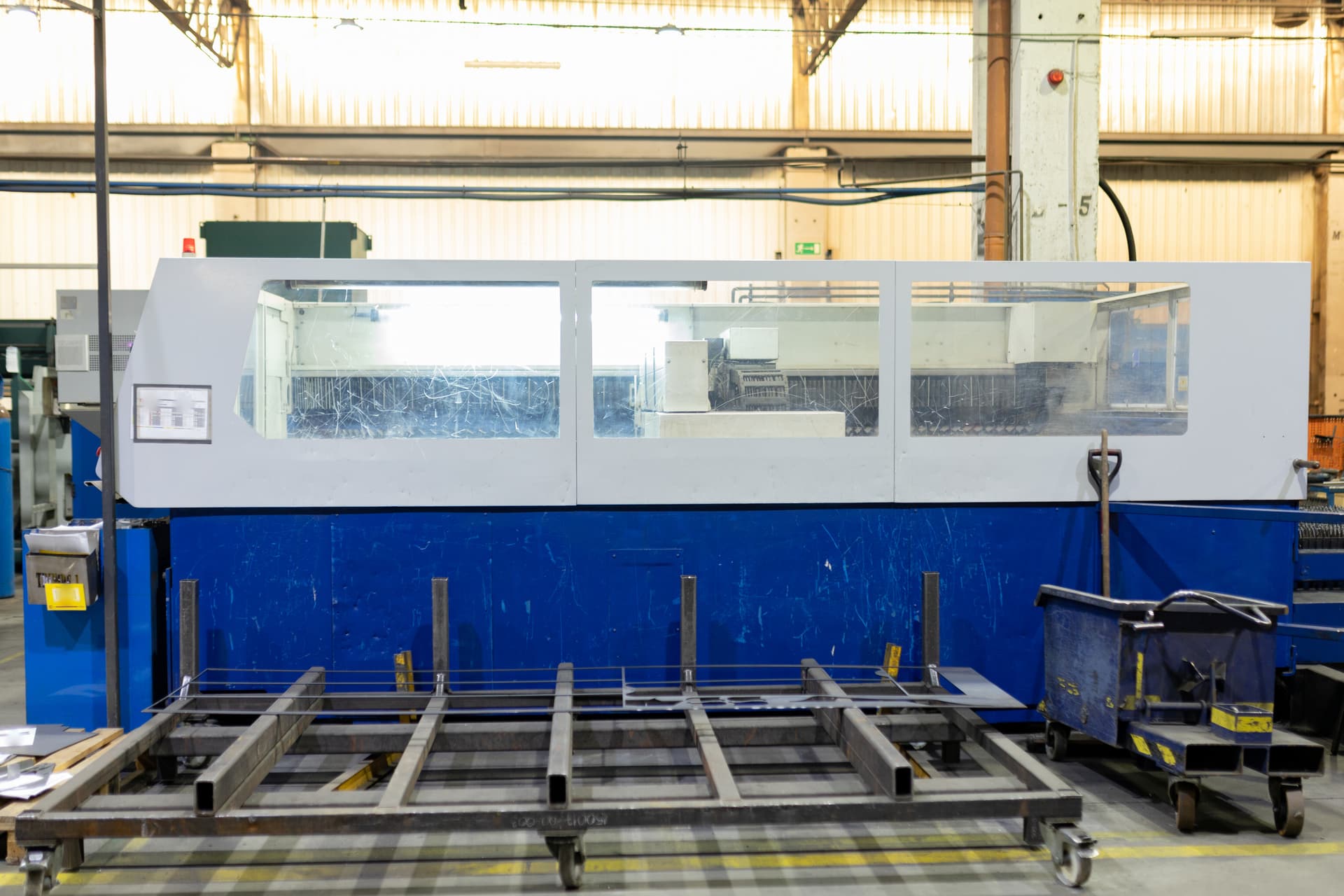

TRUMPF TruLaser 3030 laser cutting machine built in Germany in 2007 provides excellent laser cutting quality while maintaining low operating costs. Designed for even the most demanding challenges, the machine machines workpieces with a maximum thickness of 12 mm with high precision and quality, making it suitable for any production facility. The stable 2 kW laser beam used during cutting produces very smooth and even edges along the entire length of the workpiece, regardless of the type of material. To further improve the workflow and reduce machine downtime to a minimum, the work table is equipped with an integrated automatic pallet changing system which allows workpieces to be loaded and unloaded simultaneously during the cutting process. The TRUMPF laser cutting machine weighs approximately 11500 kg.

Technical specifications of the TRUMPF TruLaser 3030 laser

- laser power: 2 kW (2000 W)

- feed rate in the X/Y/Z axis: 3104/1580/122 mm

- working range in the X/Y/Z axis: 3000/1500/115 mm

- positioning speed parallel to the axis: 60 m/min

- positioning speed with simultaneous operation of the X and Y axes drives: 85 m/min

- maximum sheet metal thickness: 12 mm

- smallest programmable path dimension: 0.01 mm

- position deviation: ± 0.1 mm

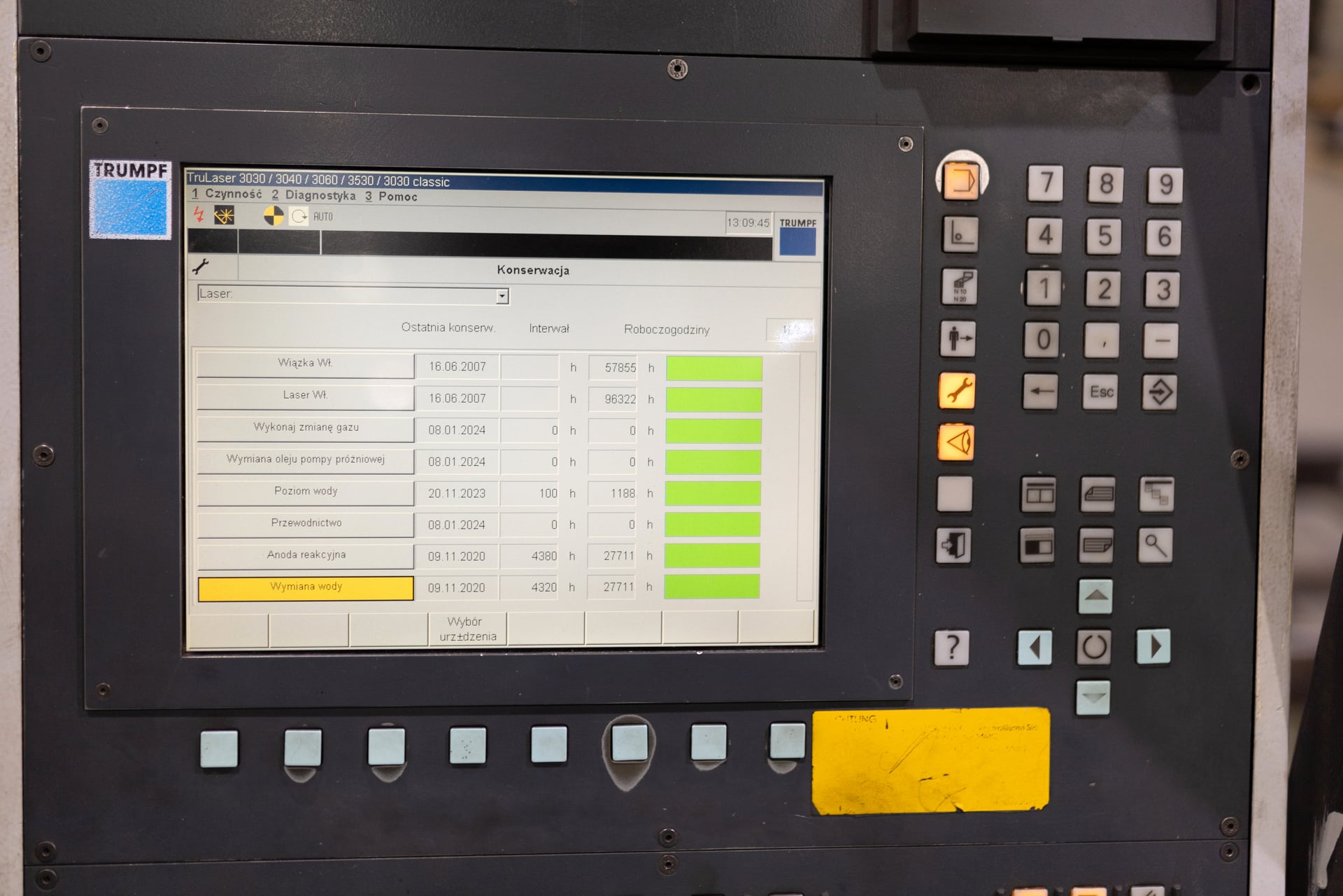

- laser switch-on time: 96322 h

- nitrogen N2 connection: 30 bar

- oxygen O2 connection: 20 bar

- compressed air connection: 7-10 bar

- compressed air consumption: 700 l/m

- power connection: 63 kVA

- power supply: 400 V; 50 Hz

- dimensions (L x W x H): approx. 9800 x 5300 x 2000 mm

- weight of machine: approx. 11500 kg

Equipment of the Tru Laser 3030 laser cutting machine

- TRUMPF CNC control based on SIEMENS SINUMERIK 840D

- laser source: TruFlow 2000

- automatic pallet changing system

- servo motors in all axes

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe