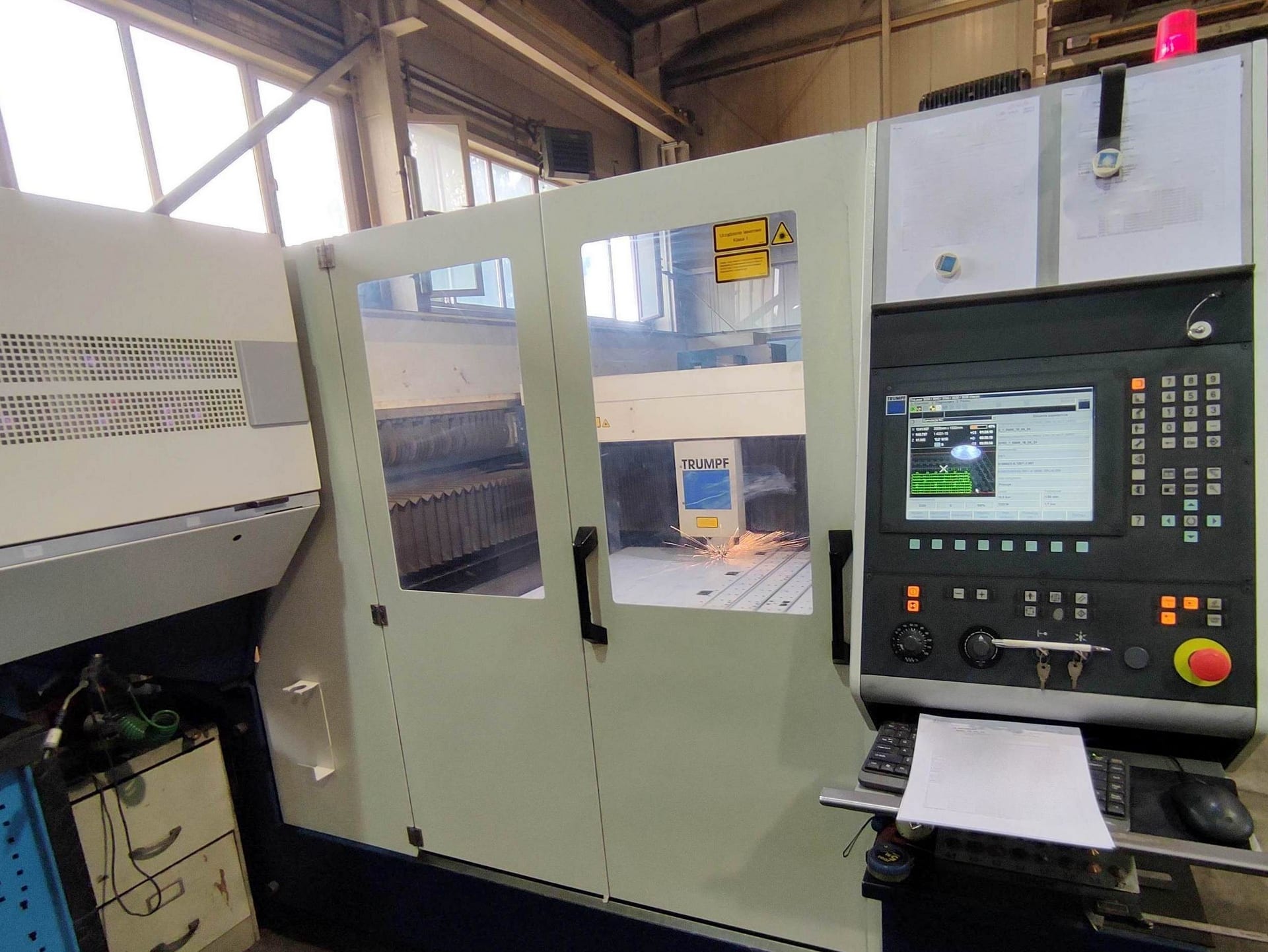

TRUMPF TruLaser 3030 laser cutting machine was built in 2012. The machine, used for precision cutting of structural steel, stainless steel and aluminium sheets, uses a stable 3200 W laser beam, which is generated by a reliable laser source with the highest energy efficiency. Thanks to high-frequency current gas excitation, excellent cutting results are achieved with low gas consumption. The laser beam itself is additionally repeatedly ventilated with filtered compressed air to prevent the entry of contaminants.

The cutting unit, consisting of a head and a 7.5″ lens, is mounted on a lightweight, laser-welded crossbeam. The beam is driven by a backlash-free double-sided rack-and-pinion drive, running on roller and ball bearings on flat guides. This solution ensures that the mobile unit provides optimum speed and accuracy in machining. On the other hand, the work table with integrated automatic pallet changing system allows simultaneous loading and unloading of workpieces during the cutting process, resulting in increased production efficiency and reducing machine downtime to a minimum.

The TRUMPF TruLaser 3030 BE laser comes with an extensive range of equipment, including the high-tech ControlLine system. This system maintains a constant distance between the head nozzle and the surface of the sheet during cutting, so that the working head does not collide with the workpiece. The operator also has at his disposal the CAD/CAM software system TruTops, which optimally distributes the cut shapes on the workpiece so as to make the best possible use of the material. The machine has been serviced regularly throughout its life – the last service took place in January 2024. The TRUMPF TruLaser 3030 Basic Edition laser cutting machine weighs 10500 kg.

Technical specifications of the TRUMPF TruLaser 3030 laser

- laser beam power: 3.2 kW (3200 W)

- feed in X/Y/Z axis: 3000/1500/115 mm

- maximum sheet thickness (structural steel): 20 mm

- maximum sheet thickness (stainless steel): 12 mm

- maximum sheet thickness (aluminium): 8 mm

- maximum sheet weight: 710 kg

- positioning speed with simultaneous operation of the X and Y axes drives: 85 m/min

- positioning speed parallel to the axis: 60 m/min

- smallest programmable step: 0.001 mm

- positioning deviation: ± 0.10 mm

- average positioning deviation: ± 0.03 mm

- operating hours: 34573 h

- compressed air connection: 7-10 bar

- N2 nitrogen connection: 30 bar

- O2 oxygen connection: 20 bar

- CO2 gas consumption: 1 l/h

- N2 gas consumption: 6 l/h

- He gas consumption: 13 l/h

- connection power: 68 kVA

- maximum electricity consumption (with resonator and cooling unit): 53 kW/h

- compressed air consumption (with resonator): 42 Nm3/h

- maximum ambient temperature: 43°C

- power supply: 400 V; 50 Hz

- dimensions (L x W x H): 9300 x 4600 x 2000 mm

- weight of machine: 10500 kg

Equipment for TRUMPF laser cutting machine

- CNC controller: SIEMENS SINUMERIK 840D

- CAD/CAM software: TruTops

- servo motors on all axes

- ContourLine function (special overlapping techniques for cutting holes with diameters much smaller than the thickness of the sheet metal)

- NitroLine function (high-pressure cutting for stainless steel and aluminium alloys)

- ControlLine function (digital, intelligent distance measuring system, which maintains a constant distance between the cutting head nozzle and the sheet surface during the cutting process, even with uneven sheets)

- FocusLine system (a system which makes it possible to set the focal length according to the type of material and its thickness)

- Plasma Line system (plasma detection system)

- LensLine system and output mirror control (to protect the laser and the beam guide from contamination)

- pallet exchange system

- laser resonator: TRUMPF TruFlow 3200

- cutting head with 7.5″ lens

- automatic laser status monitoring system

- waste container

- cooling unit

- integrated mirror telescope

- programmable cutting gas pressure function

- automatic shut-off

- laser positioning diode

- RJ45 interface

- USB interface

- CE certificate

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe