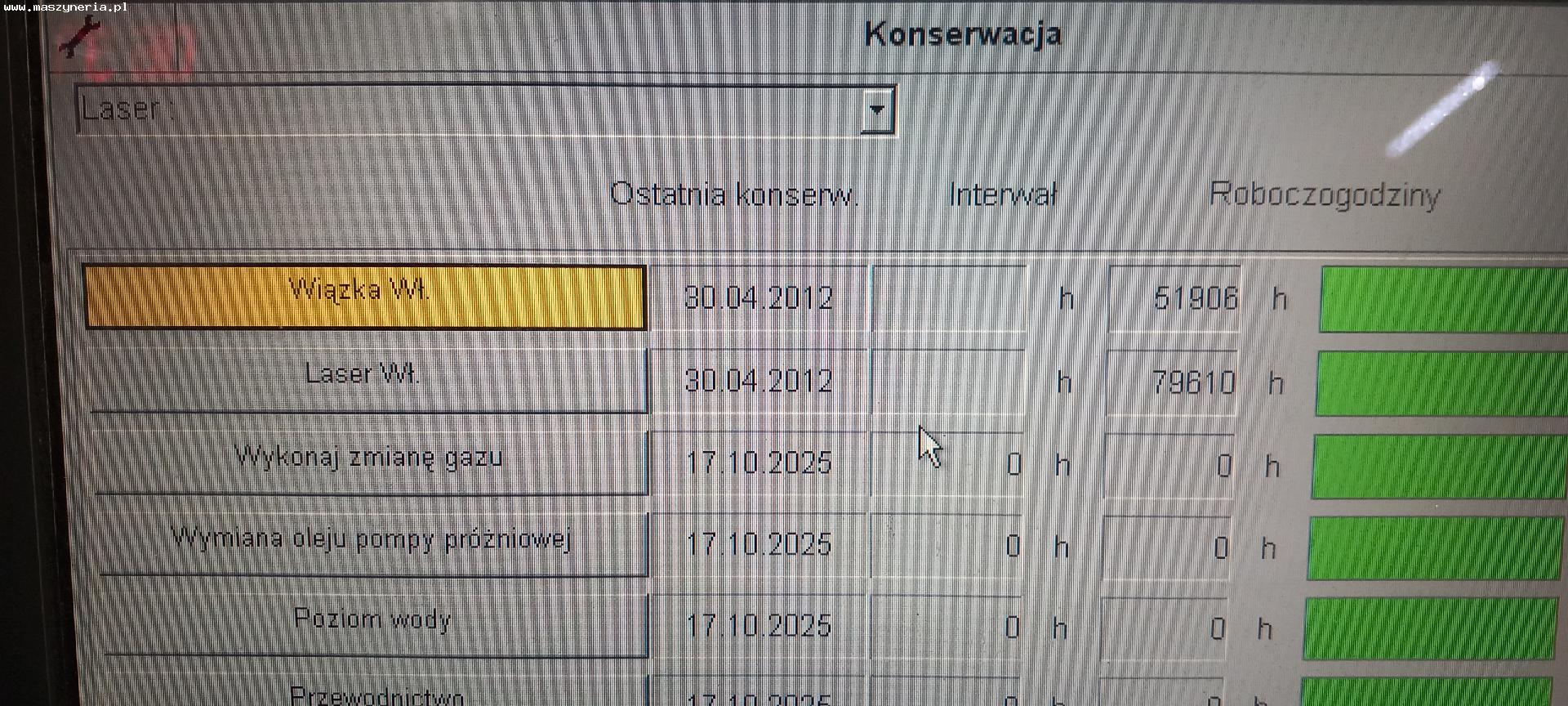

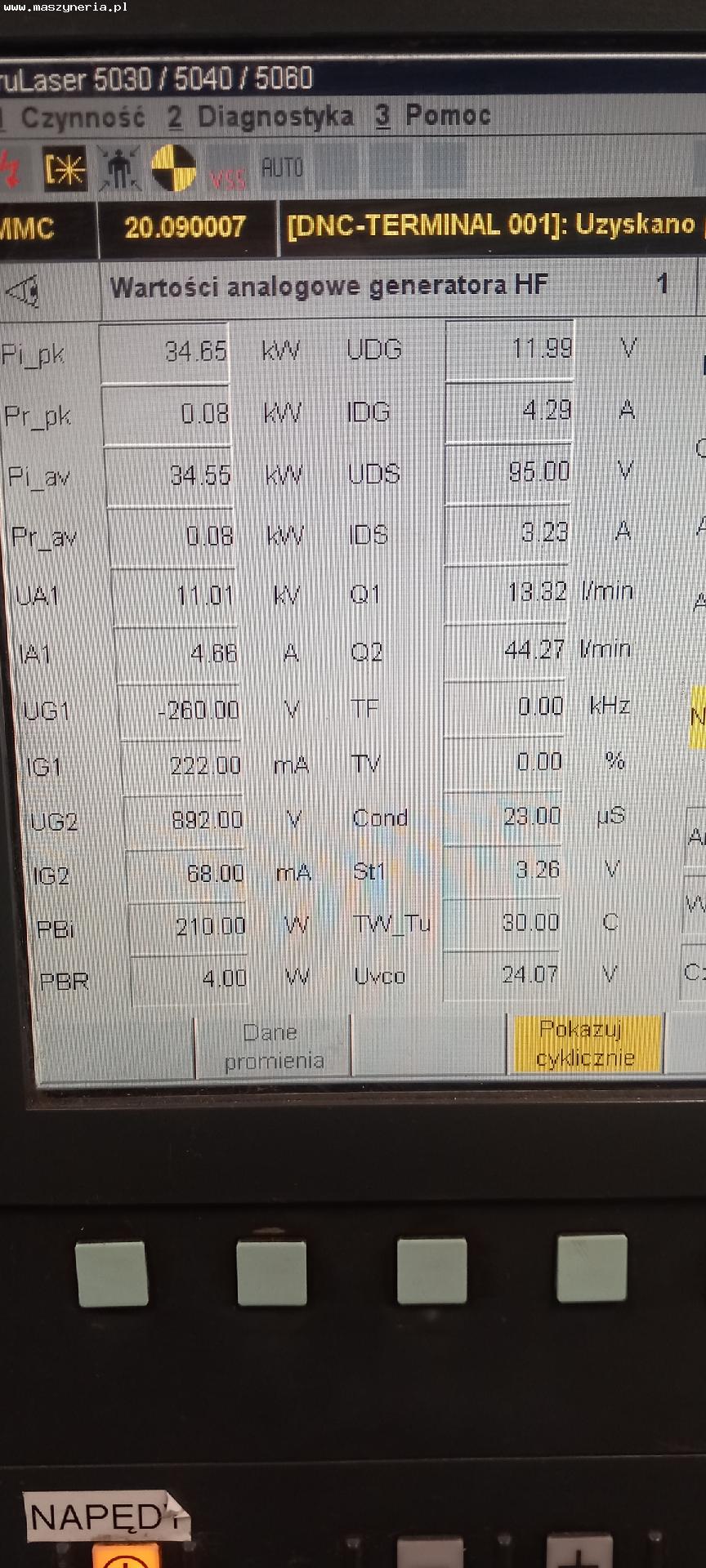

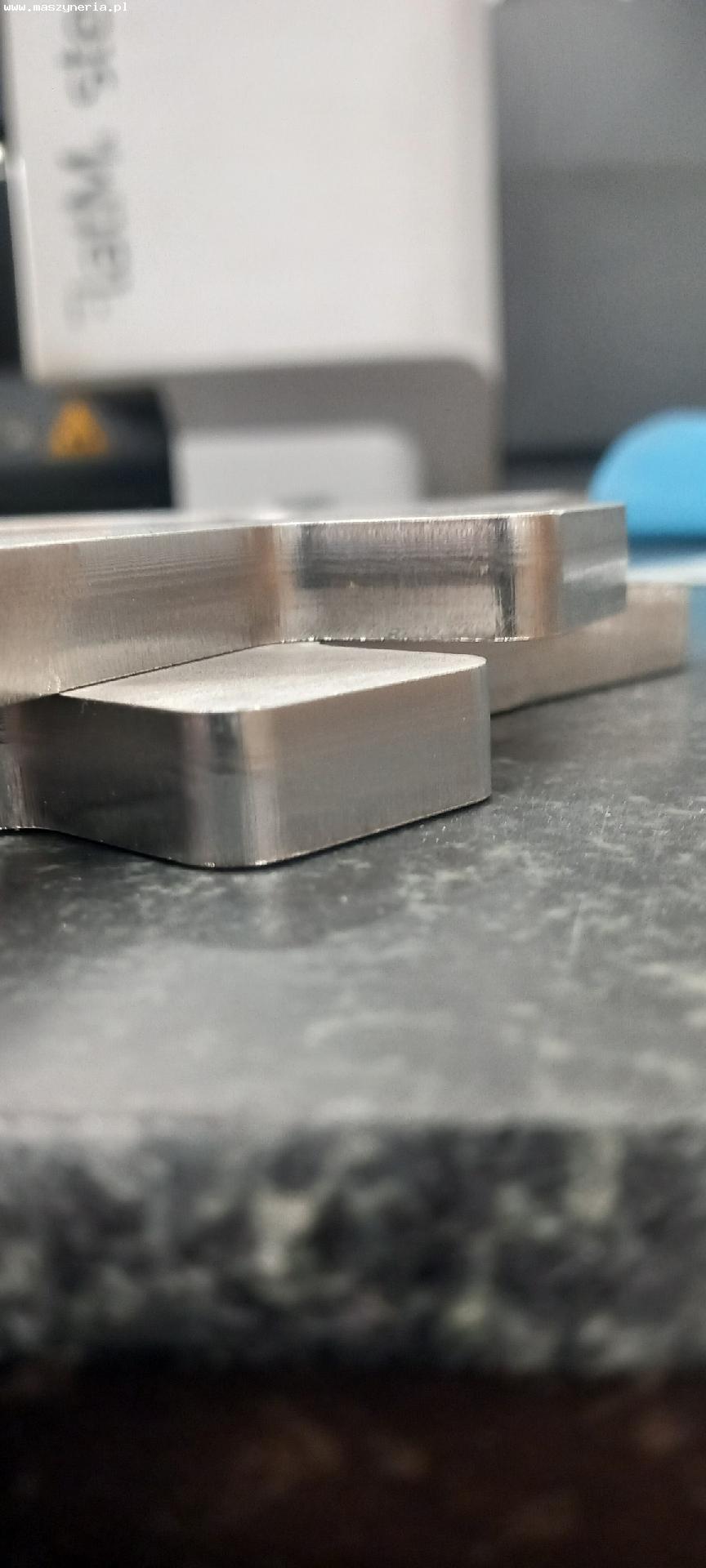

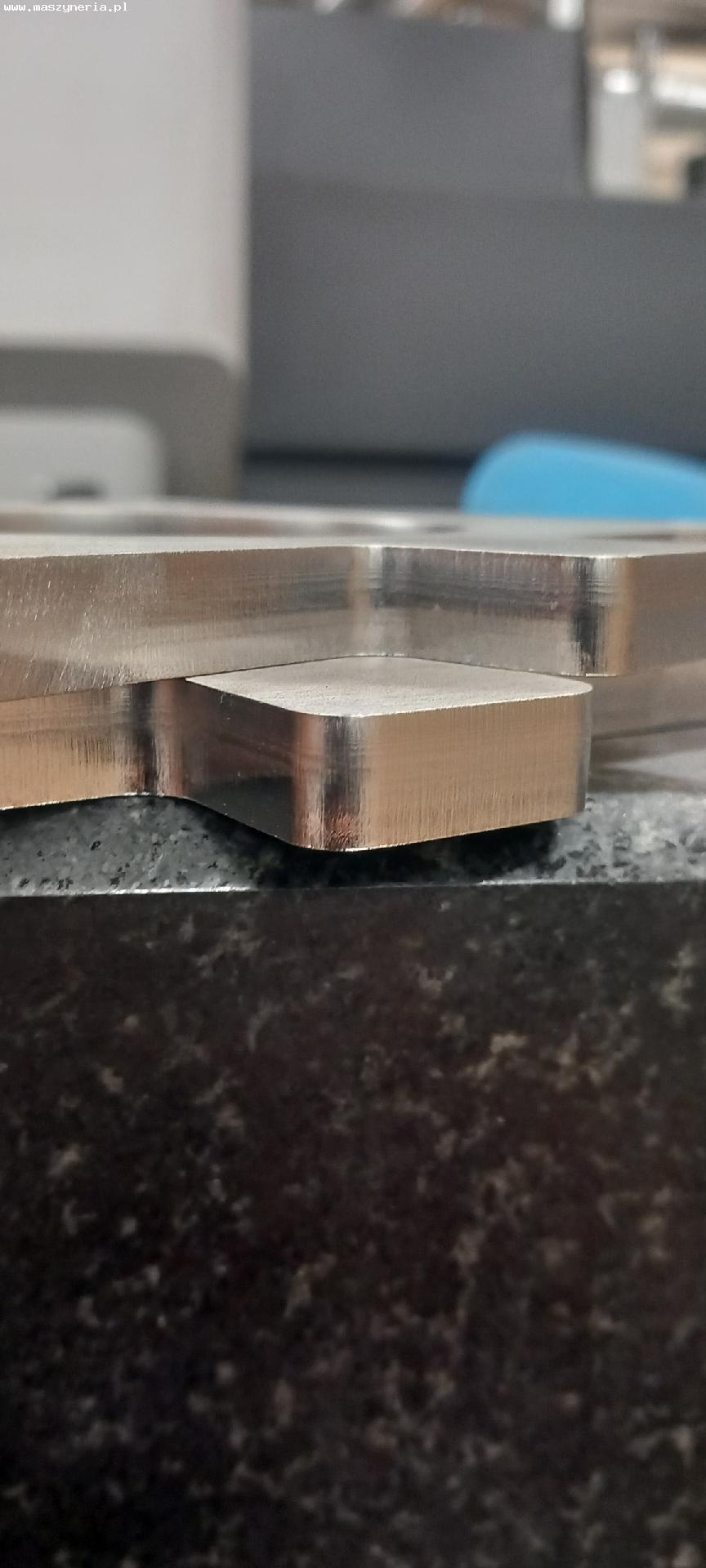

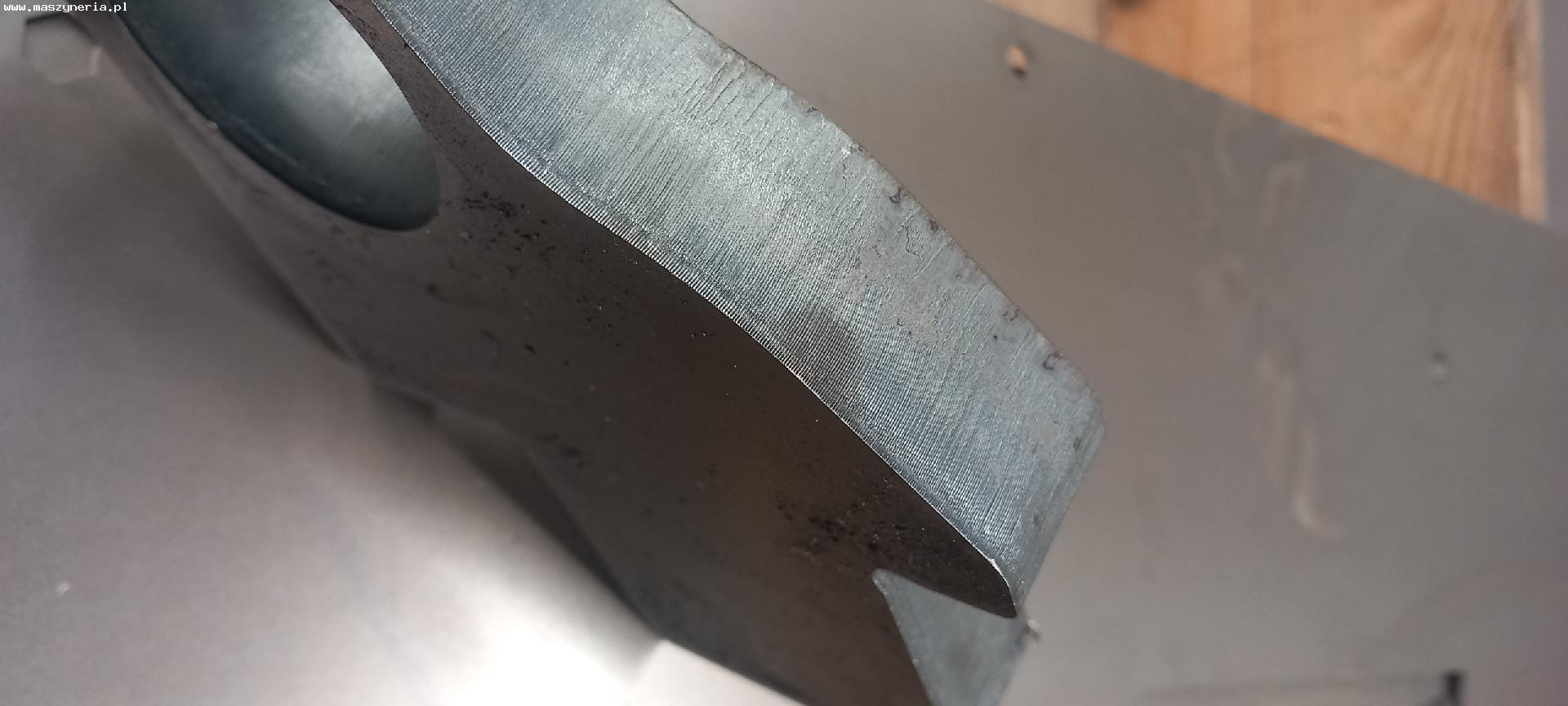

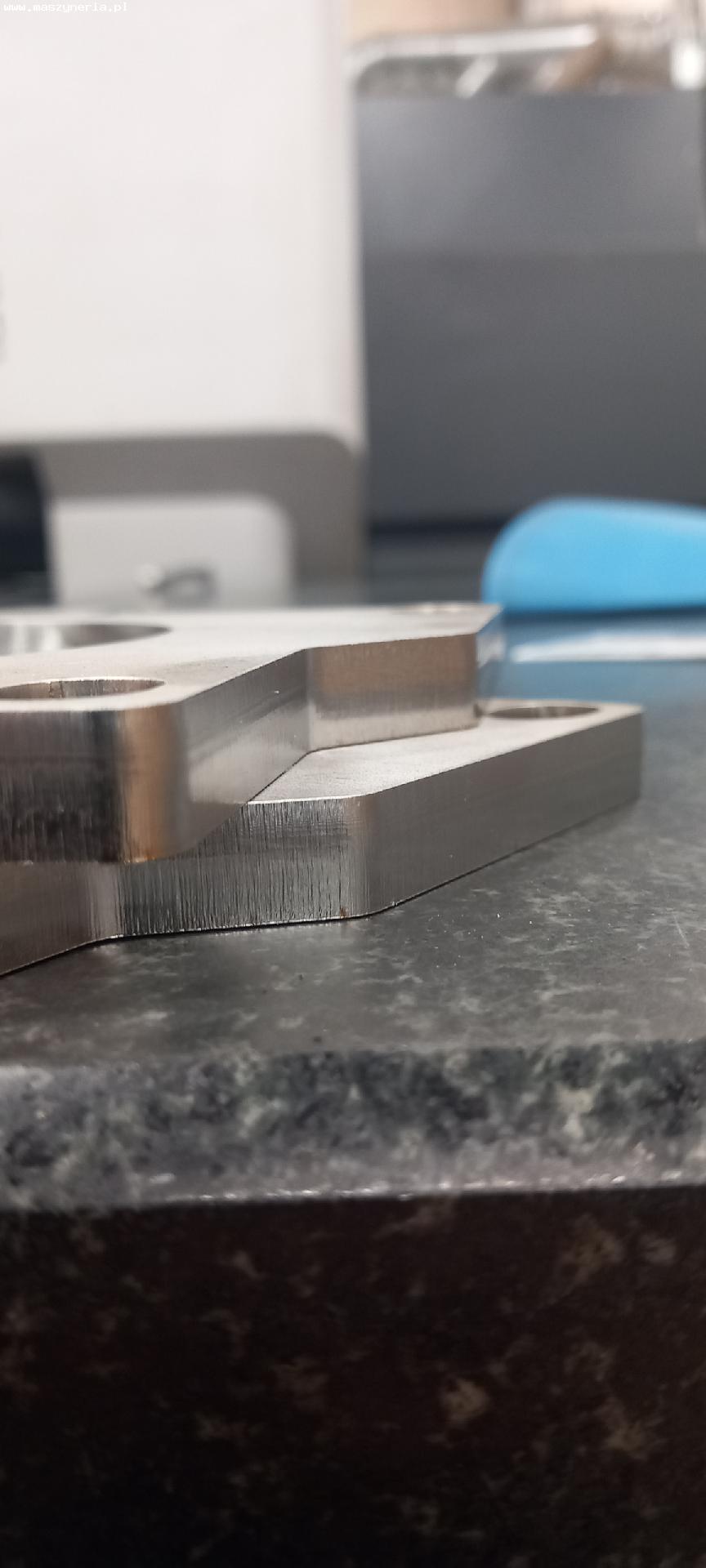

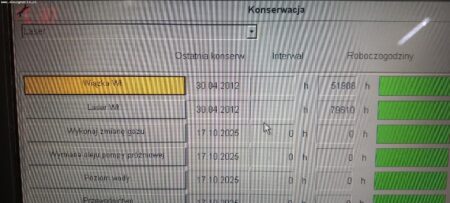

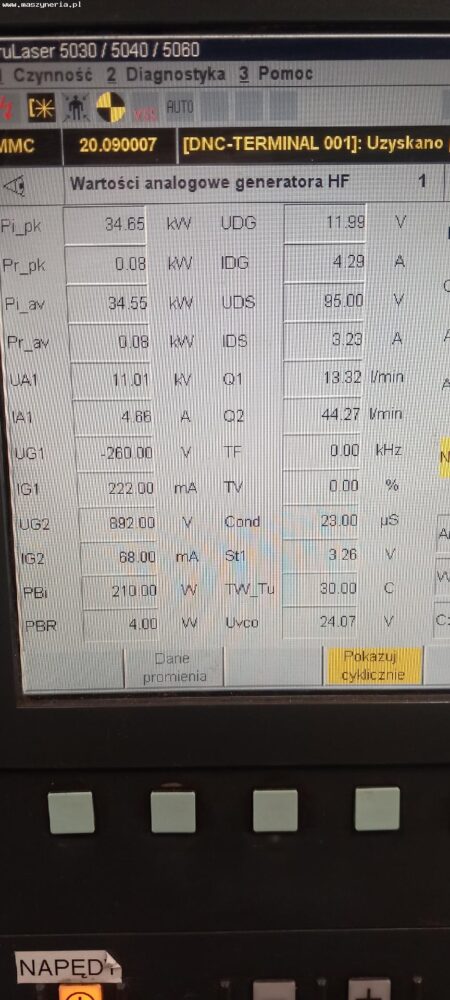

TRUMPF TruLaser 5040 6kW laser cutting machine was built in 2012 in Germany by TRUMPF Maschinen Grüsch AG. The machine has been continuously serviced, upgraded and maintained throughout its service life. A set of quartz tubes, all internal optics and the lamp were replaced in September 2022. A cleaning and calibration of the external optics, meanwhile, was performed in September 2025. All filters and oils were changed on an ongoing basis according to TRUMPF recommendations. Water was changed once a year, along with flushing of the CU and AL circuits. All these activities are confirmed by the corresponding service reports.

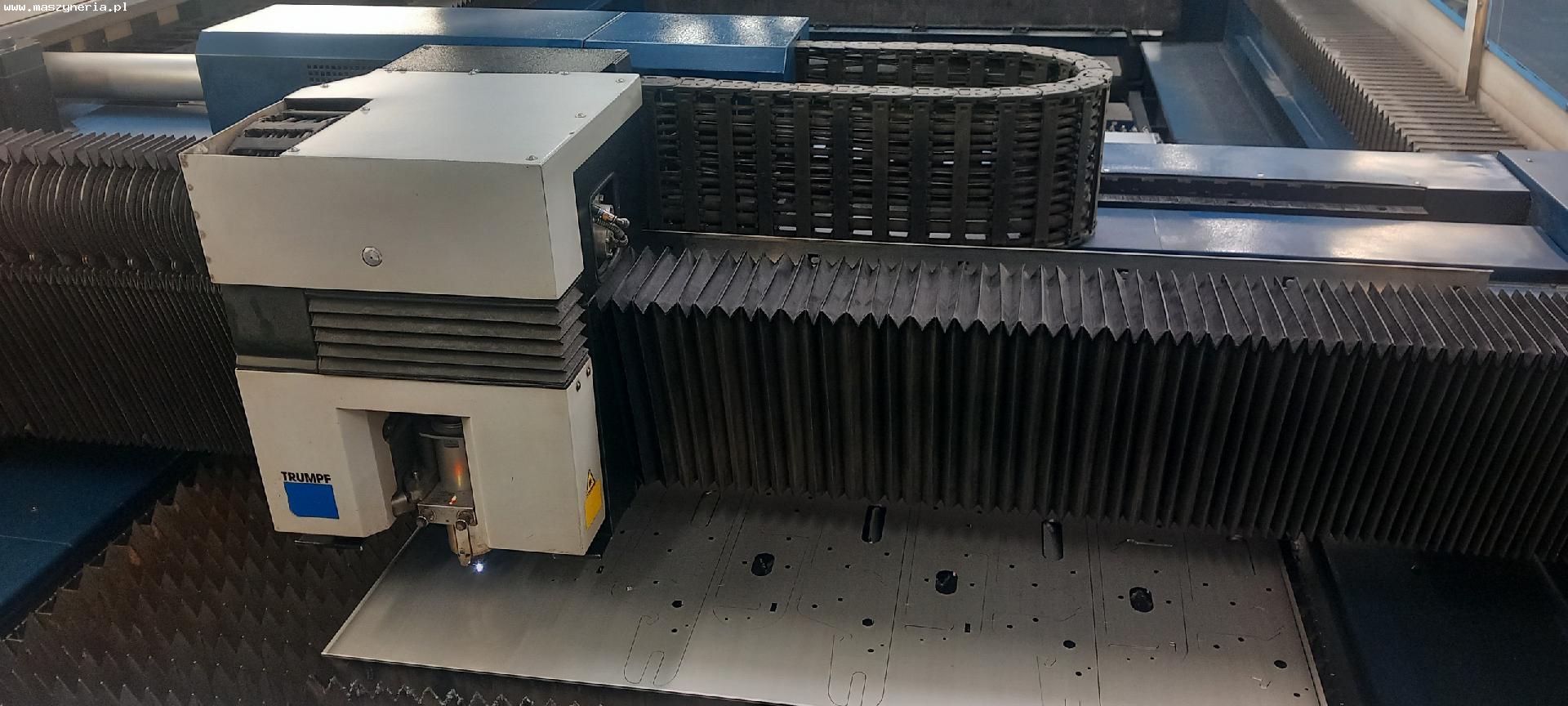

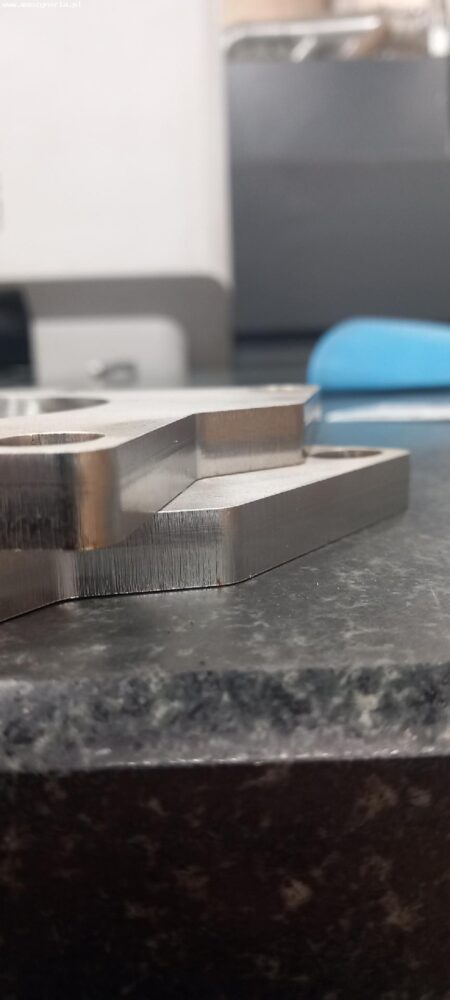

The TRUMPF TruLaser 5040 (L18) laser cutting machine is the perfect choice for any industrial plant. It enables precision cutting of sheet metal made from, among others, steel, aluminium, copper and brass. Laser cutting is performed by means of a stable 6 kW laser beam, which is generated by a laser source of the highest energy efficiency. A number of additional systems streamline the machining process, increasing the cutting quality at the same time.

The entire machining process is fully automatic. The TRUMPF TruLaser works together with an automatic pallet exchange system, which allows workpieces to be loaded and unloaded simultaneously during cutting. This solution significantly increases production efficiency while keeping machine downtime to a minimum. The TruLaser 5040 laser on offer also comes with a wide range of equipment, consisting of, among others, additional cutting heads, original lenses and an intelligent CNC control with many useful functions.

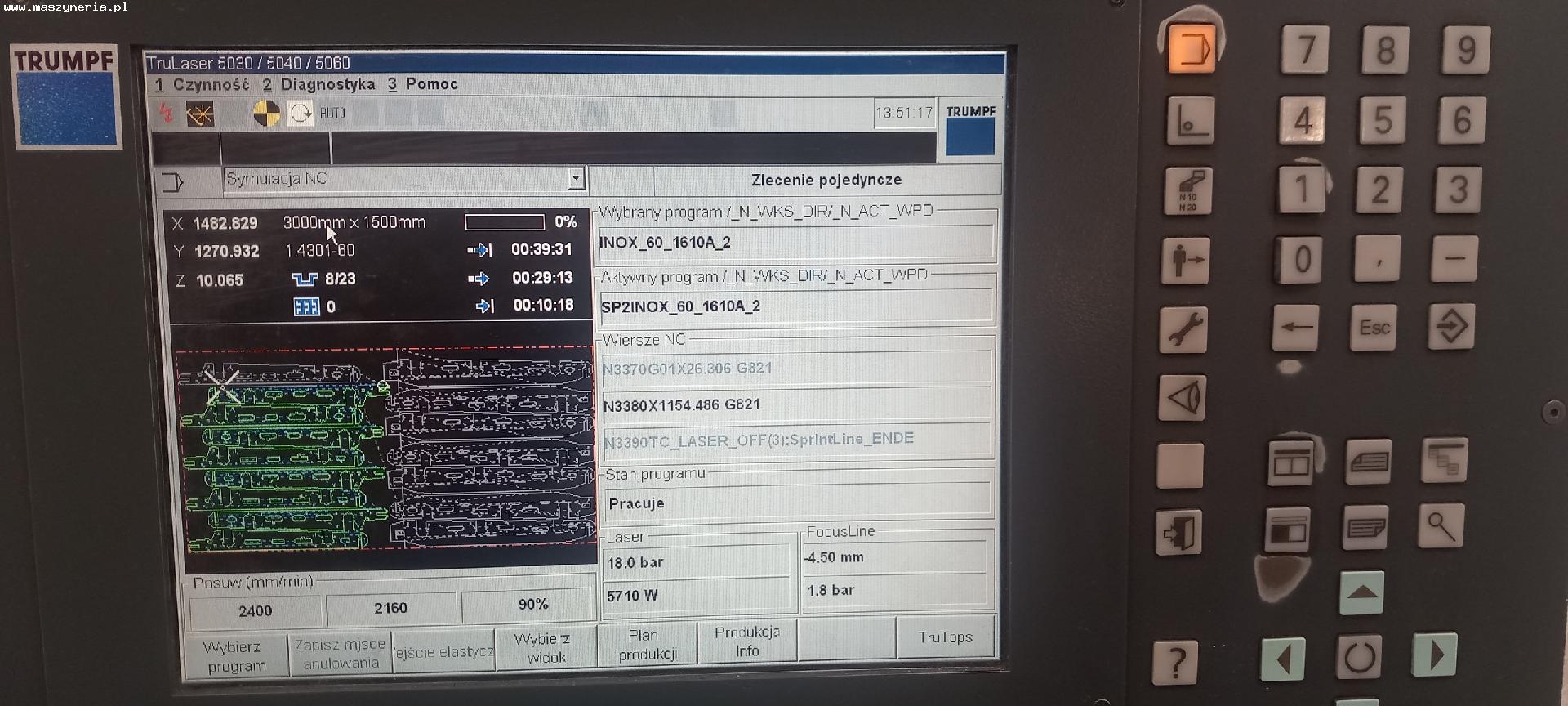

Technical specifications of the TRUMPF TruLaser 5040 laser cutting machine

- laser power: 6 kW

- feed in the X/Y/Z axis: 4000/2000/115 mm

- maximum cutting thickness (structural steel): 25 mm

- maximum cutting thickness (stainless steel): 25 mm

- maximum cutting thickness (aluminium): 25 mm

- maximum cutting thickness (copper): 10 mm

- maximum cutting thickness (brass): 10 mm

- operating hours: 51839 h

- machine switch-on time: 79497 h

- compressed air connection: 7-10 bar

- nitrogen connection N2: 30 bar

- oxygen connection O2: 20 bar

- connection power: 120 kVA

- power supply of the TRUMPF TruLaser 5040 machine: 400 V; 50 Hz

Equipment of the TRUMPF laser cutting machine

- CNC controller: TRUMPF

- laser source: TRUMPF TruFlow 6000

- BrightLine system (increased cutting quality for thick sheets)

- FlyLine system (fast cutting of holes in thin sheets without piercing)

- PierceLine system (monitoring and control of the piercing process, shortening it by up to 80%)

- cutting head 250 mm

- cutting head 175 mm

- automatic pallet exchange system

- cutting with compressed air, nitrogen or oxygen function

- conveyor belt

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe