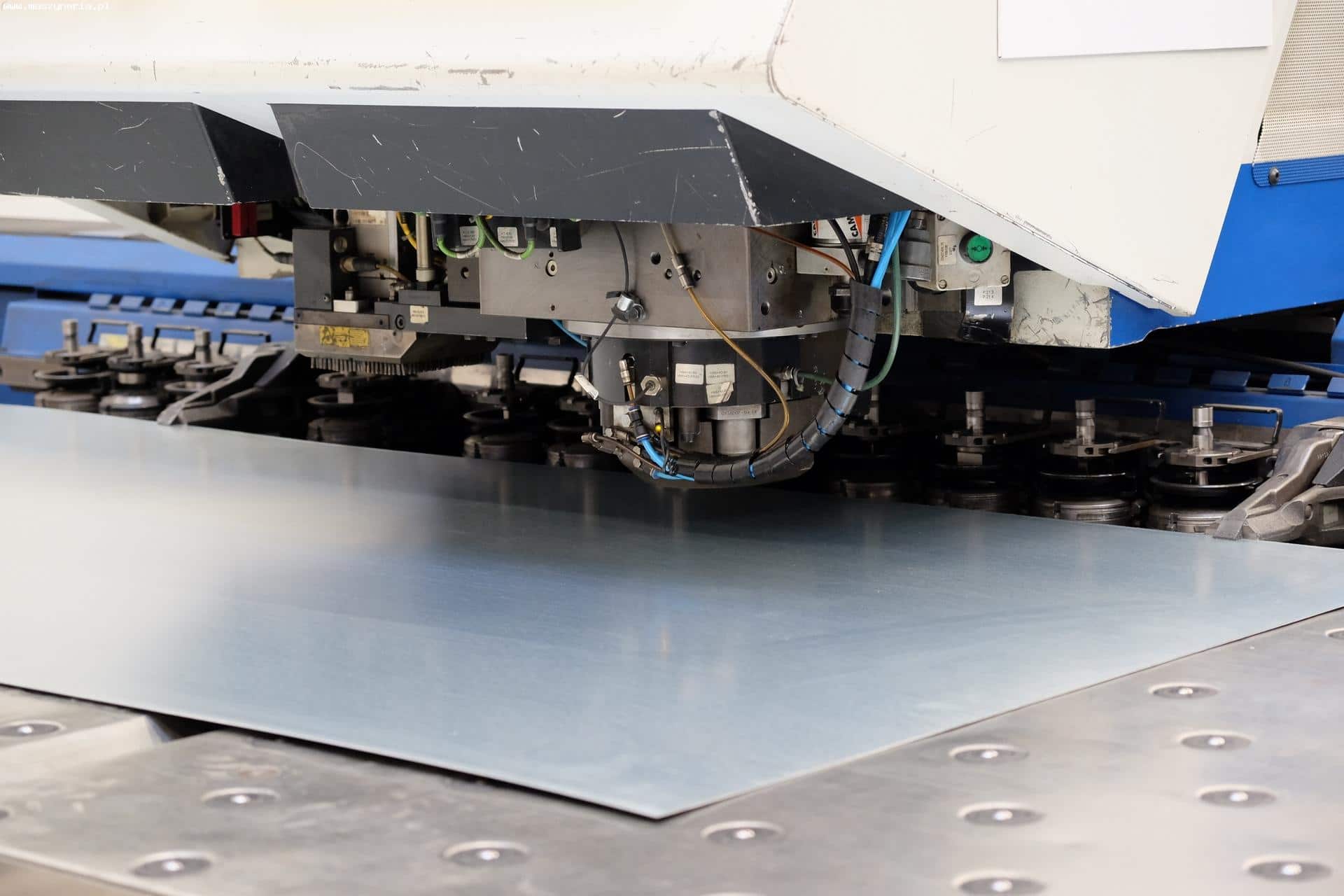

The TRUMPF TRUMATIC 6000 punch laser machine was built in 2007. It is equipped with numerical control Siemens Sinumerik 840 D. The 2700 W laser enables cutting metal sheets with a maximum thickness of 8 mm and a weight of 230 kg. The X axis moves at a speed of 90 m / min, the Y axis moves at a speed of 60 m / min, and both axes simultaneously at 108 m / min. The punching machine is equipped with a linear magazine in which we can mount 18 tools. The workspace without reposition depends on the selected mode. In the combined mode it is 1280×2585 mm, in the punching mode it is 1280×3120 mm, and in the laser mode it is 1280×3120 mm.

Technical data of the TRUMPF TRUMATIC 6000 punch laser machine

– CNC control: Siemens Sinumerik 840 D

– laser power: 2700 W

– maximum sheet thickness: 8 mm

– punching force: 220 kN

– laser cutting time: 2603 h

– laser activation time: 52,833 h

– active clamp (programmed in steps): 4.5-20 kN

– maximum weight of the workpiece: 230 kg

– maximum through-height in punching mode: 35 mm

– maximum cruise height in laser mode: 22 mm

– speed in the X axis: 90 m / min.

– speed in the Y axis: 60 m / min.

– speed in the X and Y axes simultaneously: 108 m / min.

– number of strokes, punching: 900 min-1

– number of strokes, marking: 2800 min-1

– C axis, punching: 60 rpm.

– C axis, threading: 330 rpm.

– places for tools in the linear magazine: 18 with 3 sheet holders

– number of tools when using MultiTool: 18 to 180 tools

– rotation of all tools: 360 degrees in rotation

– tool change time: 1.5-5 s

– maximum punching diameter, single stroke: 76.2 mm at all tool positions

– maximum punching diameter, standard multicut cut: 200 mm

Workspace with no reposition:

– combined mode: 2585 x 1280 mm

– punching mode: 3120 x 1280 mm

– laser mode: 3120 x 1280 mm

Punching head:

– electro-hydraulic drive of the pusher allows for a frequency of 900 strokes / minute

– smooth tool rotation, 360 degree rotation of all tools

– automatic tool length compensation

– lubrication of spraying tools

– safety: light barriers

– Trutops v offline programming software, floating license

Advantages of the TRUMPF TruMatic 6000 punching machine

– stable C frame

– guide with a coordinate system, linear magazine, 18 tool stations, 3 clamps

– drives: maintenance-free, three-phase servo motors

– 2 programmable active hold-down cylinders for repositioning

– cutting head for laser cutting: 5 “lens, quick-change device, DIAS height adjustment

The TRUMPF TruMatic 6000 machine is ready for operation and can be checked on the move.

– the machine with its periphery covers an area of 7.5 x 7.5 m

– total weight: approx. 16,000 kg

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano