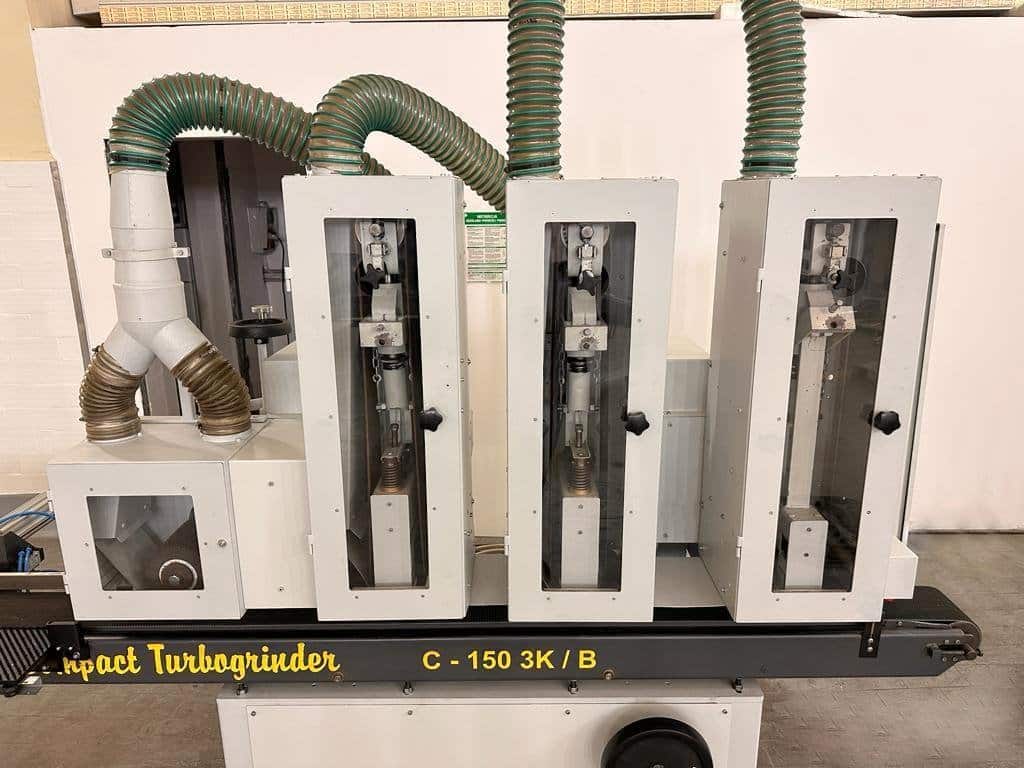

VANGROENWEGHE C-150-3K/B grinding machine was built in Belgium in 2011. Equipped with a grinding and brushing unit, the machine is used for deburring, edge rounding and grinding a wide range of workpieces. The 1900 mm long and 150 mm wide abrasive belt is kept on the right track by the adjustment system used in the grinder, guaranteeing the most accurate surface finish on the workpiece.

Designed for edge rounding, the brushing unit of the VG BELGIUM C-150-3K/B deburring machine allows adjustment of the individual brushes to reduce wear. Precision is maintained even under heavy load, making the VGMACHINES C-150-3K/B deburring machine suitable for connection with other machines or conveyor belts in the production line.

The grinding machine is additionally equipped with a conveyor belt to capture and transport the sanded workpieces back to the machine operator. The machine has undergone an overhaul and has a total weight of 800 kg.

Technical specifications of the VANGROENWEGHE C-150-3K/B profile grinding machine

- grinding unit (K)

- brushing unit (B)

- thermomagnetic protection on all motors

- manual switch

- main switch with emergency stop

- total power requirement: 16 kW

- weight of the C-150-3K/B machine: 800 kg

– spirally grooved contact roller – 70° SH (20 m/sec) or 40° SH (10 m/sec)

– abrasive belt dimensions (L x W): 1900 x 150 mm

– minimum grinding length (roller ⌀ 122 mm): 190 mm

– mechanical abrasive belt tension

– motor: 3 kW

– grinding thickness: 0,5 – 200 mm

– spindle diameter: ⌀ 50 mm

– spindle speed: 1500 rpm

– minimum brush length: 240 mm

– maximum brush diameter: ⌀ 200 mm

– maximum brush width: 150 mm

– rubber pressure rollers in front of and after each unit

– non-slip feed belts: 5 & 10 m/min – motor 0,55/0,75 kW

– motor: 3 kW

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe