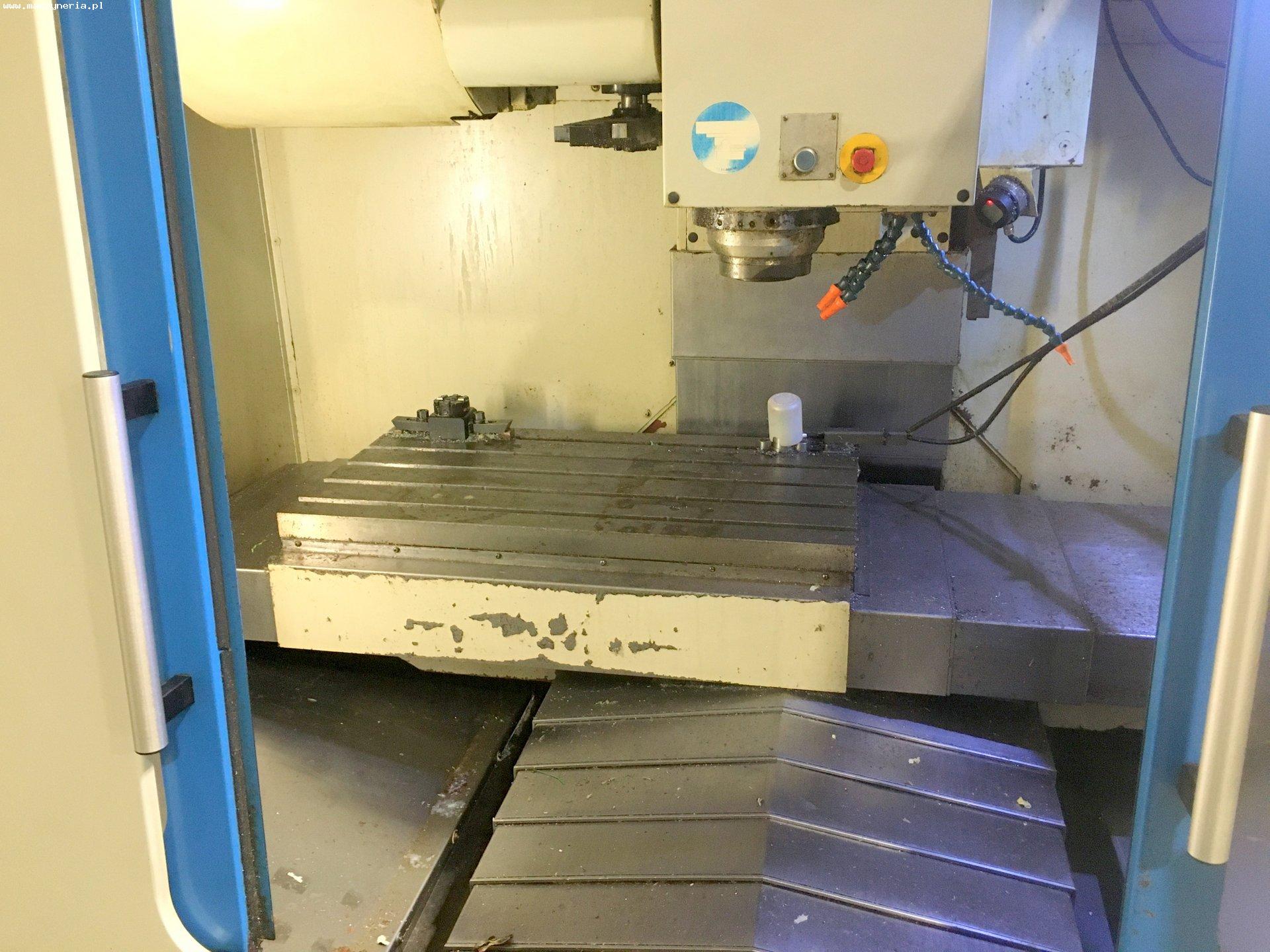

The vertical CNC machining center AVIA VMC 800 HS was built in 2004 by the Polish factory of precision machine tools AVIA S.A. in Warsaw. The AVIA VMC 800 HS machining center enables the processing of workpieces weighing up to 750 kg, on a table 1000 mm long and 540 mm wide. The machine works in three axes (X, Y, Z), and their maximum feeds are respectively 800 mm, 540 mm and 620 mm. Rapid feeds in the X, Y, Z axes are, in turn, 35, 35 and 24 m / min. The milling machine is equipped with Heidenhain iTNC 530I numerical control , HEIDENHAIN drive, Heidenhain TS 632 A40 optical workpiece probe and Heidenhain TT130 touch tool probe.

Technical parameters of the CNC AVIA VMC 800 HS milling center

– the number of grooves in the table: 5 pieces

– spacing of grooves in the table: 100 mm

– width of the grooves in the table: 18 mm

– X / Y / Z axis travel: 800/540/620 mm

– rapid feed of the X / Y / Z axis: 35/35/24 m / min.

– coolant tank capacity: 300 l

– tool magazine capacity: 24 pcs.

– tool change time: 3.5 s

– maximum tool diameter: 80 mm

– maximum tool length: 300 mm

– maximum tool weight: 7 kg

– number of frames: 31 pieces

– network pressure: 0.7-0.8 MPa

– electro-spindle revolutions: 50-24000 rpm.

– minimum distance of the spindle face from the table: 180 mm

– maximum distance of the spindle face from the table: 800 mm

– machine dimensions (L x W x H): 2500 x 2360 x 3850 mm

– machine weight: 4672 kg

– table dimensions: 1000 x 540 mm

– maximum table load: 750 kg

Equipment for the milling center

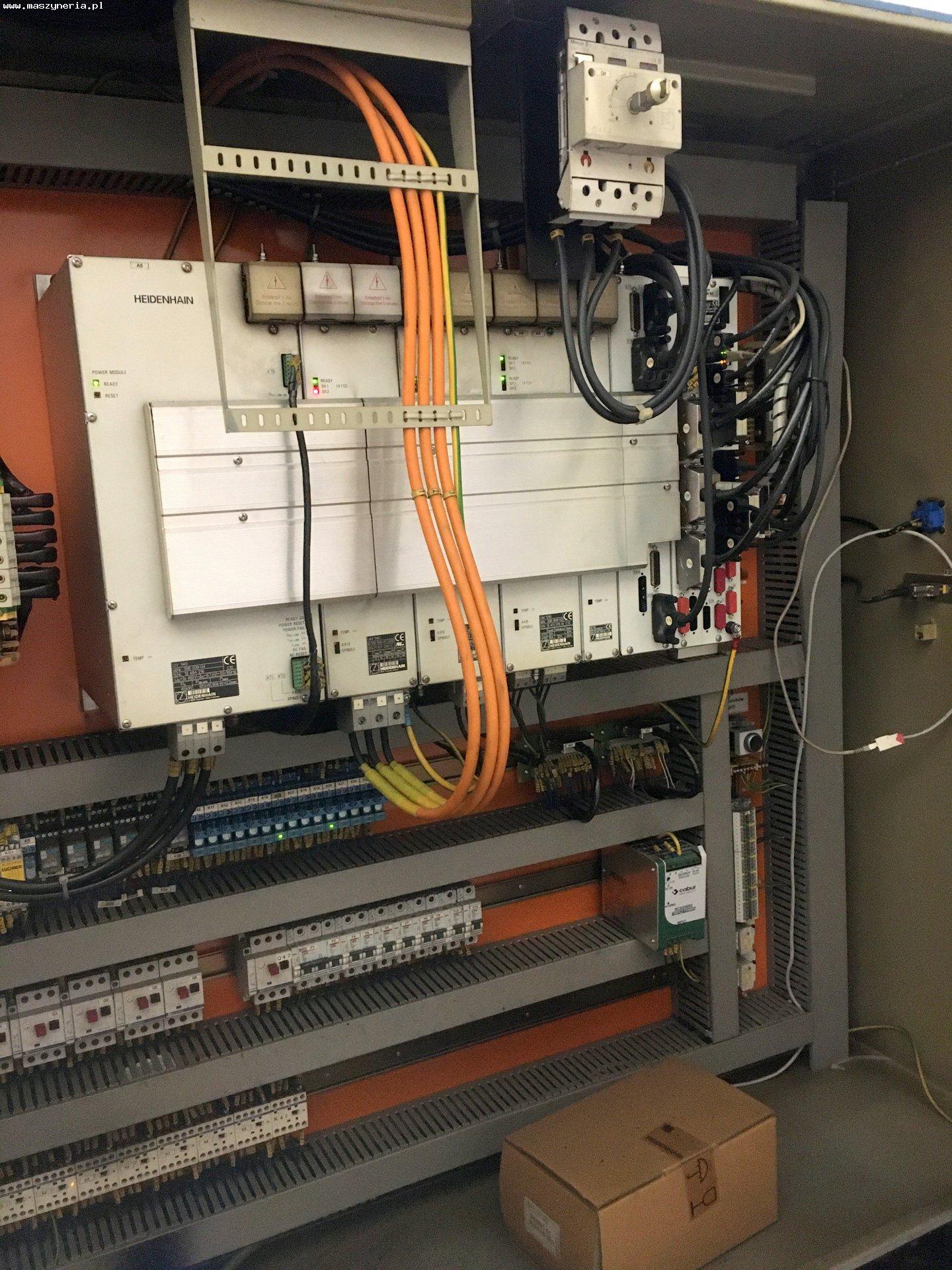

– CNC control: Heidenhain iTNC 530I

– optical workpiece probe: Heidenhain TS 632 A40

– touch tool probe: Heidenhain TT130

– drive: HEIDENHAIN

– Worm type chip conveyor

– Electrospindle type: DMS 080.32.4.FHS

– spindle taper: HSK A63M

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano