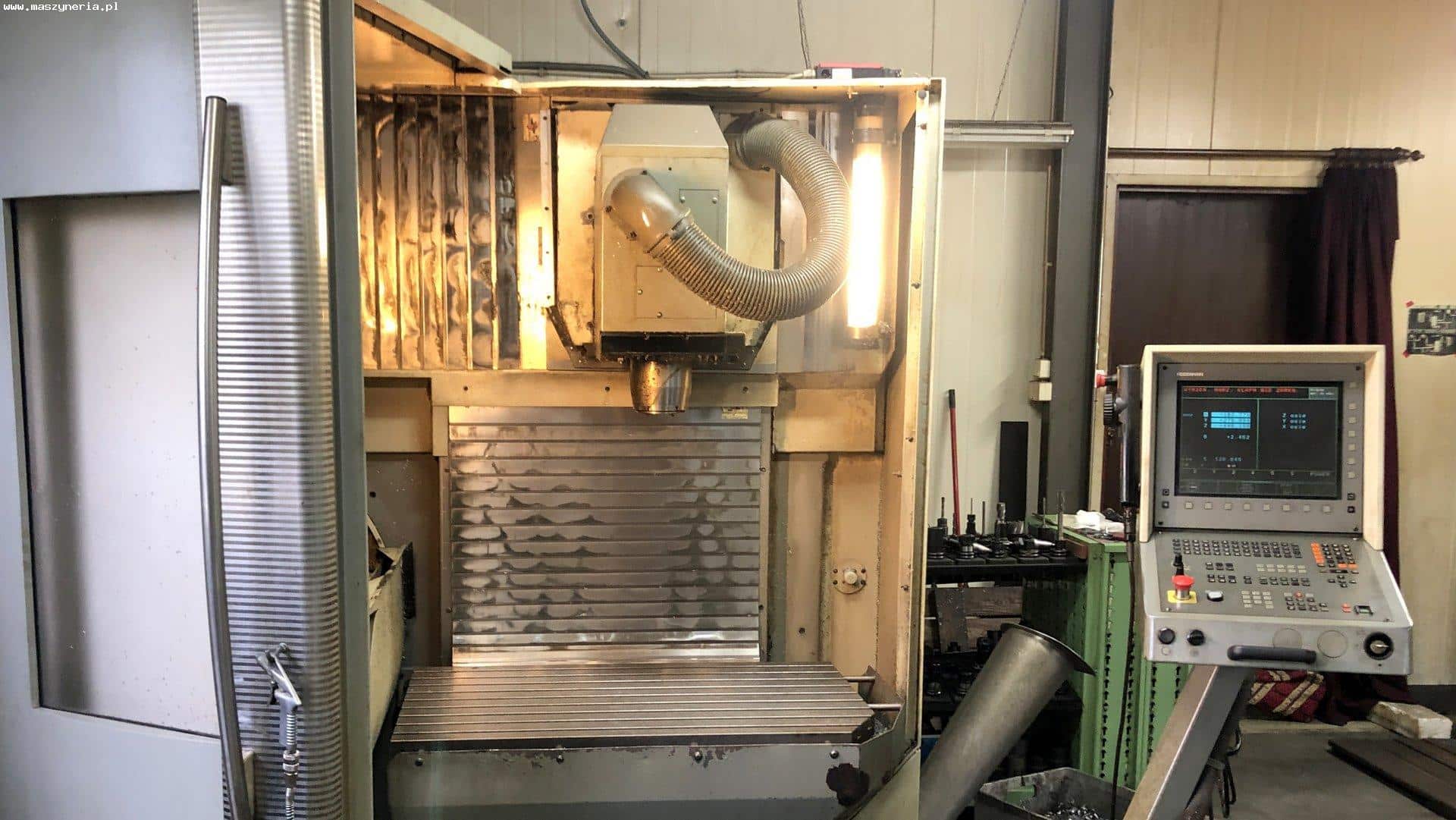

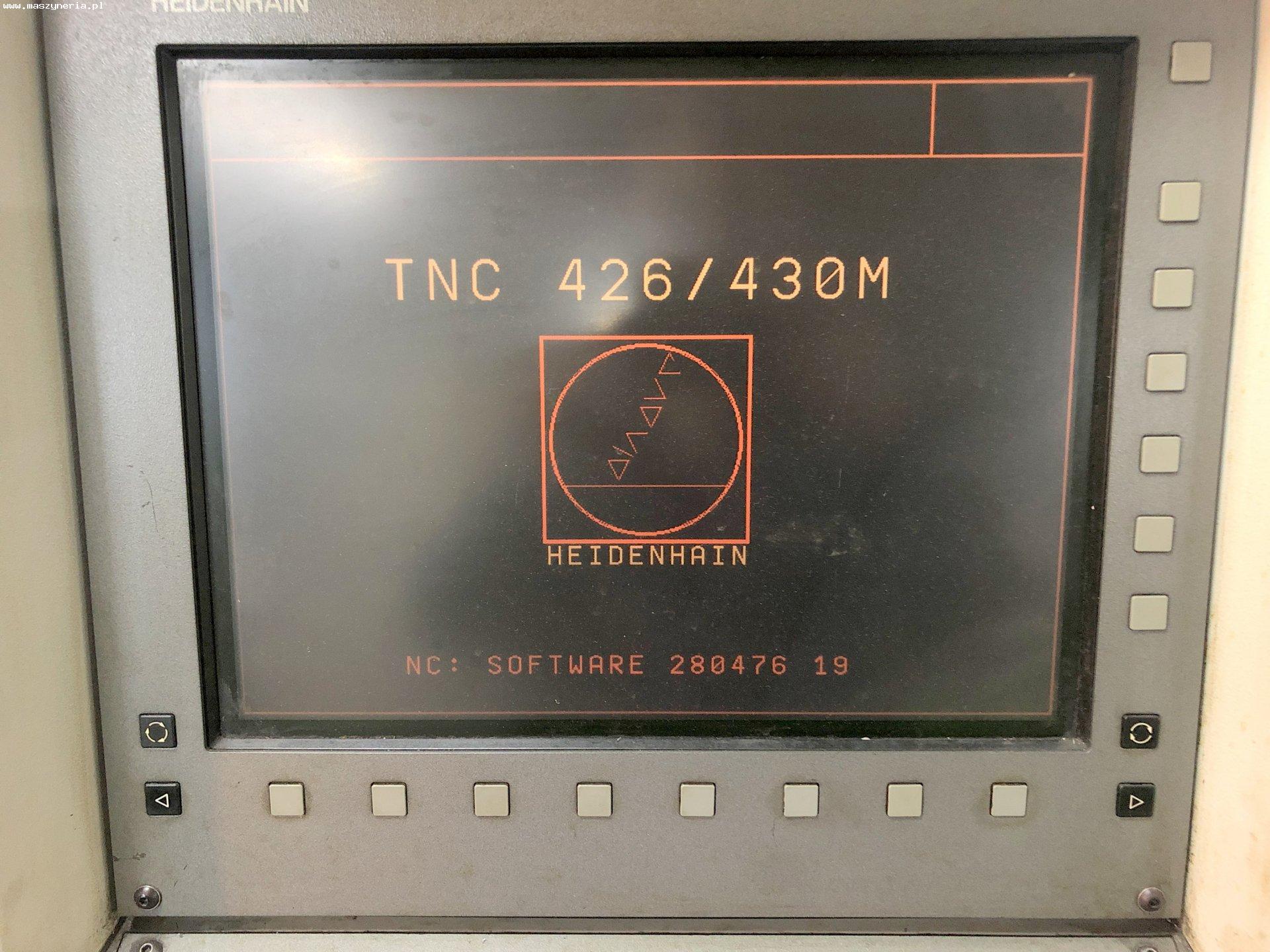

The vertical machining center DECKEL MAHO DMU 60 T was manufactured in 2001. The machine is equipped with three synchronous axes (X, Y, Z) with a maximum axis travel of 630 mm, 560 mm and 560 mm, respectively. Additionally, the milling machine has been equipped with a manual steering B axis , a chip conveyor, an electronic handwheel, and its warehouse is able to store a total of 24 tools. The control is carried out thanks to the HEIDENHAIN CNC controller – TNC 426 / 430M . The spindle revolutions of the CNC milling machine reach 12,000 rpm. The machine is serviced regularly.

Technical parameters of the DECKEL MAHO DMU 60T CNC milling machine

– number of synchronous axes: 3

– X / Y / Z axis travel: 630/560/560 mm

– B axis: manual steering

– air blow through the spindle

– spindle speed: 12000 rpm

– electronic handwheel

– chip conveyor

– table surface: 1000 x 600 mm

– coolant pumps (W x L x H): approx. 60 x 200 x 100 cm

– height of the milling machine: 225 cm

– machine width: 200 cm + 60 cm protruding computer (the computer can also be moved to the front)

– machining center length: 300 cm

– machine weight: 6.5 t

Accessories for a CNC milling machine DECKEL MAHO DMU 60T

– CNC control: Heidenhain TNC 426M

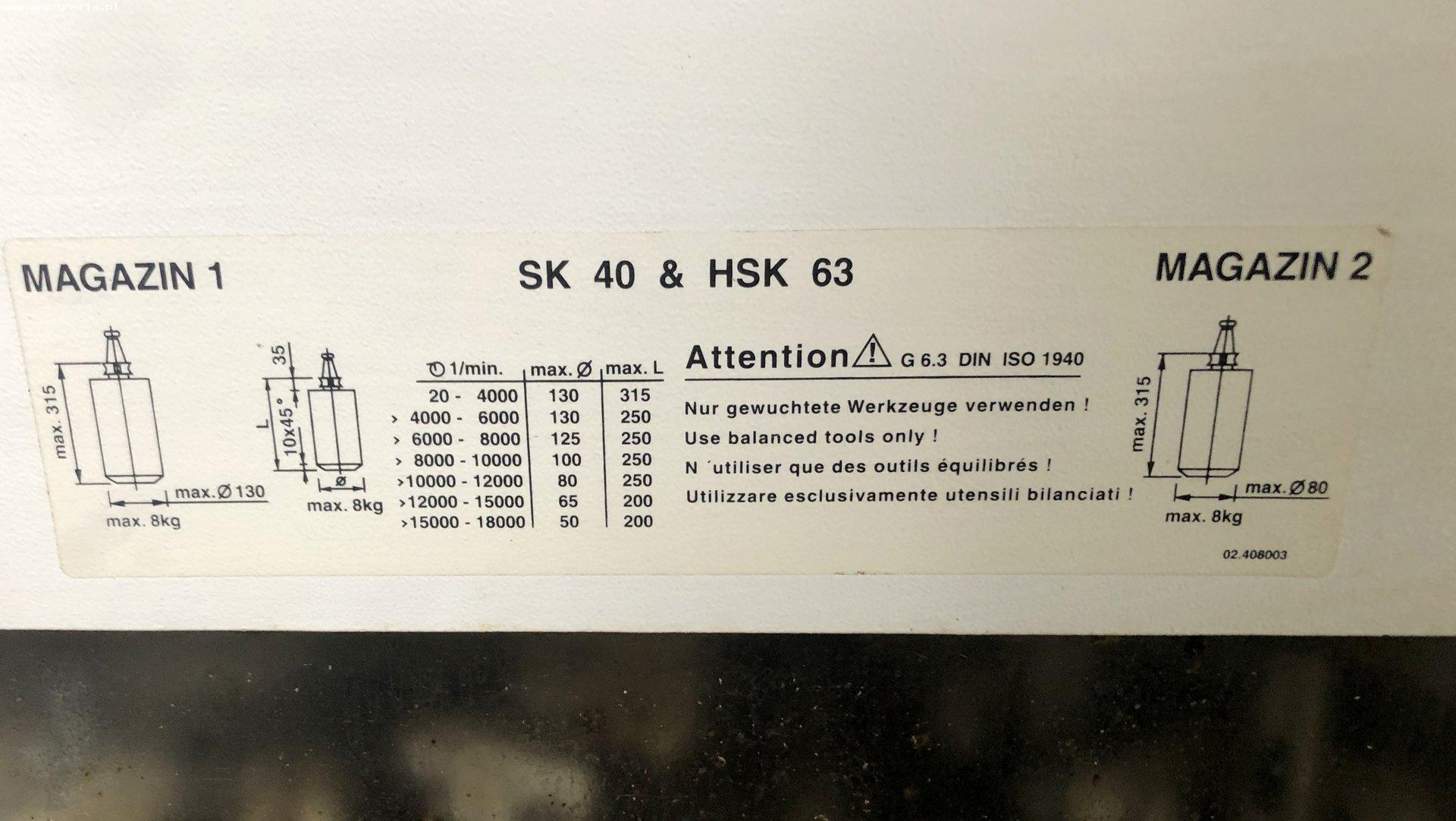

– tool magazine capacity: 24

– spindle taper: SK 40

– tool holder: BT 40

– total power requirement: 32 kW

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano