The WALTER HELITRONIC MINI POWER CNC grinding machine was built by the German company Walter Maschinenbau GmbH in 2011. The machine grinds tools for wood and metal processing with a diameter ranging from 1 to 100 mm and weighing up to 30 kg. The length of the peripheral grinding of the workpiece is 255 mm, and the front grinding 185 mm The machine is equipped with: 5 axes (X, Y, Z, C, A), CNC control FANUC Series 31i Model A5, integrated measurement system (IMS) and CAD / CAM software HELITRONIC TOOL STUDIO. The grinding wheel in the grinder can have a maximum diameter of 150 mm, and the machine spindle rotates at a speed of 0-10,500 rpm. The grinder with the cooling system weights 3.6 tons.

Specification of the CNC grinding machine WALTER HELITRONIC MINI POWER

– 5 axes

– maximum workpiece length in peripheral grinding: 255 mm

– maximum workpiece length in face grinding: 185 mm

– maximum weight of the workpiece: 30 kg

– maximum feeds in the X / Y / Z axes: 320/200/470 mm

– accelerated feeds in the X, Y, Z axes: 15 m/min

– C axis of rotation: ± 200 °

– linear axis A: ∞

– minimum diameter of the processed tool: 1 mm

– maximum diameter of the processed tool: 100 mm

– maximum diameter of the grinding wheel: 150 mm

– spindle diameter: 70 mm

– grinding spindle speed: 0-10500 rpm

– power: 9 kW

– cooling system tank capacity: 350 l

– pump: 120 l/min

– power demand: 25 kVa

– weight of the HELITRONIC MINI POWER grinder (with a cooling system): 3.6 t

Equipment of HELITRONIC MINI POWER

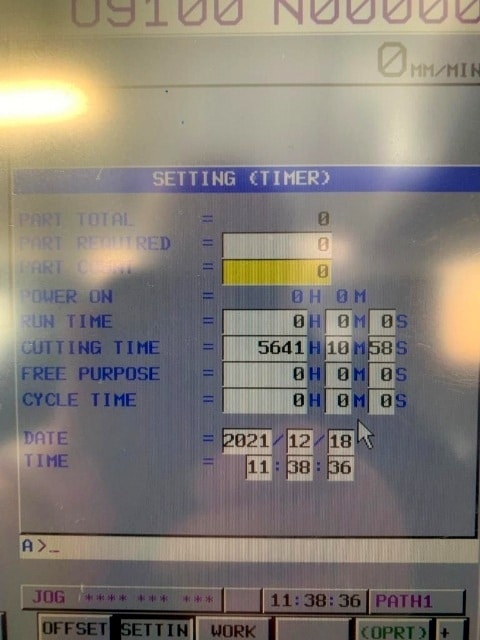

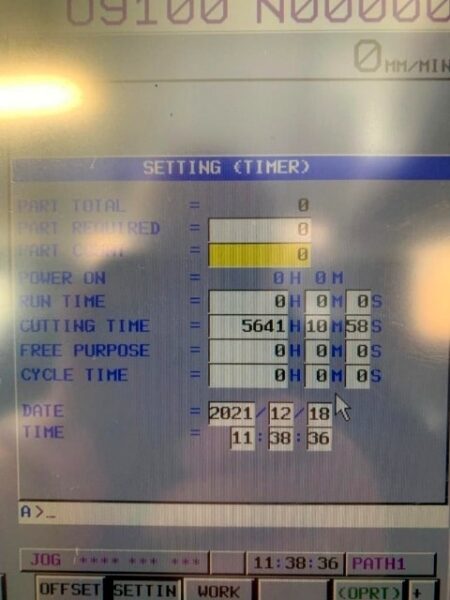

– CNC control: FANUC Series 31i Model A5

– CAD / CAM software: HELITRONIC TOOL STUDIO

– robot with a tool feeder

– package 1,2,3,16

– drip tub

– oil tank with pump

– grinding wheel changer (up to 6 grinding wheels)

– integrated measurement system (IMS)

– handles for grinding wheels (4 pcs.)

– grinding wheels (5 pcs.)

Čeština

Čeština Français

Français Español

Español Deutsch

Deutsch polski

polski Русский

Русский Slovenčina

Slovenčina Magyar

Magyar Italiano

Italiano Türkçe

Türkçe